After years of maglites, $1 flashlights, $1.25 flashlights, custom LED lights, phone lights that all came up short in some way, it was time to try another custom solution.

25 years ago, it was acceptable to burn $20 on a gigantic maglite. They were substantial aluminum, D cell eating beasts. Halogen was the best anyone had. Maglite had a $50 halogen version with a metal reflector. Flashlight hacking peaked when the lion kingdom hacked a $20 maglite with a plastic reflector to use a halogen bulb & 5 D's to make the voltage it required. This melted the reflector & the bulbs burned out quickly, but it scared away all the zombies. Today, flashlights are much more expensive but a lot less substantial. A crummy AA burning LED is now $20.

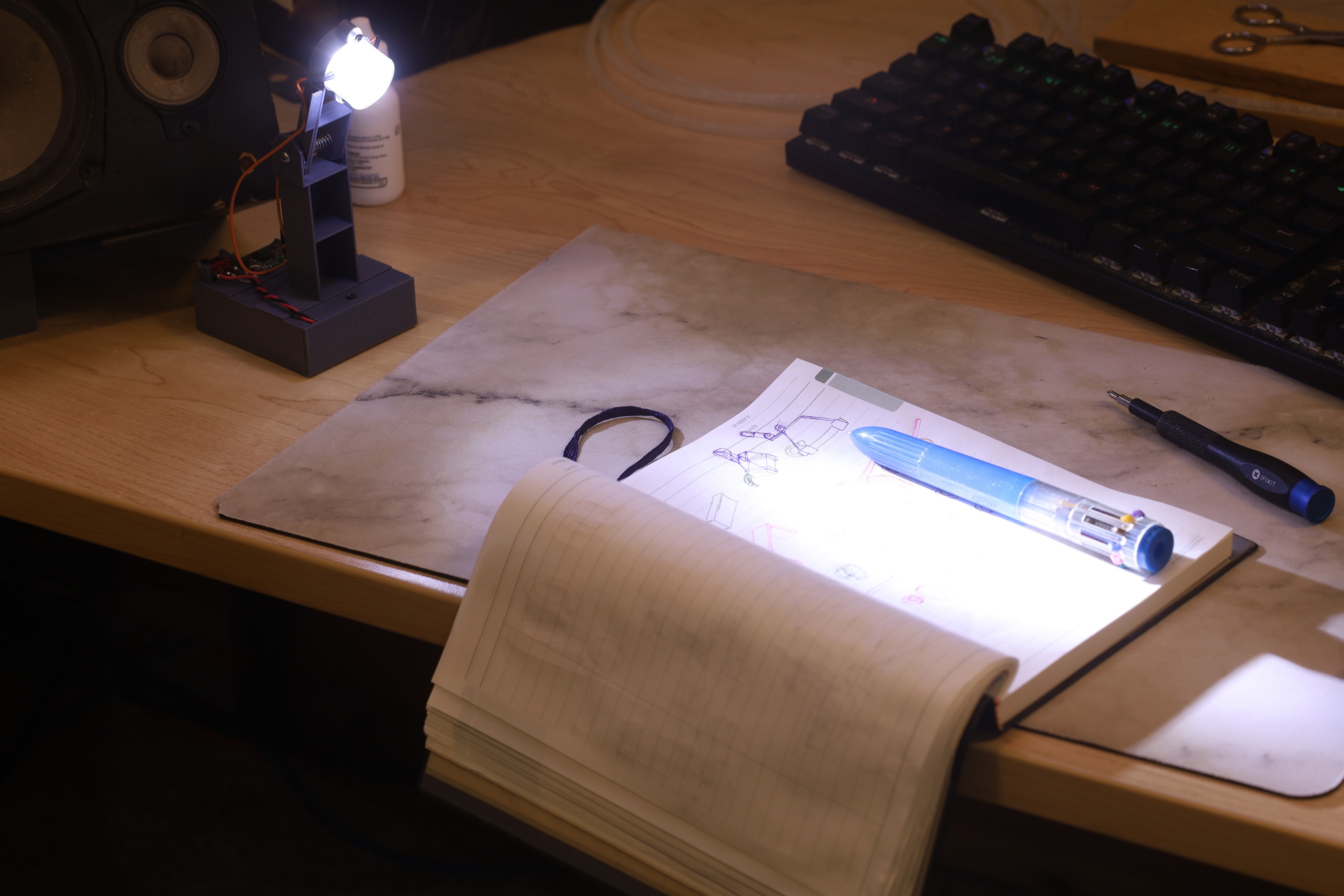

The mane requirements in a flashlight today are a long storage life, reliable electronicals, constant voltage, pivoting light, ability to stand up on its own & point down, compact size. Low capacity NiMH's have been the only thing capable of a long storage life. Alkalines & carbon zincs all corrode. Lipos all puff.

These dollar store flashlights ended up being a very good source of parts. 10 garbage bags are a deal in countries where free grocery bags are illegal.

They contained a very bright & even LED reflector assembly.

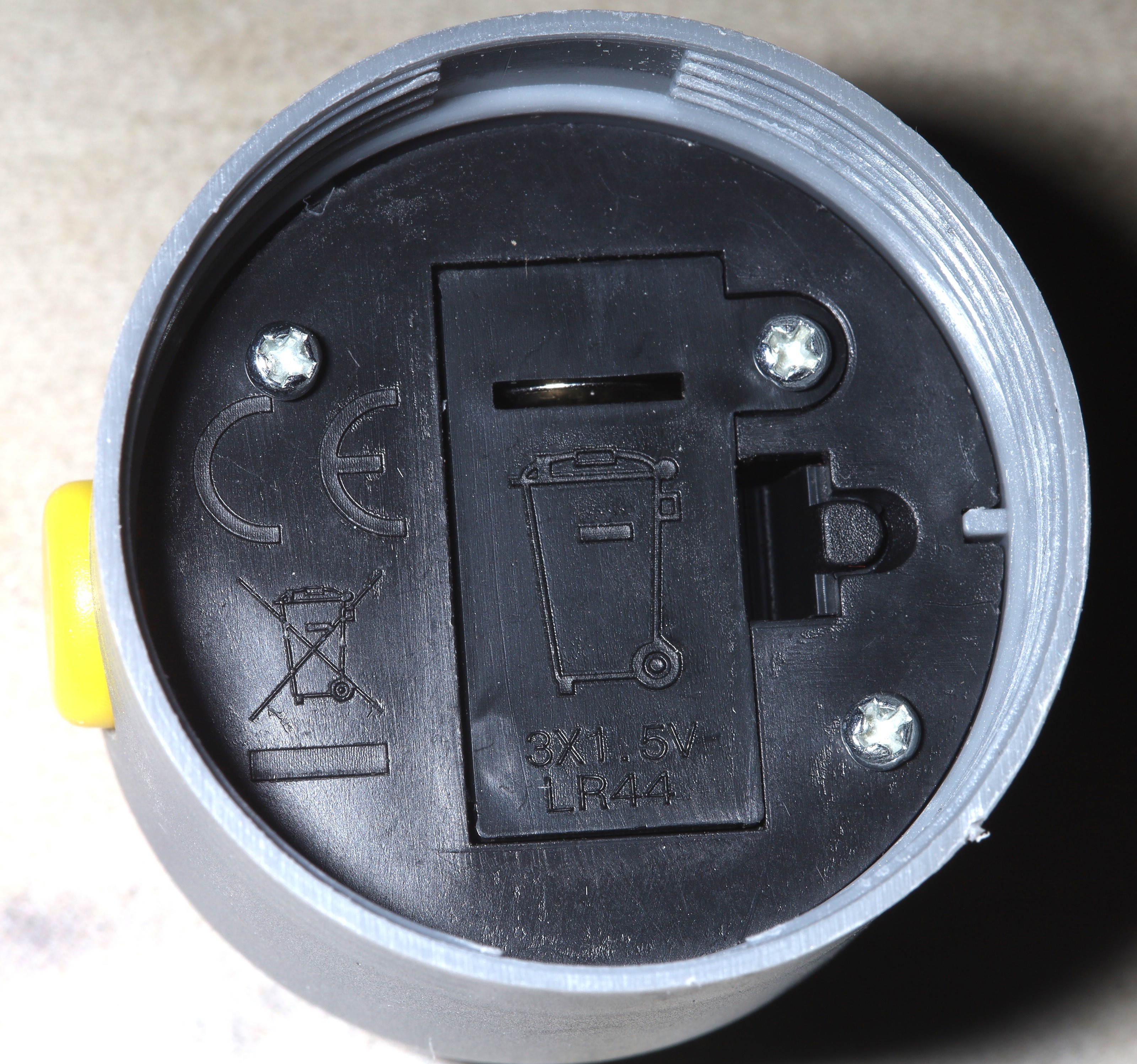

Really expensive caliper batteries.

They showed farsteners are fair game for battery doors.

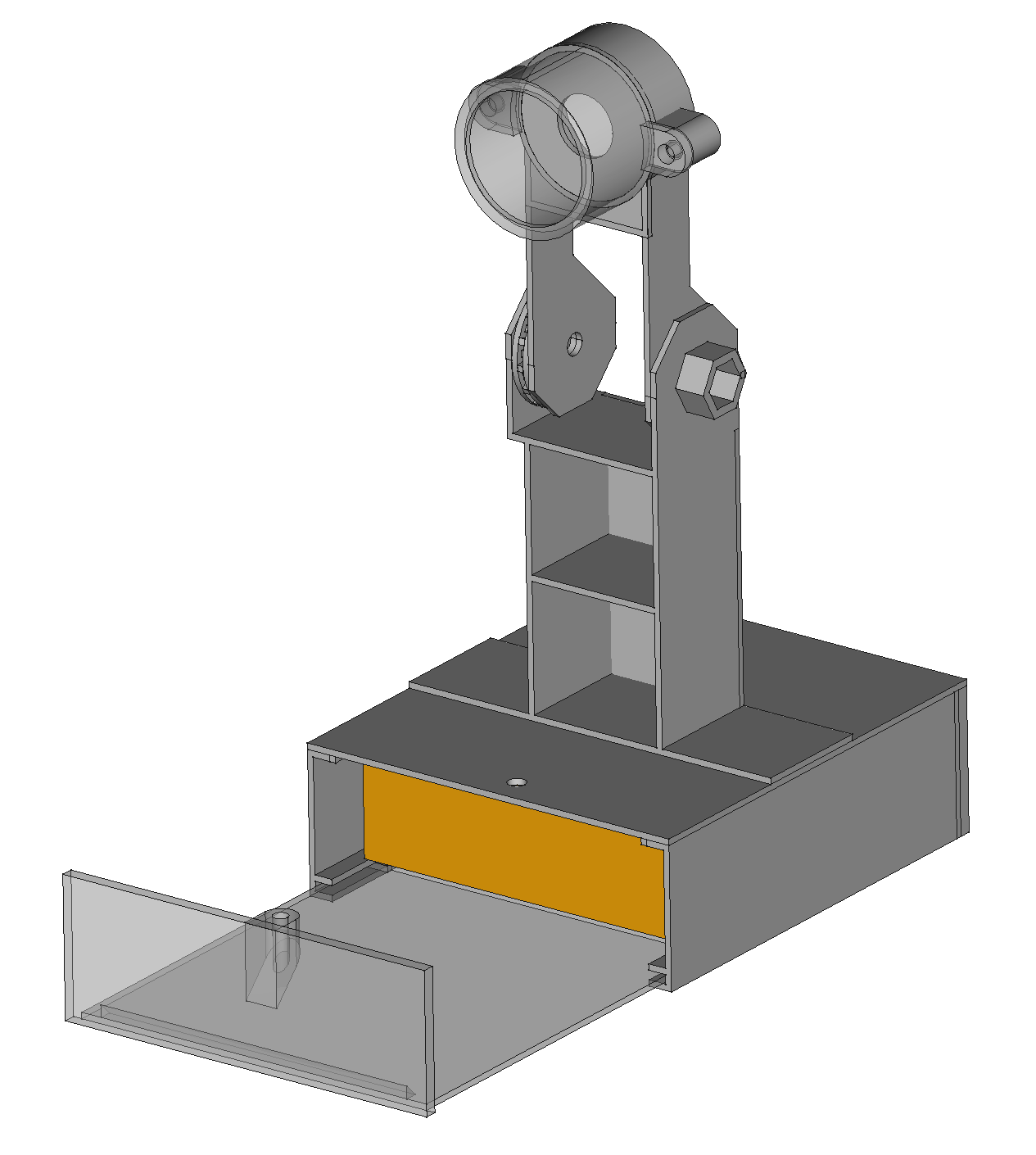

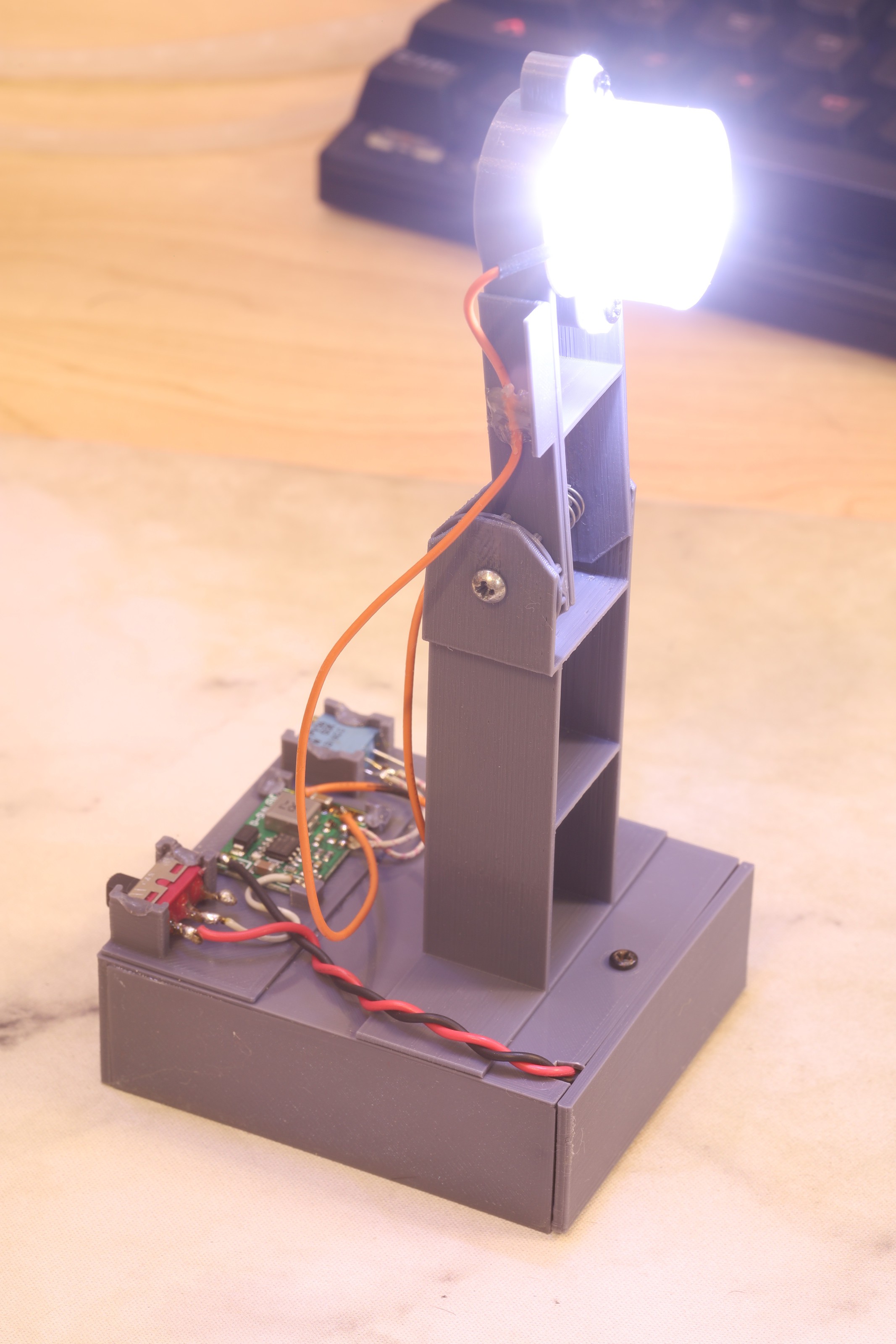

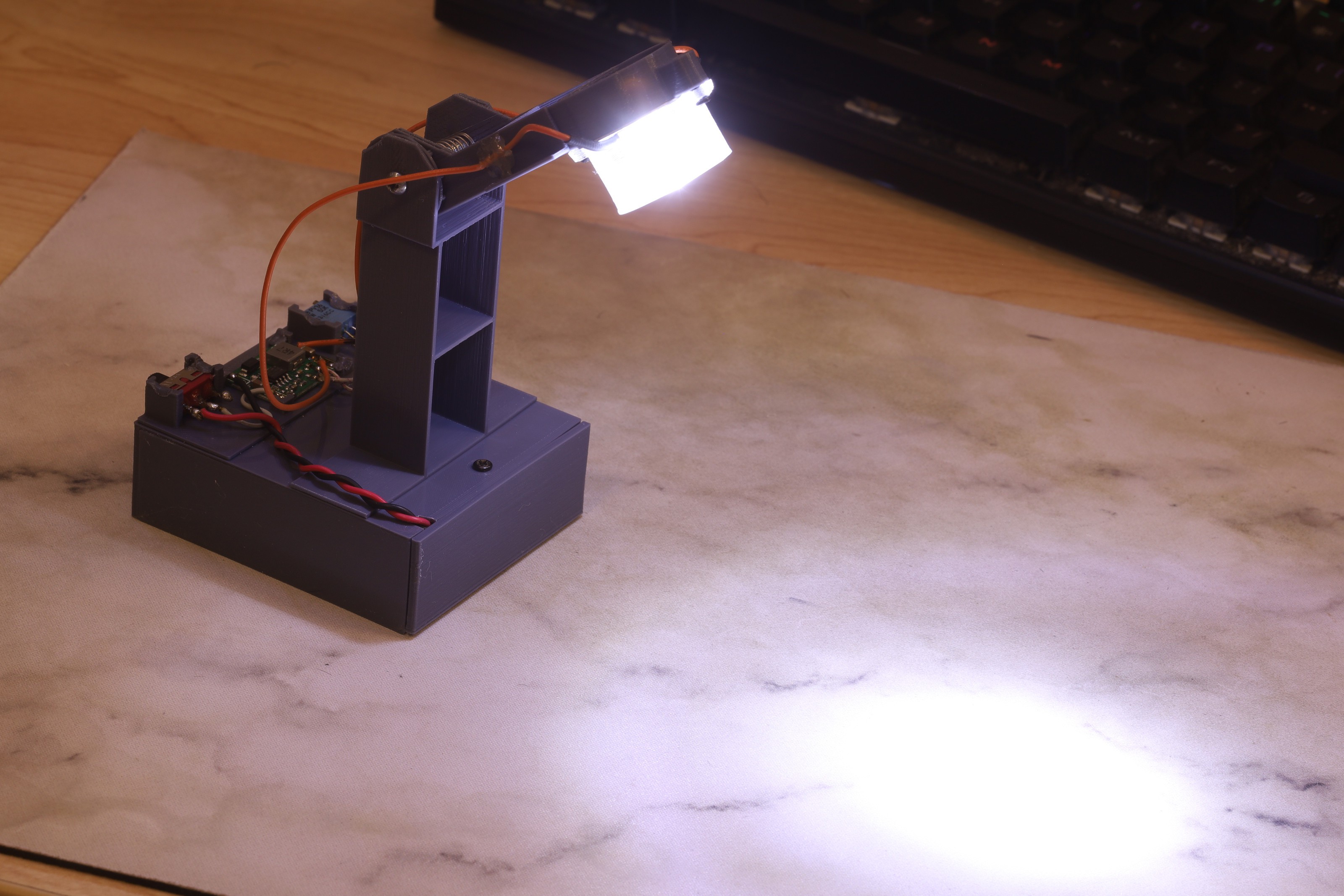

The dollar store flashlight provided a decent LED & reflector. 4 AA's would provide a constant 3V. The best battery placement was finally determined to be flat on the very bottom. A lot of agony went into the battery placement. None of the commercial gooseneck lights with vertical AA's stand on their own. They rely on magnetic bases.

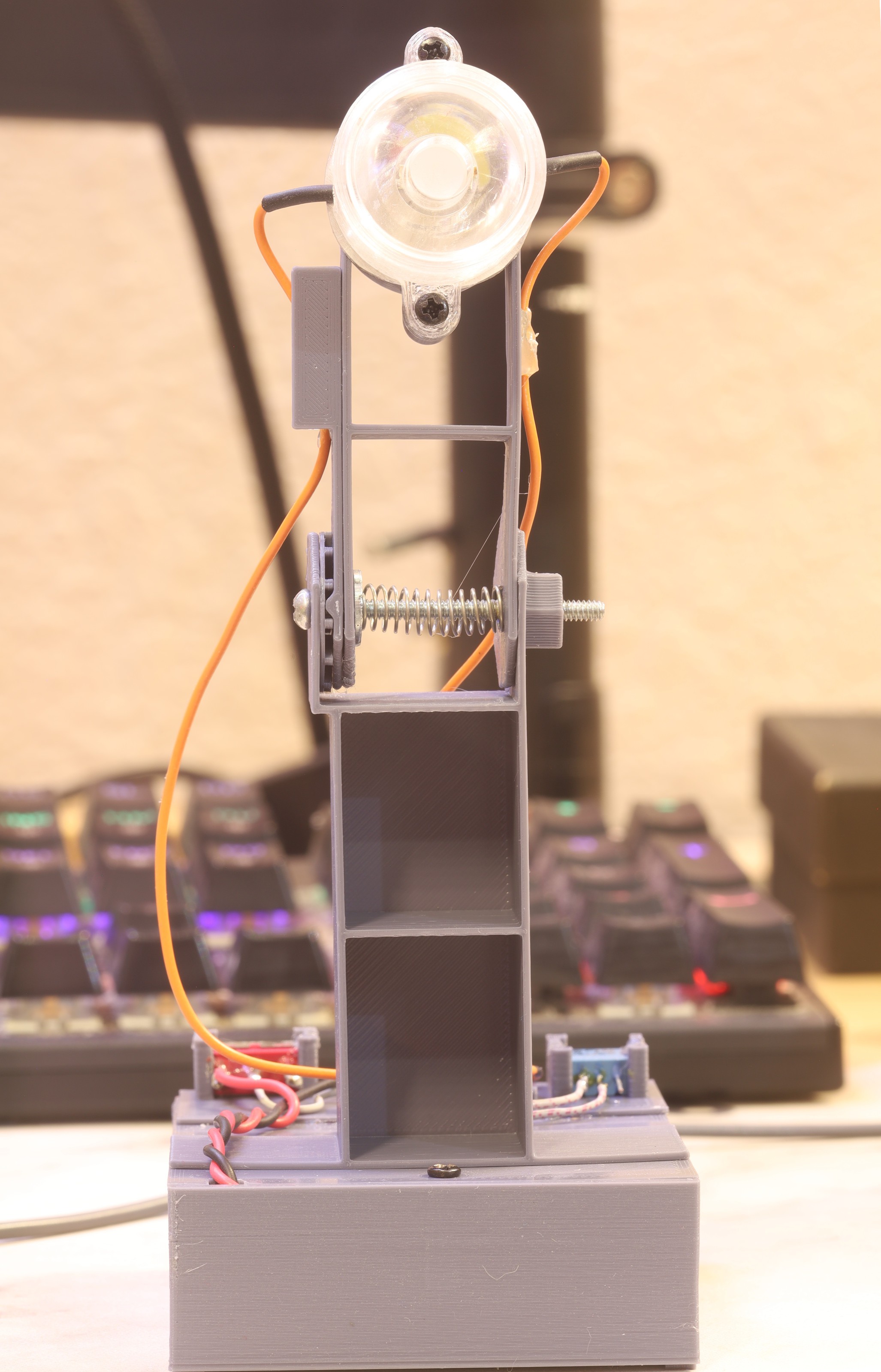

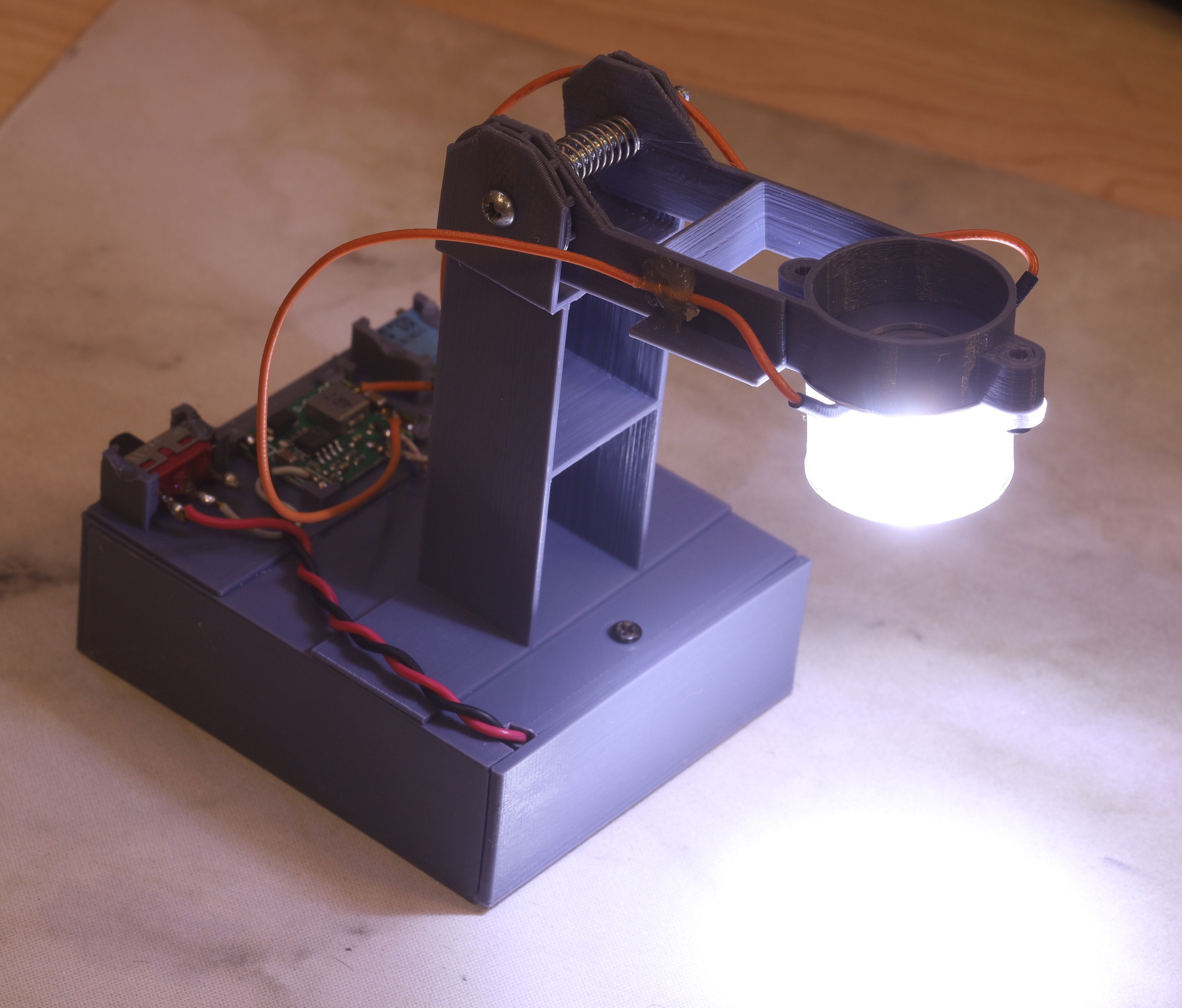

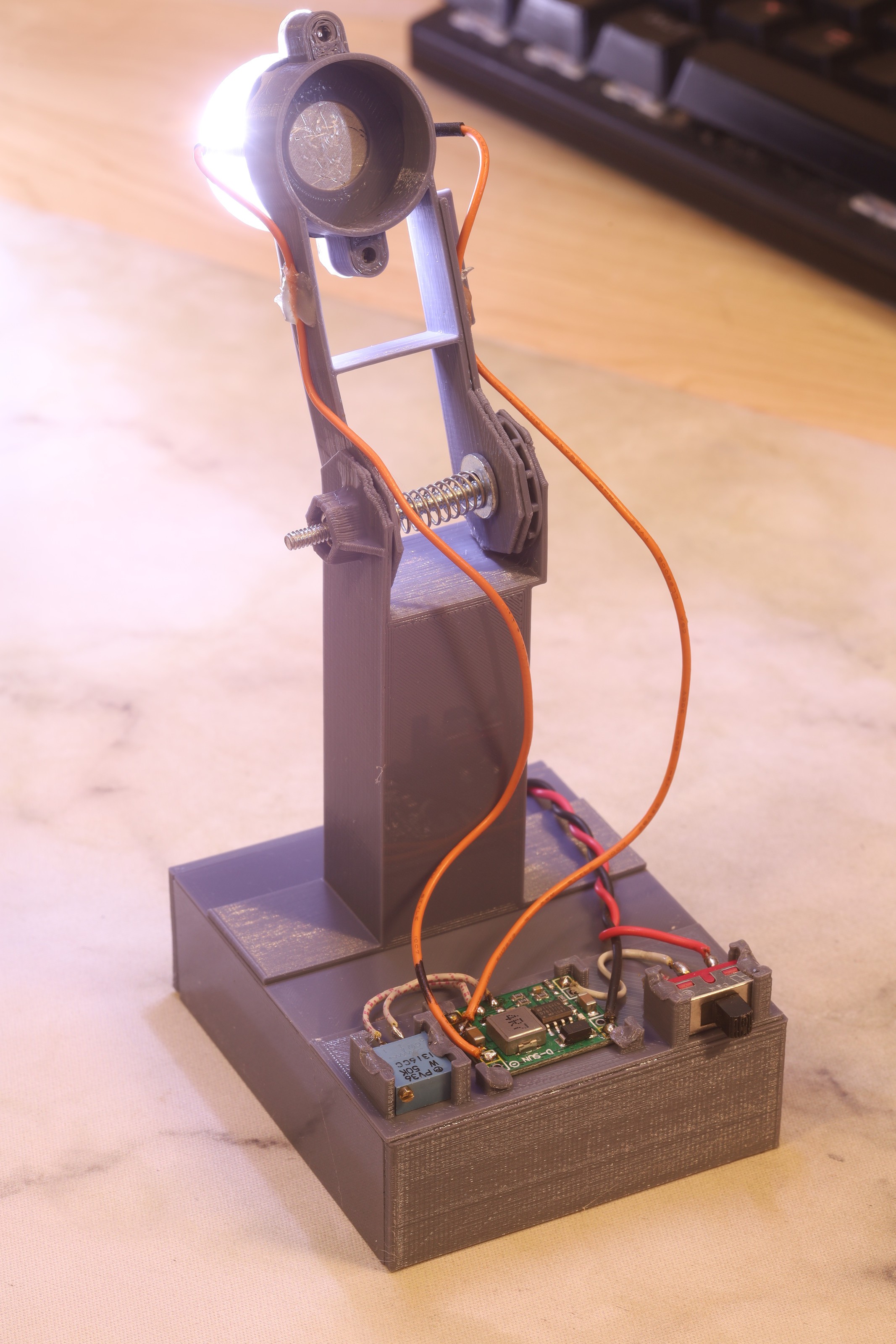

The mane unknowns were the ratcheting mechanism & the heat sink. It definitely needs a heat sink. A buck converter & switch would stick on the battery compartment somewhere to make it bottom heavy.

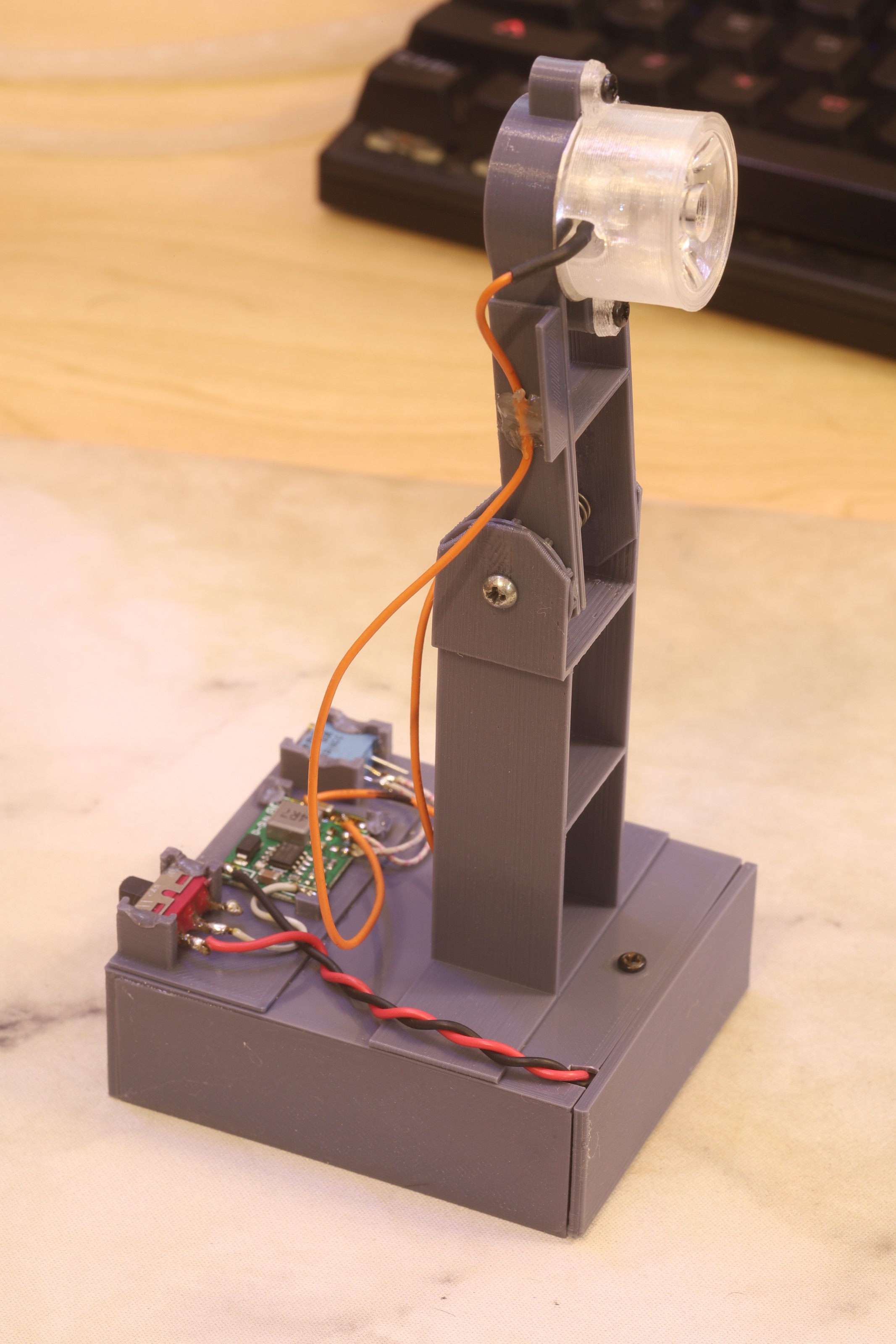

Helas, a 3D printed flashlight using dollar store parts looks exactly like a dollar store flashlight.

The mane thing lions would now change is making the ratchet a fully variable angle, but as it is, it's lightyears beyond what lions had before. The ratchet has slight maneuvering ability. The mane problem with the ratchet is the lack of precision in 3D printing. A fully variable one would need some kind of rubber.

The hard parts were the wiring & creating the heat sink. The brightness can be painful, but lions have never used anything but maximum brightness before. Brightness can be permanently changed with the pot. It burns 100mA at 6V so reduced brightness would bring a welcome increase in battery life. There's a 1V drop in the voltage converter. Full brightness is 3V.

The batteries provide plenty of mass to stand up on. It could benefit from being taller.

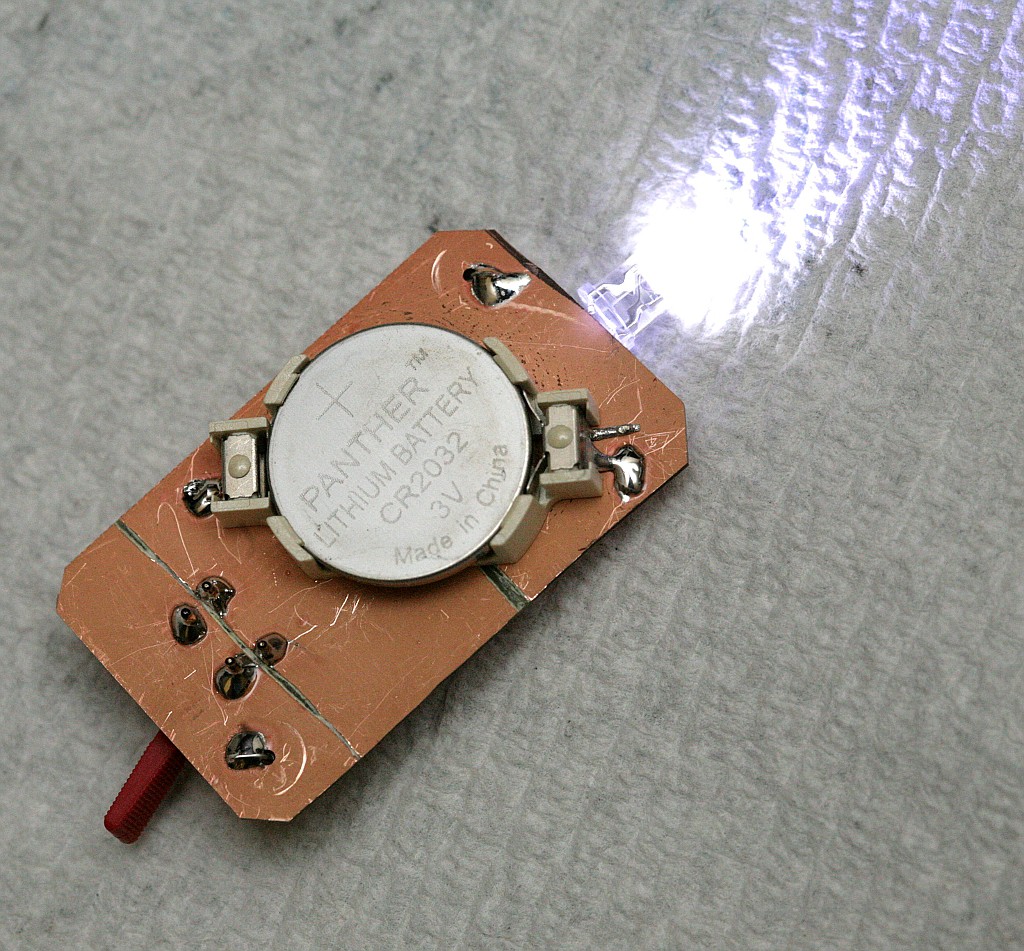

This was the lion kingdom's biggest foray in 3D printed a breakout board carriers. Single boards with positions for mounting multiple breakout boards & through hole parts are how most stuff is going to be made.

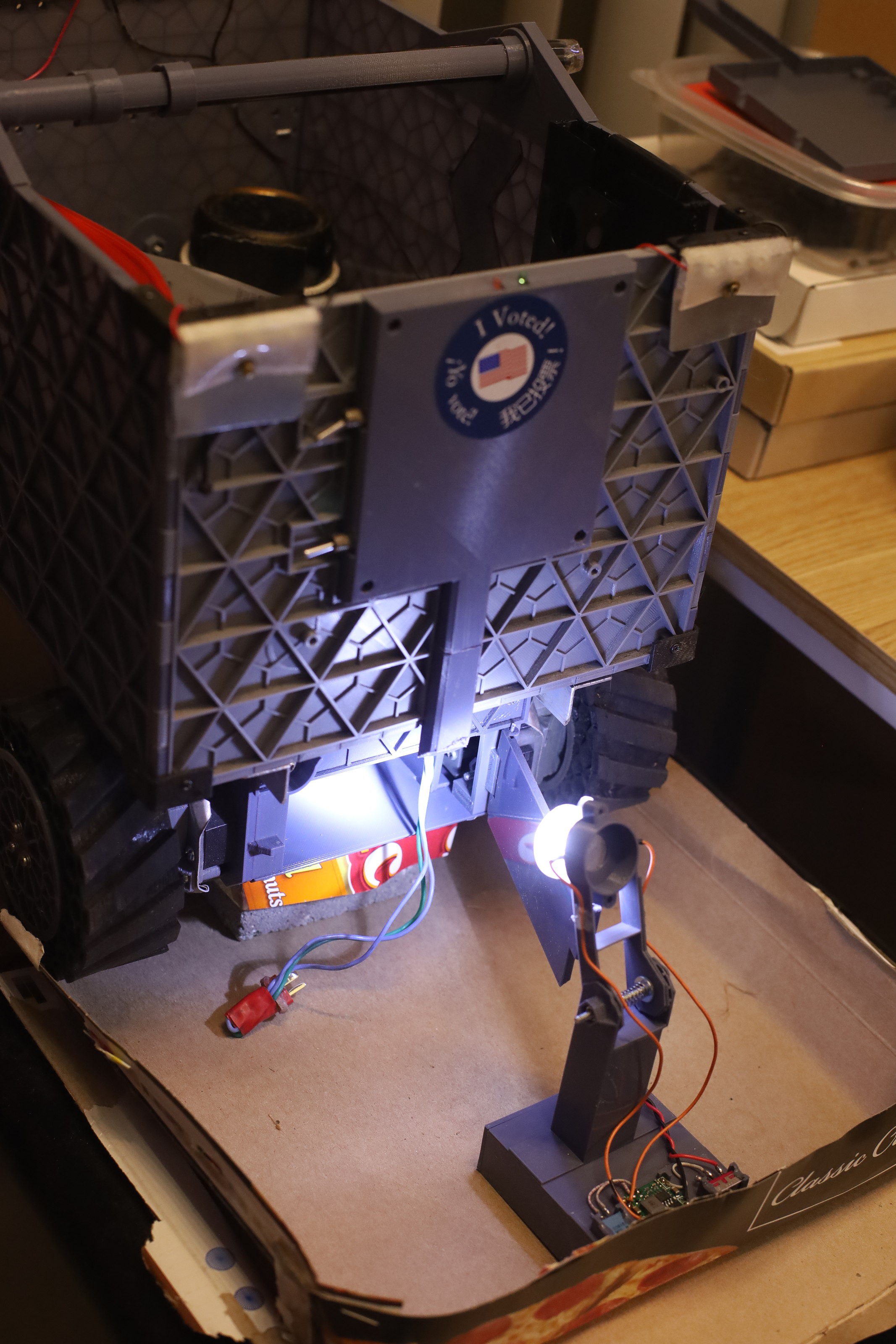

Another thing noted was the light should face towards the electronicals since animals prefer holding it from behind. Then, the wires are in the same part lions grab onto for moving it so they need a better route if they're going to last.

Putting the electronicals in front makes this harder. Another desk beside the 1 desk would be ideal, but lacking enough space, there's working on the floor. The arm would have to get longer.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.