PCB panelization is a nice way to get more bang for your buck, be able to do more projects at the same time and, in general, receive more boards at once. Say, you have two 10x4cm boards, and a seller offers you to either take . You could order them separately, as two 10x10cm PCBs (10x5 at best), or you could merge them into one panel.

Panelization means merging together PCB gerber files in one gerber. The main problem that needs to be solved is that you can't just put boards together - they usually need to be connected somehow. They also need to be easily splittable once you receive them - you won't want to split them using a cutting disk =) There are two main ways to panelize boards so that they can easily be split - V-grooving and tabs with mousebites. "Tabs&mousebites" means - connecting boards using tabs, they're added in between boards and are basically pieces of PCB material connected together (mousebites are holes drilled in tabs so that it's easier to break them off). V-grooves are cuts done with a machine with a cutting disk, that cuts lines through PCBs, leaving them connected but just barely, so that you can snap the boards apart.

V-grooving (failed) - picture from somewhere on here

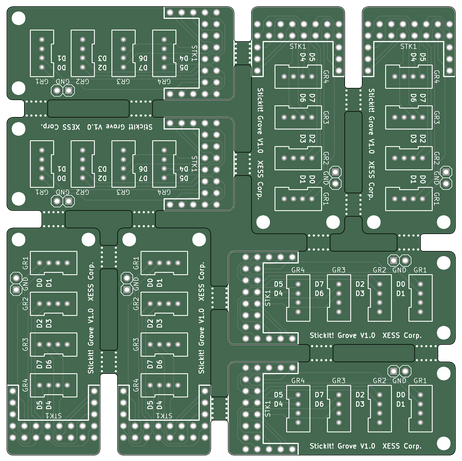

Tabs with mousebites (inner area is not actually filled) - picture from here

Tabs with mousebites (inner area is not actually filled) - picture from here

There's a problem, though - not all PCB houses support panelized boards. There are houses which are panelization-friendly, there are those who will ask you to pay extra per ech individual design on panel (and usually it's so much money it's not worth it), and there are those that flat out don't work with panels. Some only support V-grooving, too. Check your PCB house. I'm using DirtyPCBs since they're panelization-friendly, doing tab panelizing for free and V-groove for additional 5$ (as of 9 May 2017) (minumal V-groove length is 8cm), and also for the fact that, in my experience, they're actually maker-friendly and not just somebody doing business.

Arya

Arya

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Can we start a discussion about which fabs are panel friendly and which not?

To start off here's my reading of JLCPCB's stance. Their web page is a bit ambiguous about the issue:

https://support.jlcpcb.com/article/49-pcb-panelization

On one hand they say:

1. Note: This additional charge only applies if the PCBs on a panel are different. Boards such as in the left hand image below will not incur an additional charge because they are easy to pick up but boards such as in the right hand image would incur an additional charge.

On the other hand before that they say:

2. Similarly, using holes or slots as break off sections between boards are treated the same way as putting more than one design on a panel, each with its' own board outline.

Then they go on to suggest drawing some lines on the silk screen so that you can separate them yourself, but this would require me to have a dremel.

So which is it? If I use slots and mousebites to put 2 of the same design inside 100x100 mm, will they invoke rule 2? I suppose I could submit it and see what their sales engineers say.

Are you sure? yes | no

I haven't (yet) had a problem with putting multiple different boards on a single panel (with mousebites) when ordering from JLCPCB - they haven't charged me extra for multiple designs. Maybe I just got lucky, but I have had several orders go through okay with no extra charges. ¯\_(ツ)_/¯

Are you sure? yes | no

Ok, maybe I'll give it a go. Maybe in these straitened times fabs won't be too picky about taking a job.

Are you sure? yes | no

DirtyPCBs is very panel-friendly, in my experience - I've been ordering panels from them for many years, however, their 10x10 does cost $16. With JLCPCB, however, I would expect to get slapped with additional charges, as I use panelization heavily. These aren't experiences, just expectations, and they do tell you that they will check your design before sending it off to be manufactured, requesting additional money where applicable. I do expect JLCPCB to have *some* leeway - hence the "JCLPCB-friendly" panels for ZeroPhone https://wiki.zerophone.org/index.php?title=PCB_panels#Delta-B_PCB_panels , these should allow people to save ~$10 on a ZeroPhone PCB order, though not as much as if you were to use DirtyPCBs.

Answering your question - I'd submit the design, then wait for their answer - it's possible it will not really be noticed =) Do report back with your findings!

Are you sure? yes | no

This was a while back but JLCPCB did not charge extra when I put 1 design twice on a board, as recounted here: https://hackaday.io/page/6633-a-review-of-jlcpcbs-service So it only cost $2 for 5 boards = 10 smaller boards.

I don't know whether they will really charge according to their rules if there is > 1 design on the board. I haven't got a board like that yet.

At the moment I'm trying another fab, LocoPCB, which offers free V-cuts. V-cuts are not as flexible as slots, breaktabs and mouse bites; it's a subset of panelisation. I'll write a page about that fab later.

Are you sure? yes | no

It is indeed all about "different designs on the same panel", that's when they're going to ask money from you. They *will* charge you if they notice, if they don't, it will be ok =)

I'd be interested in your page! Maybe want to write it on this project? Request to join this project, then you'll be able to add your own pages to this project.

Are you sure? yes | no

>They *will* charge you if they notice, if they don't, it will be ok

That's what I figure, it depends on the checker doing the visual inspection. Slots and mouse bites only add a bit of routing and drilling to the job and not an extra step as V-cut does, so if the whole panel containing other jobs has a lot of slots, they might just let your job past.

I only use panelisation as a tool so it's not a project per se for me. Besides, that page, which will be about the whole experience, the panelisation is just one detail, will join previous reviews of other fabs in my pages. When I build circuits, I use the opportunity to learn about PCB techniques and try different fabs.

Are you sure? yes | no

I've written about my experience with V-cut panelisation in my review of LocoPCB: https://hackaday.io/page/6724-a-review-of-locopcbs-service

Are you sure? yes | no

Hey. Your program does not work with KiСad 5.0Gerber file does not open. The program falls into error. Can I fix this?

Are you sure? yes | no