So, instead of the "move fast and break things" approach that Me In January did, I took a more cautionary approach and did some dry-runs first. It's a good thing I did, because I caught issues like the G3 crash ahead of time and was able to increase my Y current to 900mA because it was skipping steps.

After a successful test-run of everything running except fillament through the extruders, I installed filament into them. The large gear on the DDEs are useful because I can see / feel if the filament has actually gone inside or if it caught on the bowdens. Seemed that the PETG understandably went through the system a lot easier with the c8or set to 224 degrees instead of the 188 I had originally set and used in the dryrun.

After getting the skin on my thumbs iirritated and peeling from all the high-torque scrolling of the gear, I used my handy M165 R to set the mix to A1 B1 and see that it was set correctly before then extruding perhaps 200mm of filament in. While this was happening, I took a flashlight to see if there were any obvious leaks and I didn't see any, which is a good sign at least.

Whilst wondering if this filament was actually getting anywhere, I saw a whisp come out of the nozzle and ghasped.

There's filament, and it's grey! I'm only extruding in White and Black PETG. Thus I changed the start-gcode to heat the Coaxial8or to 224C and pressed print.

Now this is where all the goodness ends, because my Z offset was wrong and so I was scraping on the bed. Whilst trying to increase the babysteps, the printer just turned off. This wasn't like the G3 crash where it would restart after a bit, because the PSU LED was off too! Whilst turning the printer off and on again brought power back and I was able to re-tram the bed, the power cut perhaps 1 second into the homing and heating procedure.

So I did the calculations and when I add:

- 140W Coaxial8or

- 115W CHC Pro

- 24V extruders with currents (in amps)

- X: 0.6

- Y: 0.9

- Z: 0.6

- E0-7: 0.45 x 8 = 3.6

...I get 392W. Considering everything else would be probably another 15W, I've likely exceeded the overcurrent protection of my £6 PSU.

Look, I bought it because it was small, looked nice, was silent and would arrive fast (and £6 for all that sounded amazing). When I did the original calculations, I was getting maybe 80% utilisation, likely because of the lower initial motor current estimates of 0.6 for Y and 0.3 for each E.

This kinda makes a bit of sense because, during tests, I could hear the fans drop in frequency and the multimeter tested a shaky 20V value, most likely because the heaters are only toggled at a relatively low 7Hz from what I've heard in the Marlin discord.

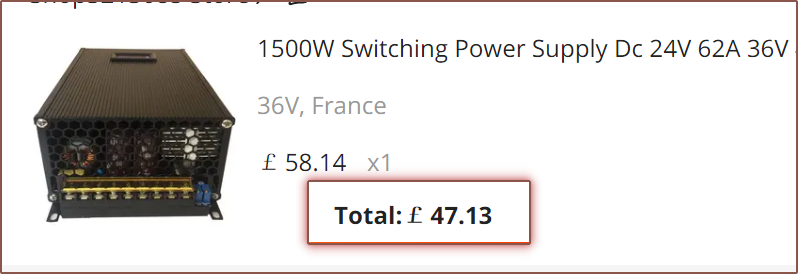

I've still got my £60 (that I bought on sale for £11 off), 0 - 36V, 1.5KW PSU beside me so I guess I can install that, but first I need to lower the voltage to 24V or else I'll fry everything.

Just not a fan that the voltage and current adjustment are two tiny trimpots.

Surely this won't be the third power supply this project eats up. The good thing about this PSU is that it's got a current and voltage reading so I'd be able to spec the next one accordingly.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.