I decided to use plywood for the electronics enclosure, since I have access to a laser cutting at my local hacker space. Plywood is cheap, and the laser cutter is fast, so it'll let me prototype quickly and quickly build more if I need to. Using a laser cutting also gives me confidence that I can give the design enough stiffness and minimize vibrations.

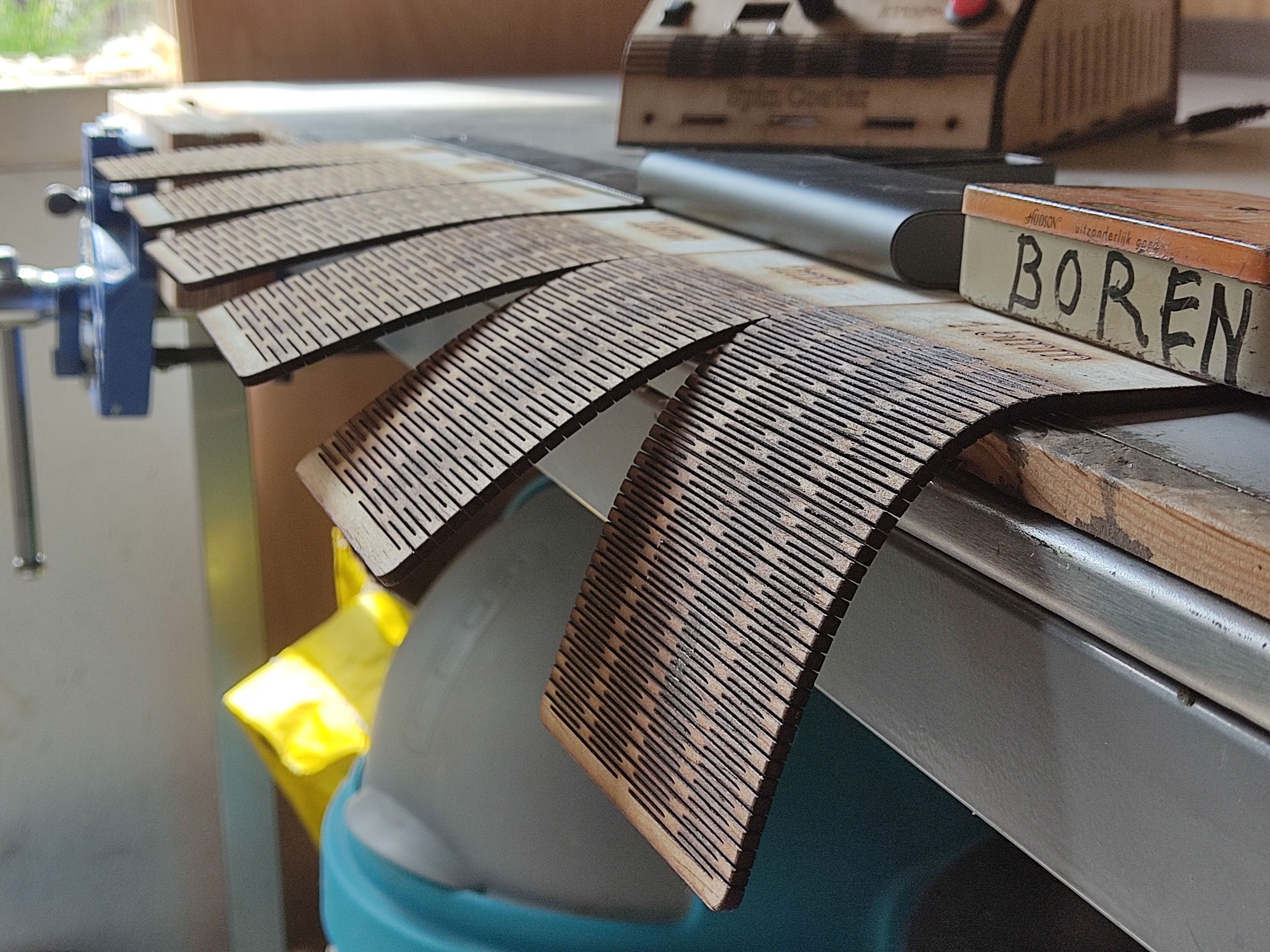

Of course, I could just use a standard box with interlocking finger joints. But I wanted a design that gave me quick access to the inside, without having to undo a ton of screws. I also wanted to challenge myself and make it look more interesting then just a box. I ended up going with a design where the front, top, and back is made from a single curving piece. It's held in place using only 4 screws: 2 in the back and 2 in the front. To give it a little more rigidity, the top is held in place by the side pieces with small tenon joints that are loose enough to come undone easily when I need access. To open it up, all I need to do is remove the front two screws and lift up the top like the hood of a car. It's not the sturdiest design (and can be awkward to put back together), but it gives me easy access to the internals to fix any issues that undoubtedly will arise. Plus, I think it looks neat!

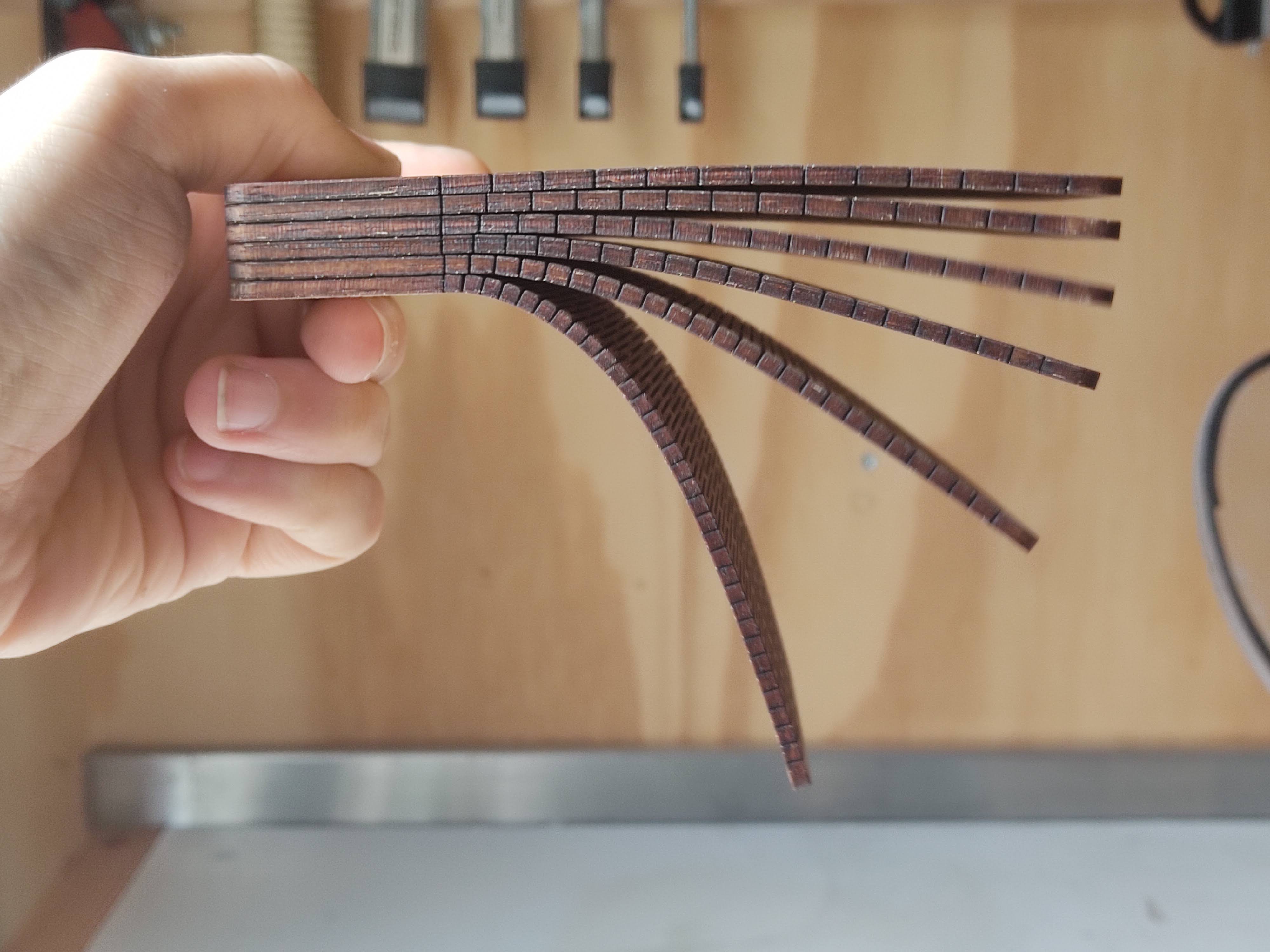

I had never curved plywood before. I know it can be done using moisture and heat and applying pressure, but that sounded like a lot of work and hard to do consistently right. So instead I cut a dense pattern of alternating slots into the plywood using the laser cutter. This is a trick that's often used to create bends in plywood. It degrades the strength of the plywood, but it should be fine for this piece.

To figure out how close the slots needed to be to get the curve radius I wanted, I cut a few test pieces. Turns out they needed to be pretty close together. It felt weird to hold wood that's so flexible. I know it mechanically makes sense, but it still made me giggle like a schoolgirl.

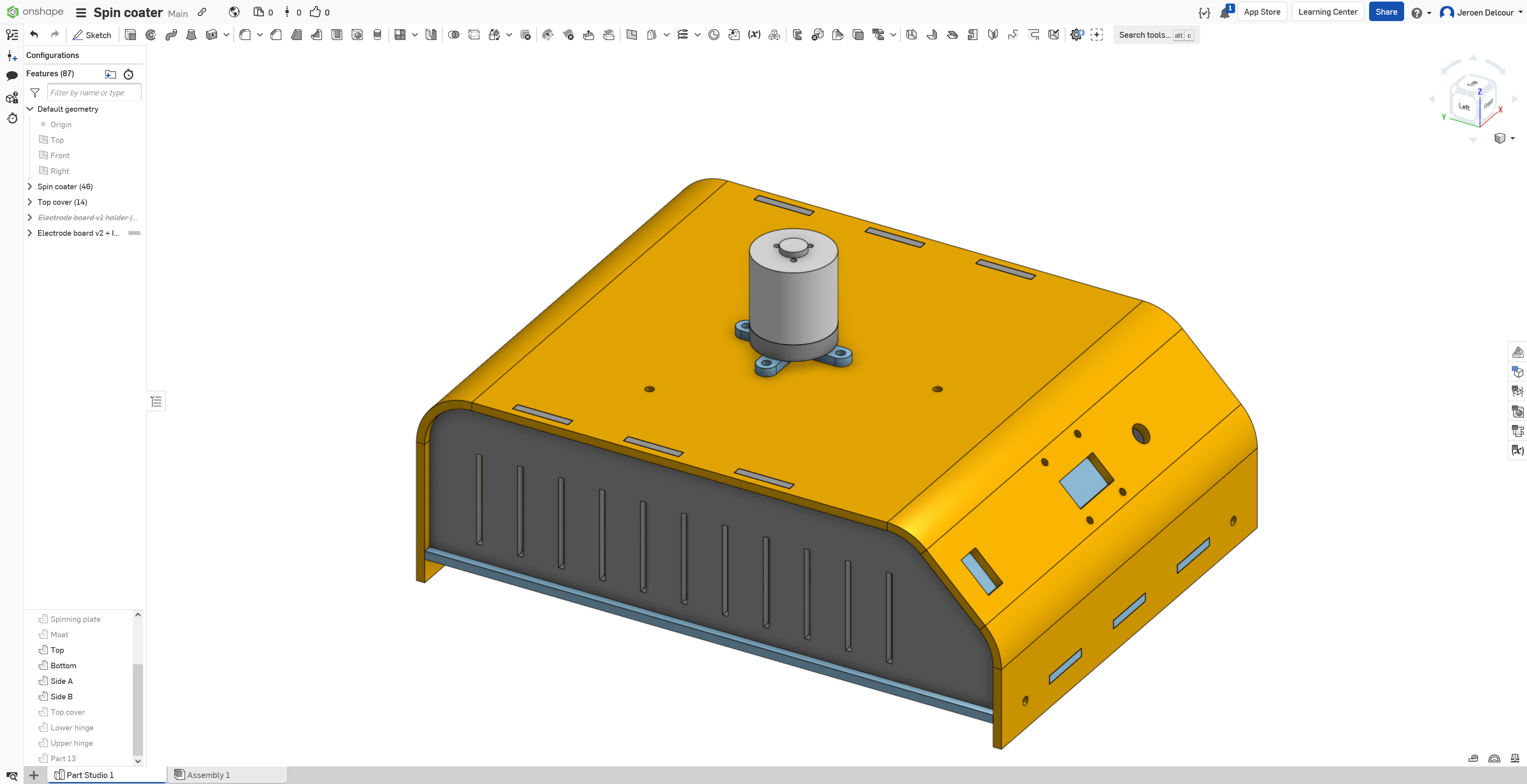

Here's the OnShape CAD document.

Jeroen Delcour

Jeroen Delcour

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.