[X] = Experiment / Test

I wake up.

It's 9am.

I think "If I test the hotend now, I might be able to make it to the uni if things go wrong."

It took 6 hours, with the first 3 hours just finding my seldom used soldering gear because the thermistor I have wasn't pre-soldered to the included dupont connector. It's not like Trianglelab's CHC that conveniently had everything ready to go.

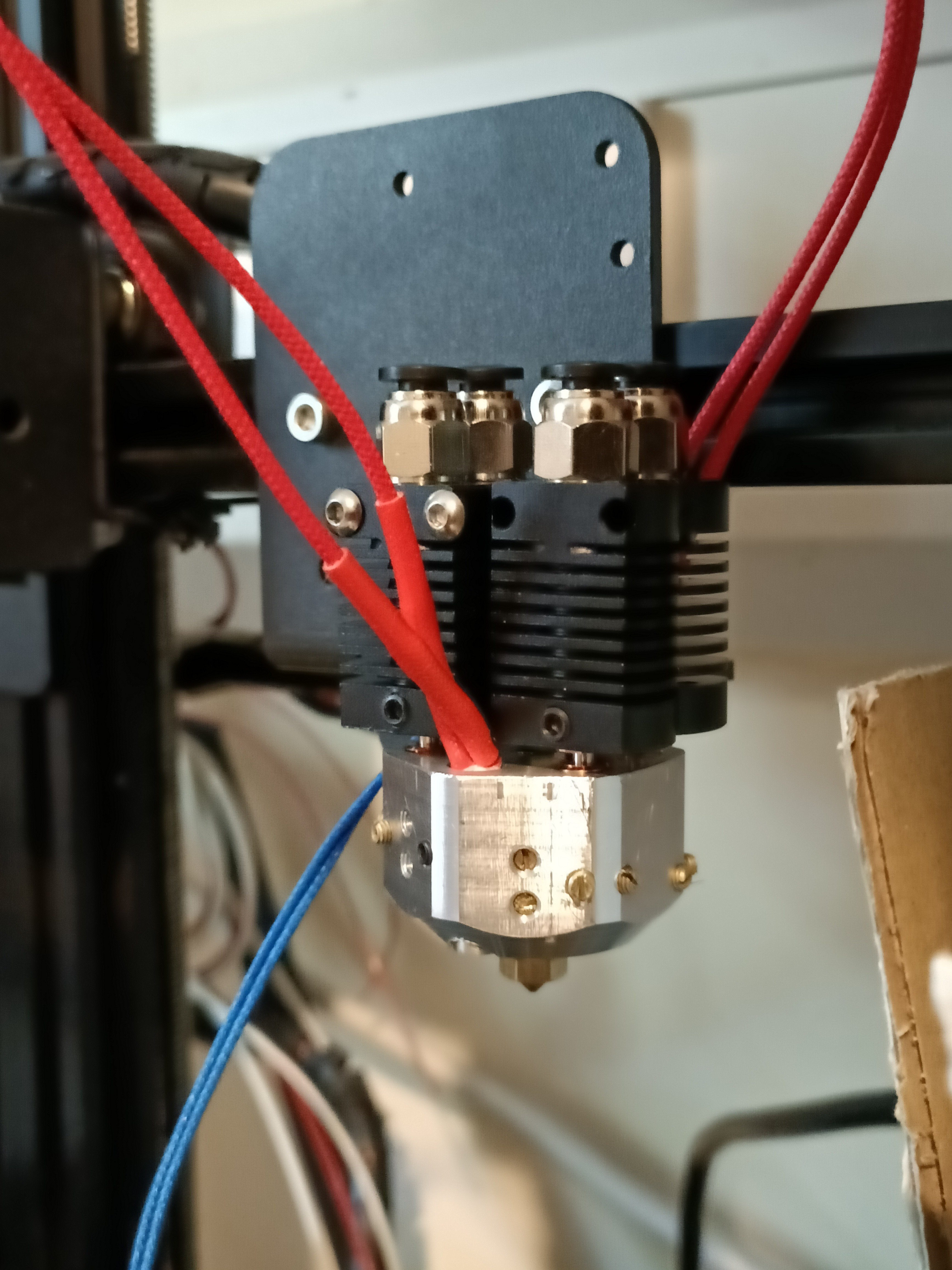

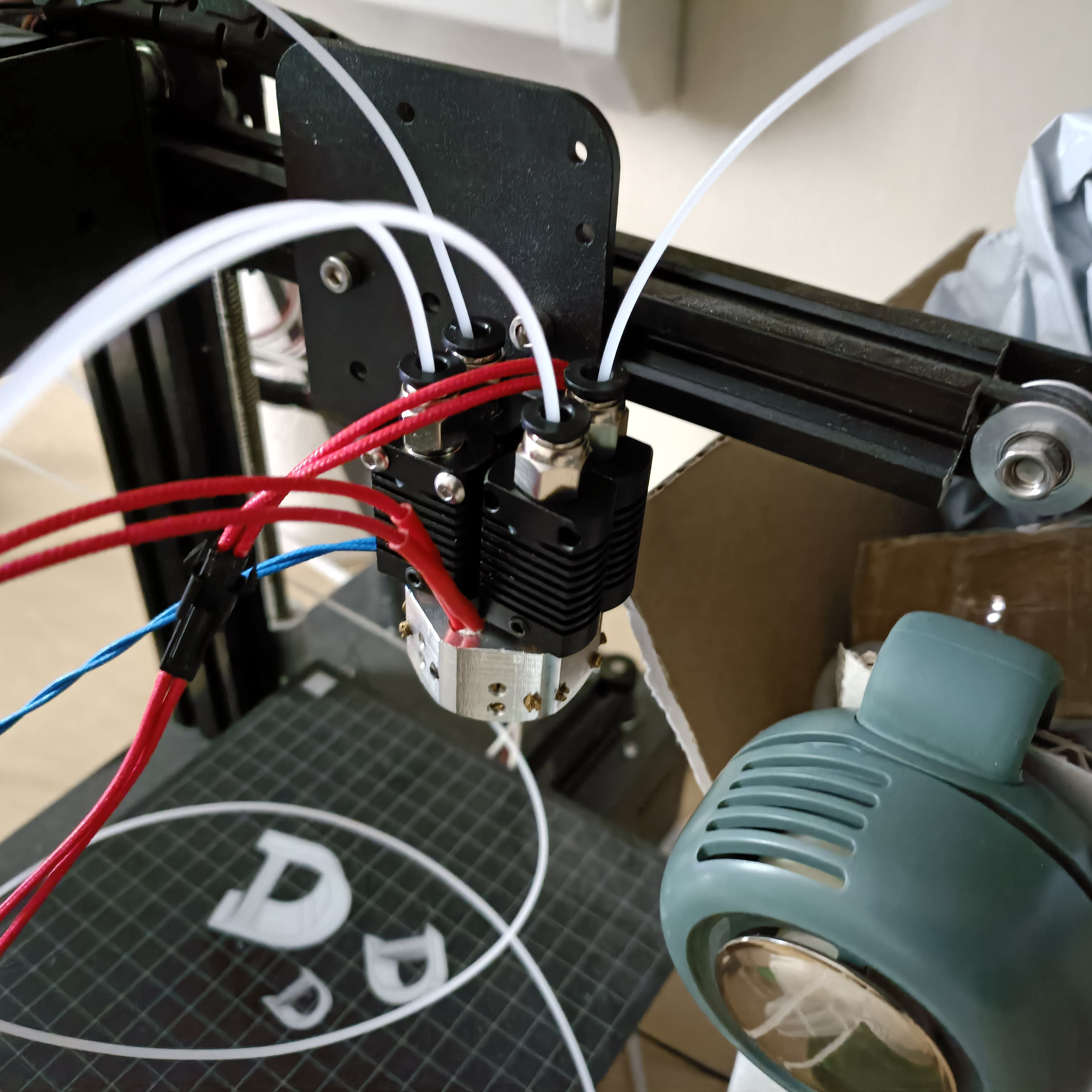

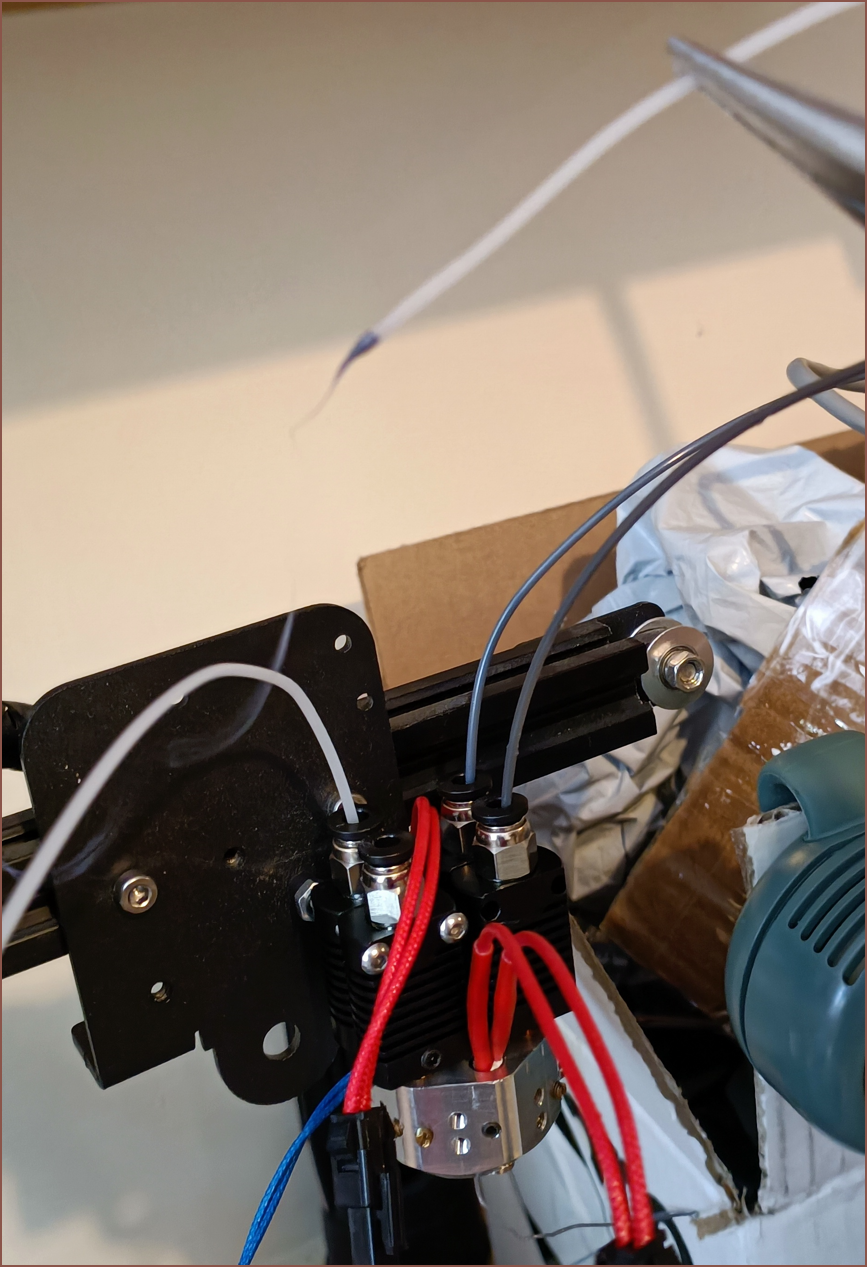

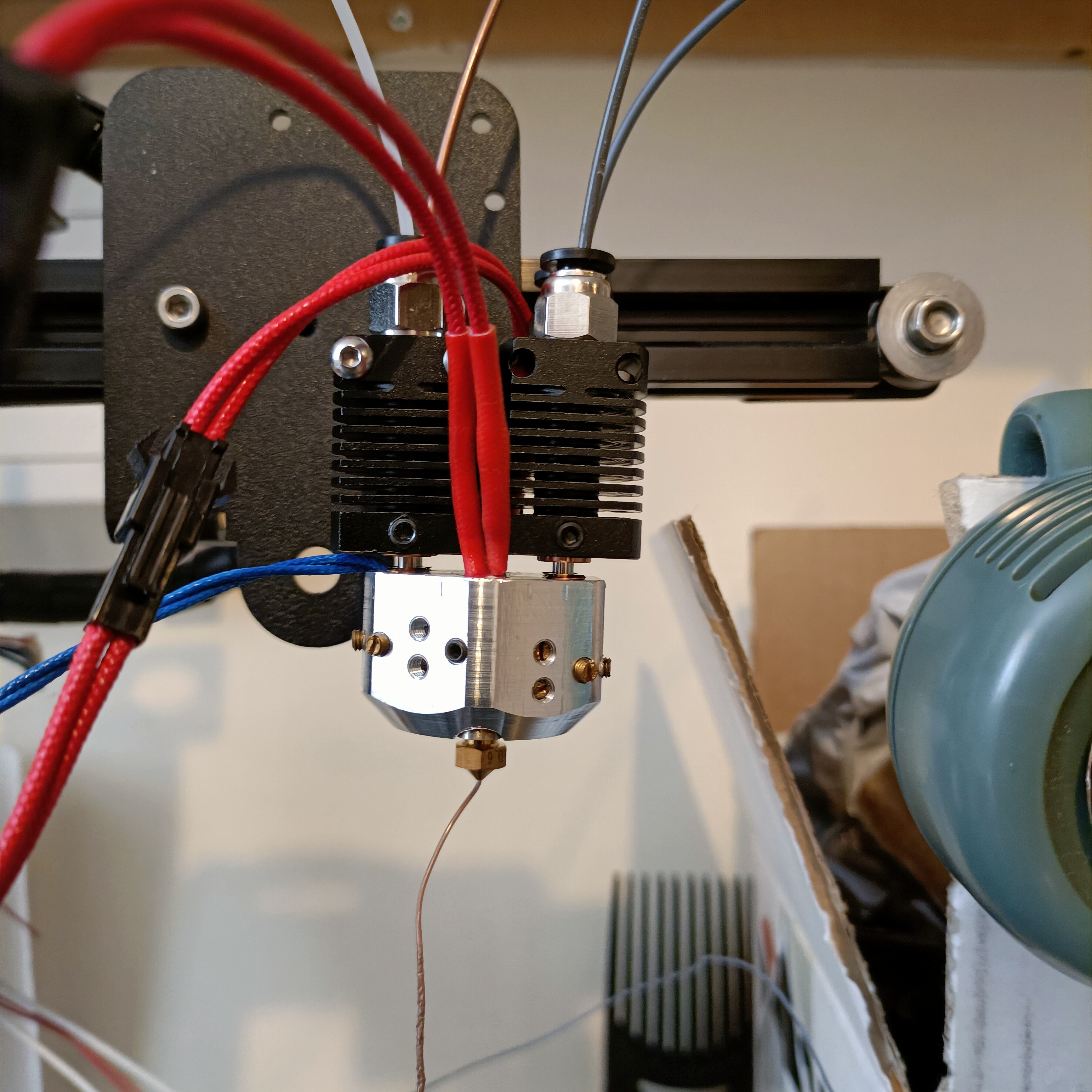

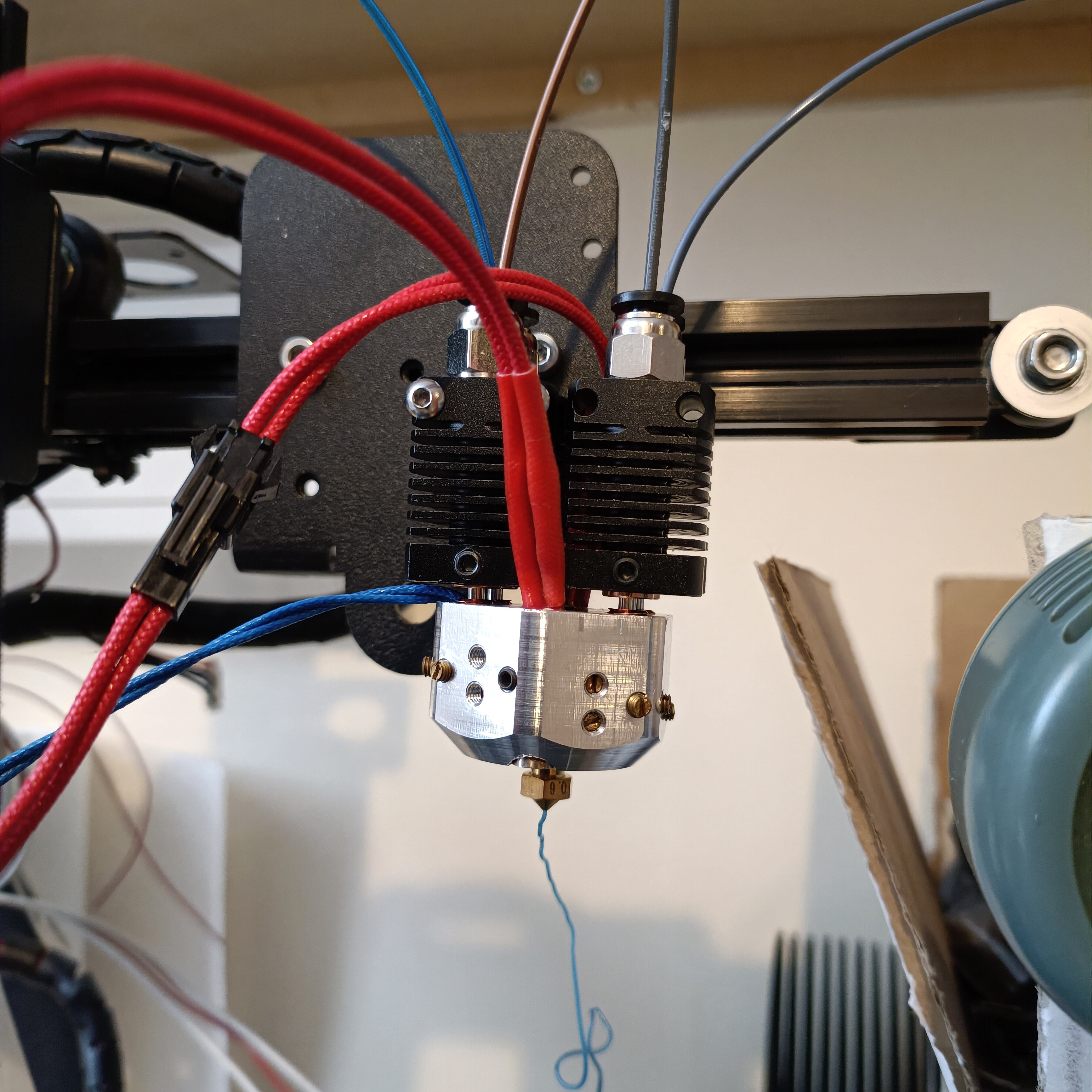

I found the CR10 mounting plate intended for the #Revolving Hotend [gd0012] and used that to mount the Coaxial Hotend on the currently unused DP2 printer, just like the last time.

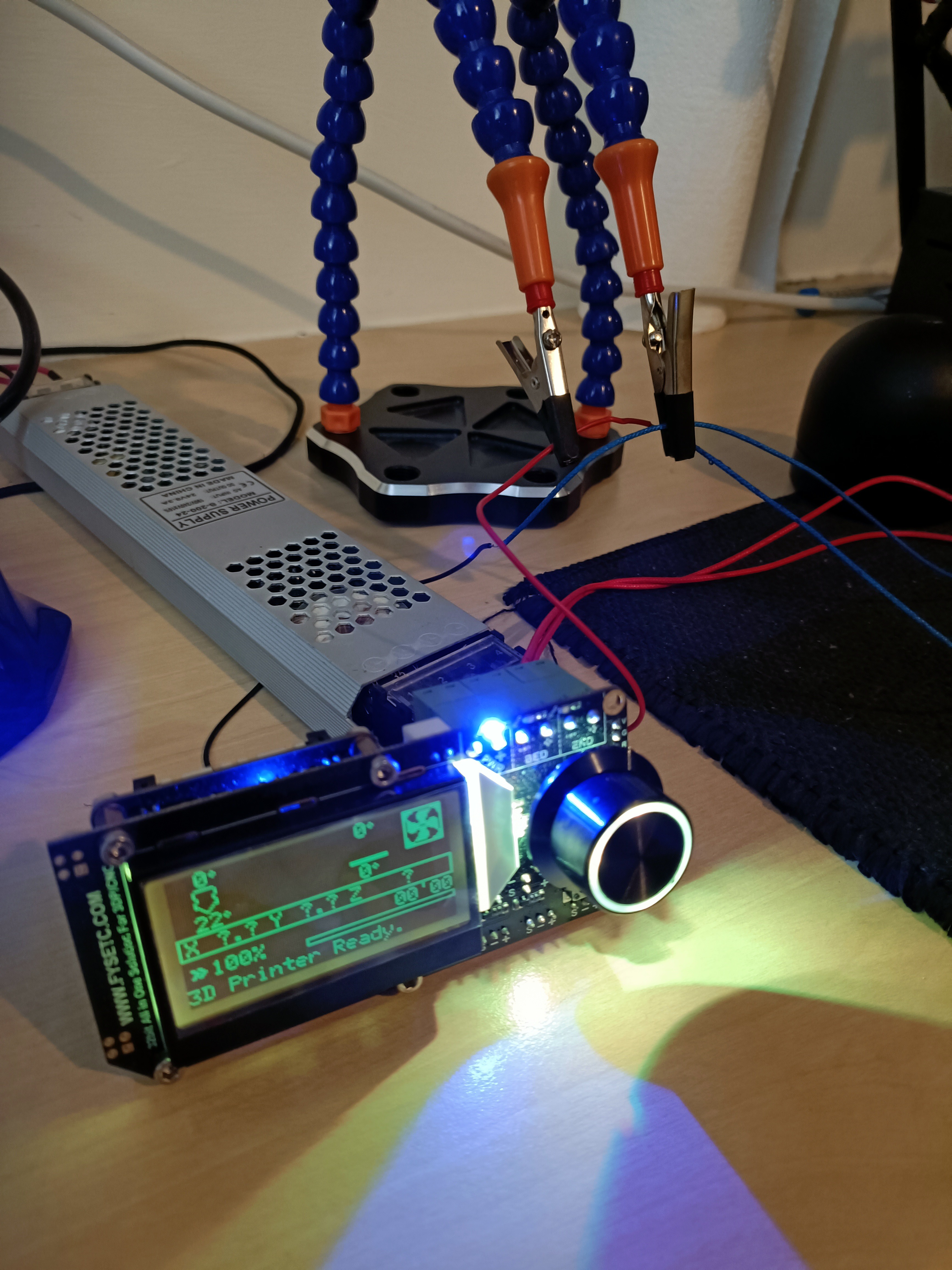

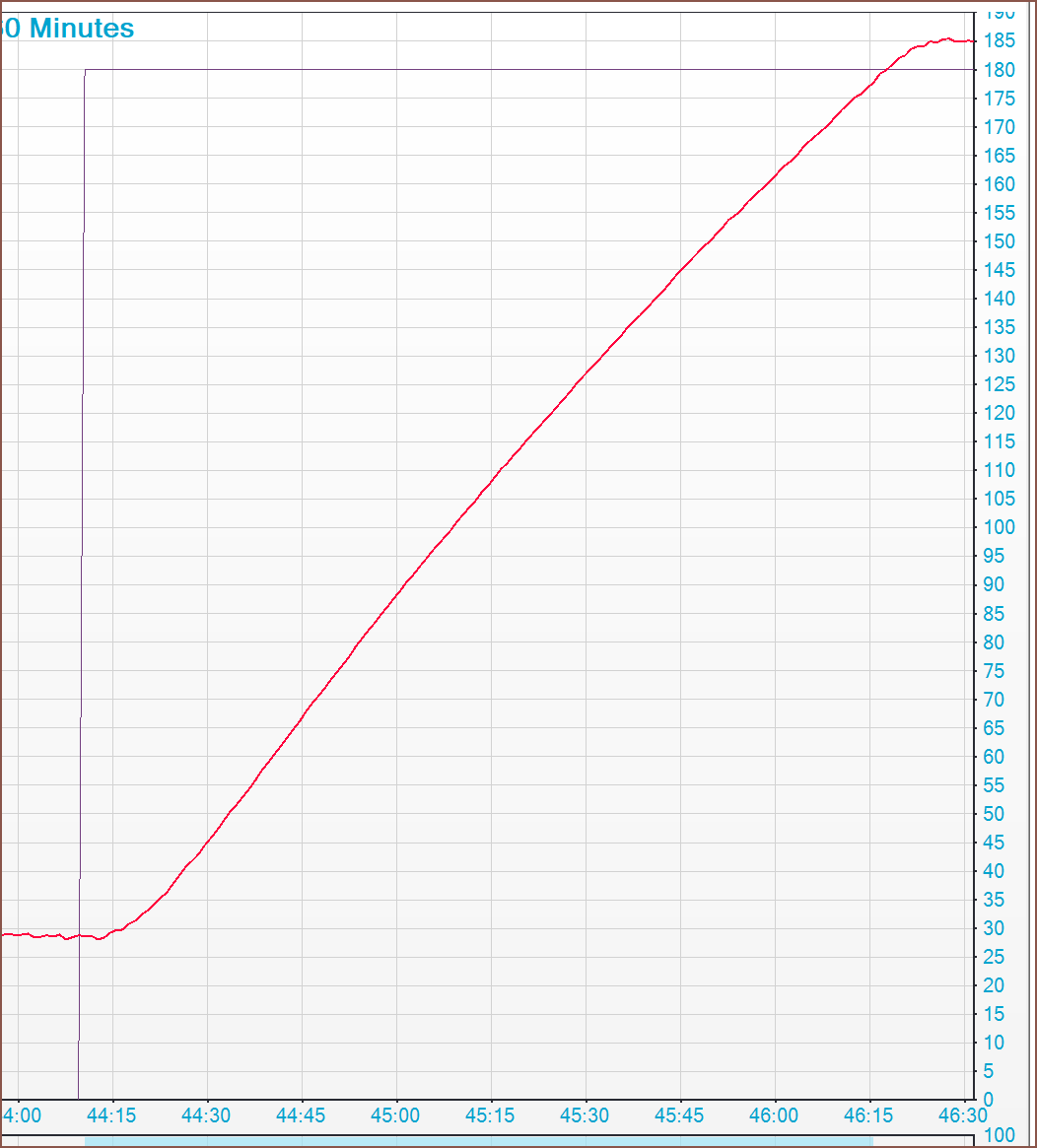

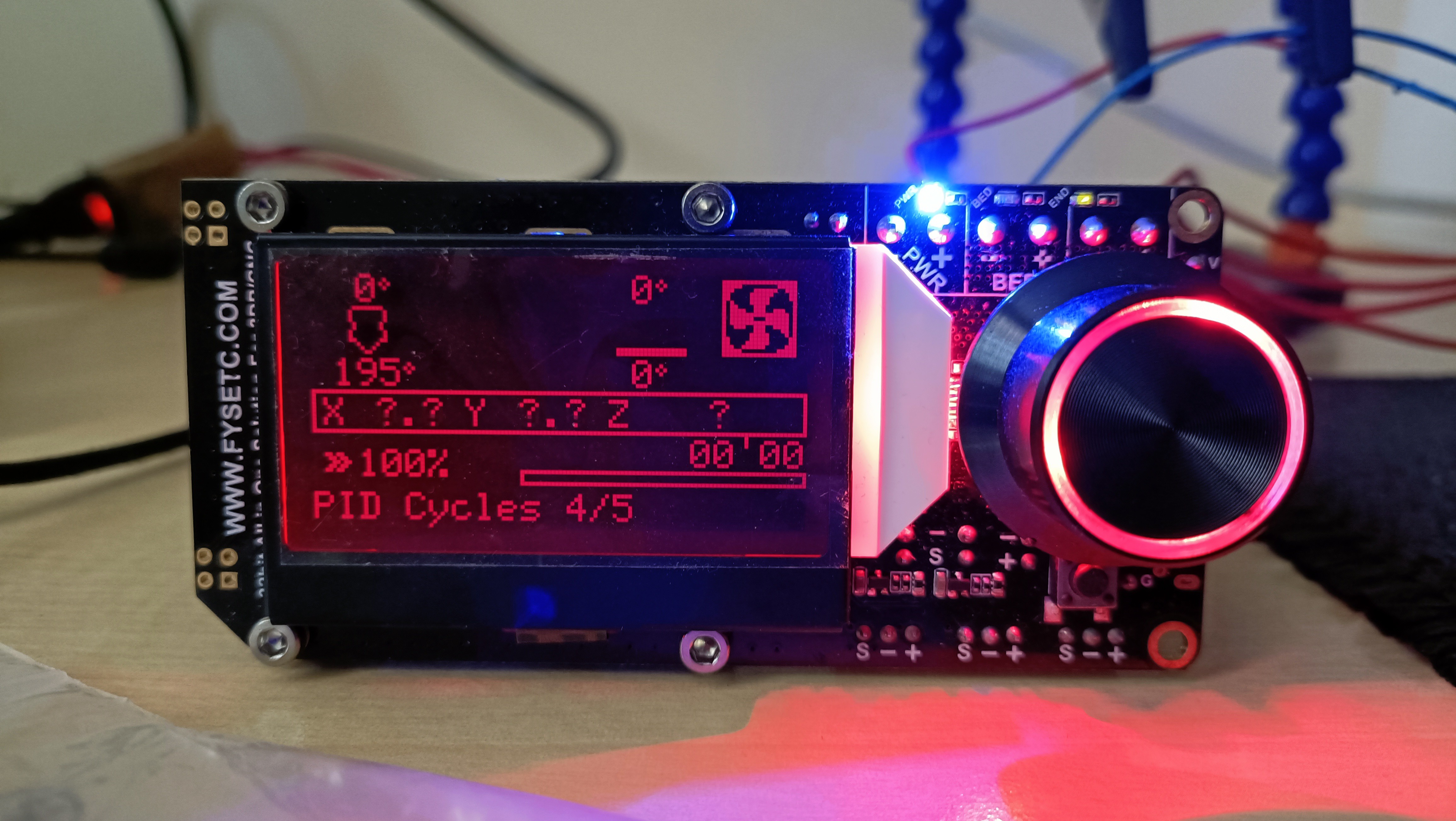

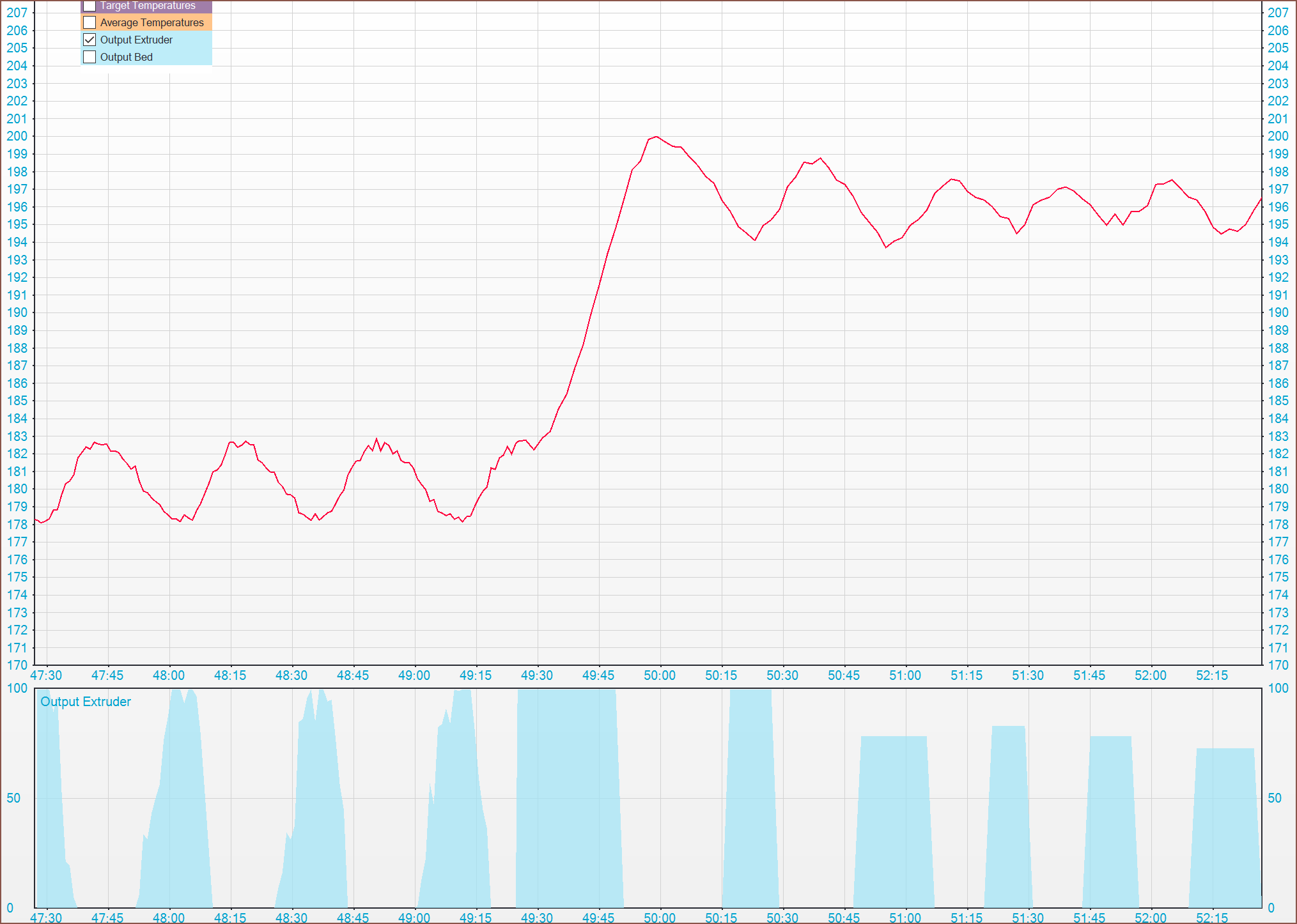

I got my FysetC AIO out and the firmware is conveniently already configured to the correct thermistor. I started a PID tune, but the temperature climbed really slowly when only a single 40W cartridge was powering the hotend.

Since 80W at 24V is 3.33A and the AIO is good to 5A, I plugged in the second cartridge and now the temperature was increasing at a standard rate.

Usually, the auto PID swings around the target (in this case 196) by a couple of degrees, but this time it only differed by +/- 1 degree. I can only assume it's because there's a lot more thermal mass than for a typical hotend.

The first PID was rather poor so I ran it again, starting from 180C not room temp.

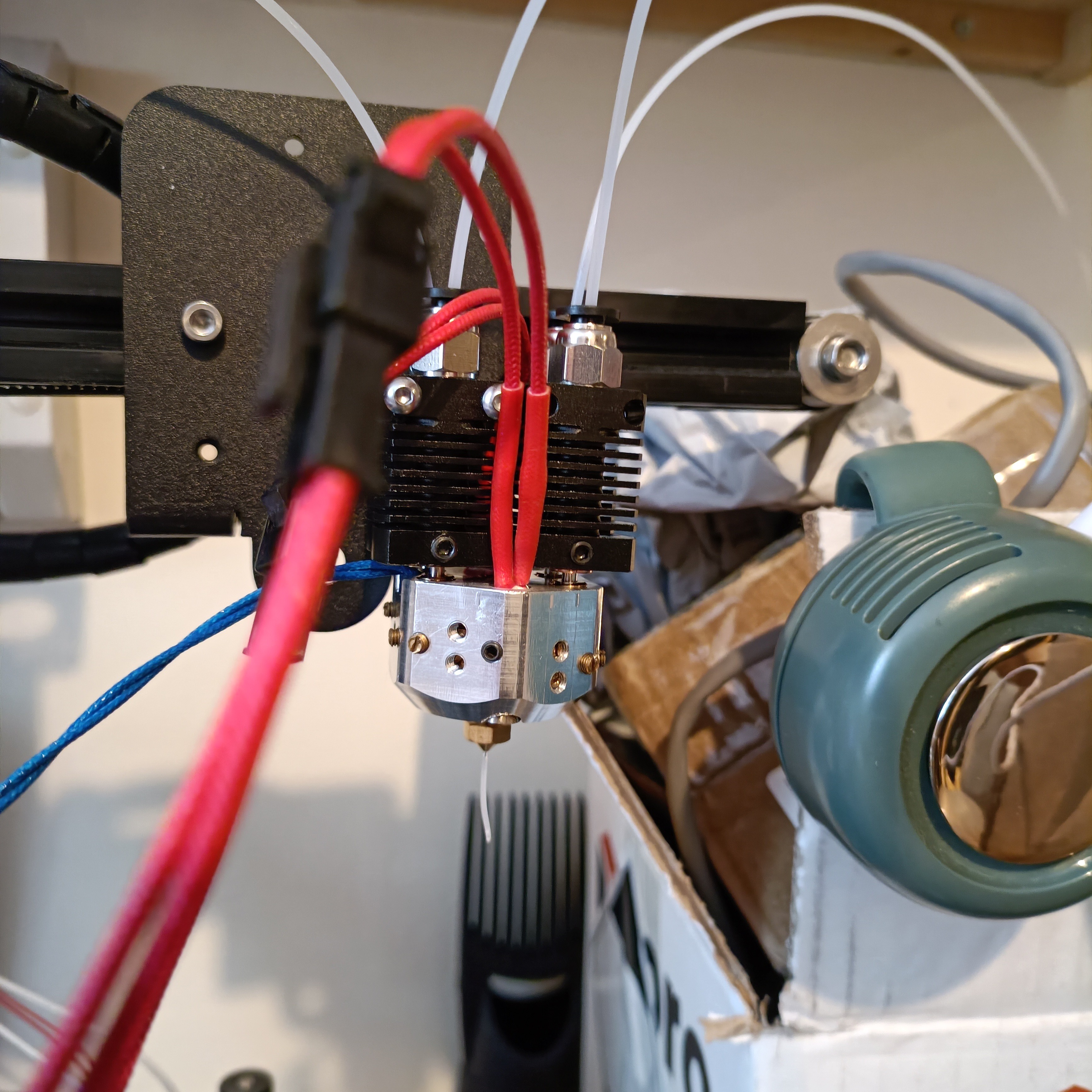

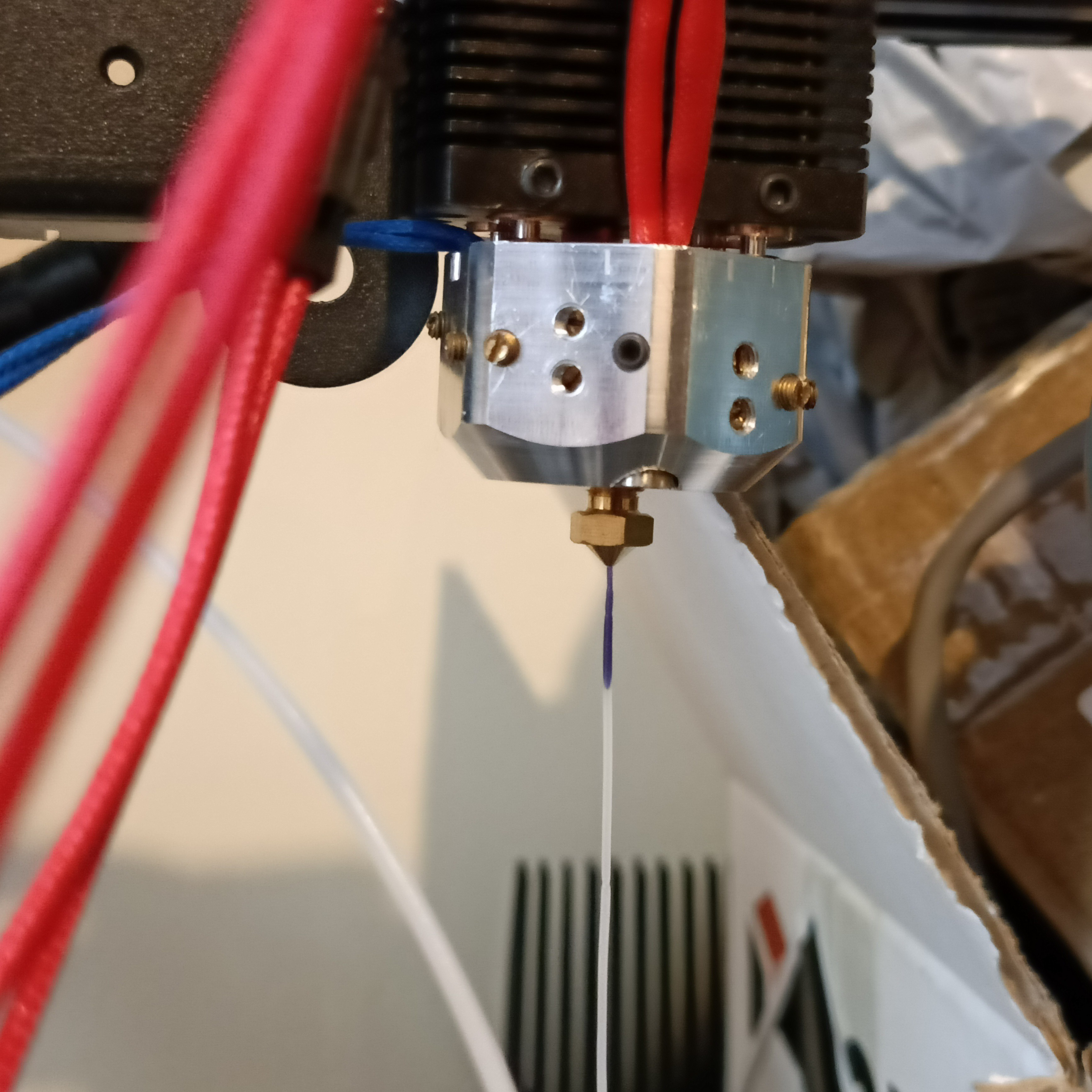

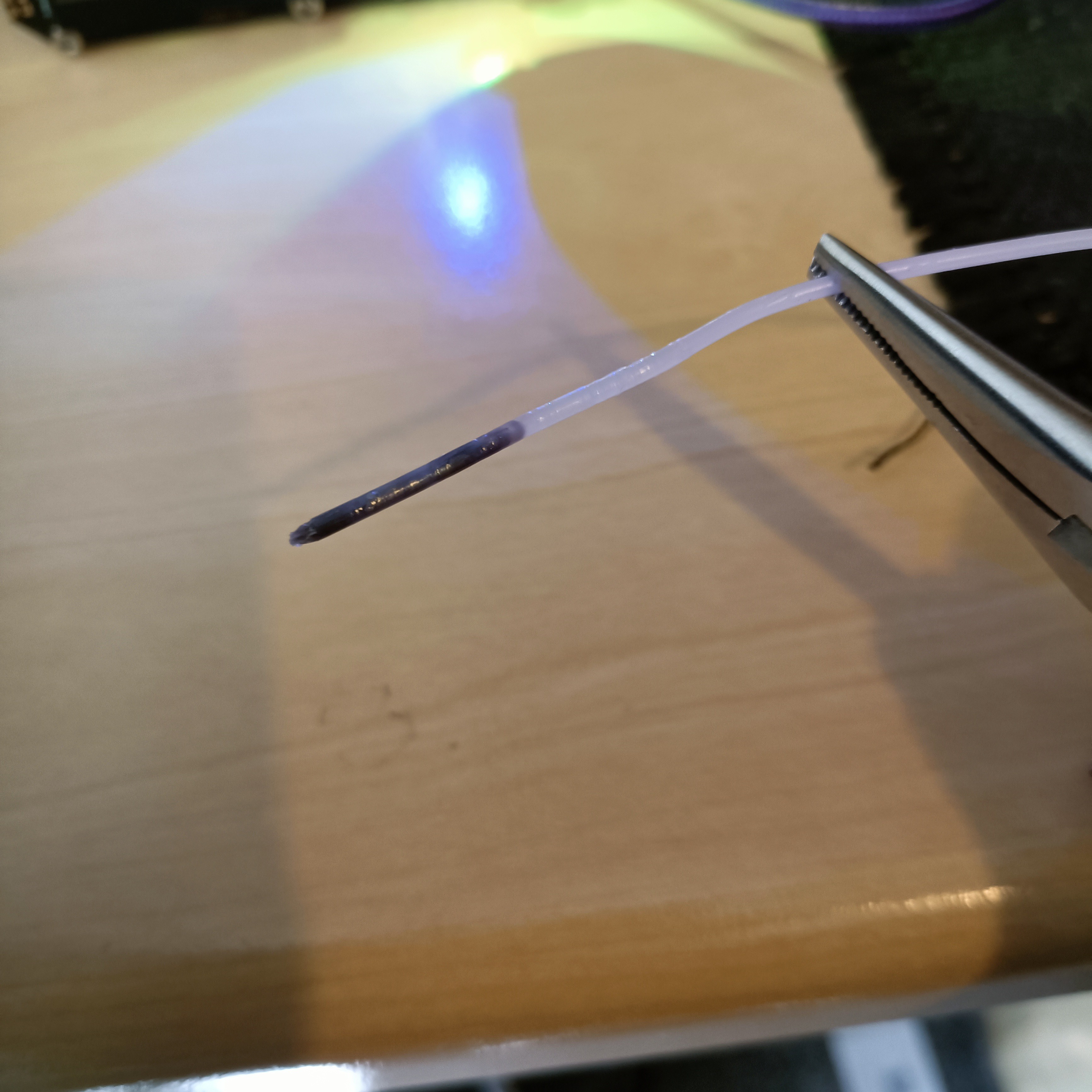

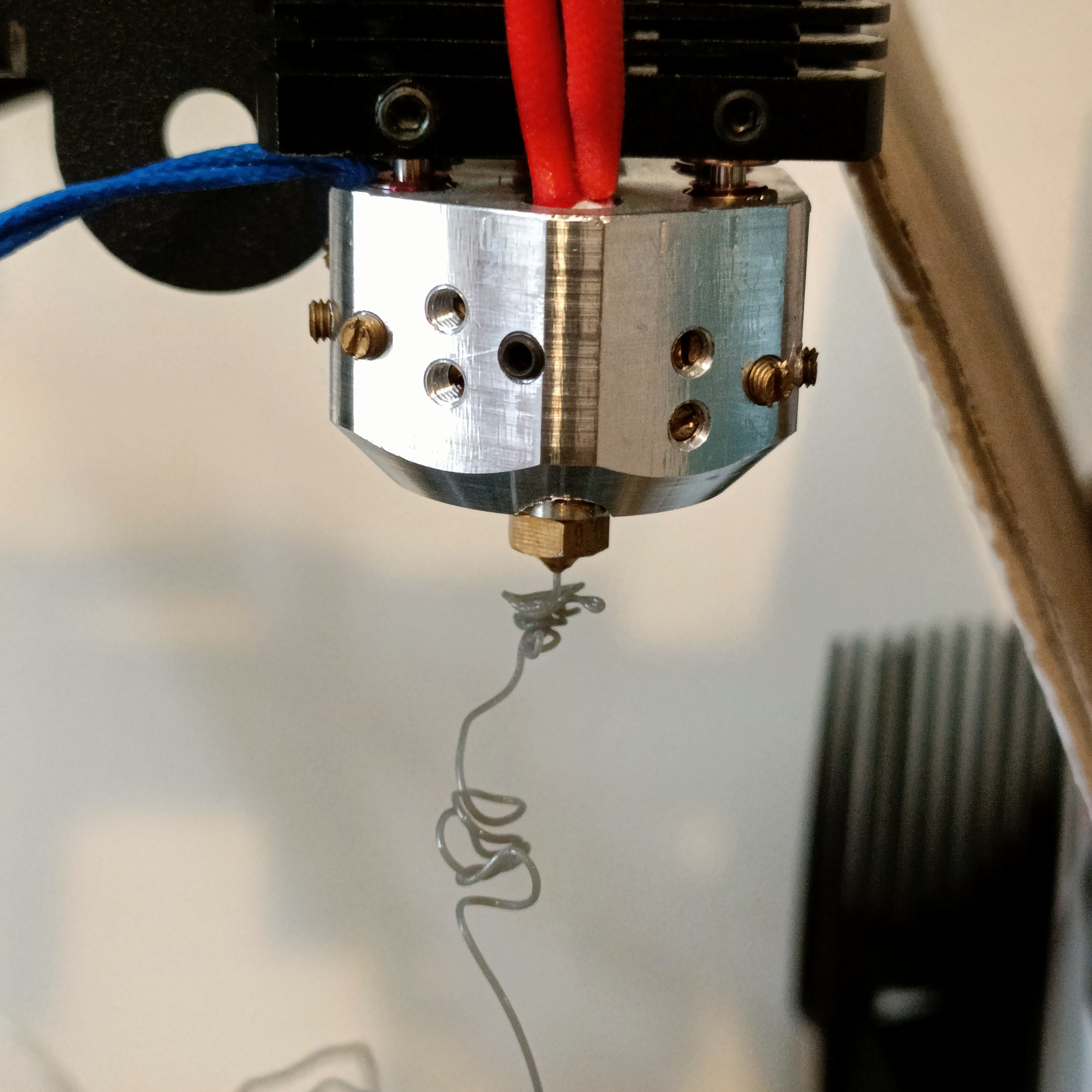

So the first thing was to purge with cleaning filament. It took a while, but I eventually saw something actually poke out the nozzle! (image below)

This was me running the hotend at 200C because 180C was kind of tough. I'm also starting to think I've just bought a lifetime supply of cleaning filament because I've still got loads left.

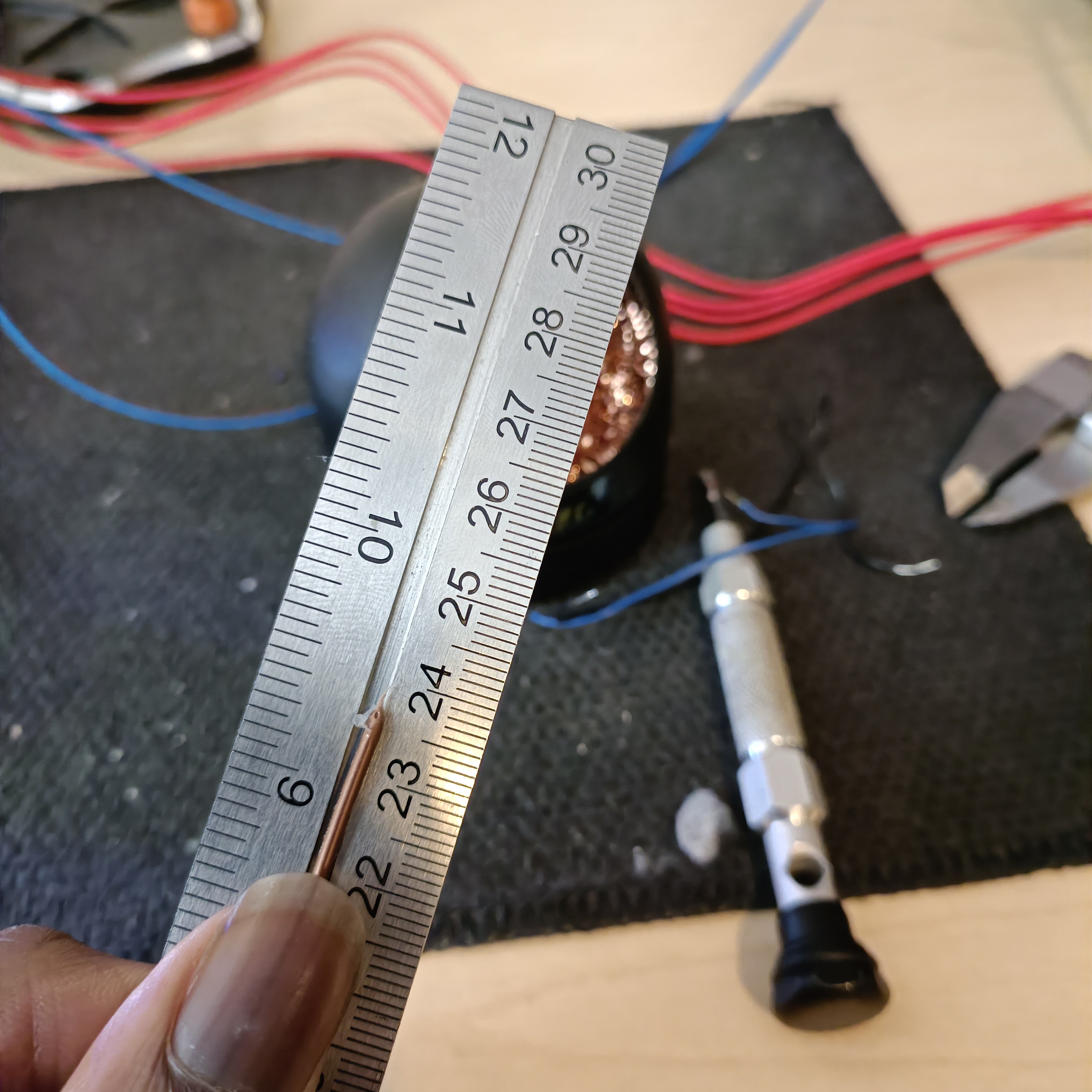

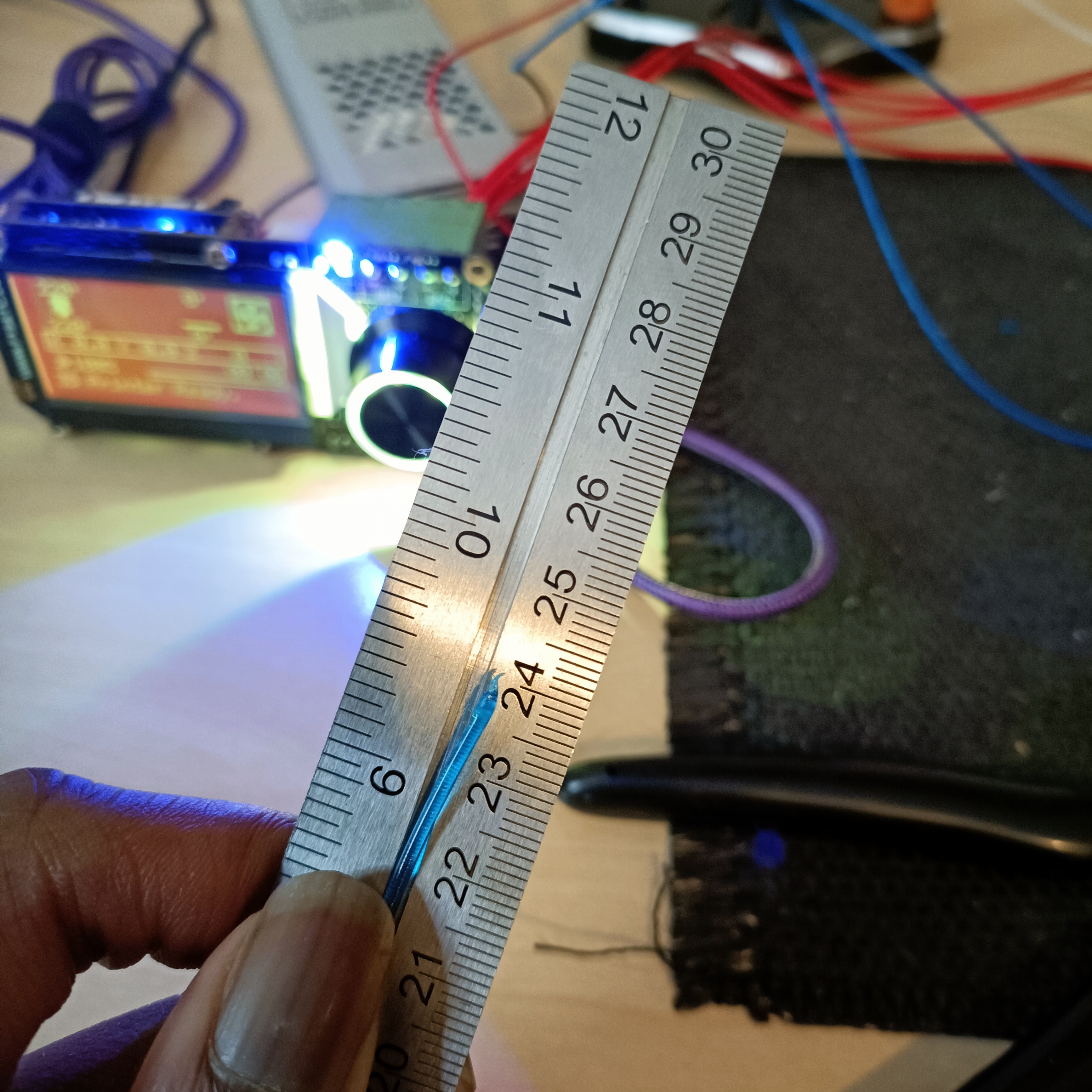

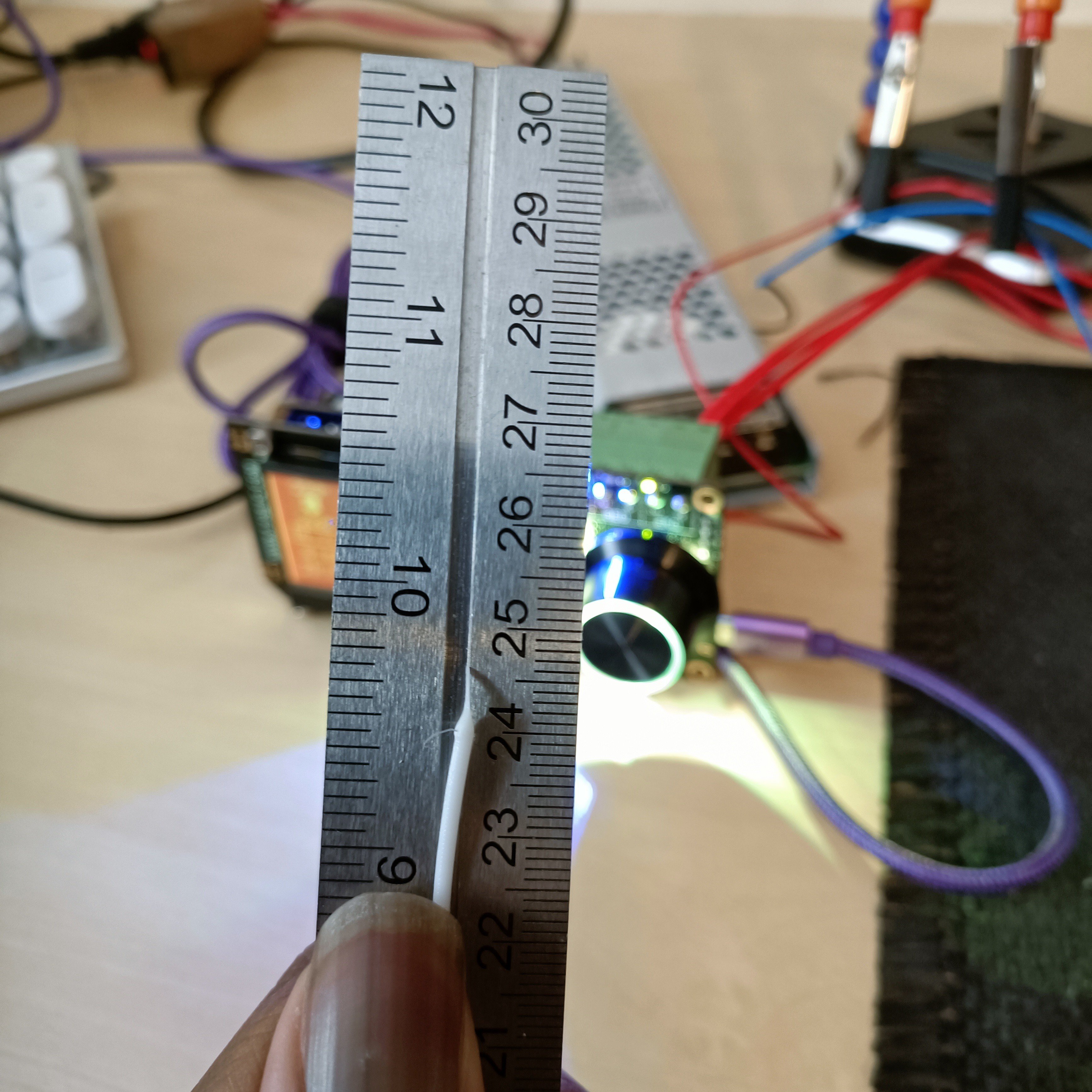

I put in some PLA to try extruding it, but then I worried about the fact that PLA clogs easier than other materials for all-metal heatbreaks and switched to PETG instead. Before I did that, I cut of precisely 1 ruler length (305mm) of material to see how much I needed for the colour change.

The first change was rather sharp. That's the dark blue PLA I used before switching to the "Solid Grey" PETG.

This was the first, but since I already started with some PLA beforehand, it's probably not accurate.

I didn't do the length test for the Dark Grey PETG I put in next because it's so similar to the Sold Grey in colour. I'm starting from the lowest filament path and progressively going upwards. Interestingly enough, some material still got to the next cleaning filament input.

The next filament I put in was the extremely wet copper filament, and it didn't take long to see it's identifying bubbliness though the nozzle.

The last input looked like this. I then realised that the pressure inside the hotend is probably pushing up the other inputs since there's nothing actually holding them in place. Thus, when I was extruding one filament, I was periodically extruding a tiny bit of the other 3.

I'm starting to think 24cm is the magic number. It means that 6.5cm of filament needs to be purged for a colour change.

This is white... ish. It seemed off-white when it came out of the nozzle. I also think it's safe to say that the purge length is 6-7cm.

Lastly, I just wanted to make sure that the grey input was working correctly. Since I've already extruded before, the measurement would be inaccurate.

Lastly, I just wanted to make sure that the grey input was working correctly. Since I've already extruded before, the measurement would be inaccurate.Conclusions

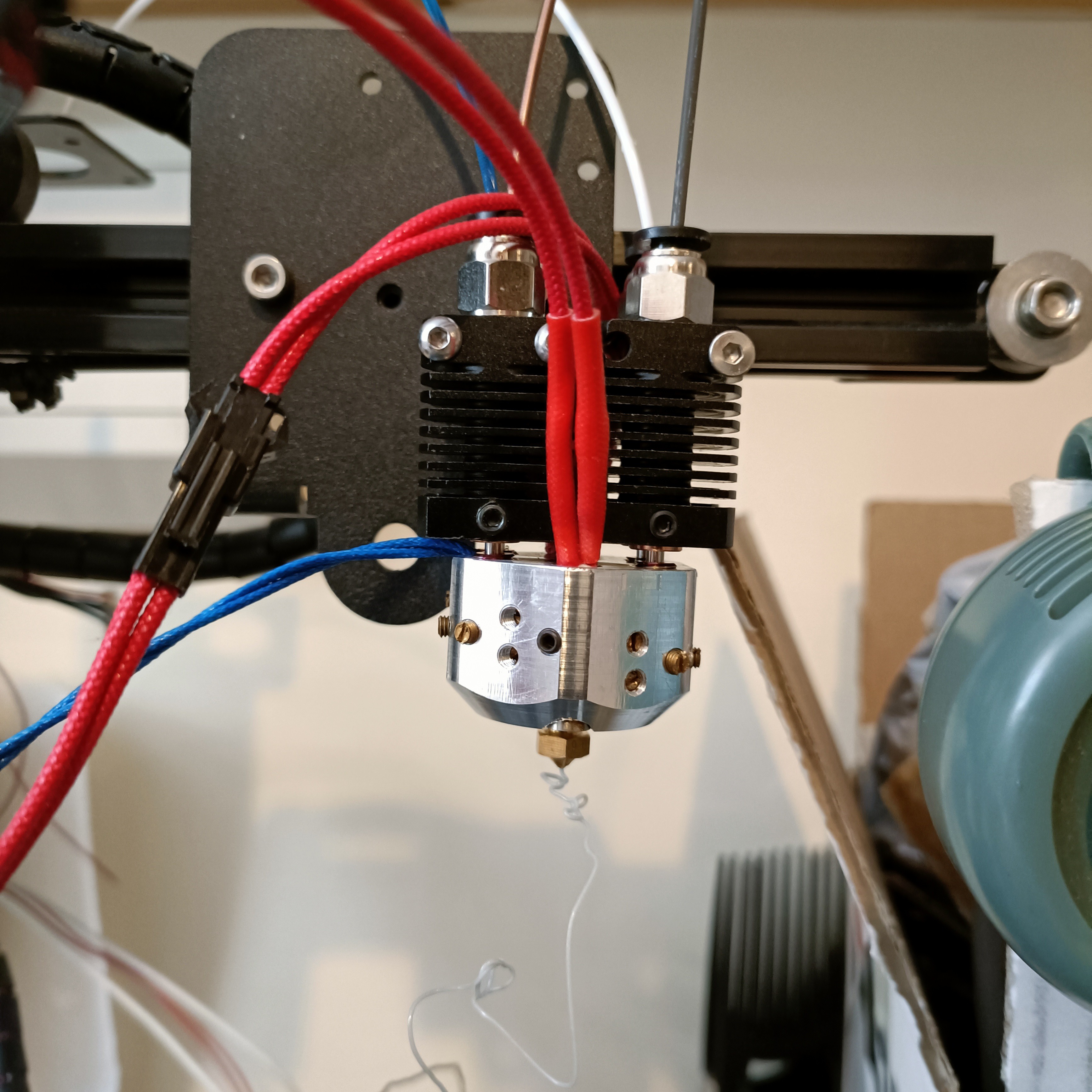

Perhaps some kind of high-temp Loctite will suffice, but I'm thinking of having a grub screw to prevent the heatbreaks from potentially twisting out of place. I feel like the 2 inputs that weren't mounted have probably loosened, and have precautionally tried to turn the heatsinks in the tightening direction before turning off the heat.

Taking the heatblock off, I havent' seen any signs of leaks yet, though I'd likely need to put in a lot more than the 50cm or so I've done in this test to see that. Just like how SpaceX's main target for their last Starship launch was "it leaves the launchpad", my main target is "Filament actually comes out of the nozzle via all 4 paths, and the hotend is still shiny afterwards".

I'm now taking off what grub screws I can to see the damage report.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.