I was first inspired for this project by viewing a demo last year by Jon Mendenhall:

Unlike every other scale model coaster out there, this one:

- Scaled gravity correctly

- Allowed for programmed behavior in different sections

- Didn't require high velocity in order to overcome frictional track forces

- Sounded nice still, and was more realistic than a typical scale coaster

However, Jon painstakingly created this track in a simulation software (and played back the recorded speeds) and also 3D modeled every last joint and curve for 3D printing. Could I actually improve on this? After a few fitful nights, some thoughts crystalized:

- Why can't the car react to the track in real-time with an accelerometer? Would it need a gyroscope?

- Why can't the track creation process be in the real world? More like flexible Hot Wheels track but in mid-air? Can I enable it to go upside down too? How will the coaster stay on the track and have enough friction to precisely lift itself uphill?

- What type of motor should I use? What are the tradeoffs for this tiny toy application?

- How to power it? Is a 30 minute runtime with 2 hour charge time (lithium ion battery) better than a 3 minute runtime with a 2 minute (or less?!) charge time (lithium ion capacitor)?

- How to easily "program" different behaviors for different track sections without requiring camera processing (not reliable in darkness) or wireless transmission (drains battery)?

- Can it be made robustly and cheaply enough that families with children can afford it?

- Why bother? Why is this worth spending time enabling? What are the failure modes of other options?

I will attempt to answer these and many other sub-questions in the next few months, and look forward to your feedback and ideas!

Nolan Hergert

Nolan Hergert A similar style was pursued by the Anki Drive team for their sort of similar toy car project (more like slot car racing), with brushed motors, a bevel gear and magnetic sensors. Here's a picture from the excellent teardown by Lee Teschler:

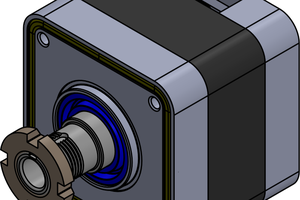

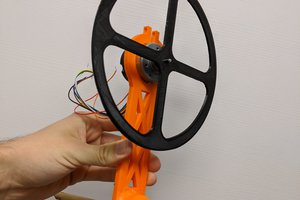

A similar style was pursued by the Anki Drive team for their sort of similar toy car project (more like slot car racing), with brushed motors, a bevel gear and magnetic sensors. Here's a picture from the excellent teardown by Lee Teschler:

Rory

Rory

Jamie

Jamie

A.M. Smith

A.M. Smith