Got the pump installed, plumbed in, and running yesterday. It has been running about 30 hours now and is at about 8e-7 torr right now. I thought I had a leak but I cant find a thing with the RGA in leak check mode and a bottle of helium. I think it must be all the water in the system from everything being up to air for so long, especially since I had to rinse the valve body out with hose to get all the crud I scrubbed off out of the system. Well see where it is before I leave for work tomorrow.

I still need to tie the pump into the frame and hook up a couple more pneumatic lines for the roughing valve on the chamber. I used a dual stage valve that allows you to softly pull down the chamber without disturbing things in the chamber.

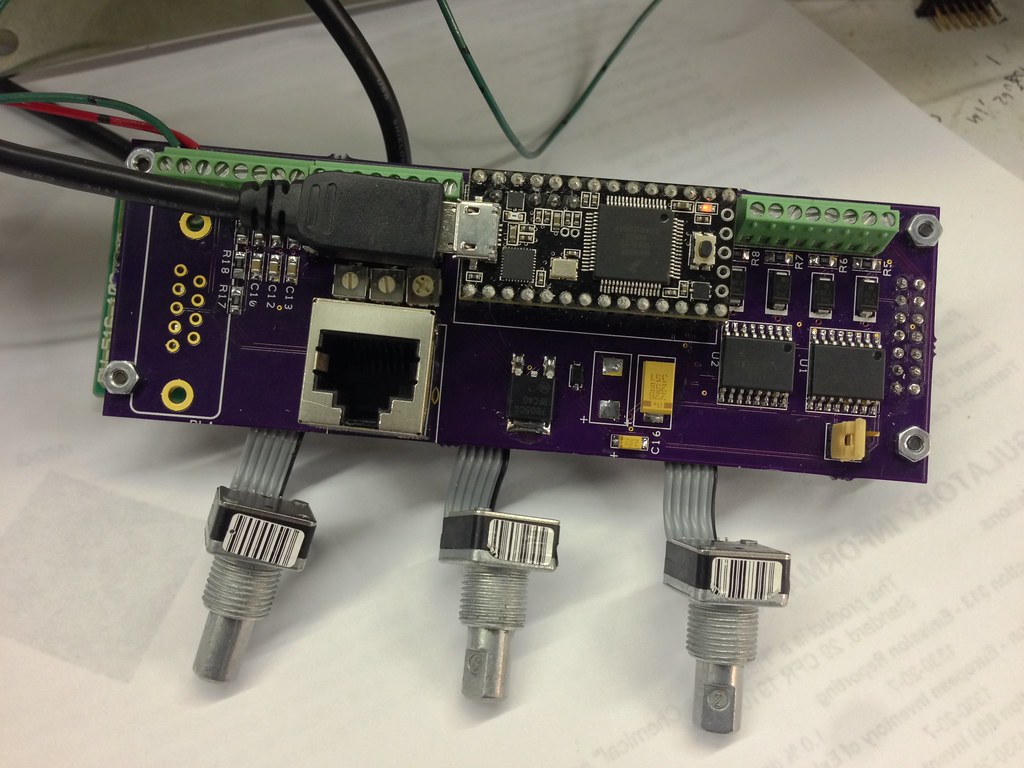

Here are some pics of the filament controller I have been building, it is based on a Teensy 3.0 and the board piggybacks on the back of a Noritake 2x24 VFD. I have used these in several other projects and they are very easy to use, they use the standard HD44870 LCD interface. The module will drive 6 power mosfets forming three controlled channels, two will be limited to about 100 amps, the third will be limited to 400 amps. The mosfets are driven by IR2110 mosfet drivers with a 40khz base frequency at 12vdc gate voltage. The controller gets current feedback from LEM hall effect sensors and voltage feedback through a set of voltage dividers. The controller can be remotely controlled through three 0-10v external voltage sources. Interface is through three 32PPR grayhill encoders. I also installed a RS232 port for external interface if I get that far in the future.

The board also serves to interface the full range Pfeiffer vacuum gauge on the RGA. It reads the 0-8.6v logarithmic voltage signal from the sensor, does the math, and displays the result on the vfd as well as displaying any errors with the sensor.

I need to build the power section next. It will be all bolted down to a heatsink with 150 amp semiconductor fuses on the smaller mosfets and a 500 amp fuse on the 400 amp channel.

Jerry Biehler

Jerry Biehler

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.