It's here, after 6 years of work!

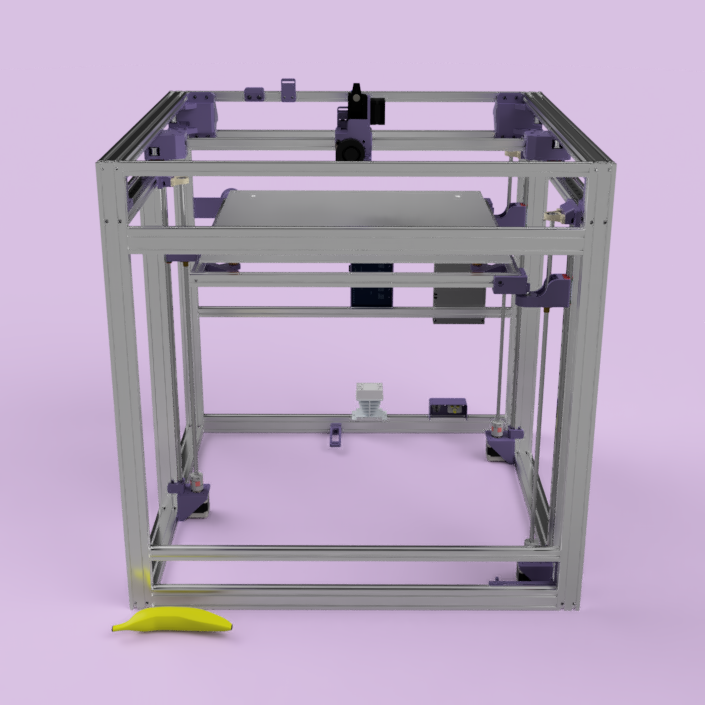

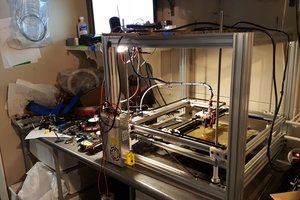

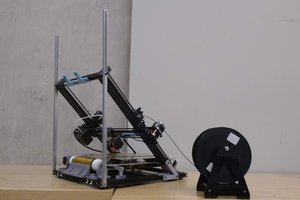

The Blackstone Cube design began in 2018 (when I was in 7th grade) as a proof-of-concept 3D printer. Today, after an entire redesign, it has been successfully built.

Now, keep in mind: This is a work in progress!

I can't stop you from building it, but the benchy that I printed in the video turned out to have lots of artifacts!

Specifications:

- 500mm (X) by 500mm (Y) by (around) 600mm (Z)

- Fully CoreXY setup with 9mm 2GT Belts

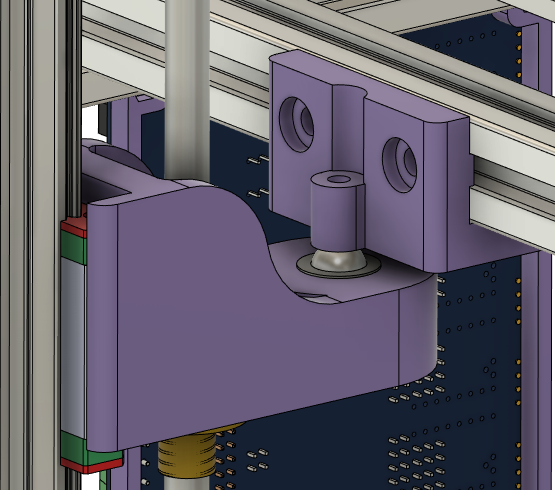

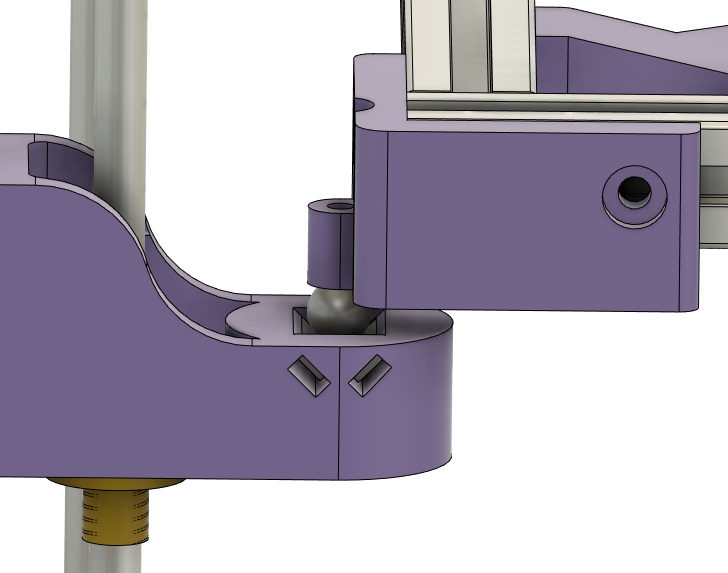

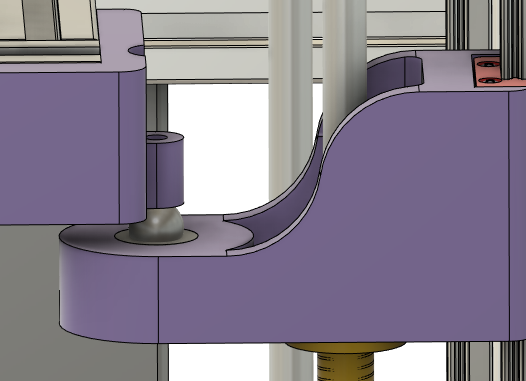

- Kinematic bed mount (allows for uneven Z heights)

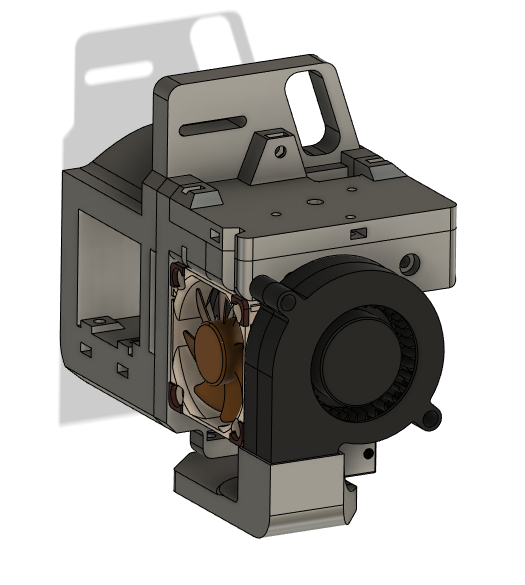

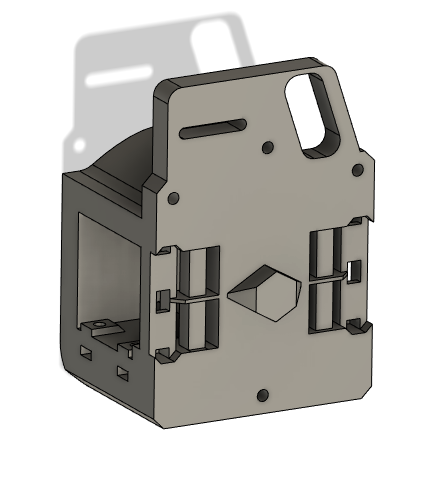

- Fully modular X Carriage

- MGN12H linear rails

- High temperature AC heated bed

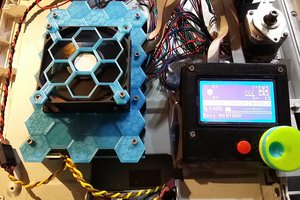

- Auto bed leveling

- Auto Z align

- Natively runs Marlin Firmware

Yes, those features all exist on the Blackstone Cube. At the time it was designed, it was fitted with all the best technologies!

Xieshi Zhang

Xieshi Zhang

adamfilip

adamfilip

RenierM

RenierM

j0z0r pwn4tr0n

j0z0r pwn4tr0n

Swaleh Owais

Swaleh Owais

Have you checked the tolerance for the "flatness" of the extrusions the print head rides on?