I was initially using 1mm steel cores harvested from paperclips, but experimentally found that the steel core doesn't take well to fast voltage changes, and heats up the coil so much, that I had a few failures while testing operational parameters.

So I went back to high school science trying to understand magnetic permeability, and properties of soft iron (and WTF is soft iron anyway) and finally found these Ferrite Rods on Digikey:

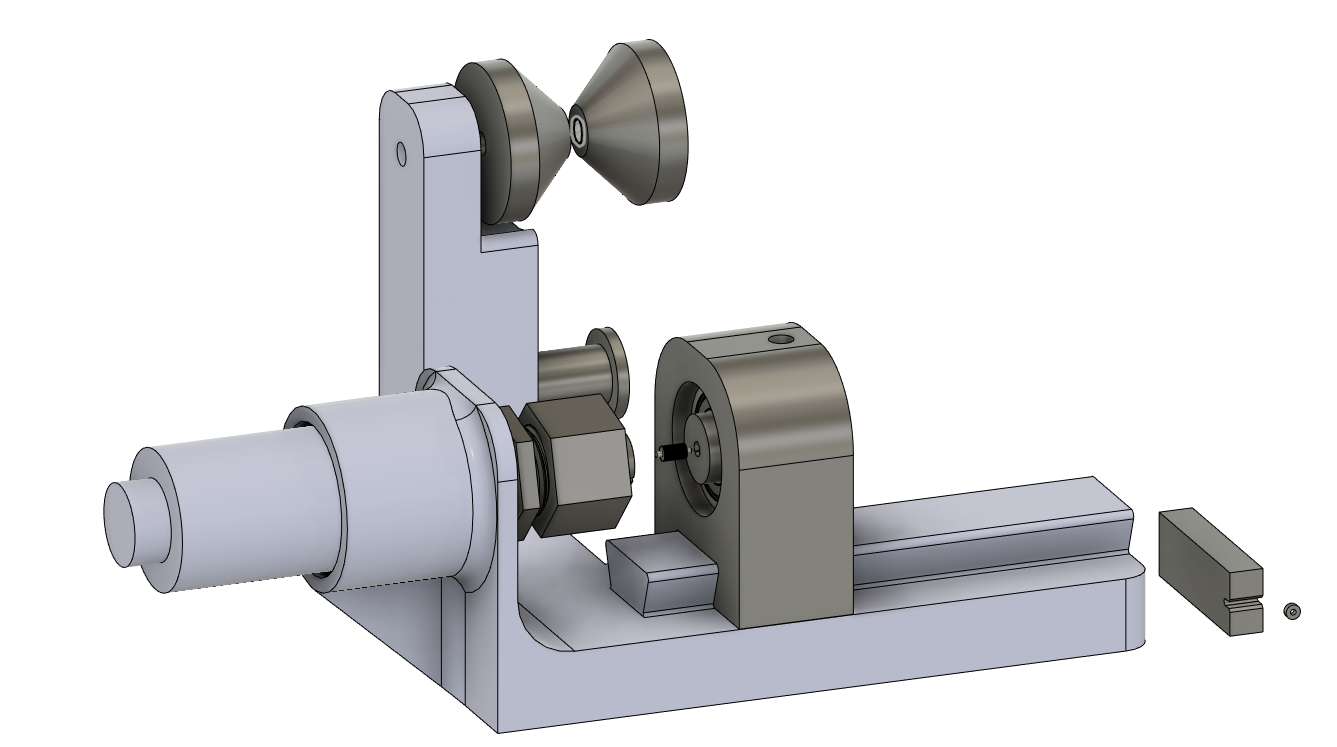

they turned out to be a lot more brittle and needed more care in assembly. The metal chuck of the first iteration would just snap the ferrite rod.

So I redesigned a complete 3D printed chuck, that IMO works even better than the earlier one, and sits nice and centered

Ive updated the Instrusions section with details of how to use the new Coil Winding Jig.

The braille cells made of the ferrite core were found to be:

- Run cooler & with lesser power requirement

- Faster max refresh rate, from 200ms to 50ms

- Overcomes the issue when the cam magnet is too close to the core, the natural attraction overcomes the opposing magnetic flux, and the cam refuses to flip. the natural magnetic attraction to a ferrite core vs the steel core felt like it was less than half of it.

THe main drawback of using ferrite cores, however, what that if you are not careful with the winding jig, the core would snap.

In the future, I see this process automated, with the same process used to wind small inductors.

The updated CAD design for the winding jig can be found here.

Vijay

Vijay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.