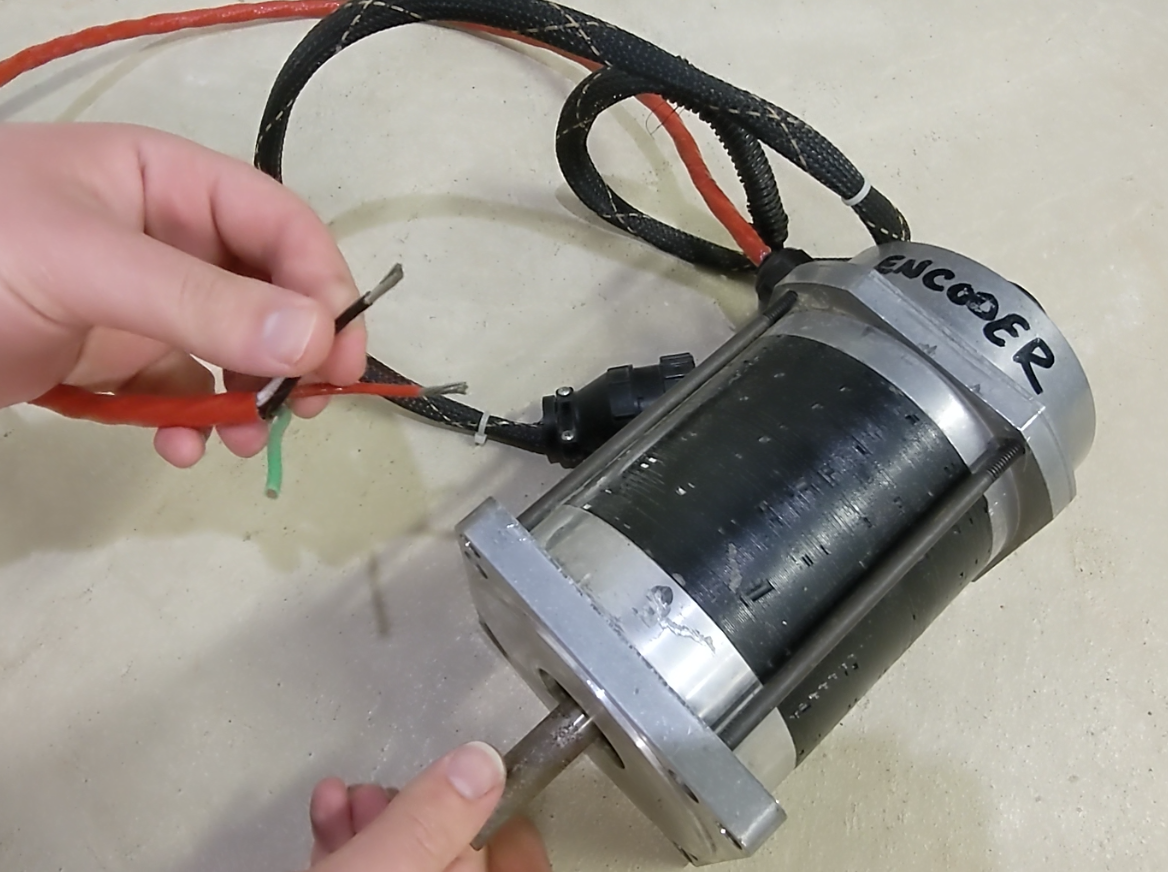

Like any proper hack, this one begins in the trash. Out of the 7 or so major components to make this build, 4 of them were either leftovers or actual trash. Let's start with the inspiration for the whole thing: an industrial servomotor I found in the e-waste bin one day.

It was obvious why it had been thrown away - there is normally an external feedback encoder on the back, but this one was sheared clean off! I guess it must have been dropped at some point. The lack of any nameplate or part number isn't a great place to start, but I knew this thing would be good for some sort of project. The idea to use it as a generator occurred to me when I took 2 of the leads, and while touching them together and turning the shaft by hand, observed a significant breaking effect at the motor's shaft. almost as though the motor was seized up. This was a very good sign, it means that even at very low RPM the motor is capable of generating significant current. Try the same thing with any common high speed DC motor and you'll barely even notice the terminals are shorted.

Another reason I thought it might make a good generator is the original use case of the motor. Most common motors convert voltage to high speed, usually in the thousands of RPM. Not the case with this one - it's designed for lowish speed at high torque - the kind of thing that could throw you across the room in short order. I do mean that somewhat literally; it came from a motion platform which a user would sit on top of, as part of a simulator system. The full travel of the actuator it was attached to is only a few motor revolutions long, but able to move that quickly with great power. It stands to reason that you would control something like this with something maybe in the 10s or 100s of volts with a good chunk of current, and if you drove the motor at a similar speed, you'd probably get what you put in back out.

Upon closer examination, it is a permanent magnet 3 phase motor, not unlike the ones we all use for quadcopters, except much bigger and much slower. In fact, the size might give us another clue about how much power we might expect to get. Something like this is similar in size and weight to my 1/2 hp motors on my lathe, mill, and drill press, so that order of magnitude.

I then started to think of some sort of use for this motor/generator. A wind turbine would be an obvious choice, but I felt that I needed a better idea of the motors characteristics before attempting a project like that. Plus, I would need to build turbine blades, do weatherproofing, construct a tower of some kind, and have it be windy in the first place, which it is usually not. I am out of my element for most of these things - especially the motor properties. I am far more used to picking the required speed and power first, maybe out of some catalog, then selecting an appropriate circuit that could provide the power I needed. Going the other way I wasn't too sure what to expect.

For now, the thing to keep in mind is that the voltage output of the generator is determined by the speed. Spin it twice as fast, and you'll get twice the voltage. As you draw more current, the motor gets harder to turn. That's the basics, although I do hope to revisit the motor / generator characteristics in better detail at some later point.

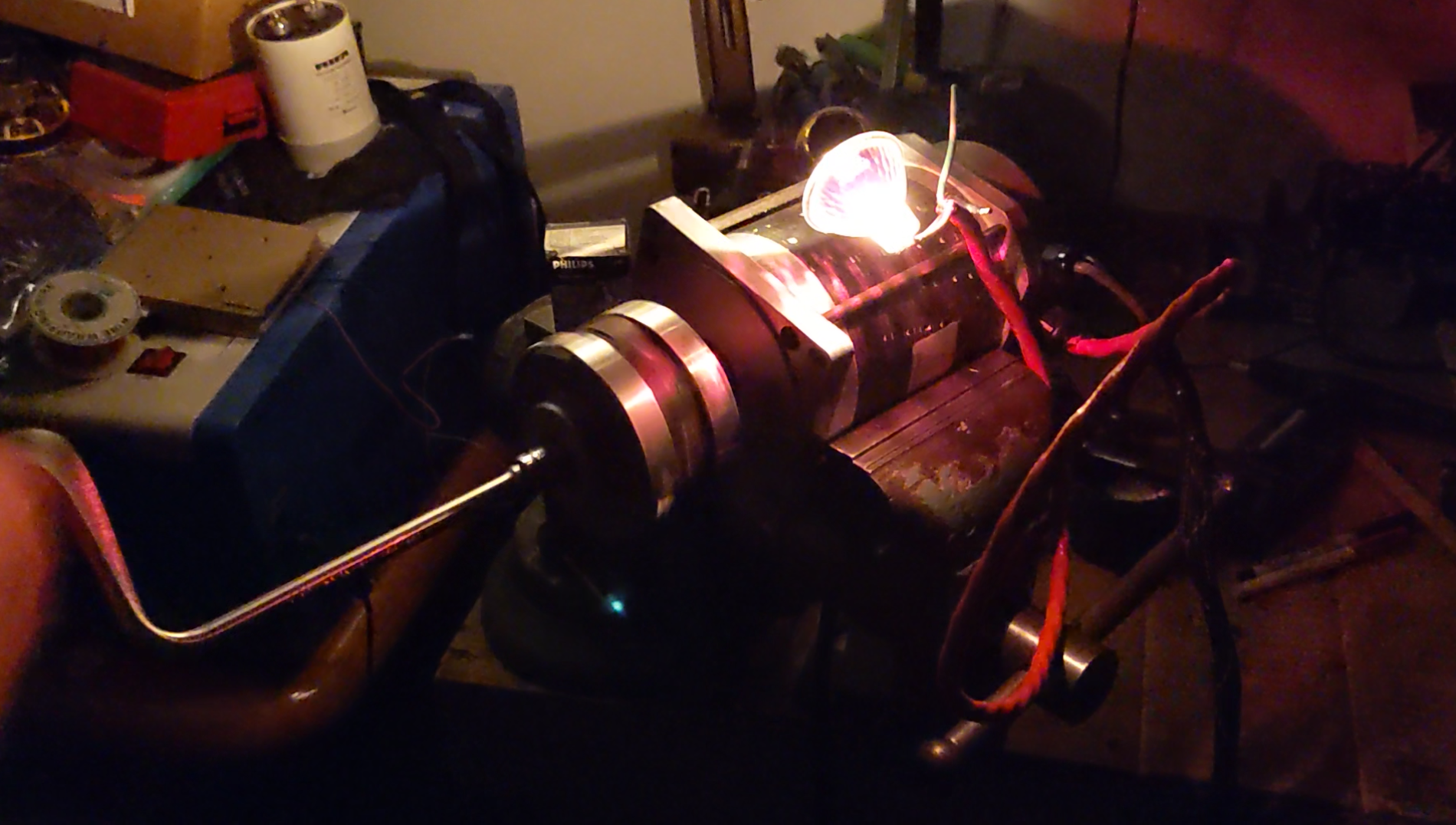

It of course takes no research effort at all to just put a voltmeter on the thing and try to take some basic voltage and current measurements to see exactly what I might get. Just turning it my hand, I was seeing 10s of volts, and with a short circuit, full amps of current. This is a huge step up over those "run an LED with a PC fan" type things that come up when you search "diy generator"

While turning the motor with a hand crank, I found I could partially light a 12V, 50W halogen lamp without too much effort. I would have had to spin the crank faster to get enough voltage to light the bulb up all the way, so it was clear something better than a hand crank was needed.

alnwlsn

alnwlsn

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.