It now has been about 18 months since I have started designing and producing the Central Scrutinizer. It has been a fun trip into building something physical, as opposed to just writing software.

I have learned a lot in the process (see my first log entry), and I'm really glad that I managed to build something that people do find useful.

However, a constant source of frustration has been the PCB assembly process. I only own a basic soldering iron, and my eyesight is not what it once was, so while I'm happy to assemble the through-hole stuff, I leave the SMD work to the PCB shop, aka JLCPCB. The whole project is configured to make it super easy to upload the design to their website and get working boards by mostly accepting the proposed default options.

I'm also not a huge operation, far from it. I produce boards in small batches (about 10 to 20 at a time), giving most of them for free to fellow open-source developers, and selling whatever is left on Tindie. This makes the buyers indirect sponsors of the open-source projects that use the boards, something I quite like. I don't make any money out of it, other than the odd beer with fellow hackers.

So it's all good, Sort of. What really gets me is the poor level of quality control that gets applied to the produced PCB. And poor doesn't quite describe it.

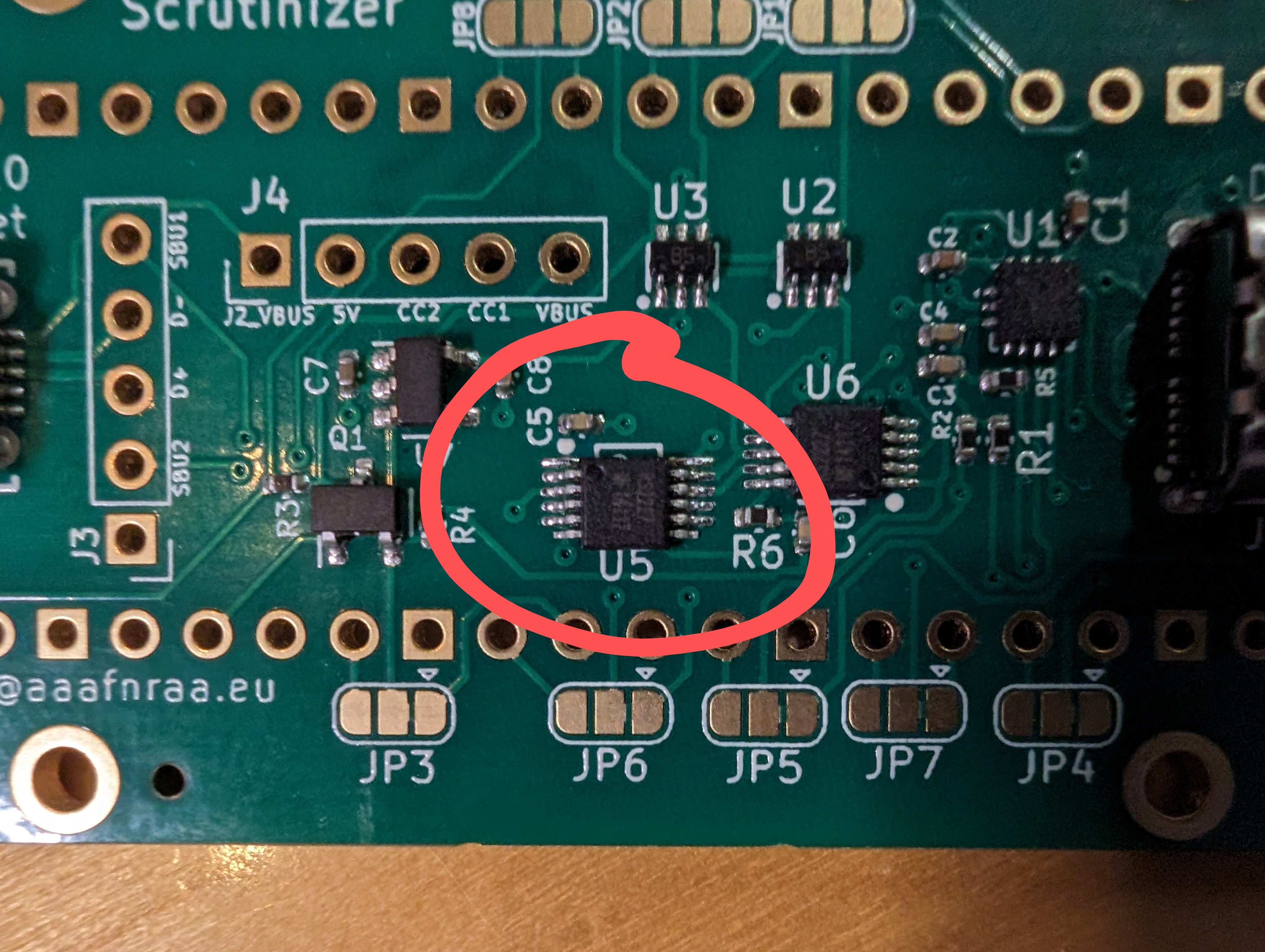

Here's the latest example:

U5 is off. Not a bit off due to the component having drifted. It is exactly off by a whole pin. Something that any automated checking should spot immediately. And that's the issue. I'm pretty sure that given the rock-bottom price for the PCBA process, there isn't any margin left for actual quality control. So whatever crap that has been produced ships.

I've seen other similar issues, such as micro-USB connectors soldered at a funny angle, solder bridges and the odd dead component. For each of those, that's another board on the scrap pile. The planet thanks you. Not. Maybe I should invest in rework equipment...

Frankly, I'd happily pay significantly more for a reliable service with an ordering procedure as good as JLCPCB's. If you know of any, please let me know! I wonder how other people with my level of experience (close to zero) and equipment (similarly null) cope with this...

On the plus side, I've grown a solid enough test procedure, so I'm able to spot a bad board within a few minutes, and only ship the good'uns. I guess that's as good as it gets for an outcome.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

My general rule is:

PCBWay for PCB + Assembly

JLCPCB for just PCBs

Part of that is quality- we've never seen any issues with PCBWay even through literally hundreds of boards- and part of that is they seem to have more parts or can order from Digikey if not available

Are you sure? yes | no

Not quite. The part supply process on PCBWay is just terrible. Every time I tried to use them, I had to provide parts separately, making the whole thing a non-starter for something as small as what I do.

Maybe it works for you as you go "through literally hundreds of boards", but that's not my scale. The ease of ordering on JLCPCB is crucial. That includes configuring my KICAD project so that anyone can easily replicate the board and assembly without having to understand anything. All from the git tree, without depending on the project being hosted by anyone else.

PCBWay falls short of that unfortunately. Aisler comes close, but is way too expensive for small quantities.

Are you sure? yes | no

Elecrow PCBA, small batch production like 5pc/10pc is supported with good quality & competitive price. Besides, we can also distribute your innovative product to help you fund from it. Any interest?

Are you sure? yes | no