The machinist technicians just happen to be quite busy at the moment, so I only asked them to mill the top faces.

Then I went to the waterjet technicians to ask for the flat parts such as the clamp plate. They just happened to have a small piece of 0.65mm copper that was large enough for 2 gaskets:

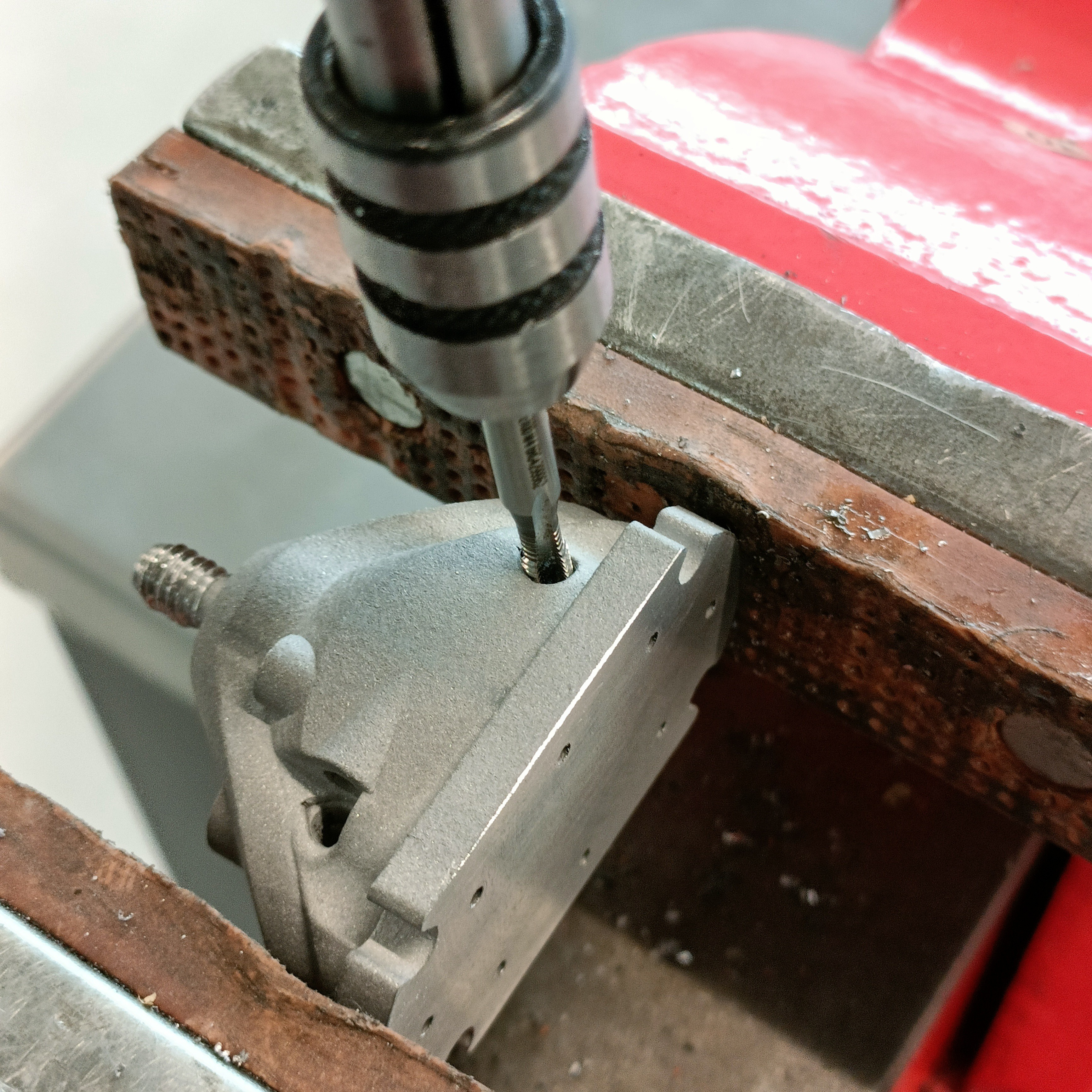

I'm thinking that I should've just left the sizing as is, because the taper through 3mm aluminium is very minor but now the holes are too small to just tap directly. I'm likely going to just wait either until the techs have time or I print a jig or something like using a pillar drill, as I don't think I'd ever get all 32 M6 threads tapped perpendicular to their faces. Worst case is just ordering more parts from PCBWay.

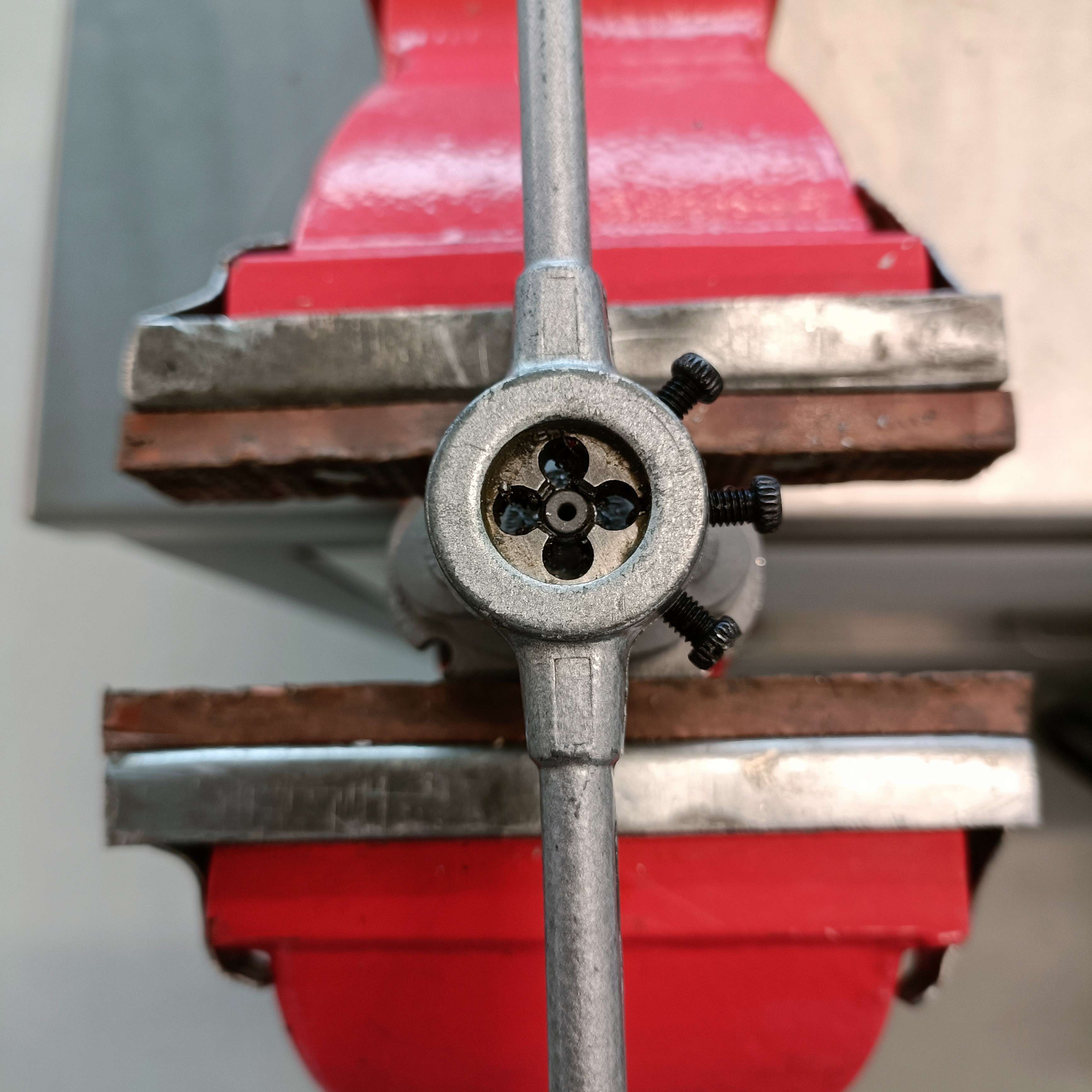

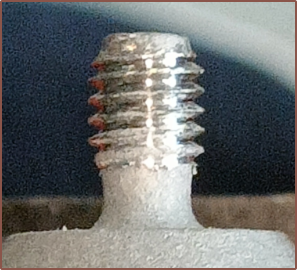

The M6 threads took a bit of careful consideration to get started, but I only got the threads to bite in one location meaning that it likely was going down the printed threads.

Lastly, I lined up my eye directly over each of the M4 holes to tap and used a fiducial marker like a shadow or tip of my foot to mark the horizontal line (to account for my head slightly drifting) and then placed the tap directly over so that I could account for any 2D angle errors.

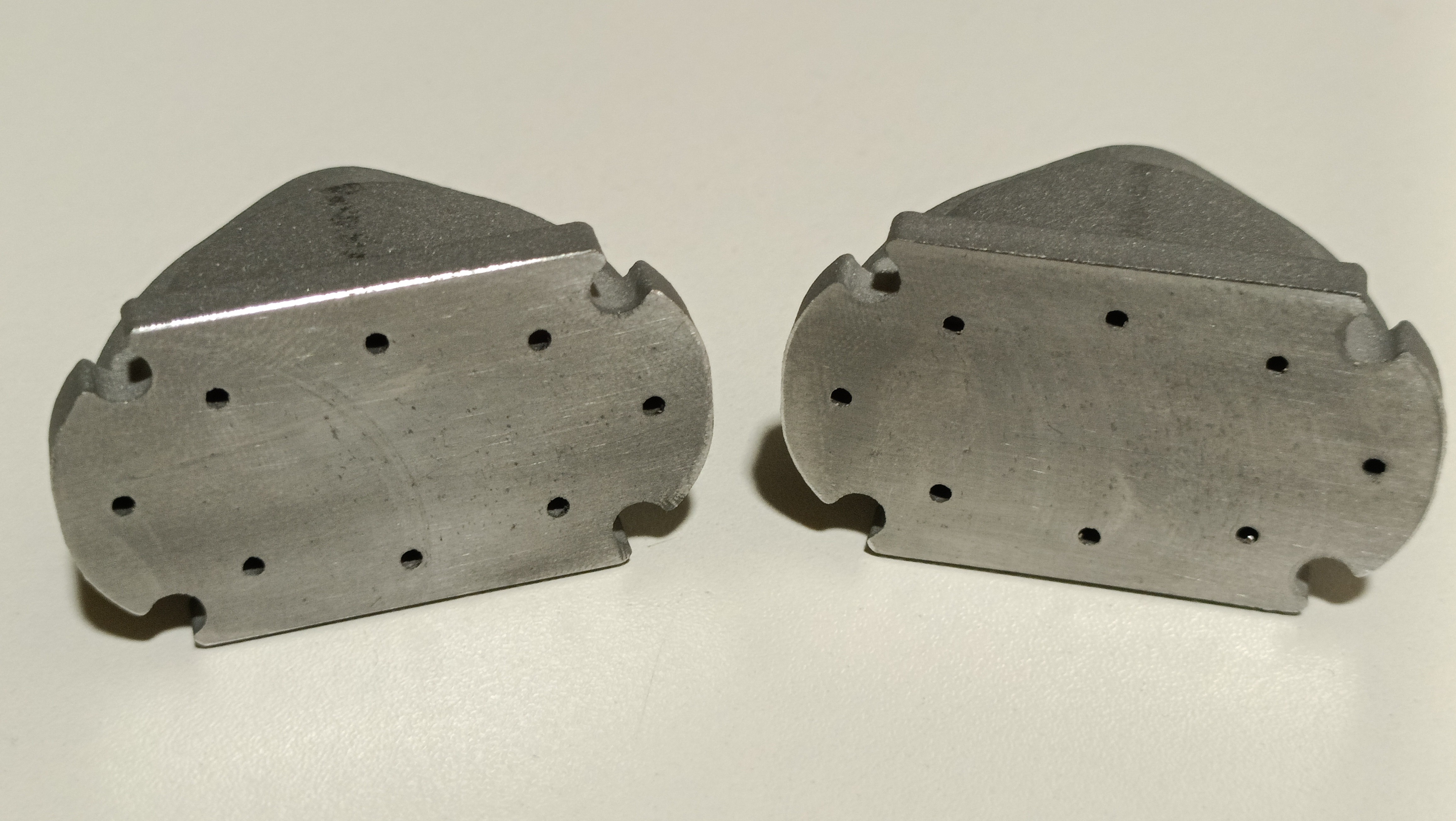

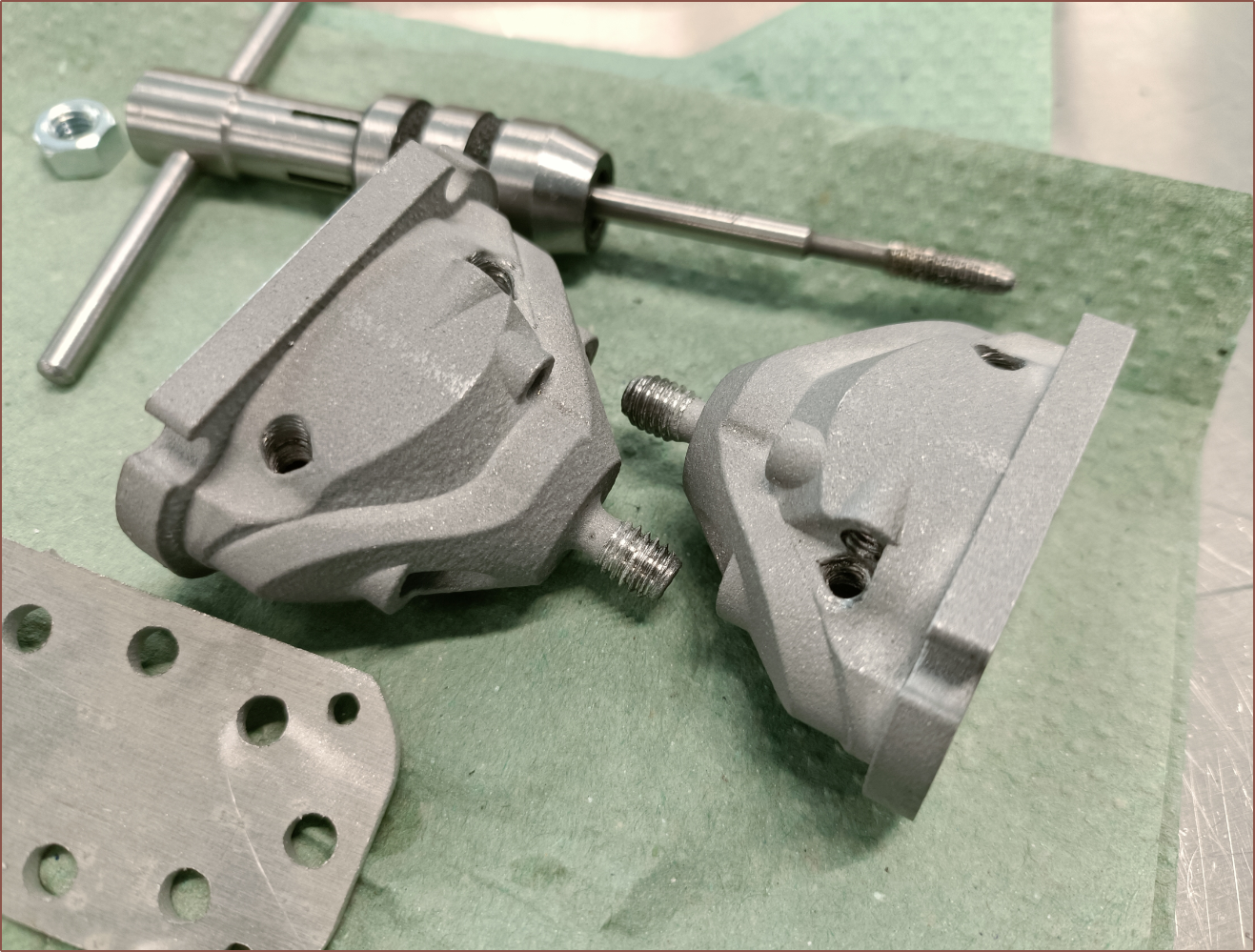

So far, it feels like the 2-for-1 offer is paying off, such as the confidence / peace of mind of knowing that I've got a second life if things go pear-shaped. I still haven't dealt with the powder inside them though.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.