Project Goals

PourFection is a project developed by Lance Go and Sean Morton for their electrical engineering capstone project at Northwestern University, ELEC_ENG 327: Electronic System Design II. The goal of the project was to design a smart coffee brewer that made the pour-over coffee brewing process easy - yet still precise - for users who’ve just rolled out of bed.

The following goals were established for what we wanted our coffee machine to incorporate:

- The PourFection will use a V60 pour over brewer, which is a common brewer used in households across the world.

- The PourFection will be able to boil water for brewing coffee.

- The PourFection will be able to maintain coffee temperature post-brew phase.

- The PourFection will distribute the appropriate volume of water for a given amount of grounds.

- The PourFection will have a companion webapp where the user can track brew metrics such as water usage, coffee weight, etc. The webapp will also allow the user to configure aspects of the brew such as brew ratio and water temperature

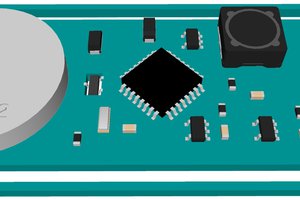

The development of the PourFection followed a typical project design process: proposal, initial prototype, full prototype, two revisions, and a final product/report. Over the course of the development process, some design aspects of the brewer changed, a notable example being the water heating method changing from an immersion heater to a kettle. However, the final product ended up being very similar to the original device in mind. Because of some development difficulties, some functionality included in the original proposal was omitted. Firmware setbacks in the later phase of development meant live data charting needed to be cut from the final web app design. On the hardware side, the custom PCB shorted during testing, resulting in the destruction of a 12v-3.3v regulator and the ESP32; consequently, the prototype breadboard was used during the final demonstration..

This article will give an in depth insight into the design, development, prototyping, and construction process of the PourFection Pour-Over coffee brewer.

Component Selection

Some components we wanted to include in PourFection were no-brainers: we bought servos to make the nozzle rotate in the circular pattern, and bought immersible thermistors to measure the temperatures of liquids - and they worked as expected. Other aspects of the project proved more complex: specifically, the heating and delivery of precise quantities of water.

We disassembled two coffee machines and watched videos online to understand how they heat and push water through the system. Drip coffee machines boil small drops of water up through a tube - a method that doesn’t provide the pressurized stream that pour-over coffee making uses. Keurig machines use pressure to push water either (a) into and out of a heating reservoir (for the K150 model) or (b) around a heating element and directly to the K-cup, in the case of some smaller Keurig models.

Credits to Altaf Khan, quora.com.

We decided using pressurized valves wasn’t a good goal for this project, as it would raise the cost and complexity of our project significantly. We also rejected the idea of using solenoid valves that open or close to passively allow water to flow through, as we found it hard to imagine this sort of valve delivering a pressurized stream of water. Instead, we decided to go with yet another option: using a food-grade pump motor to pump water from a pre-boiled vessel of water. We initially considered designing our own fluid vessel and heating it using a 1500W immersion heater; however, this posed practicality and safety concerns, so we just used a kettle as our water boiler.

Component Testing

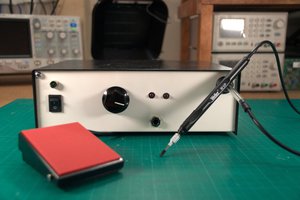

With so many components involved in our project, it was necessary to carry out independent testing of all components on a breadboard, and to build some special testing rigs in order to verify that the components worked.

The first component we put time and effort into testing was...

Read more » Sean Morton

Sean Morton

leumasyerrp

leumasyerrp

M. Bindhammer

M. Bindhammer

Alex Muir

Alex Muir