The project itself wasn't particularly challenging, given the abundance of tutorials available on YouTube. However, I would rate its difficulty at around 3 out of 10 on the scale.

Despite its moderate complexity, it turned out to be intricately detailed and time-consuming, requiring approximately 5 hours for completion. Below, you will discover a detailed parts list, a sound test, along with comprehensive instructions and accompanying images.

Keychron K3 Pro Project KC 6H "Thockyy"

Keychron K3 Pro ISO with lubed Gateron KS-33 Low Profile 2.0 and Rubber rings for keycaps.

HardwareNomad

HardwareNomad

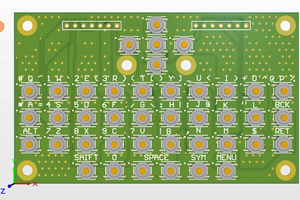

Dave's Dev Lab

Dave's Dev Lab

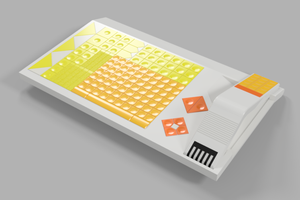

Nick Poole

Nick Poole