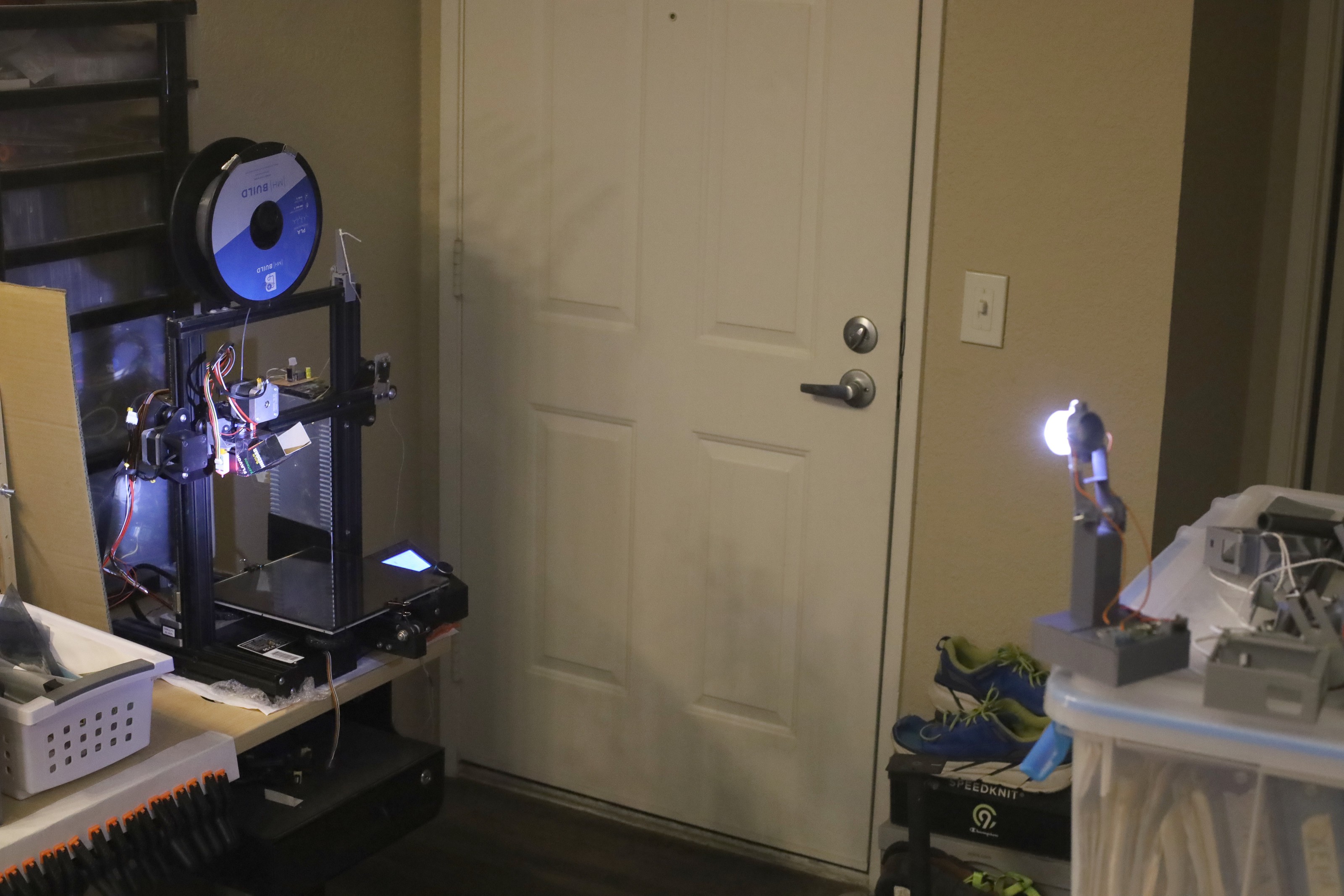

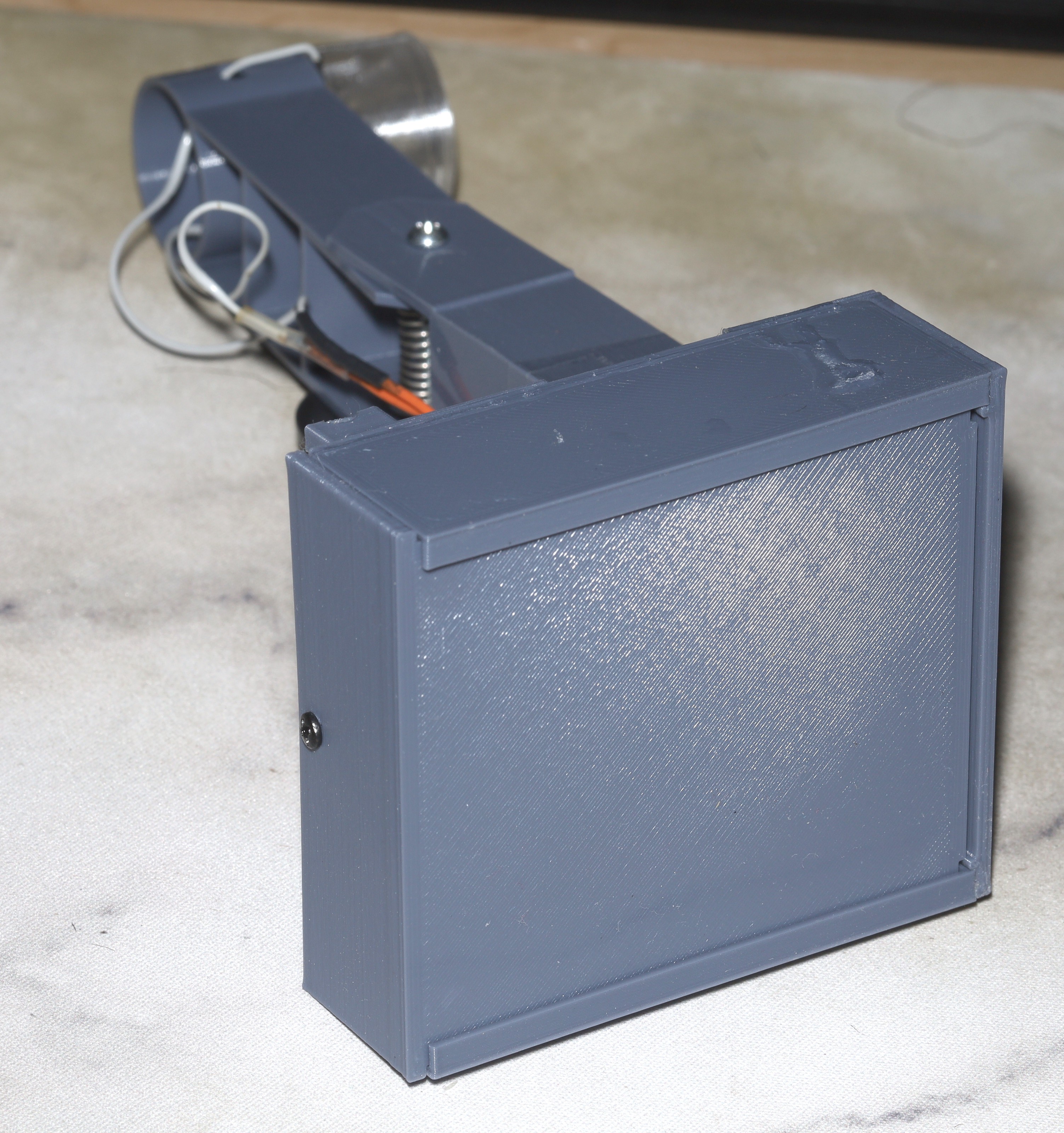

The home made flashlight worked so well, an unexpected use case presented itself, manely setting it in random locations & using the single joint to aim it at a different location. Sales pitches always show flashlights right next to the work piece, but this is not the mane use case.

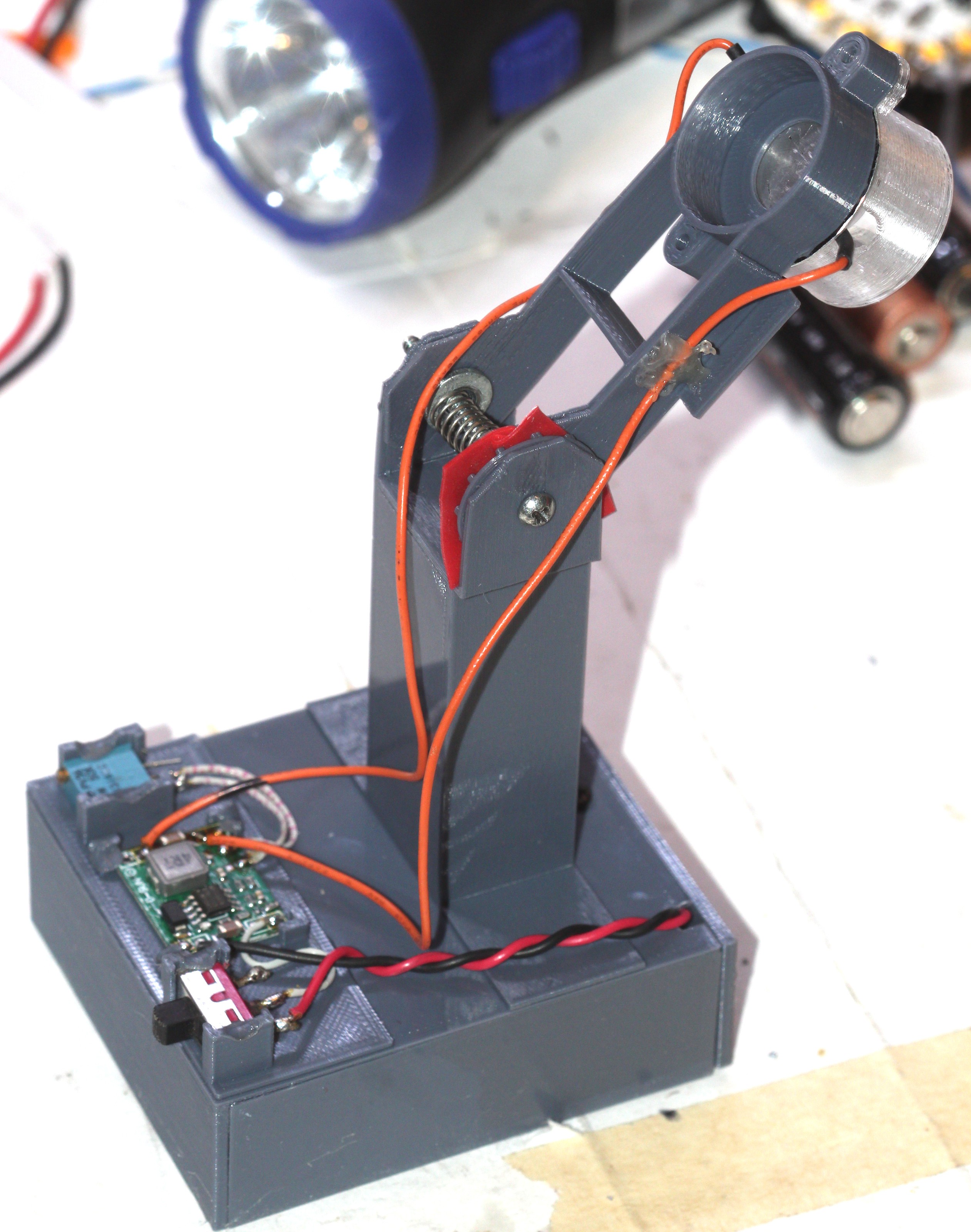

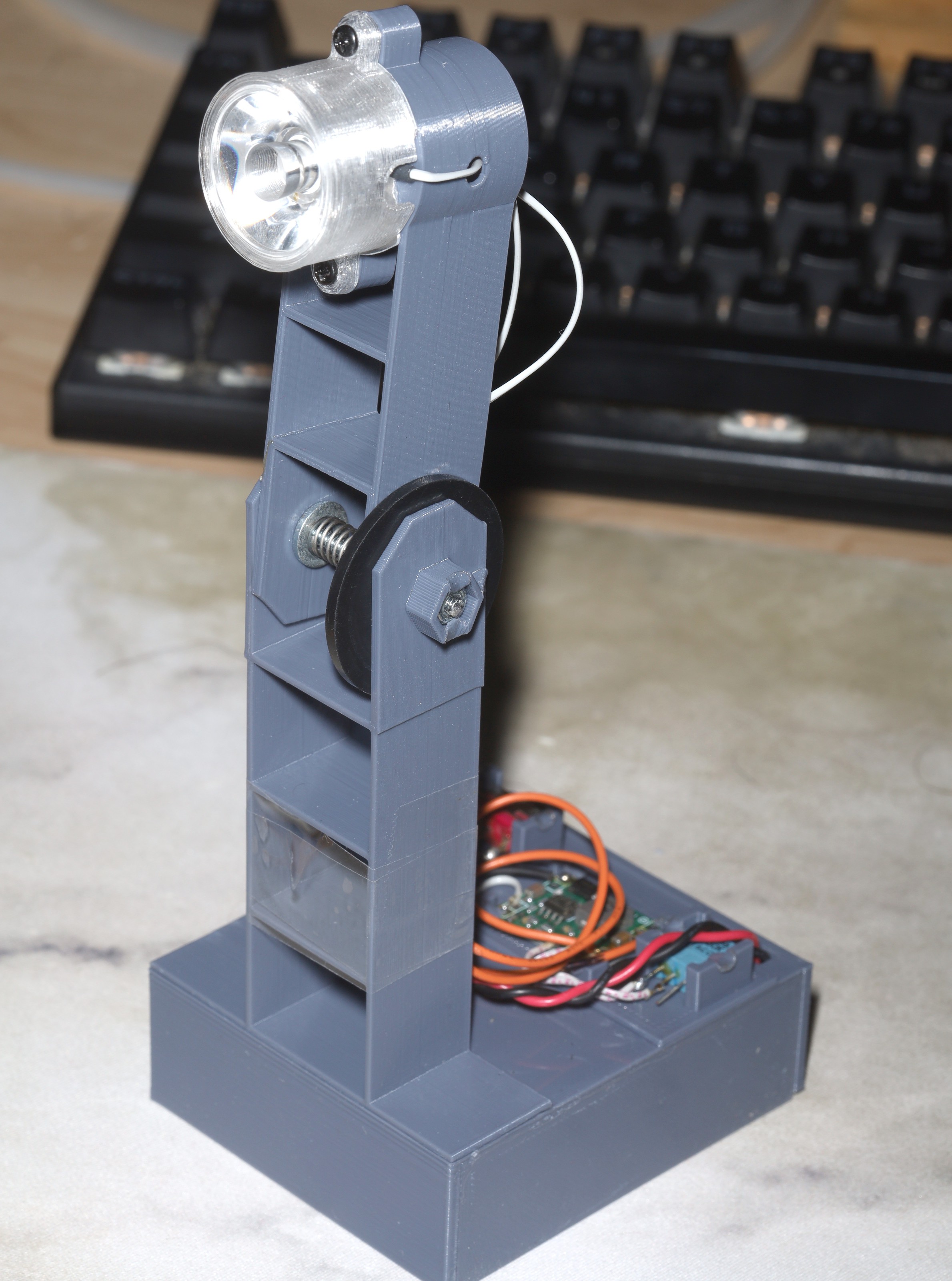

The immediate task was coming up with a better, fully variable joint.

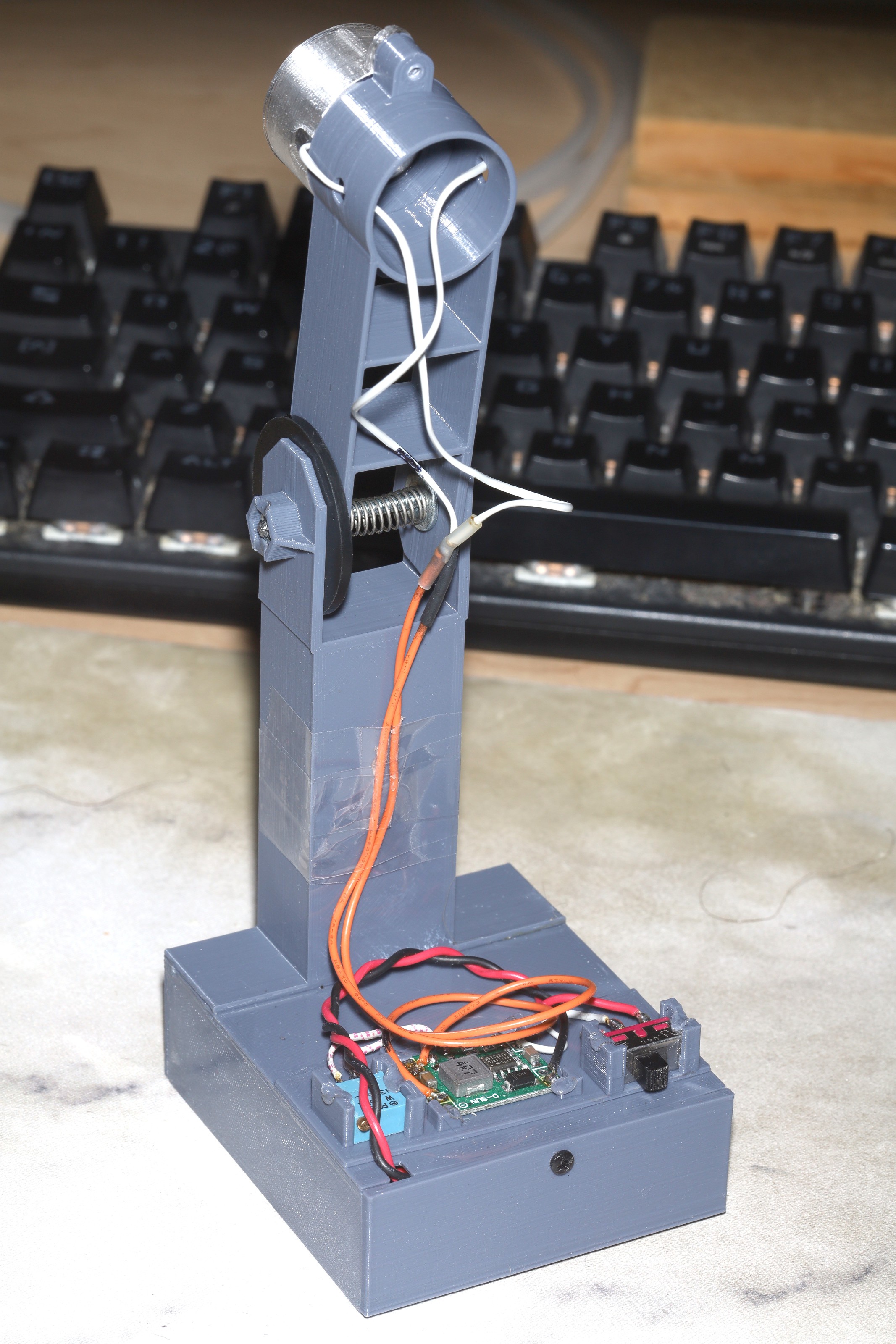

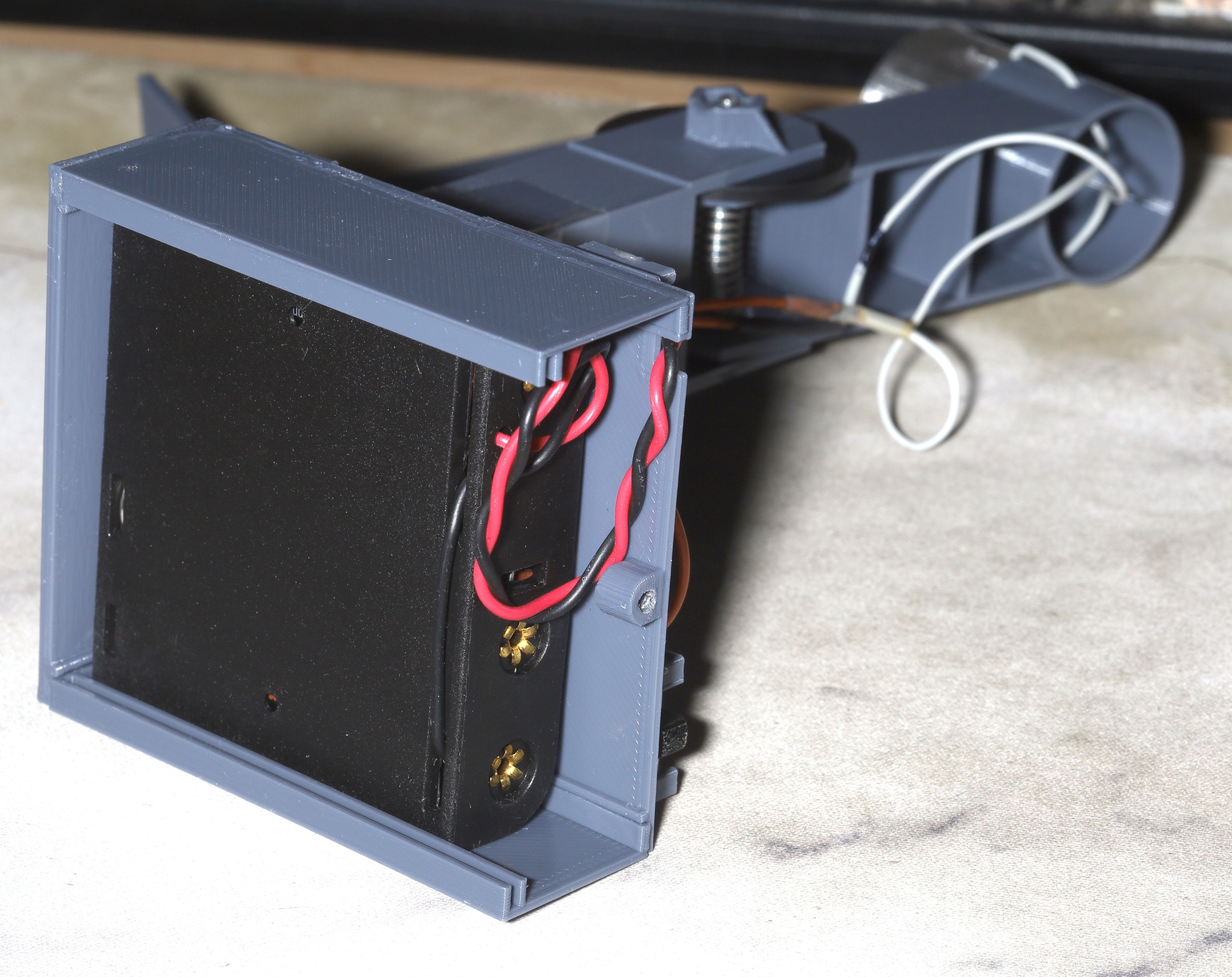

The spring idea works, but the search continues for a friction material. Ordinary O rings would cause the PLA to warp. It needs a big old disc. Non slip furniture pads are expensive. Any flexible rubber sheet just bunches up. Maybe an o-ring constrained in an oval shape could apply the friction in a straight line without deforming the PLA.

There could be a 2nd joint but it doesn't need it. The total length seems to be very close to ideal. The top segment could get longer, with an increase in size of the bottom joint to create more friction. Placement of the electronicals seems to be good enough. It might be better to have the switch face sideways & be recessed. The light should be right on the front, but the battery farstener is in the way. The battery farstener should face sideways. The wires have to be flush.

Finally uncovered some rubber washers in the plumbing section that did the trick.

The washer worked perfectly. The only issue might be the feel of the 1 PLA side grinding, but the savings in using 1 washer outweigh the feel.

The rear screw was a fail. It would require a bigger enclosure than the vertical screw. The light ended up going right on the edge where the bottom is lower.

The 1980's battery holder is the worst. The batteries slip out on their own but are impossible to get out on purpose.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.