Background

FRC (First robotics competition) is a High School program built to promote STEM education. The students build 120lb robots to compete in a new challenge every year. The robots themselves cost thousands of dollars so each team typically only builds one. I want to provide a cheaper alternative to allow for more hands on learning and development.

This project has two main objectives:

- Create a large format, low cost kit

- Teach students skills they need to build competitive FRC robots

Skills to be taught:

- Safe use of power tools

- Read and understand part drawings

- Assembly practices and trouble shooting

- Basic electricity concepts (Voltage, Current, etc…)

- Wiring

- Basic drive code using WPI library

See update log #1 for what the initial lesson plans would be.

Kit components

The following describes the target components to be used

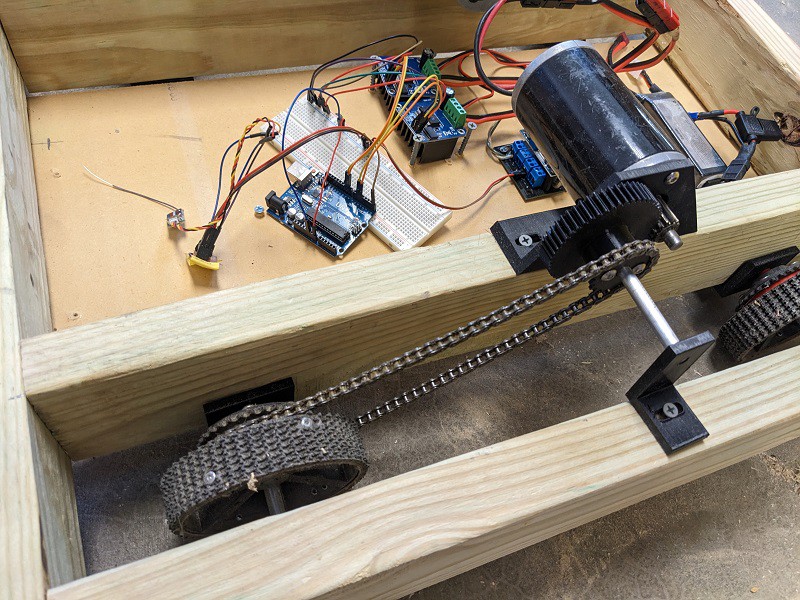

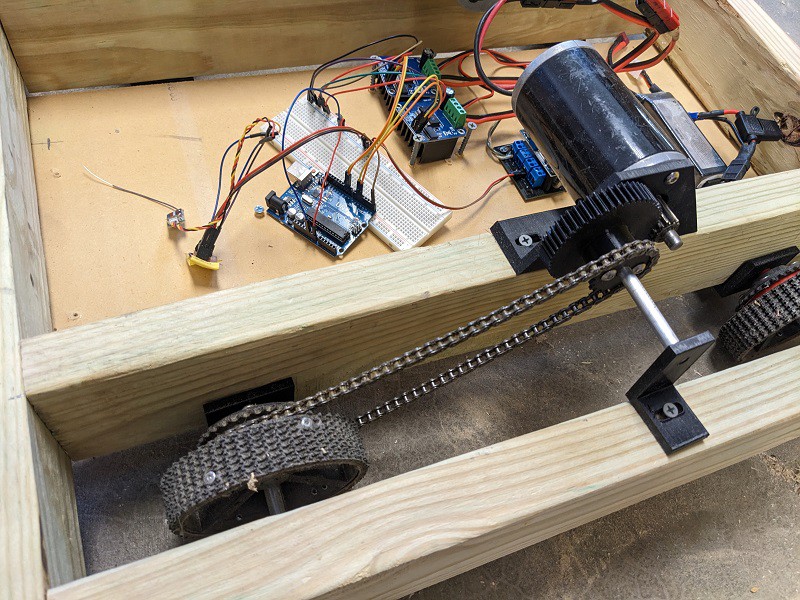

Frame

- 24"x 27" frame built with 2x4s

- Easy, cheap, sturdy. Components needing higher precision will be 3d printed

DriveTrain

- 4 4" wheels on deadaxle

- Dead axle referring to the wheel spins on the axle and not with

- Axles are 8mm to make It easy to switch to using cheap 608z bearings later on

- Axle supports are 3d printed brackets

- Have not tested turning on carpet, may need to switch to 6 wheel drop

- 2 12V Cim brushed motors, 7.7 gear reduction

- First stage is aluminum pinion gear->3d printed PETG gear

- Second stage is 3d printed sprockets

- Cims are readily available to FRC teams but may switch to another motor for reduced cost

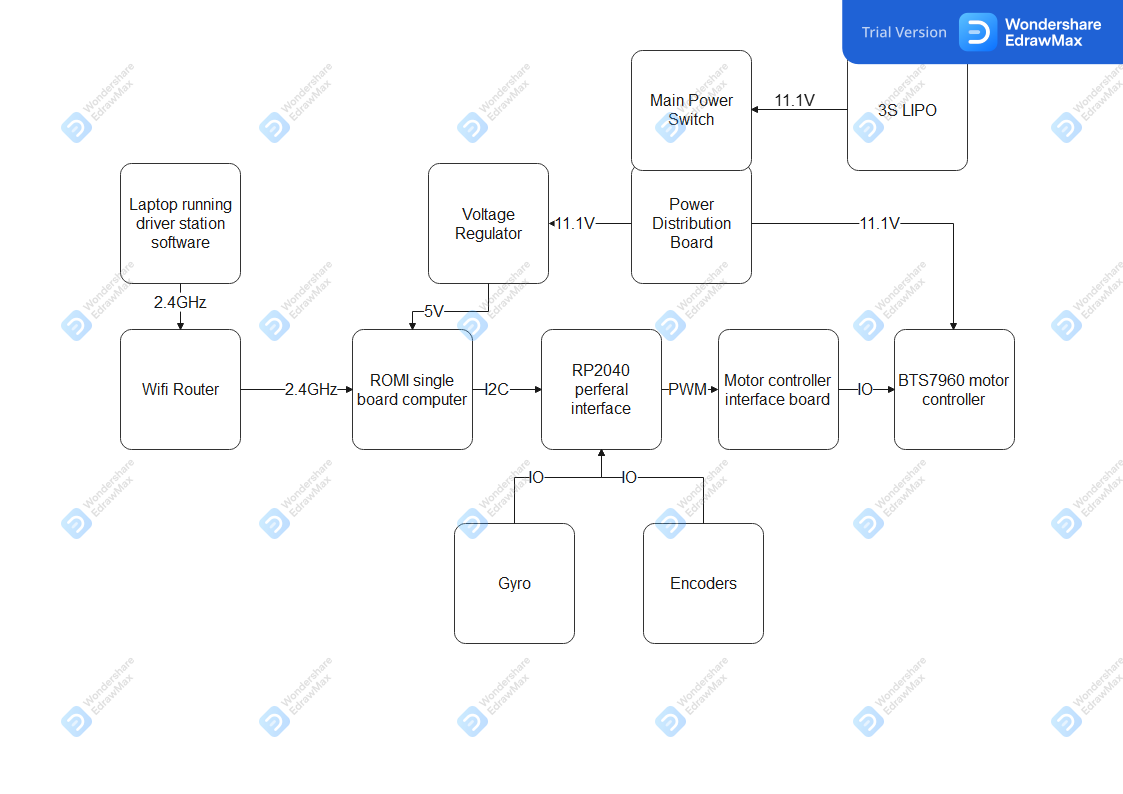

Power

- 3s lipo

- Readily available on amazon or other RC Hobby sports retailers

- Could easily be switched with standard FRC lead acid battery

- Power distribution

- Custom power distribution board

- Has mounting location for voltage regulator

- Could easily be switched out with standard FRC distribution boards

- Power switch

- 120 amp breaker switch

Control

- Linux single board computer running "ROMI" software for main controller

- Standard FRC control system uses a National Instrument's RoboRio, ROMI software simulates that device

- RP2040 for real time peripheral interface

- I2C slave device to single board computer

- Handles communication to motor controllers and sensors

- BTS7960 for DC motor controllers

- High power controller with built in over current protection

- Need a interface board to convert normal RC style PWM signal to BTS7960 control signals

David

David

Tobias

Tobias

Darren V Levine

Darren V Levine