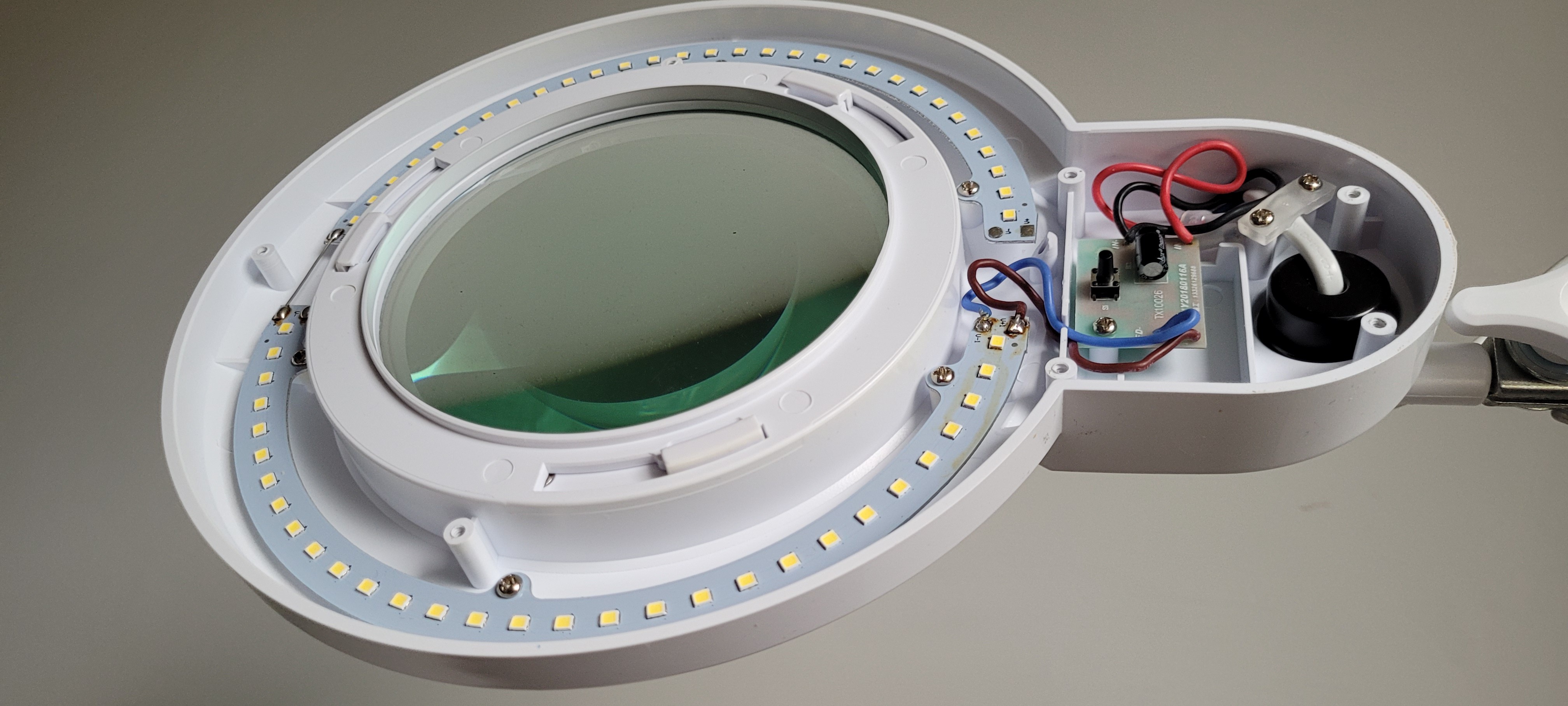

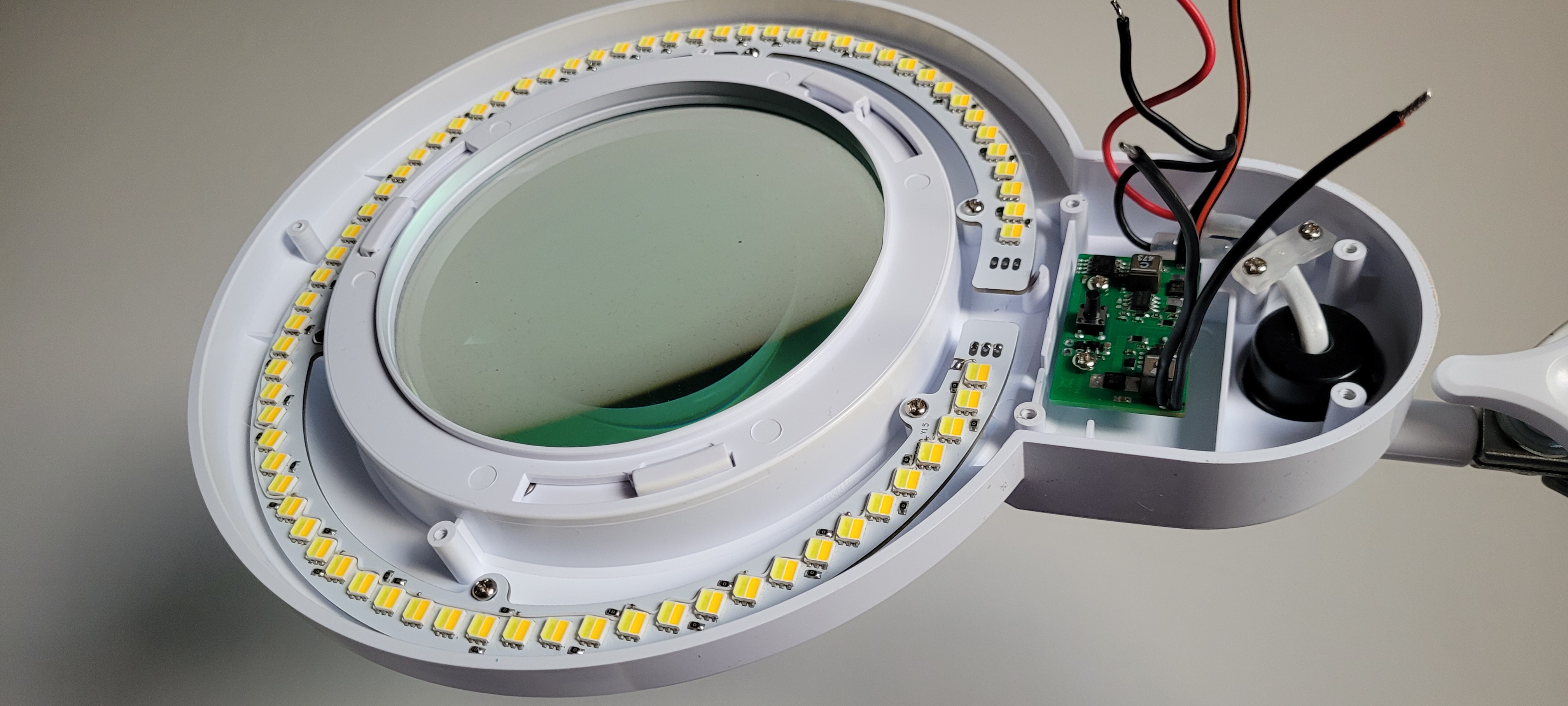

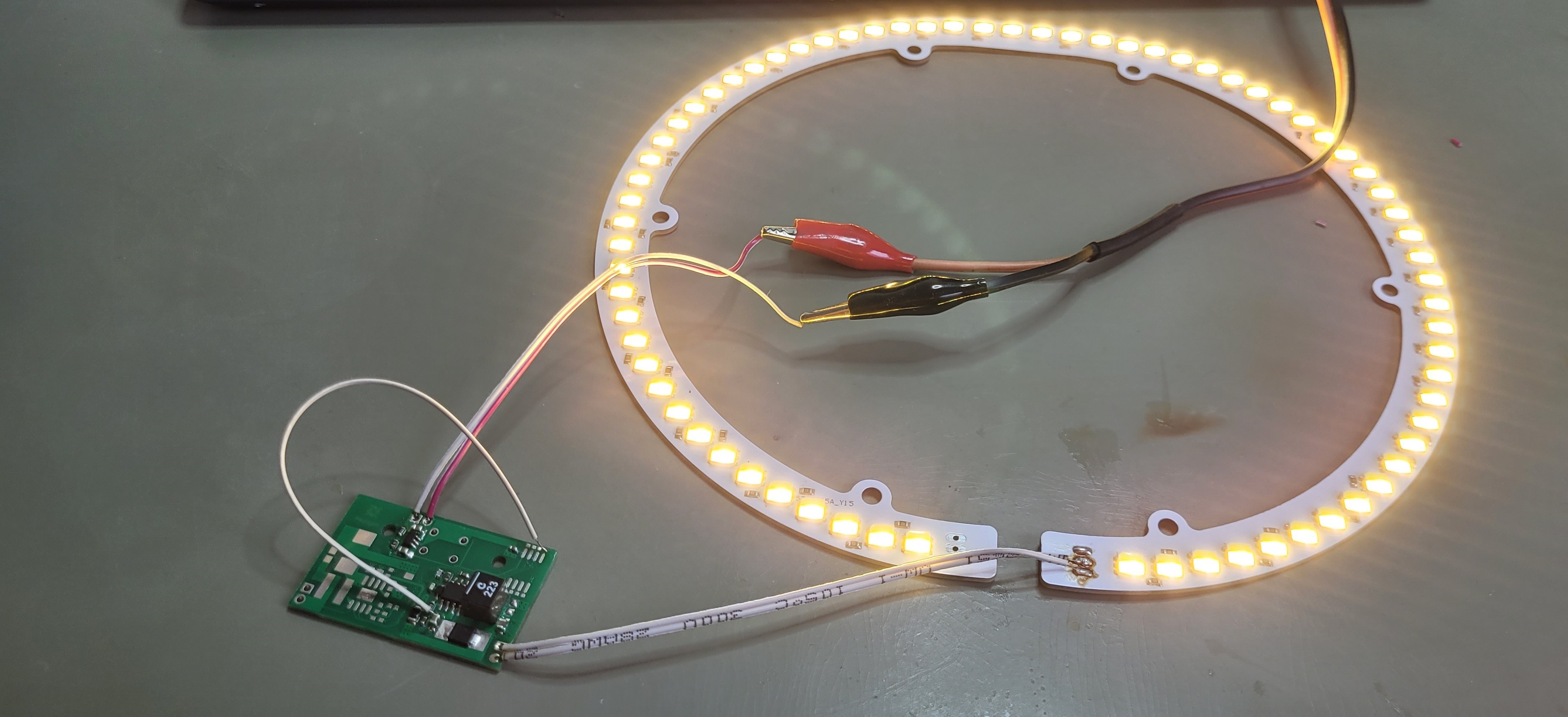

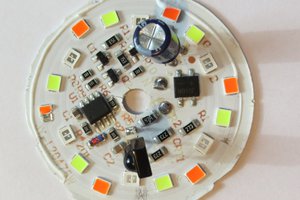

The purpose of the project is to modify the lamp with a magnifying glass model 9006LED-127. The device is available, among others, on the Polish market (European Union). By default, the lamp is equipped with lighting consisting of 60 LEDs. The color temperature of the emitted light is about 5500K. In addition, the device has three modes of light brightness control.

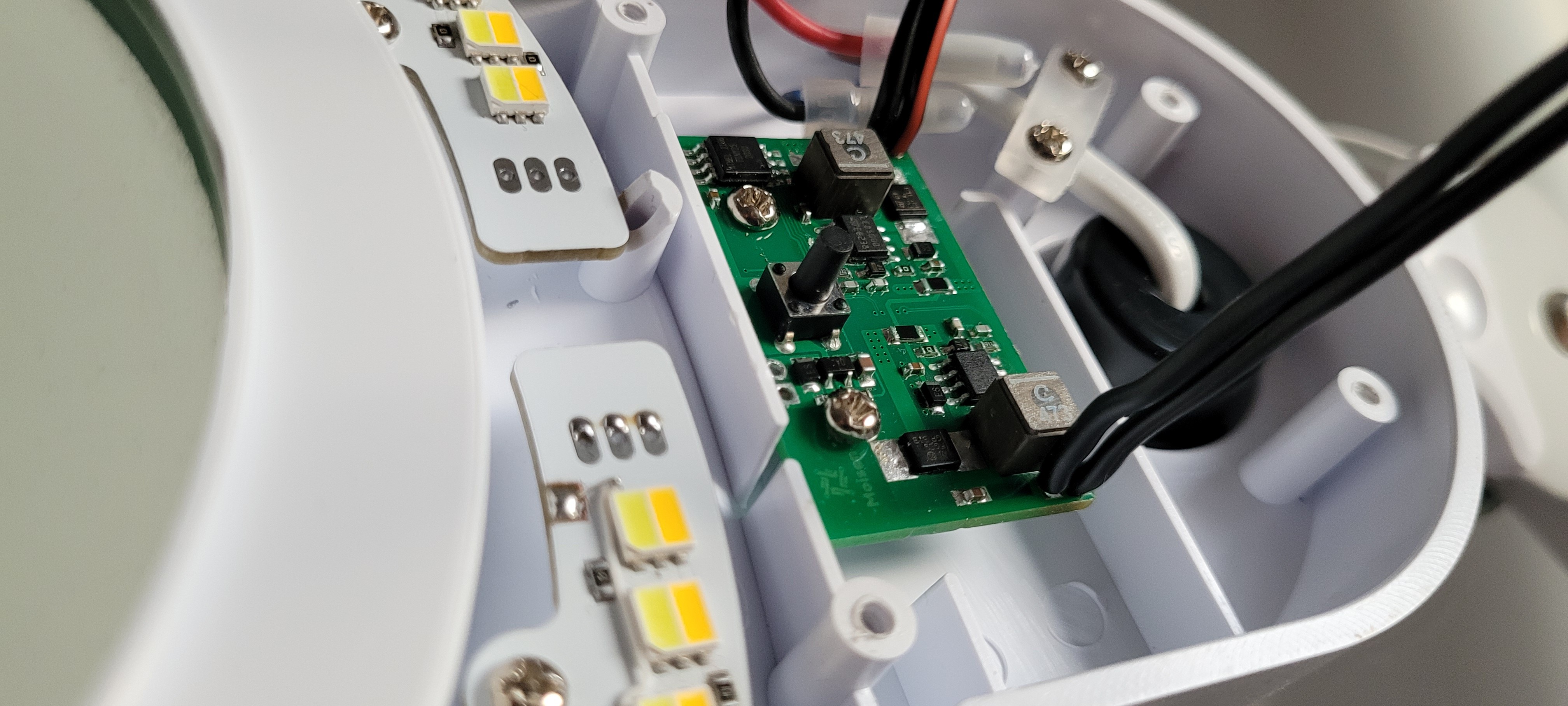

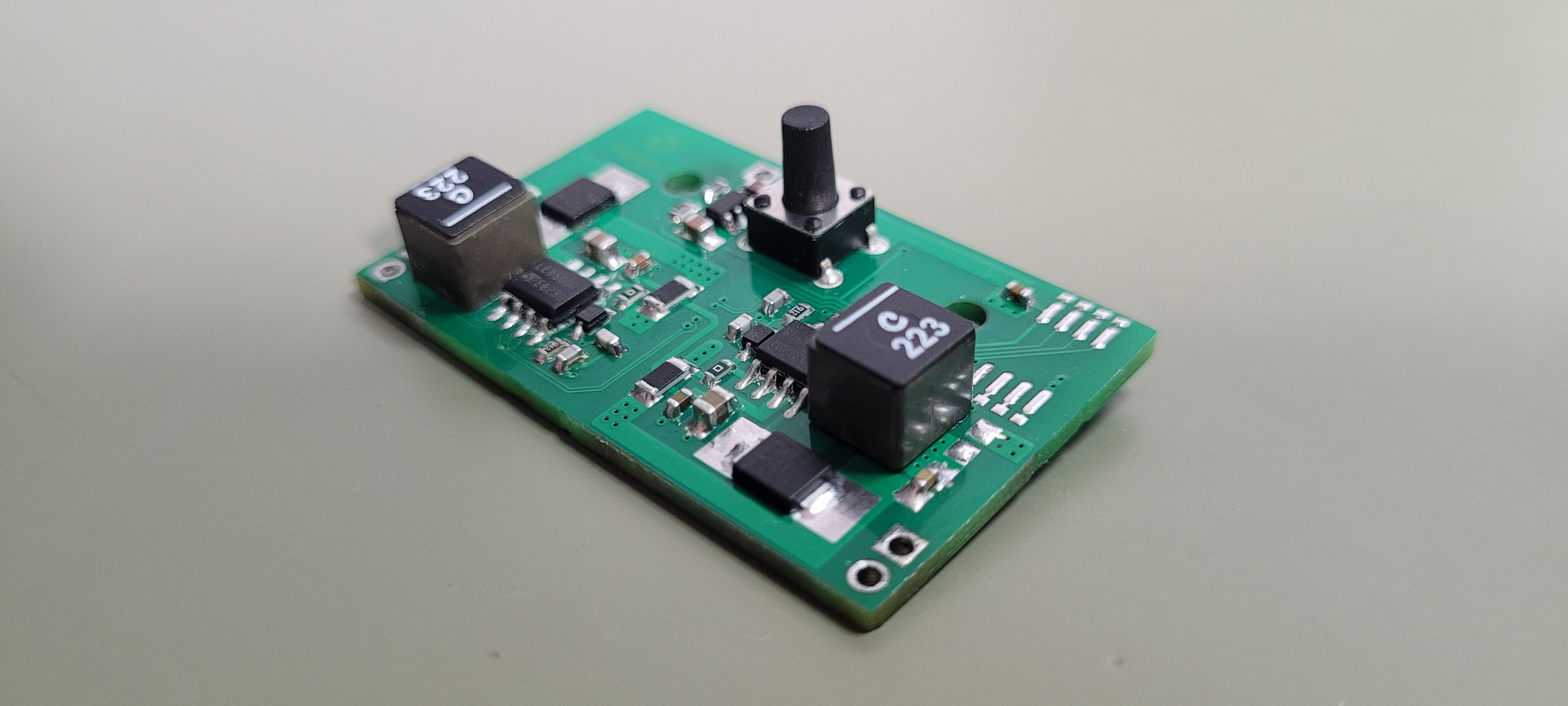

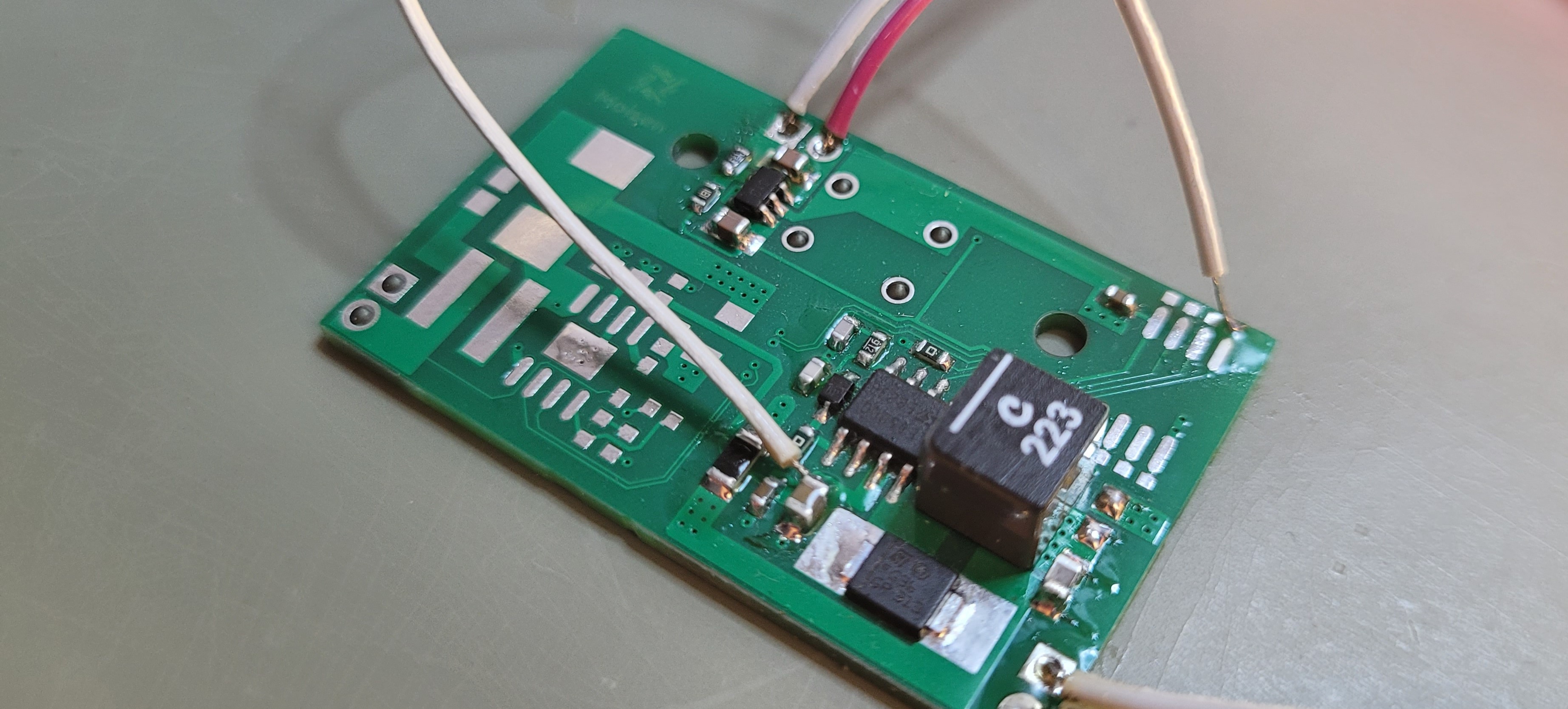

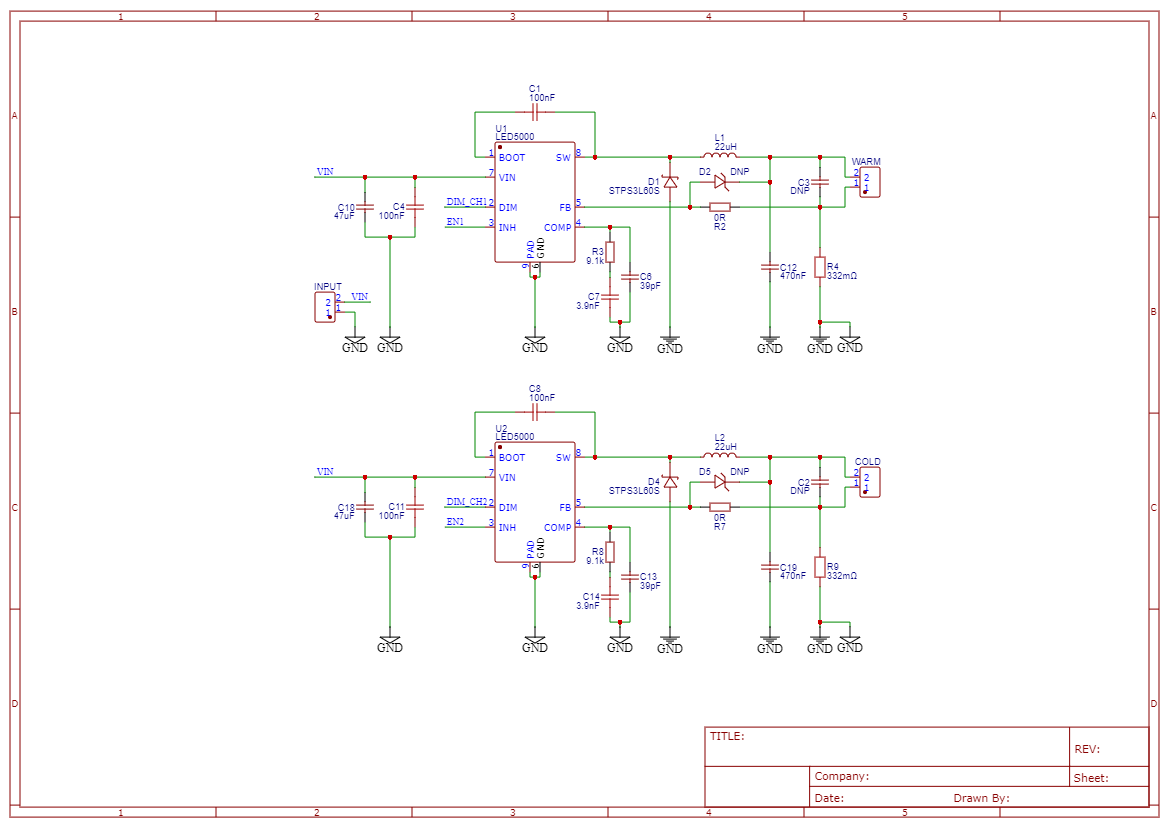

The modification involves replacing the LEDs with double LEDs in a single chip. The dual LEDs offer warm and cold color temberature of the emitted light in a single SMD 5050 chip. As a result, the device will be able to emit cold, warm and neutral (cold+warm) light.

The color temperature of the emitted light has a significant impact on our mood. Staying (office, store windows) in rooms illuminated with cold light (4500K-5000K), the human sense of sight sharpens and the person becomes stimulated. On the other hand, staying in the environment of warm light (2800K - 3100K) we become more relaxed.

Tim

Tim

Jana Marie

Jana Marie

Enrico

Enrico