As I mentioned earlier, I am adding insulation to the oven in the hope that this will allow it to heat up faster. I think that some of the uninsulated panels are also a bit dangerous. The back panel of the oven gets REALLY HOT during use. With the air inside the oven at 250 degrees, the metal panel is at almost the same temperature and just touching it is enough to give you a nasty burn. You might think it is unlikely that you will need to reach around the oven during use, but what if you drop something, or your pen rolls behind there and you need to pick it up? Accidents can happen!

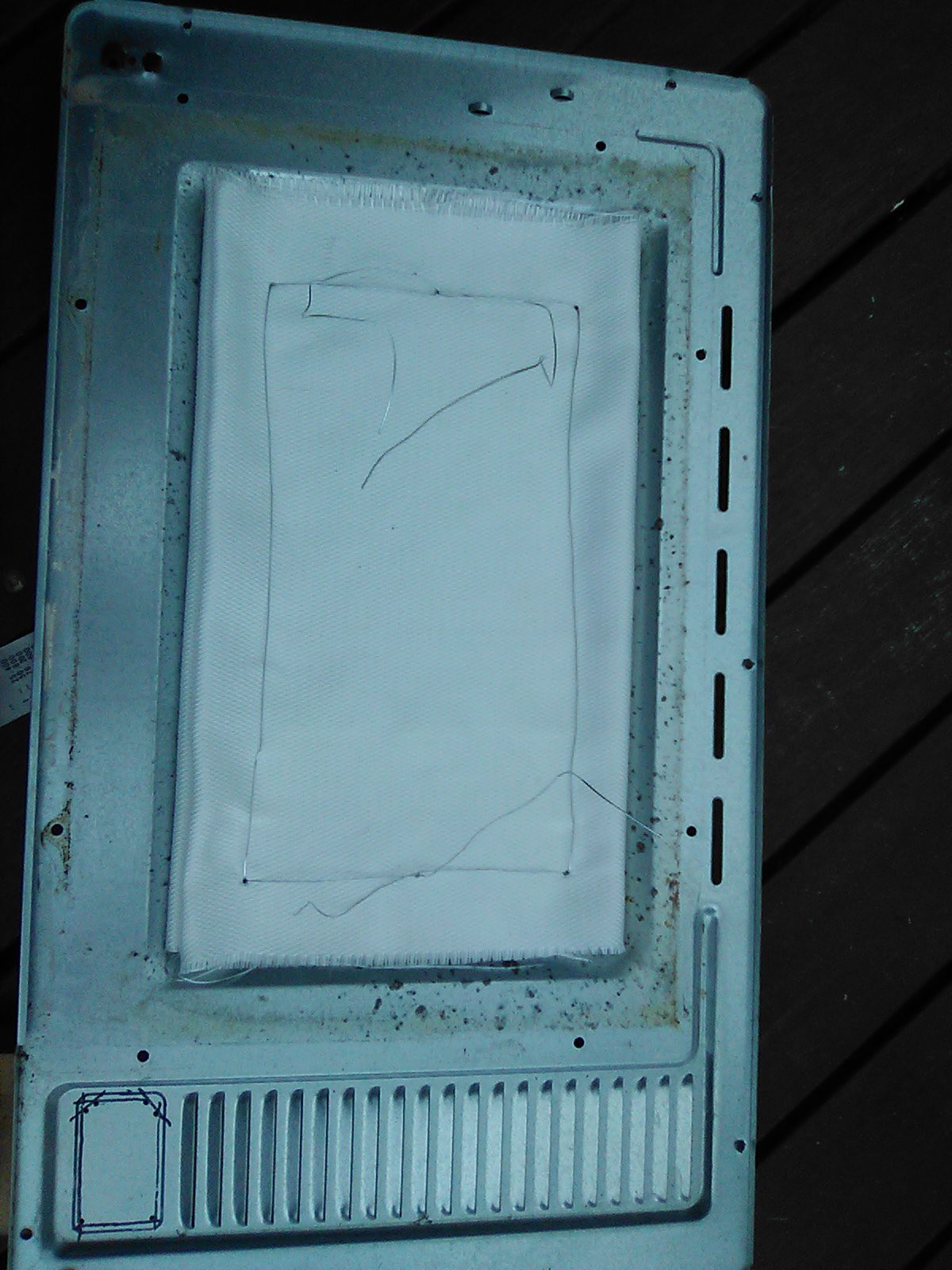

Furnace insulation or "refactory lining" is available for just this purpose, but was hard for me to find locally. Layers of fibreglass blanket should do the same job, so I bought a "fire blanket" at my local hardware store. This is made of densely-woven glass fibre and can be cut to size using sturdy kitchen shears. I folded over several layers where possible to make the insulating layer thicker.

I used shiny aluminium sheet over the top of the fire blanket to help keep it in place, and also to reflect radiant heat back into the oven. I got the aluminium from disposable oven trays, which seems like the right balance of rigidity, flexibility, durability and of course, cost.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.