I have not updated this in a while. Some of the things I have been working on:

Calibrate the Film Thickness Monitor.

To calibrate the crystal thickness monitor you coat a sample and compare the what the thickness monitor says you coated with what you actually coated. To do this you need something that can measure down to the nm range. There are several ways to do this, an Atomic Force Microscope (AFM), and ellipsometer, and a commercial film thickness monitoring device. Lucky for me I have a friend with an AFM! I took some coverslips and coated them with what the control said was 500 angstroms of the materials that are loaded in the boats. These were then taken to the lab where I scratched the coating to create a sharp edge so the AFM stylus can measure the ridge. These readings are then used to create a "tooling factor" which is entered into the control with other factors like material density to hopefully give me a correct coating thickness.

Install a Electron Beam Gun.

There are a lot of materials that just to not thermally evaporate well. To deposit these materials you need to use an electron beam gun which directly heats up the evaporant instead of heating it though a crucible. The most common kind of e-beam gun for thin film deposition is a 270 degree e-beam gun. The electron beam is emitted from a negatively biased heated filament mounted to the side of the e-beam gun. Magnets cause the beam to wrap around 270 degrees to hit the source material from above. This keeps the evaporating material from coating the filament and causing shorts. There are additional electromagnets on the e-beam gun to scan the beam in two axes over the surface of the source material similar to what happens in a CRT.

E-beam guns are incredibly expensive, a new four pocket one is pushing $10,000. And the power supply to drive it is even more expensive. Small e-beam guns run in the 3kw range at 4000v accelerating voltage at up to 750ma beam current. Larger e-beam guns run at 10,000v accelerating voltage at currents up to 1.5 amps. These supplies need to be adjustable in current and voltage, that's why they are so expensive.

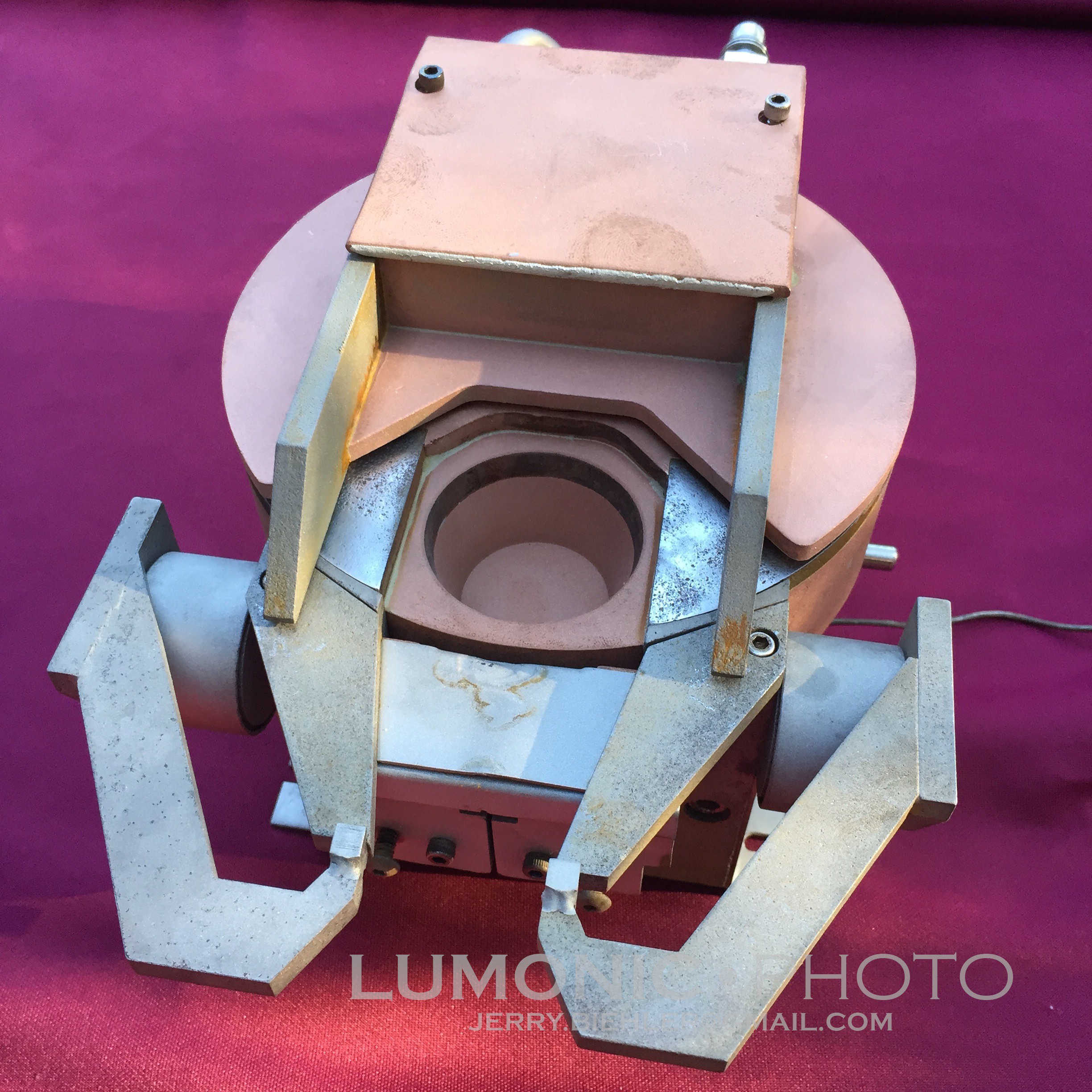

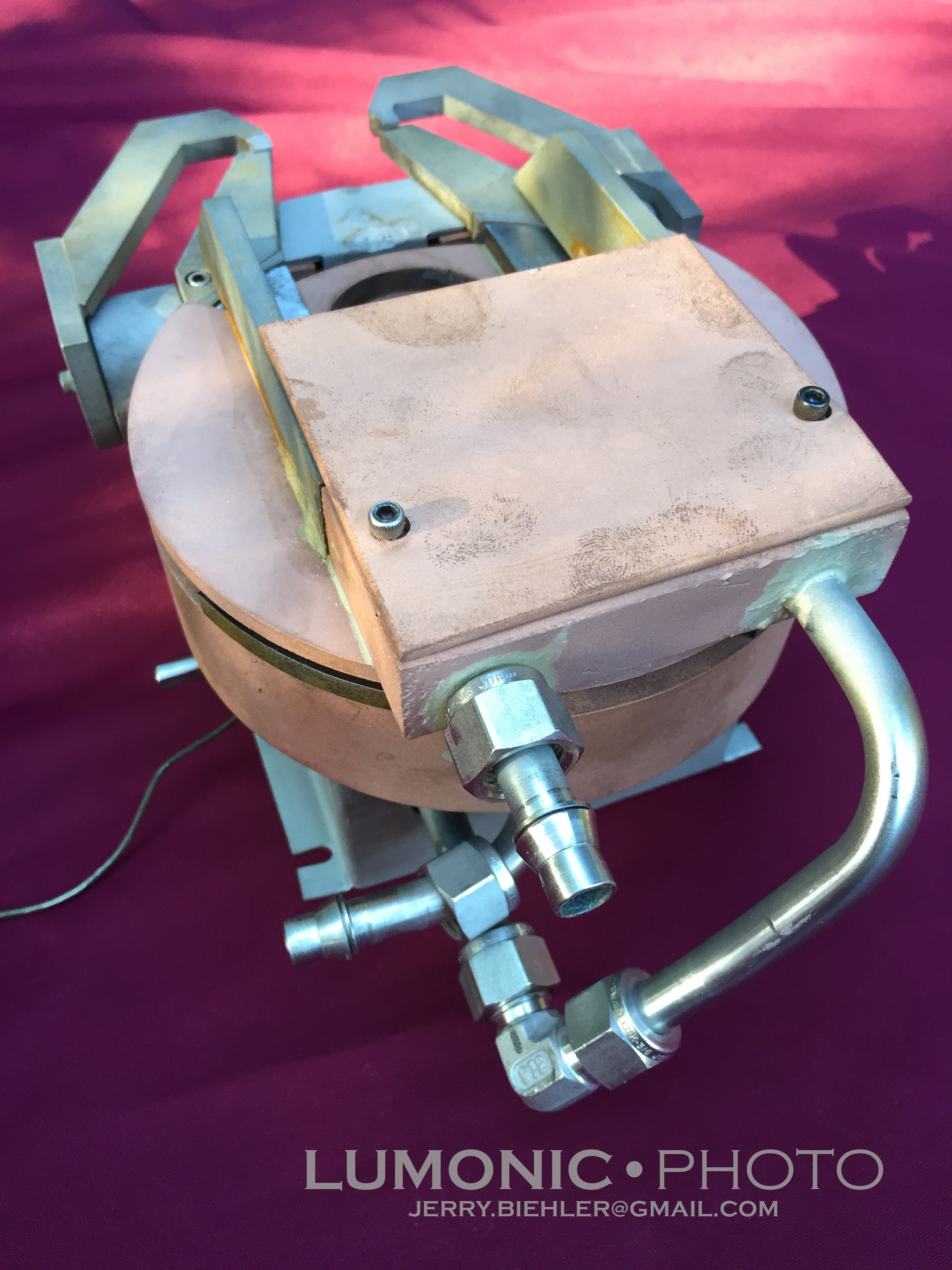

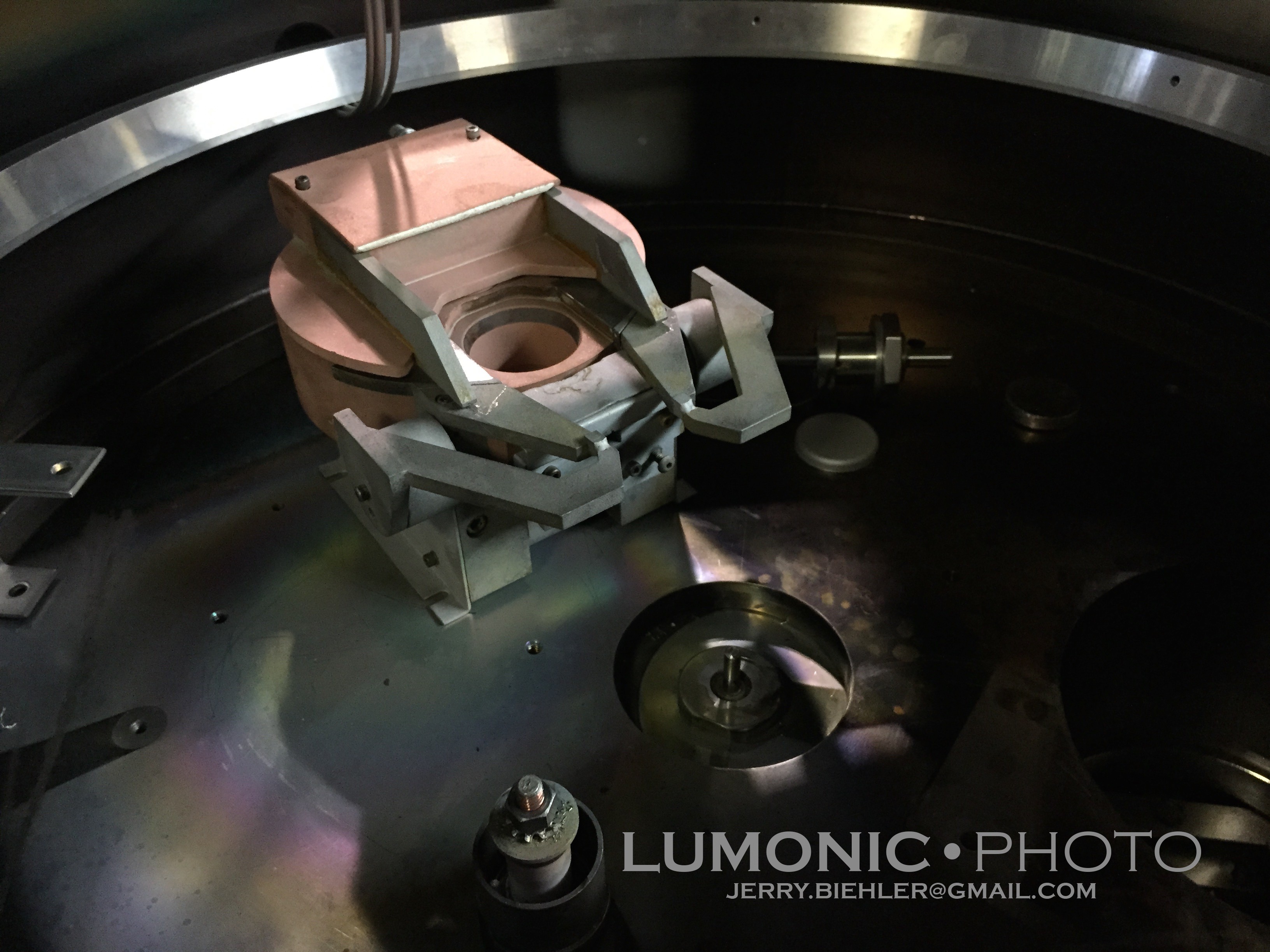

I lucked out and found a couple e-beam guns on ebay. The first was a sloan single pocket gun. It is designed to run at 10kv a up to 1.2 amps. It was designed by a company called Sloan and now is made by another company, I believe this one is made by the latter.

The seller did a awful job packing and several ceramic standoff were broken. It appears it was used to coat gold, traces can be found in the corners of the gun. Having only one pocket would be rater annoying. the plan was to mill out the copper down the center and make a sliding crucible that would allow me to change materials that I wanted to coat. Then I found this guy, a 4 pocket version of the same gun and I got it for $80 plus shipping out of canada. Not bad!

The seller had asked a guy where he worked to pack it up and ship it while he was out of town. He shipped it packed in newspaper! Not a good choice!

Standoffs were broken, cooling lines were crushed, metal was bent. It was a mess. The seller refunded me the cost of the broken parts ($80) so I basically got it for the price of shipping. I took it apart, replaced the bearing for the index drive, made and replaced a detent roller, straightened out the bent parts, replaced the broken standoffs and brazed in new stainless water cooling lines. Finally I bead blasted the gun and put it back together.

Jerry Biehler

Jerry Biehler

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.