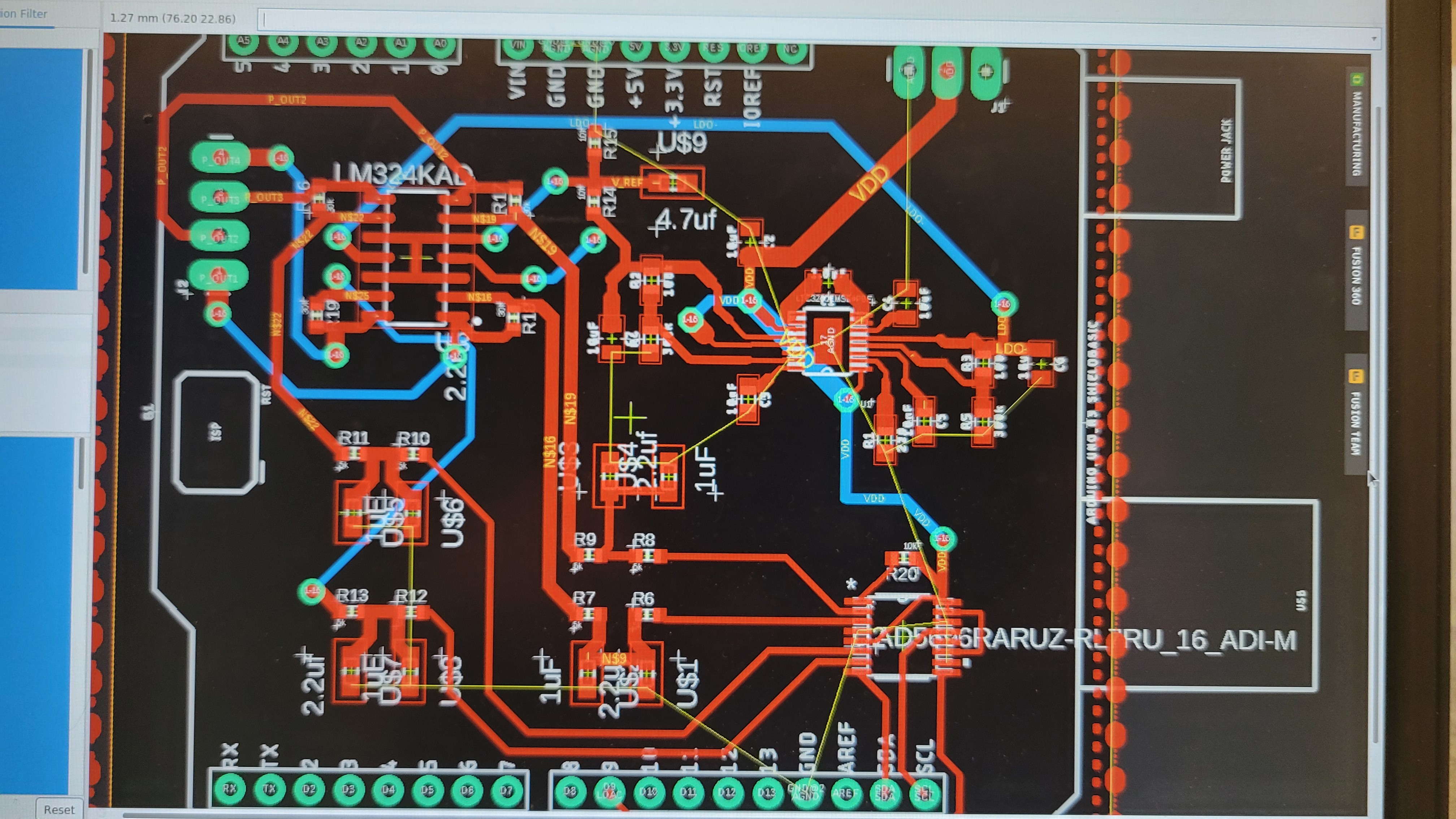

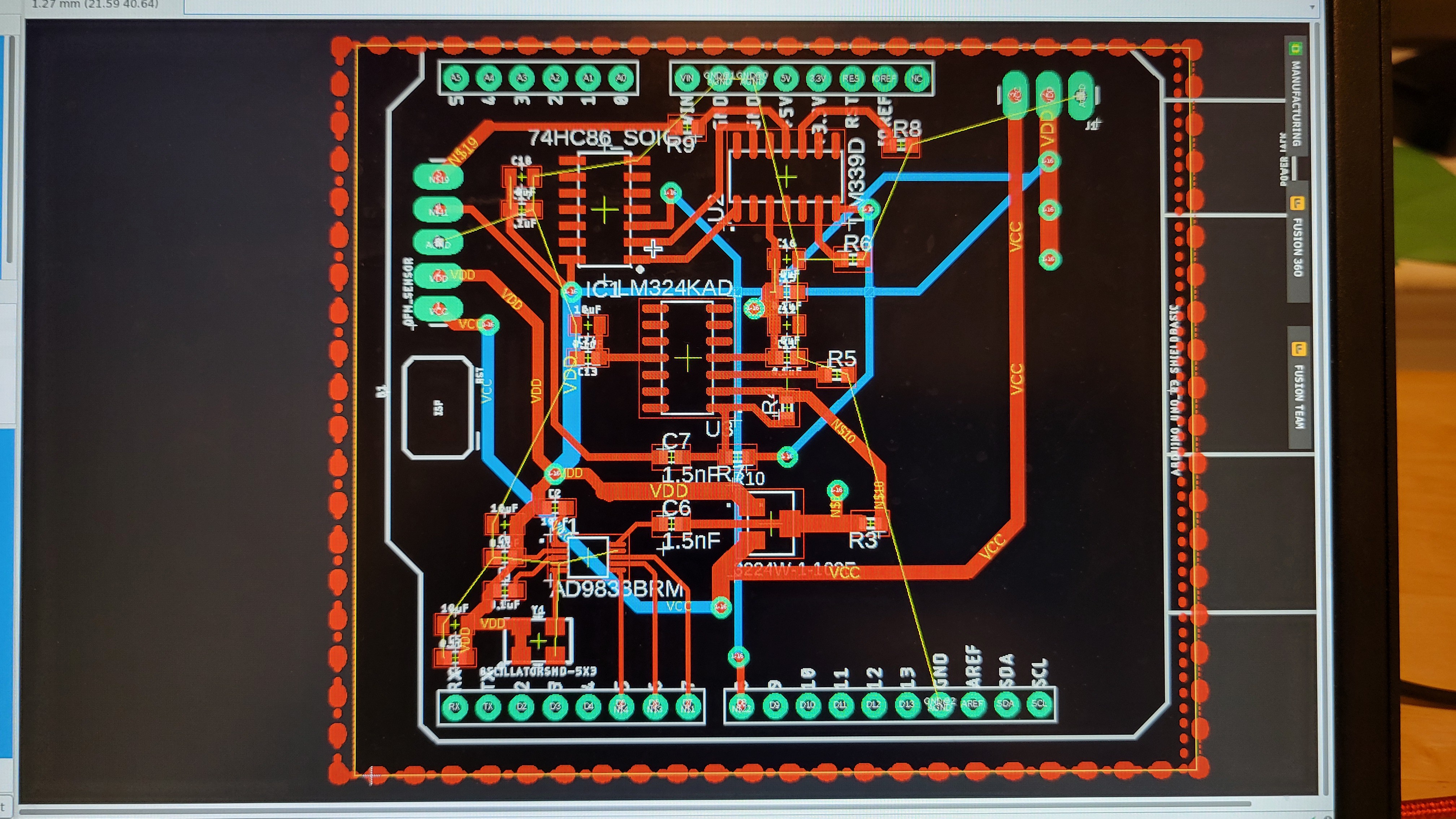

I've started to build a schematic of piezoelectric controller. I made schematic and layout. In my current version we use LM324N and it's quite old. We may switch to OPA4205 for better results. But for this version lets stay with the tested LM324N.

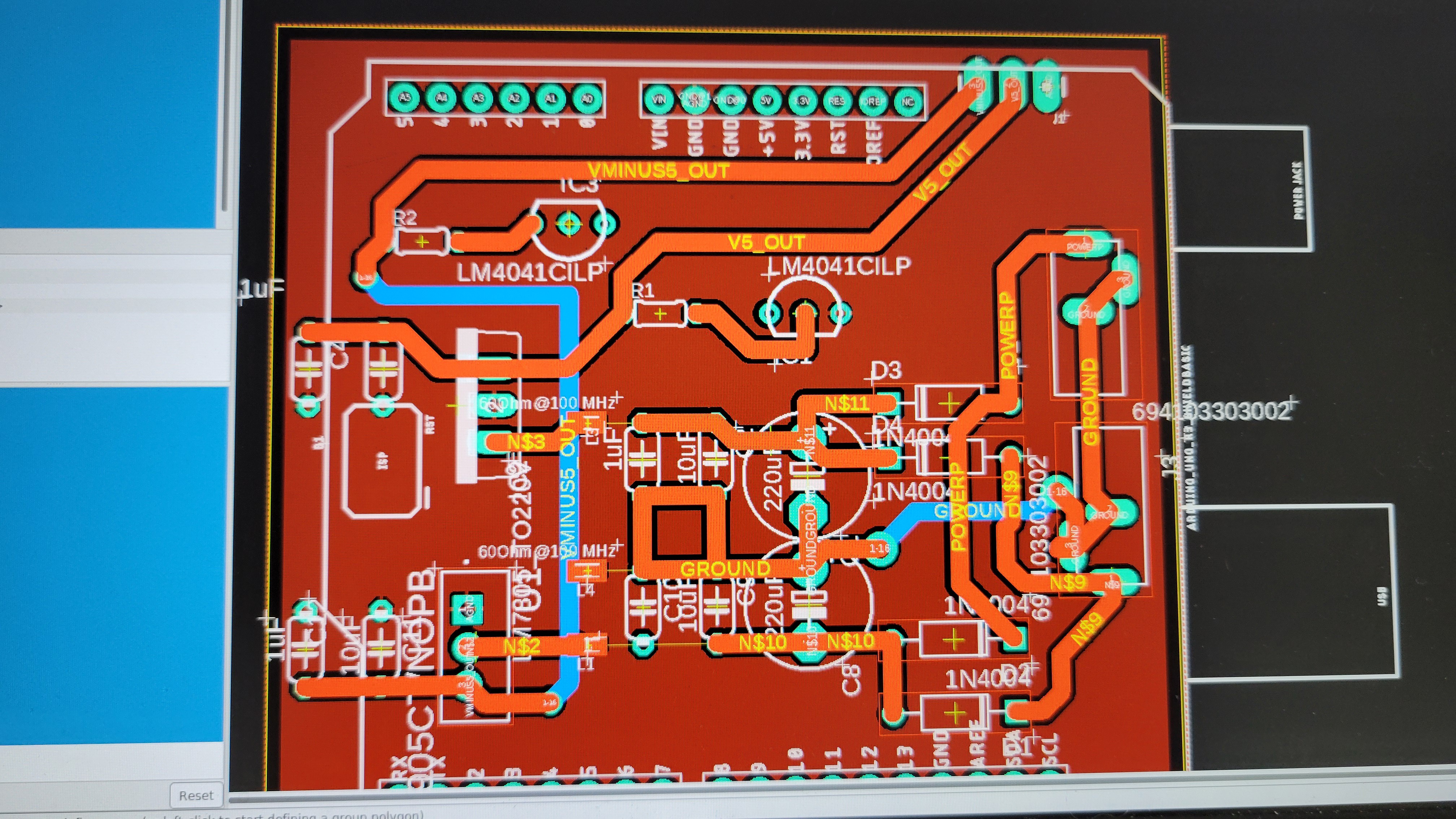

Made schematic/board of power supply board

Luckily I've noticed that the power pins are switched between those two boards.

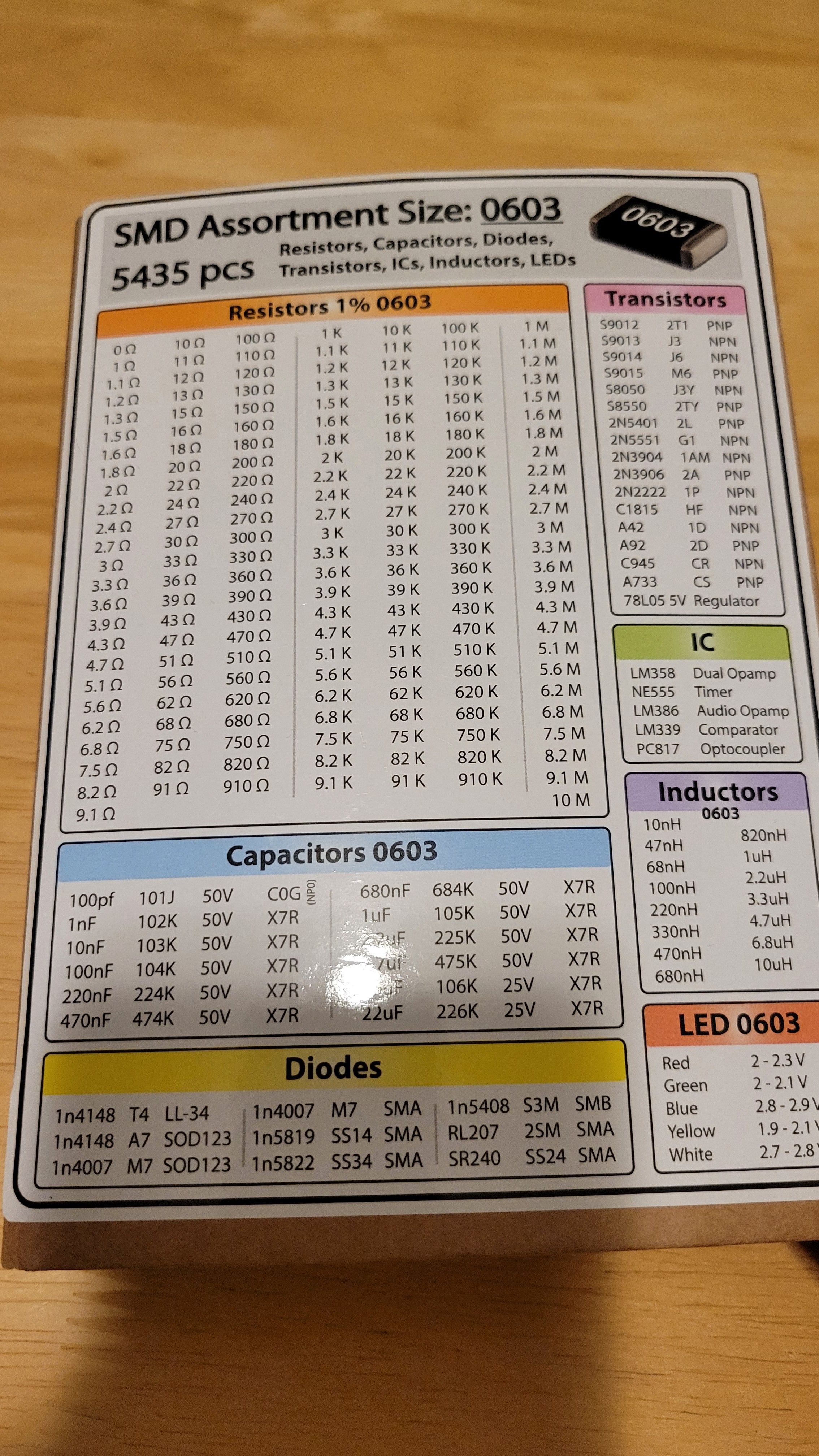

While fixing it, I've noticed that I use sime through hole components while most of the board are SMD (surface mounted device). The reason for that was to use the same components I've used in breadboard. Then the question rised do I have those components in SMD format?

Fortunately the answer is yes. I didn't buy those components I just got them while buying SMD resistors.

So I got diodes 1n4007 and lm339 comparator. Plus, I got 78L05 voltage regulator. Let's use those to make simple and cheap solution.

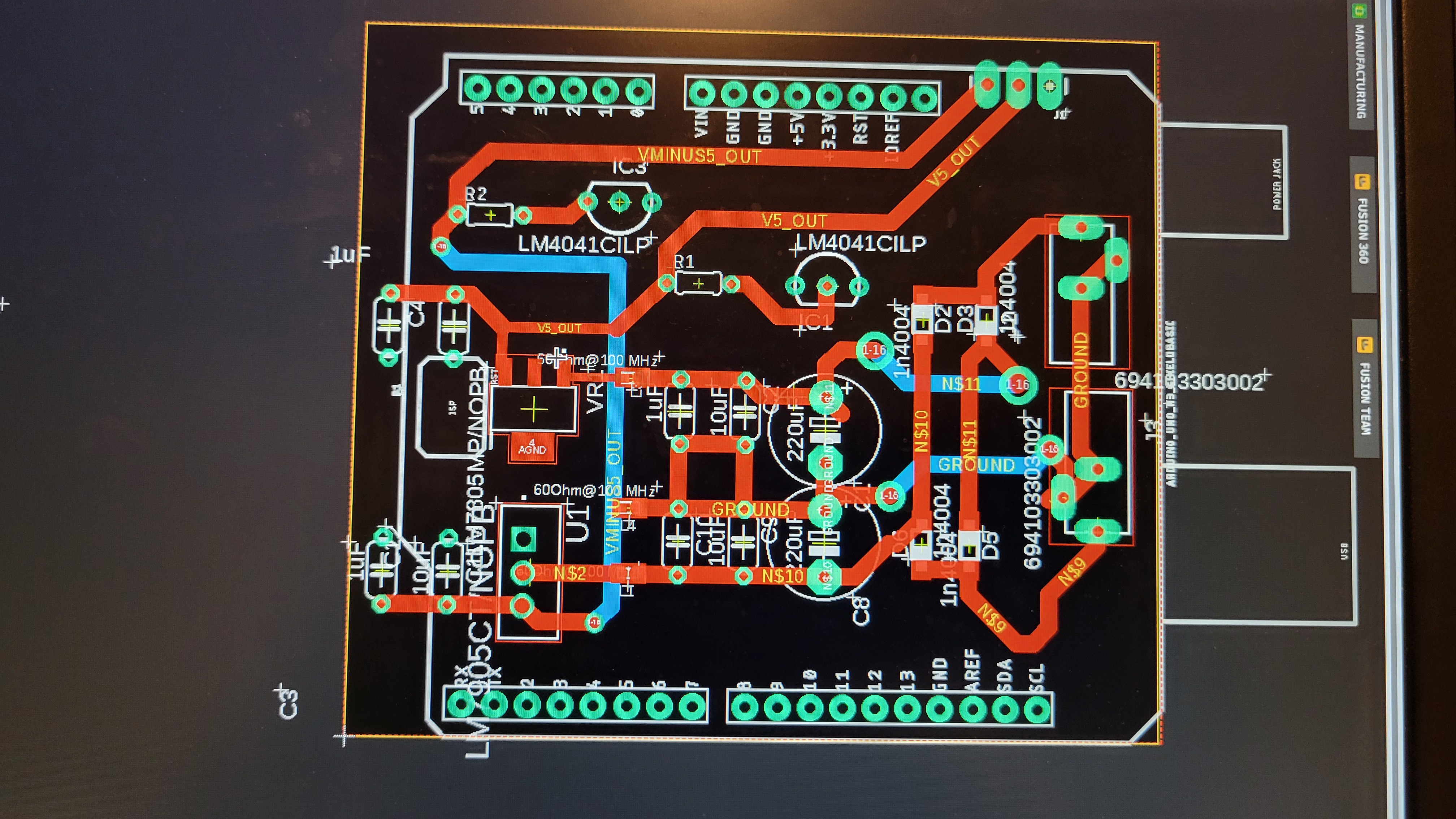

The new power board

Made input board

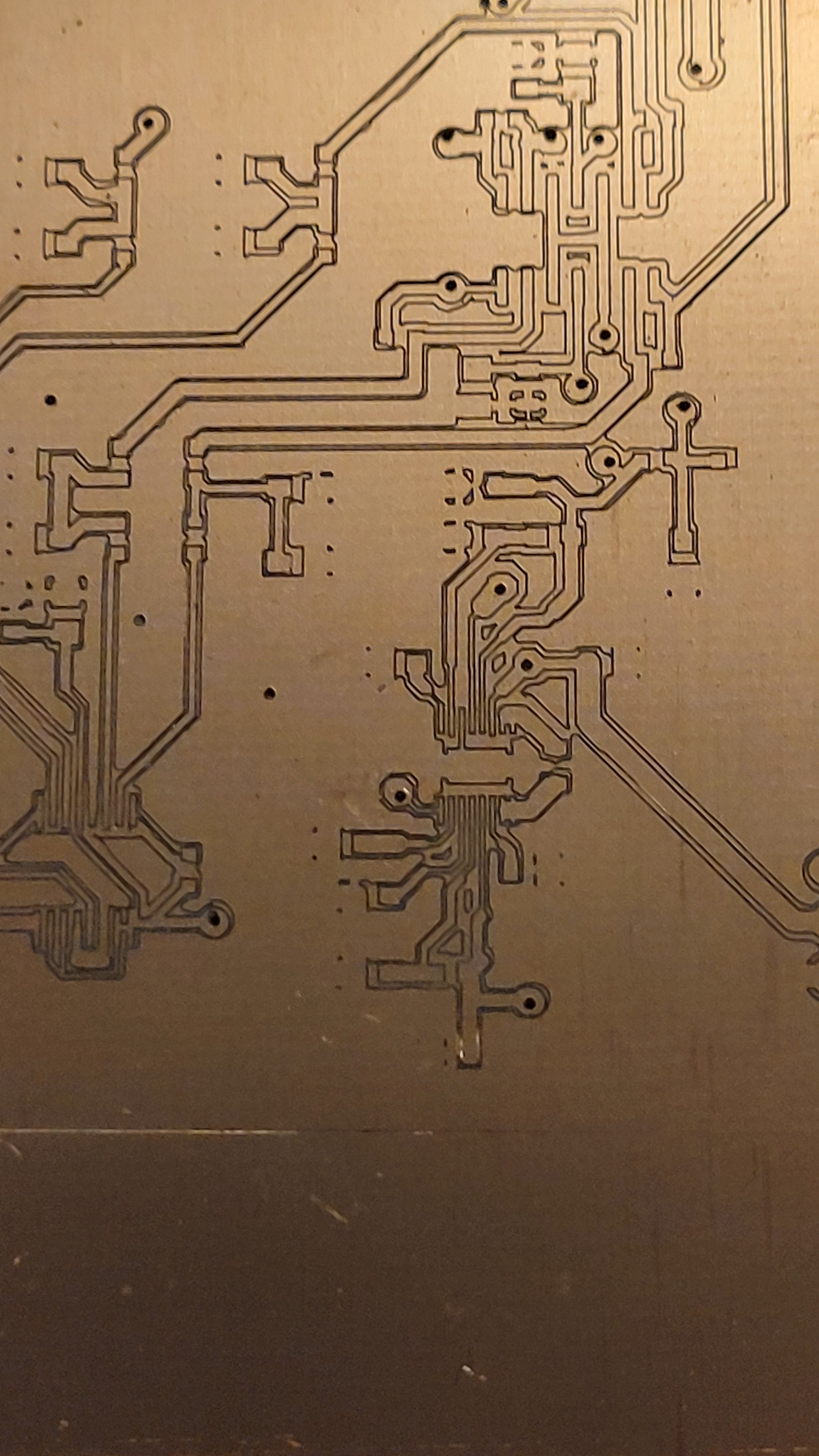

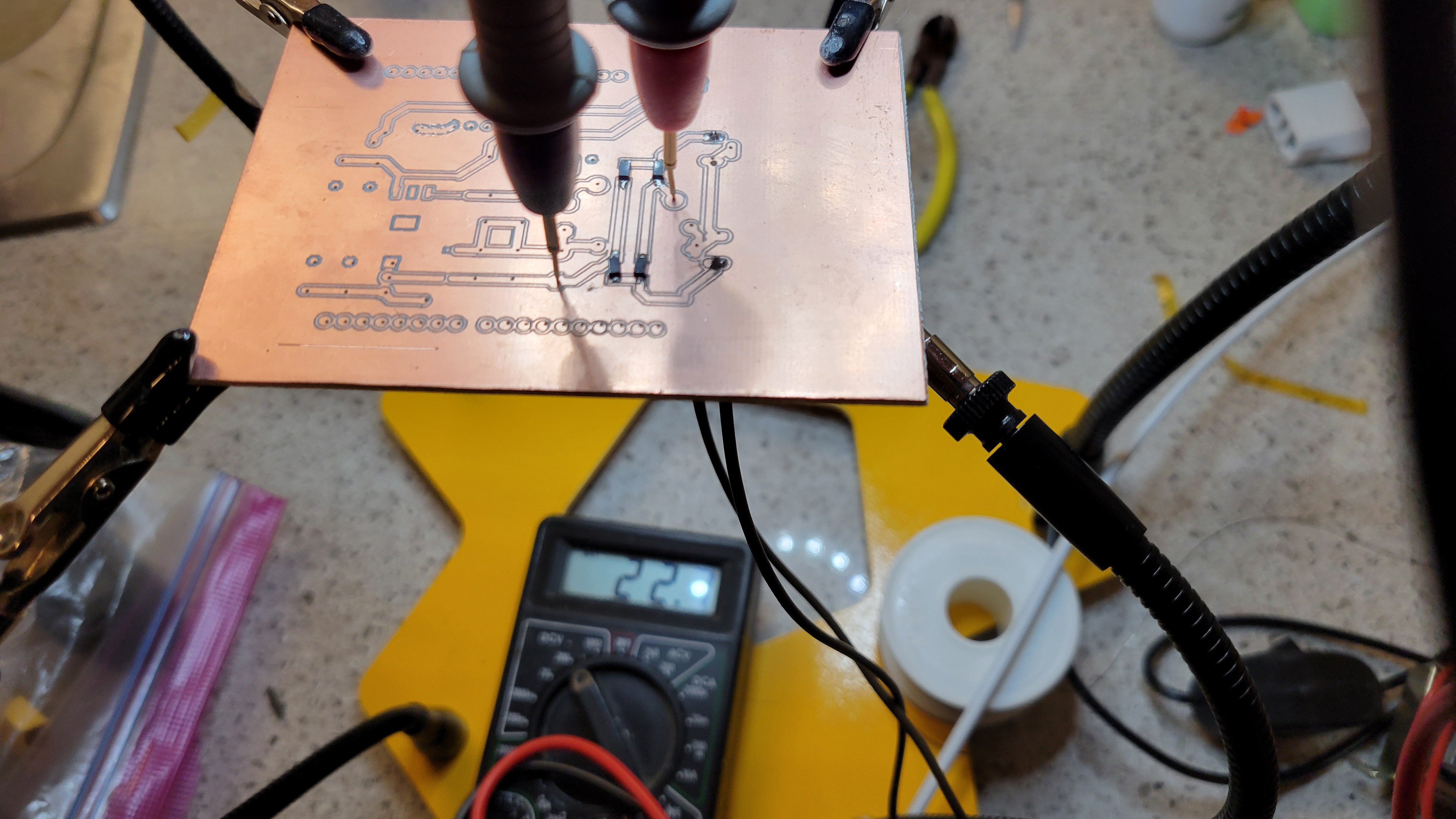

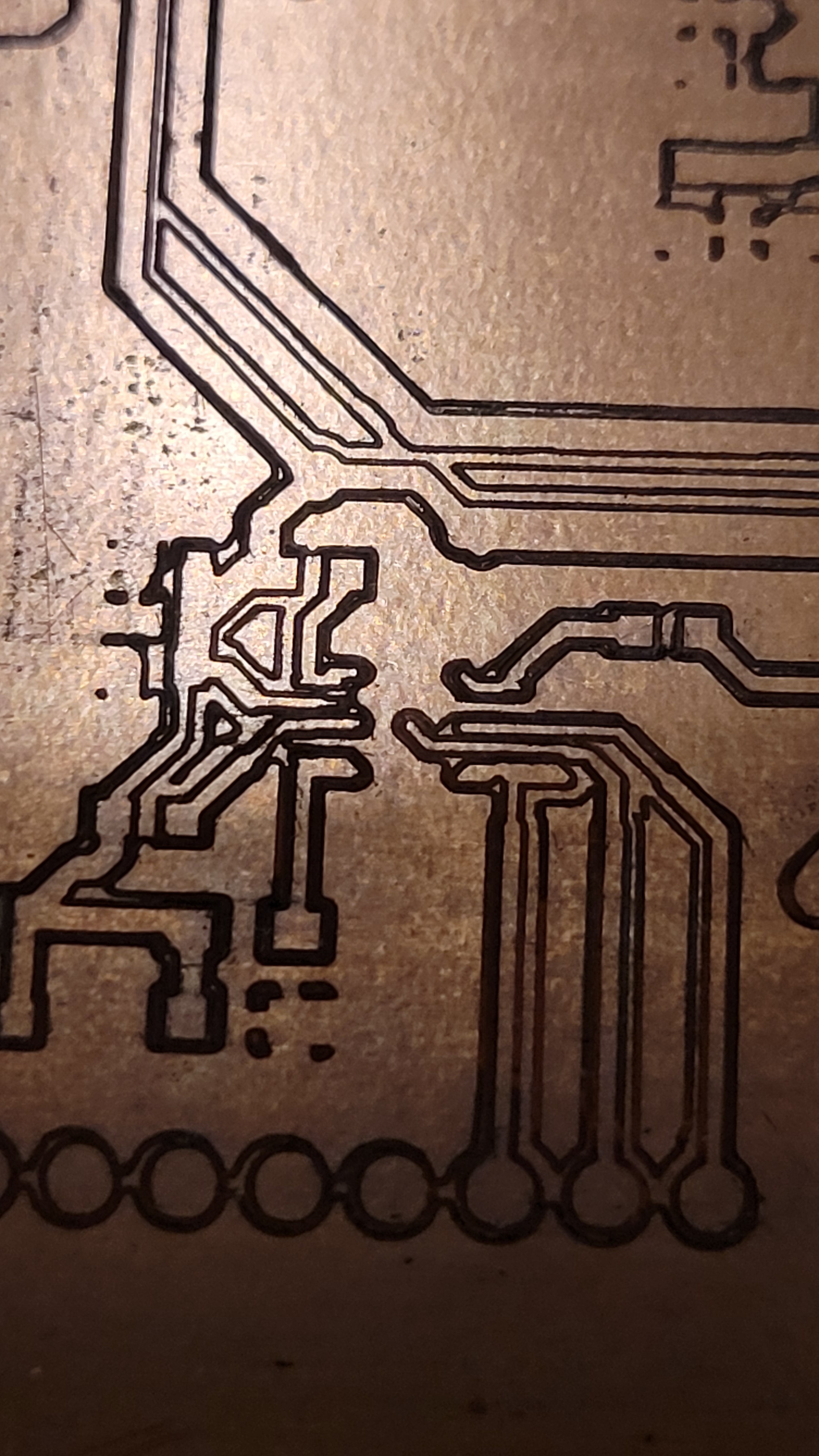

Started to create bare PCB boards using CNC, it took me at least ten attempts to get it right and learn all the tricks failing on each possible step.

Luckily a pack of ten PCBs costs only six dollars. After few minor but important adjustments I got the desired result

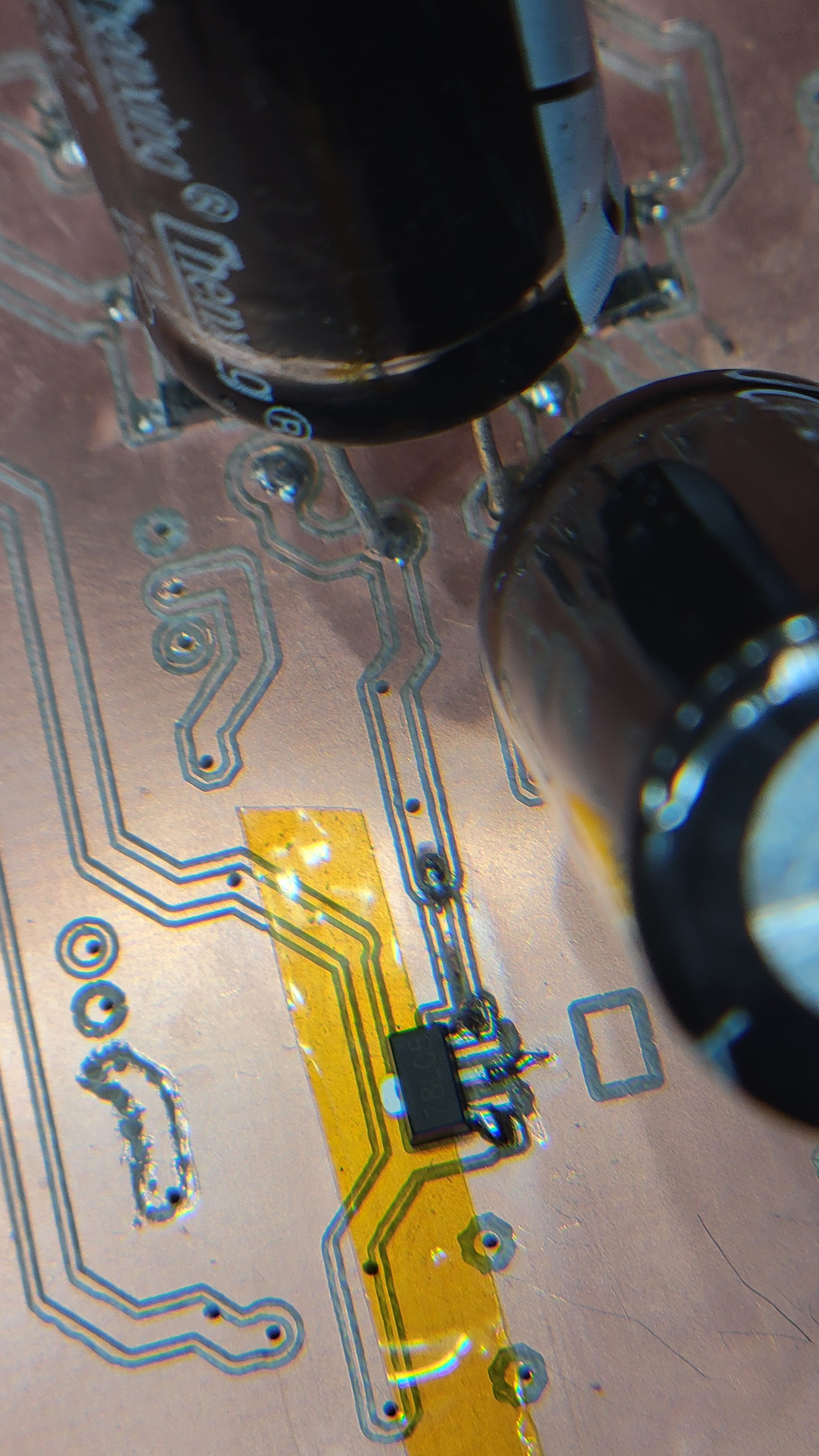

Suitable for 0.5mm pitch ICs.

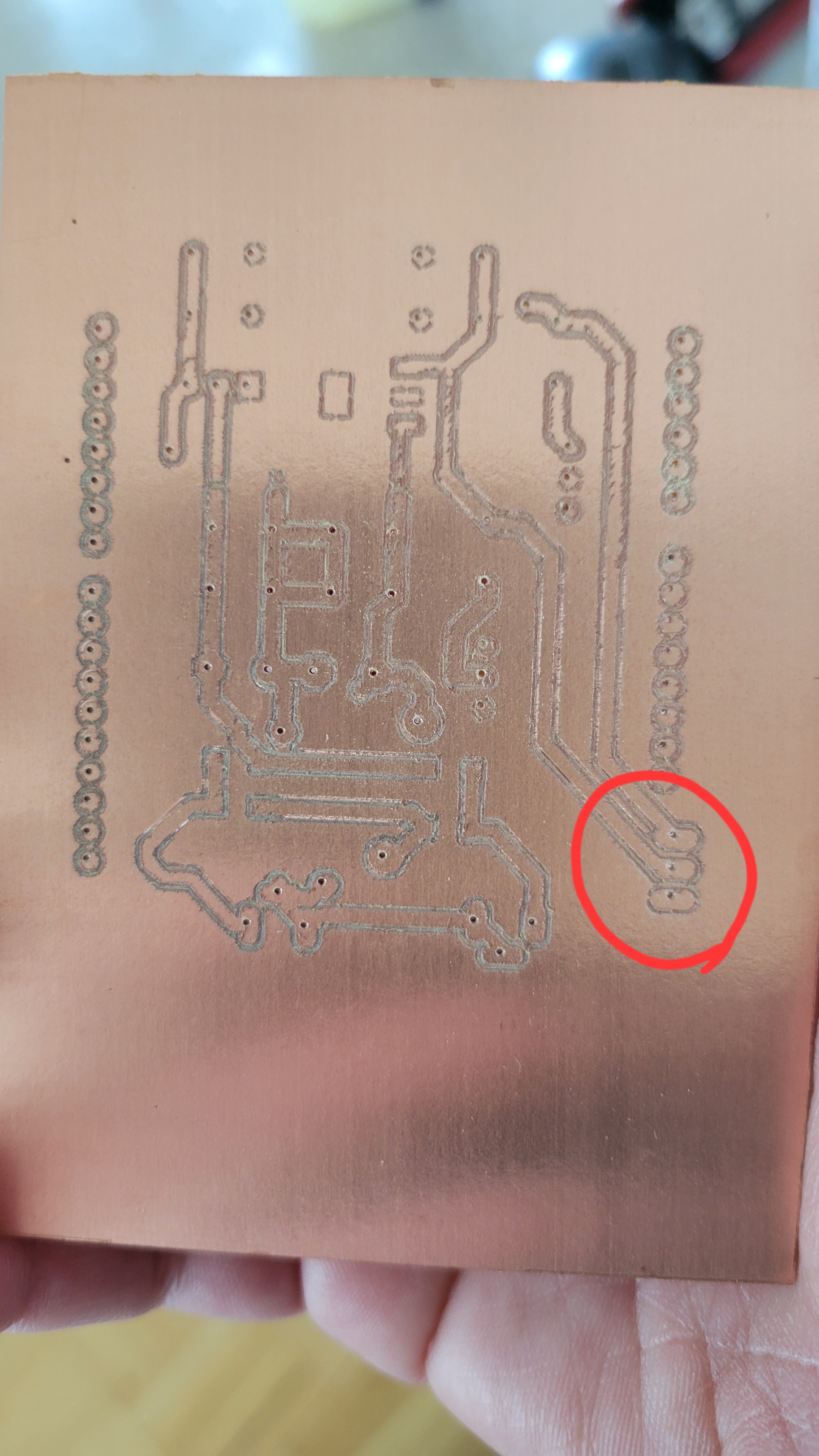

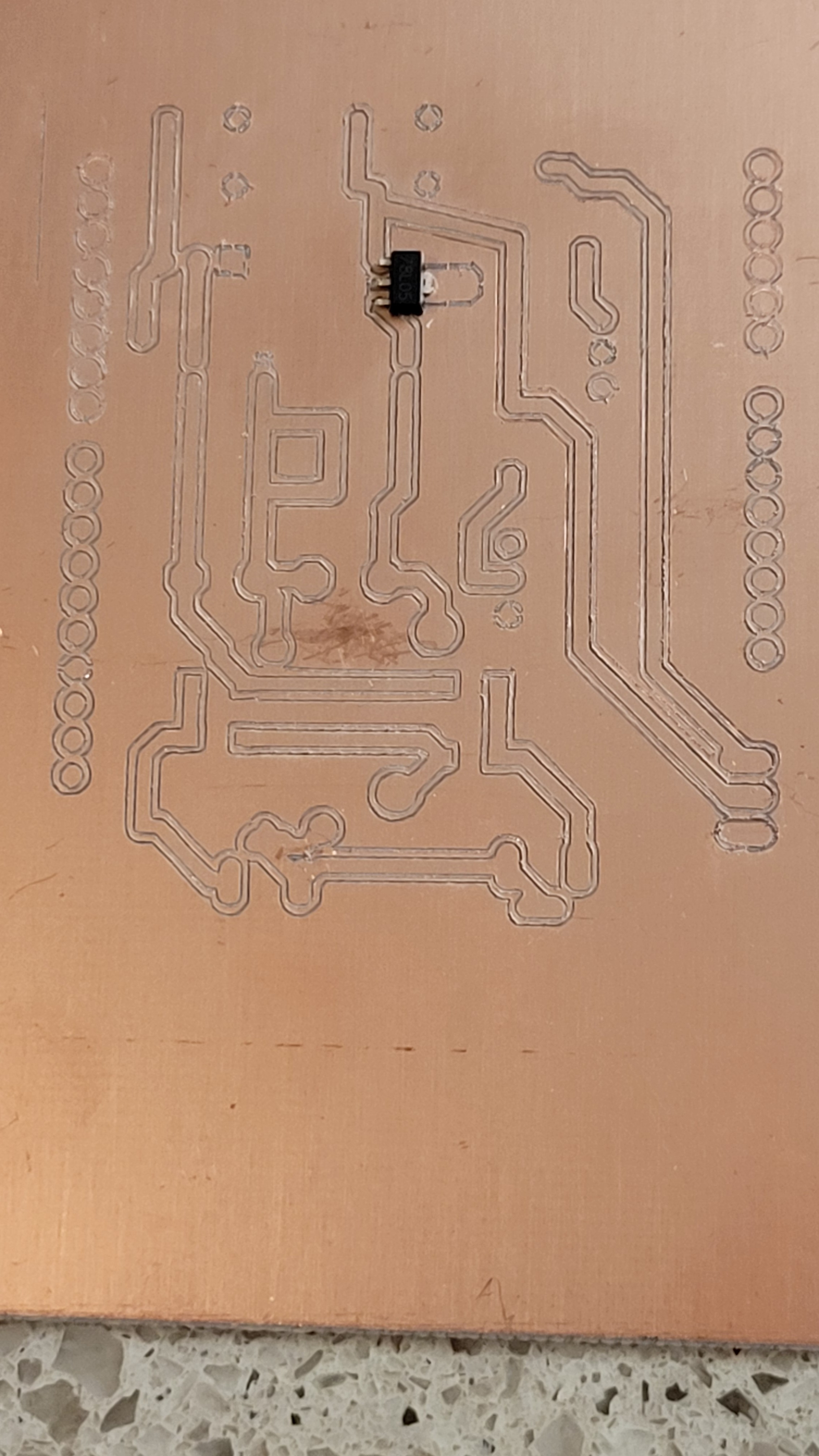

One good thing about making your own PCBs is how fast you can fix things once they go south.

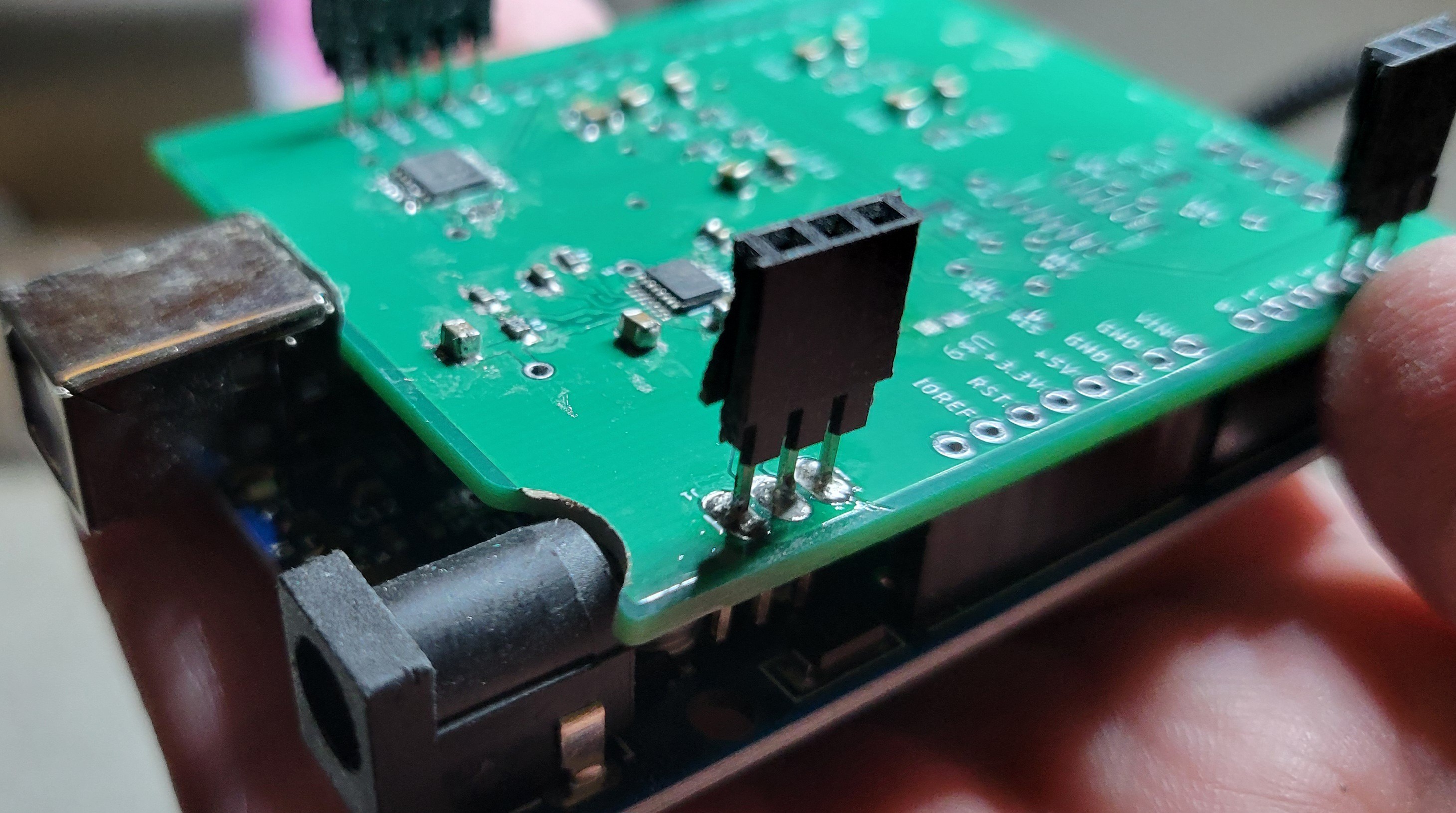

Here I made a mistake by moving the Arduino relatively to power output.(Although I don't remember doing it)

It took me few minutes to create a new one with the correction.

Now we can start populating those PCBs with components

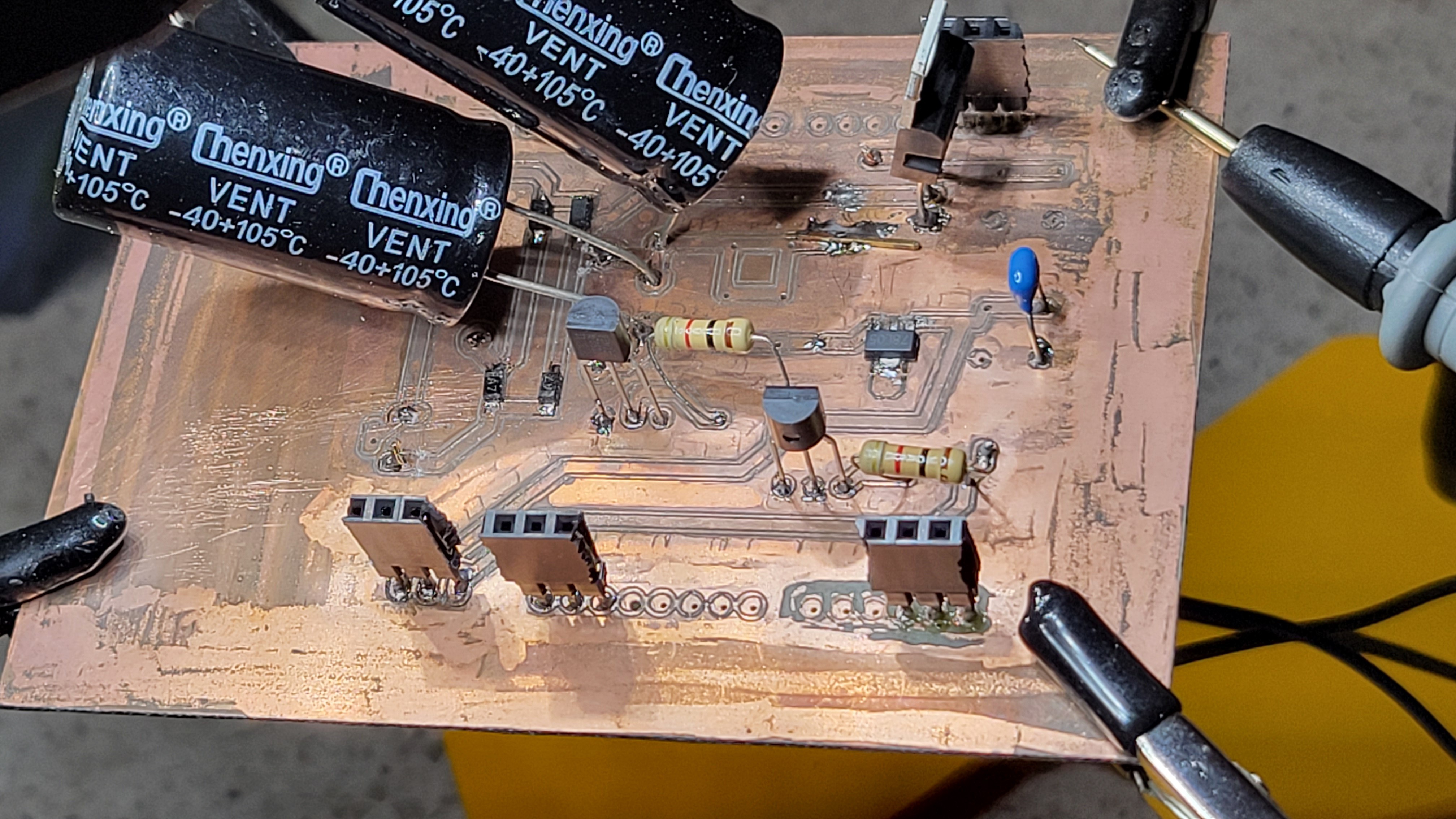

Slowly but surely, started adding components

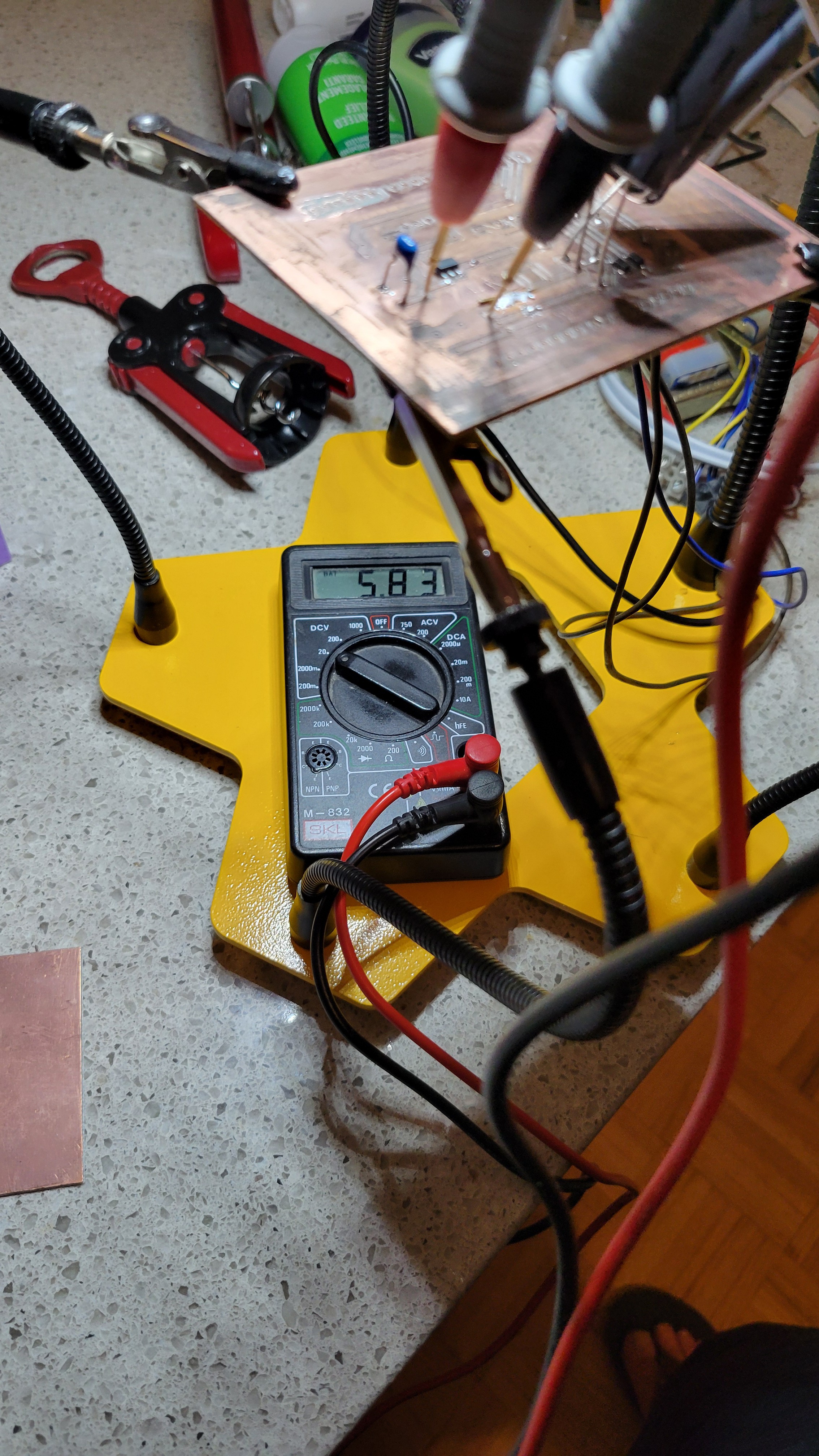

Rectifier bridge works!

Added more components capacitors and L78L05 voltage regulator just to find that I used wrong layout much bigger with opposite pinout layout. Tried to reverse and make changes on the fly with Dremel. Ended up with bricked PCB. This should be the 'easy' one.

Luckily I can print PCB at home.

Ta-da!

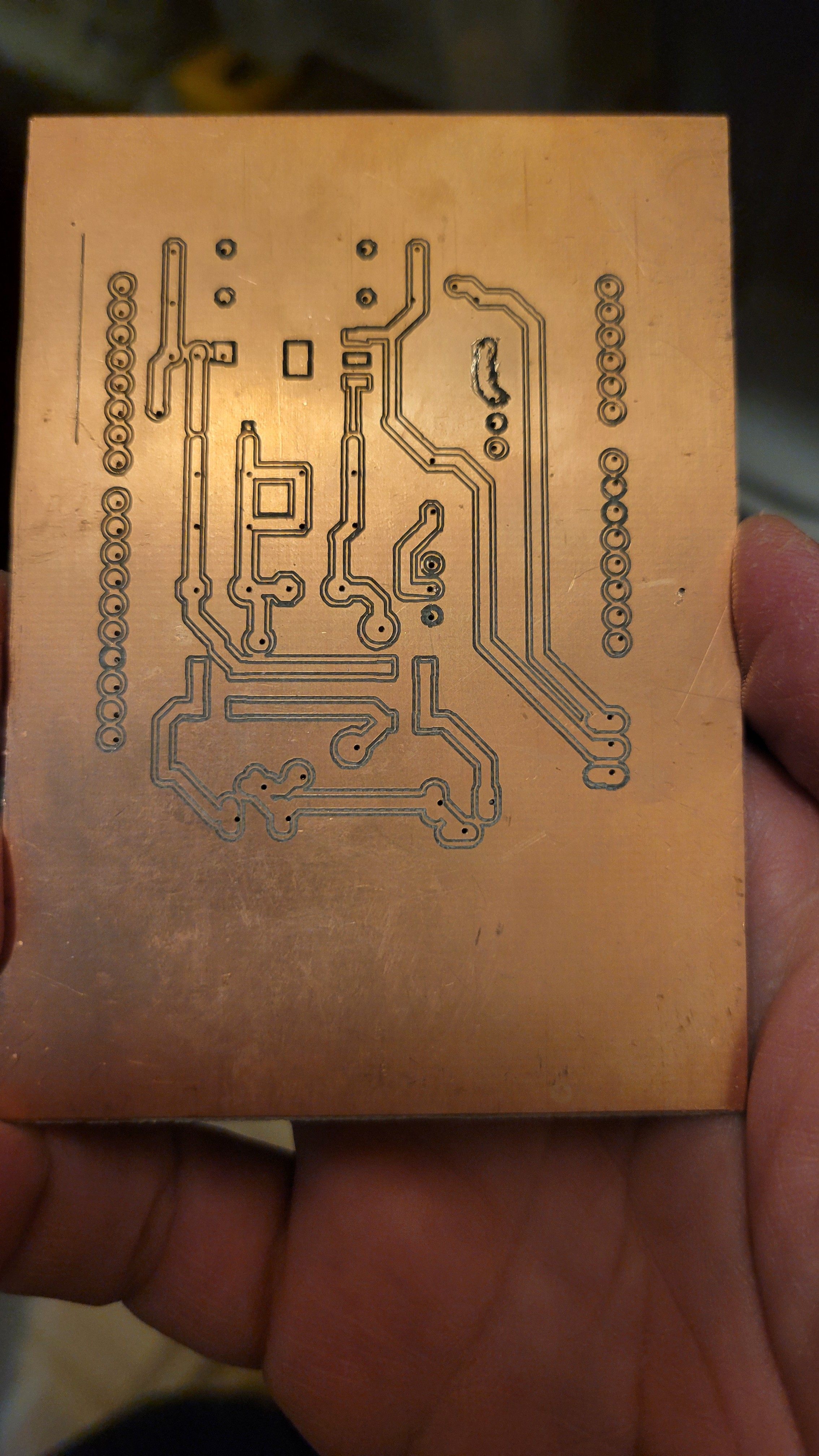

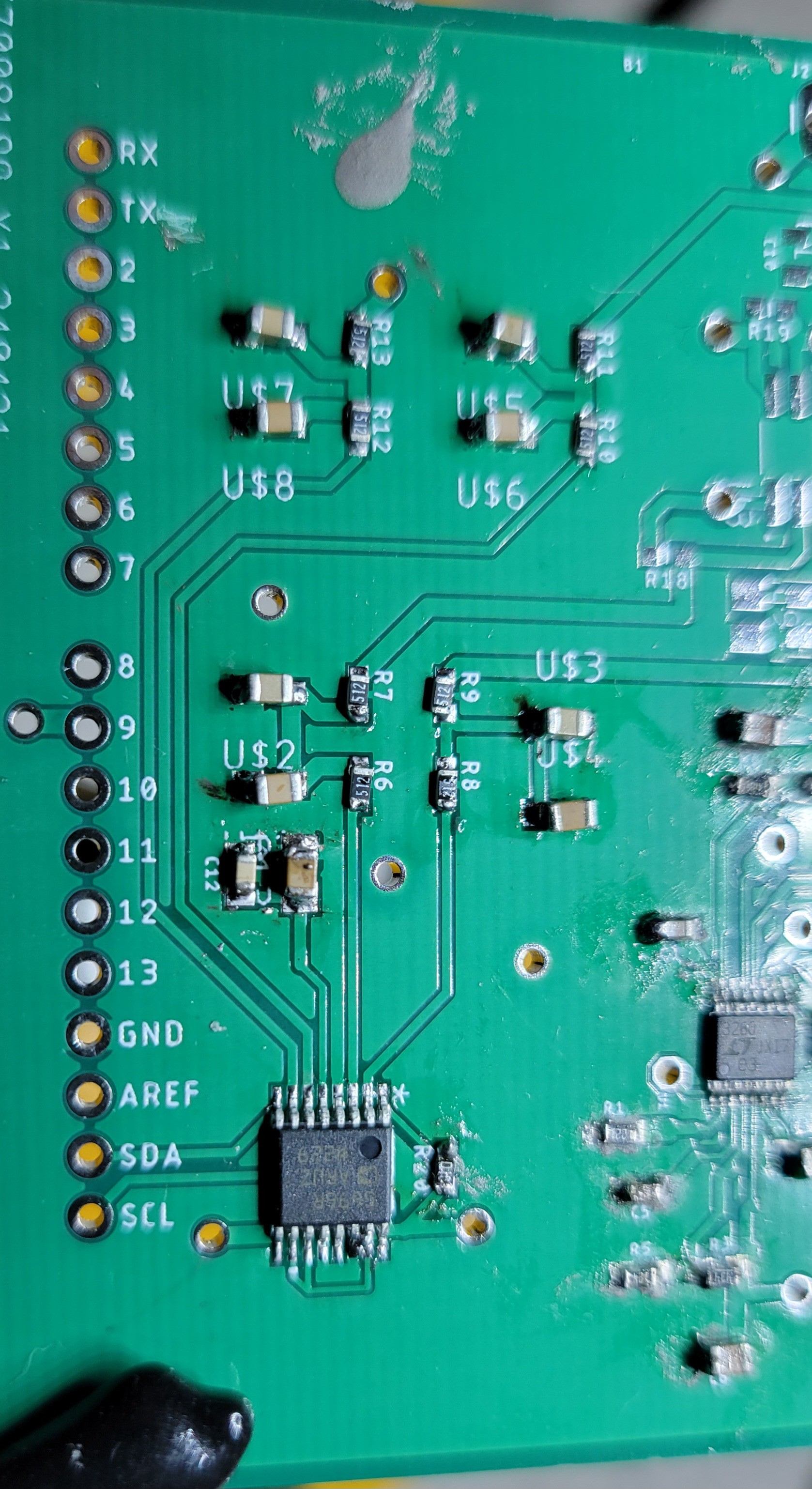

It took me quite a while to be able to create 0.5pitch PCBs. I almost gave up...

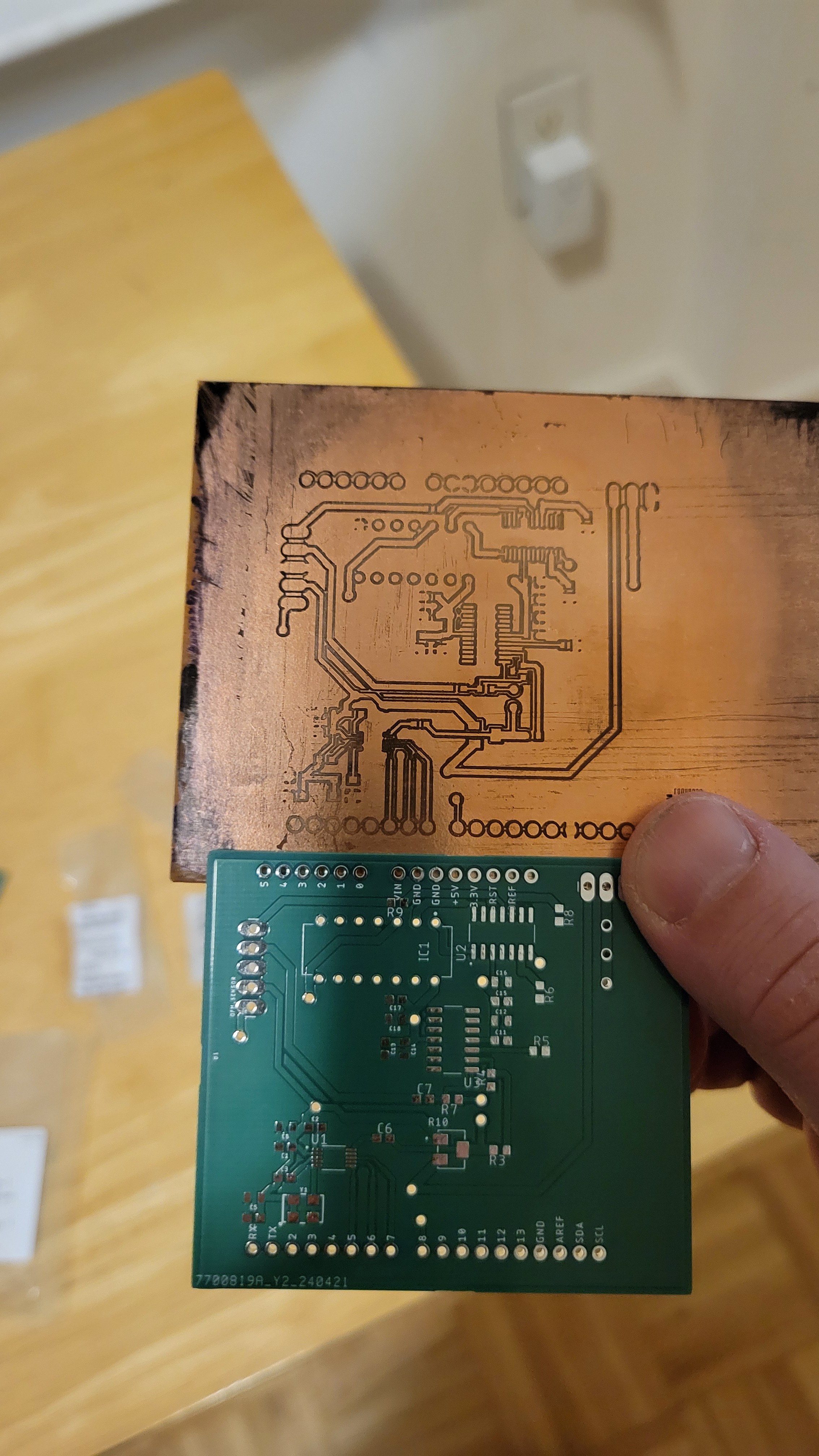

Ironically, I got my PCBs from China the same day I finally managed to create my own high quality PCBs. (I will tell it in another blog)

I must admit Chinese one looks much better :)

Anyways now we can continue 😃

* Added holes to power pcb,

* connected ac,

* Made rectifier bridge

* Added positive voltage regulator

Next negative voltage regulator

Got the positive and negative rails. How this song goes 'although I am not the prettiest thing you ever seen but I got my moments' 🤩

Finished with power supply PCB.

Started with piezoelectric controller, the hard part is charge pump. I didn't check it as it became too late

I must admit it much easier to work with a board that has solder mask and you don't risk of short-circuiting every component.

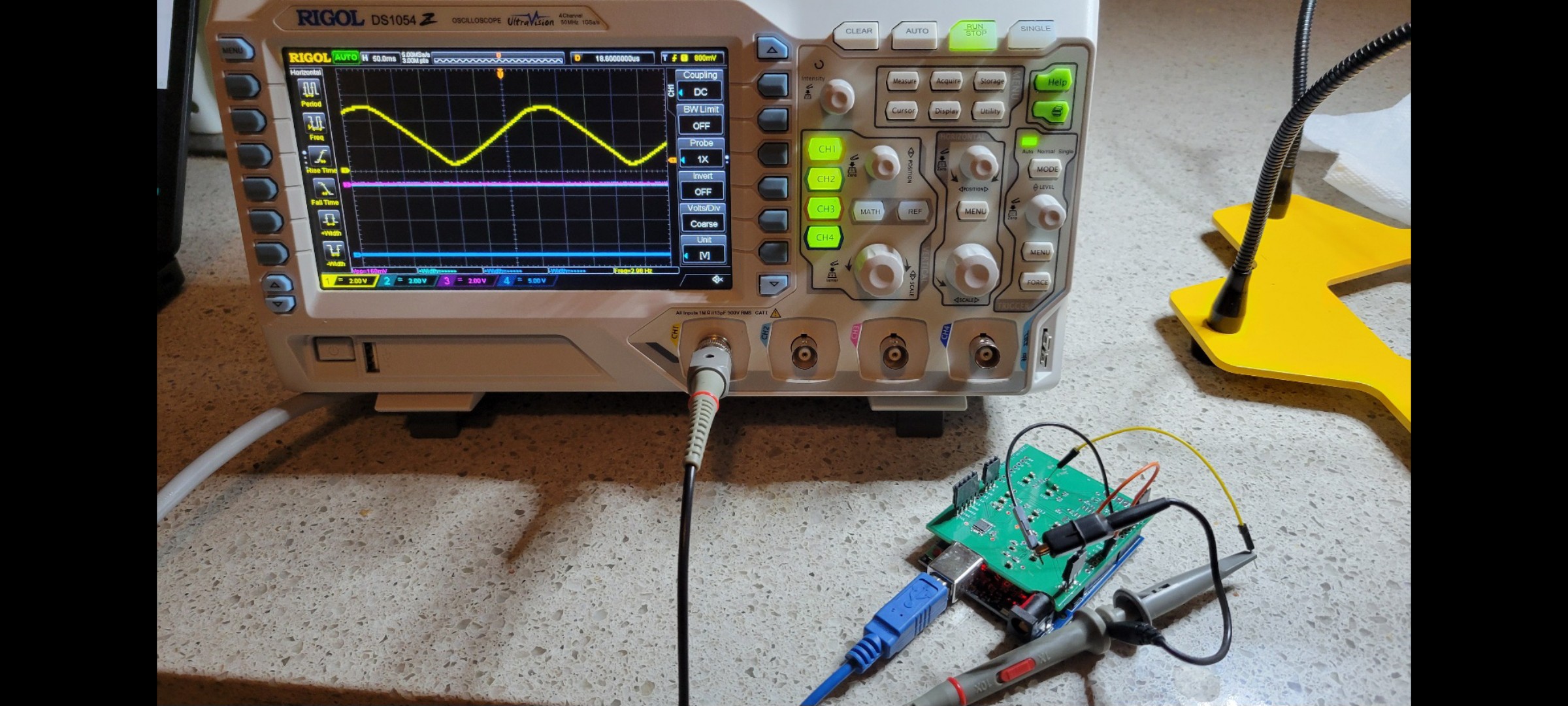

After checking the circuit it seems to be functioning as intended. Which was total surprise since last time it was such a pain in the neck.

Added DAC and fixed some design issue I had(forgot to add address pins to the ground)

Bad news I've just realized that my reference voltage is from charge pump instead of 5v. I hope I could make some fix on the spot. Otherwise another two weeks to wait.

I felt like checking if DAC is working with all this unpredictable changes. Once I tried to connect I found that it doesn't fit

Luckily there are no components and I could carve away some PCB. Testing it I found that 3of4 pins are working (one is needs to re-solder but it's mild problem)

So it just works! I was surprised in a good way.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.