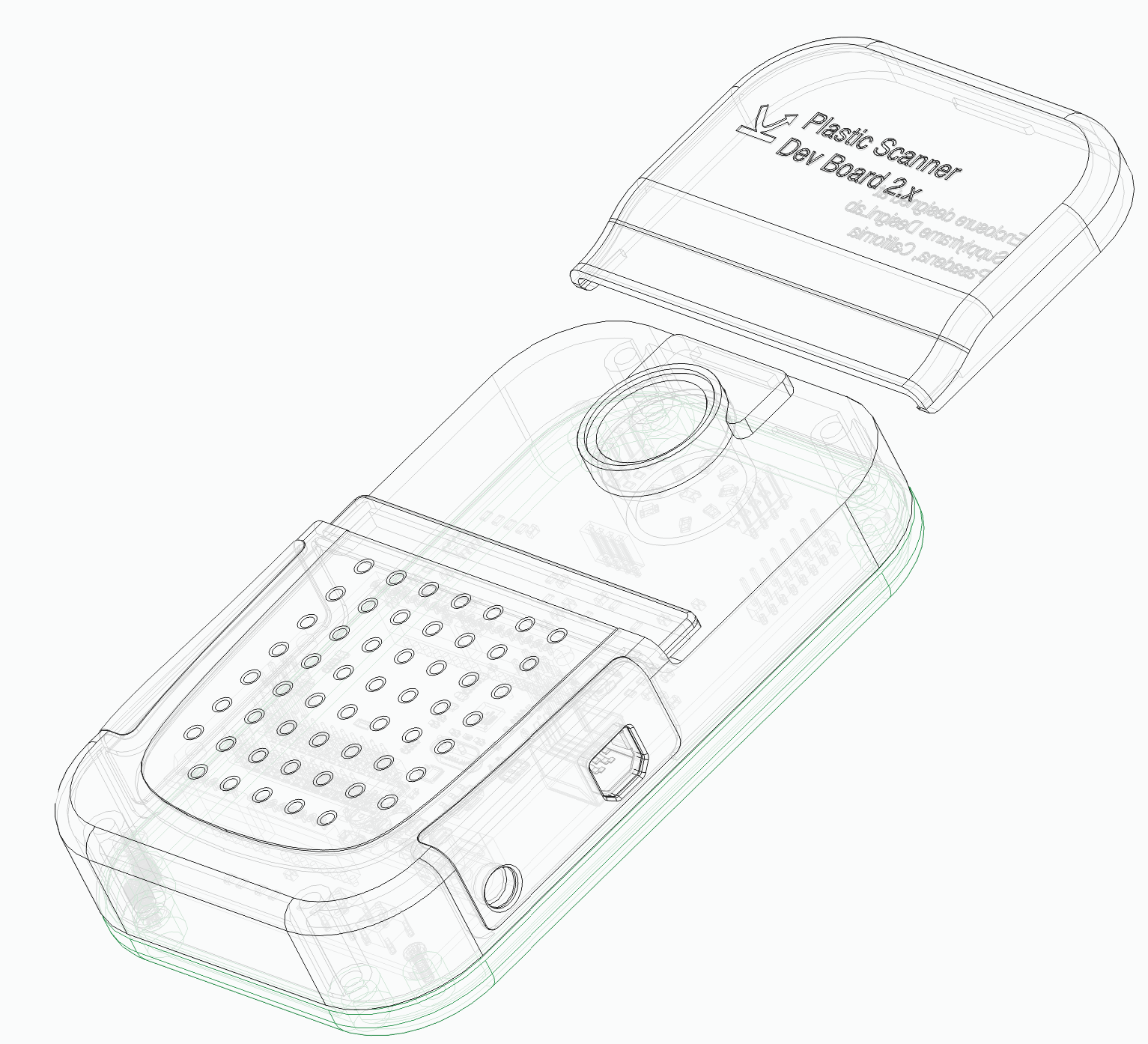

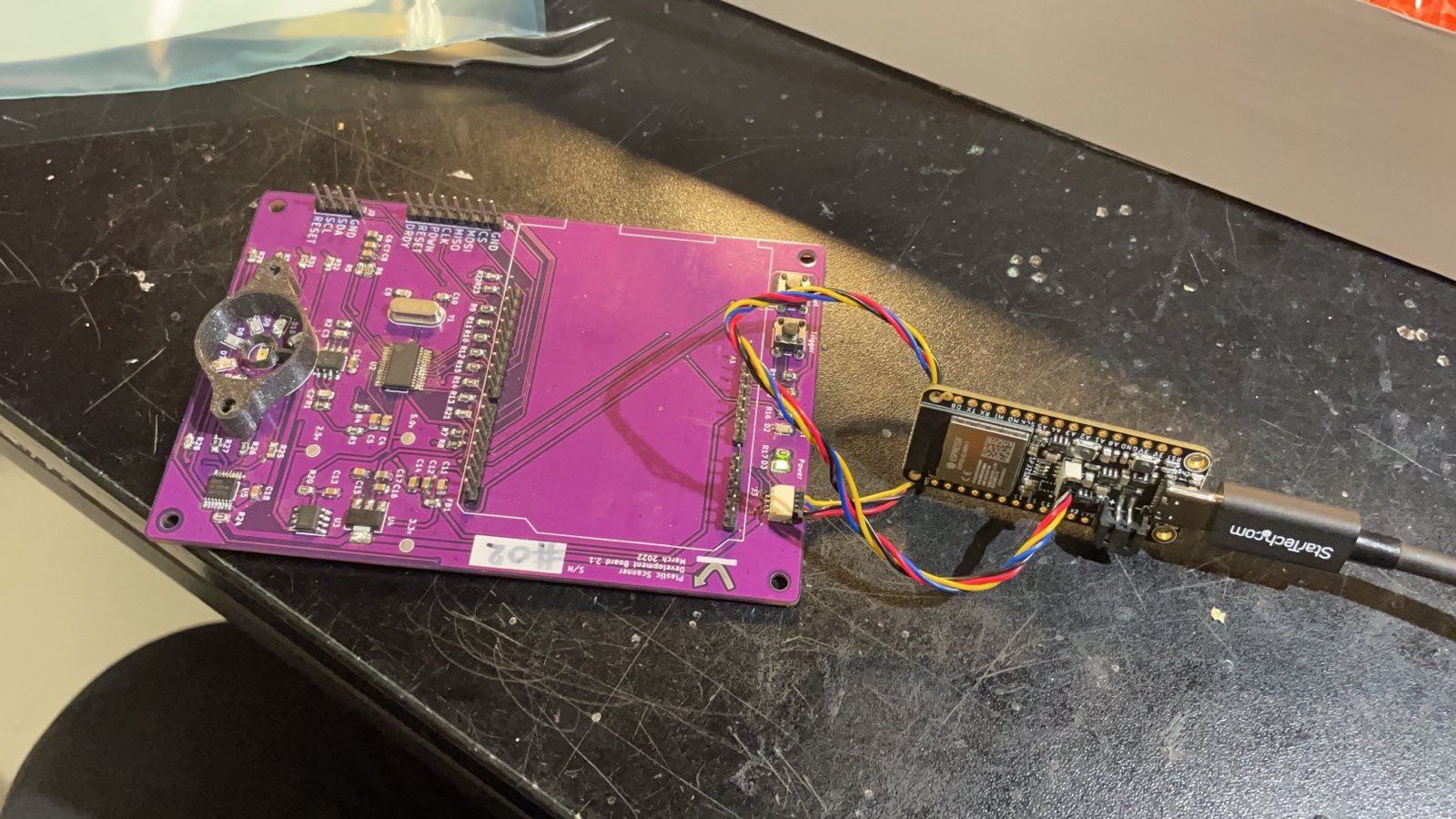

Let's say it again: Jerry's project is amazing - I really recommend you check it out! https://plasticscanner.com/

He has also built a great community of enthusiastic collaborators who are working on firmware development, electrical engineering, testing, etc.

Very importantly, the repositories are constantly updated. Droves of really interesting information.

Supplyframe DesignLab

Supplyframe DesignLab

Lucas Rolfes

Lucas Rolfes

Stephen Tranovich

Stephen Tranovich

Josh Cole

Josh Cole

Nicholas Stedman

Nicholas Stedman