The way a pellet extruder works is that the pellets are pushed into a hot zone where they melt and are then pushed through a nozzle. In injection moulding it is pushed into a mould. In my case, I wanted to make this nozzle a 3D printed one.

By looking at the work of others. A pipe with a wood drill can work, so I decided to go with that.

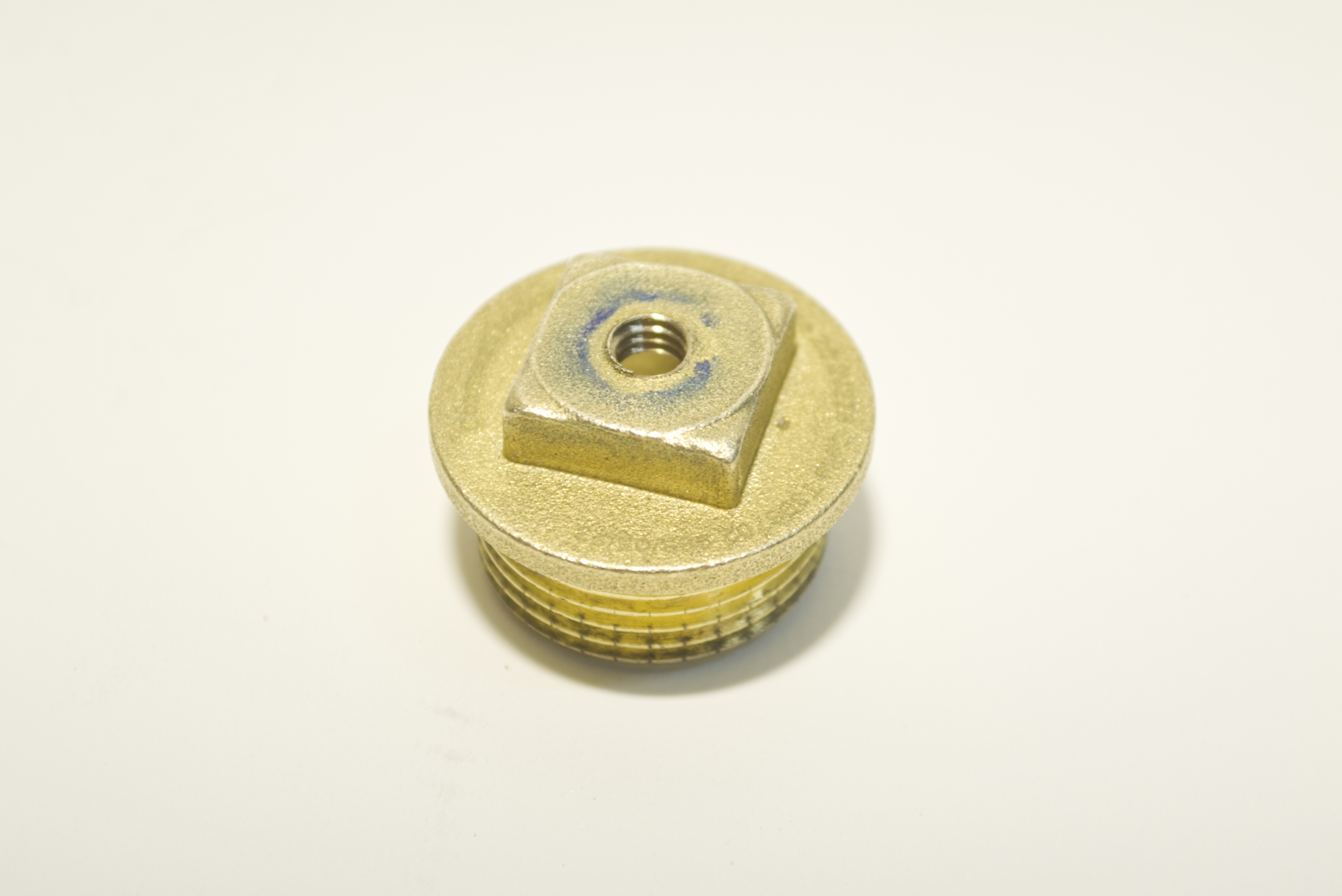

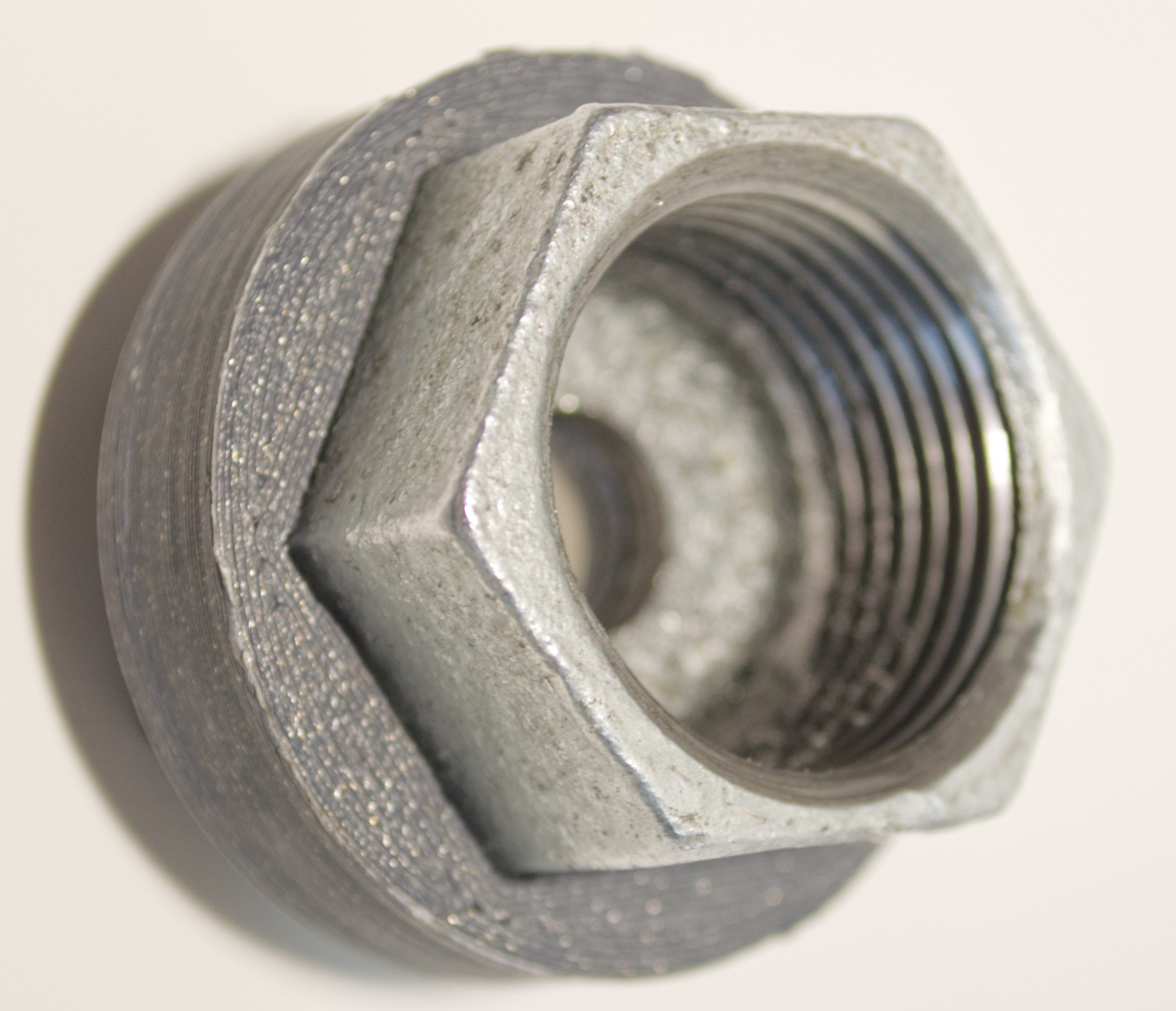

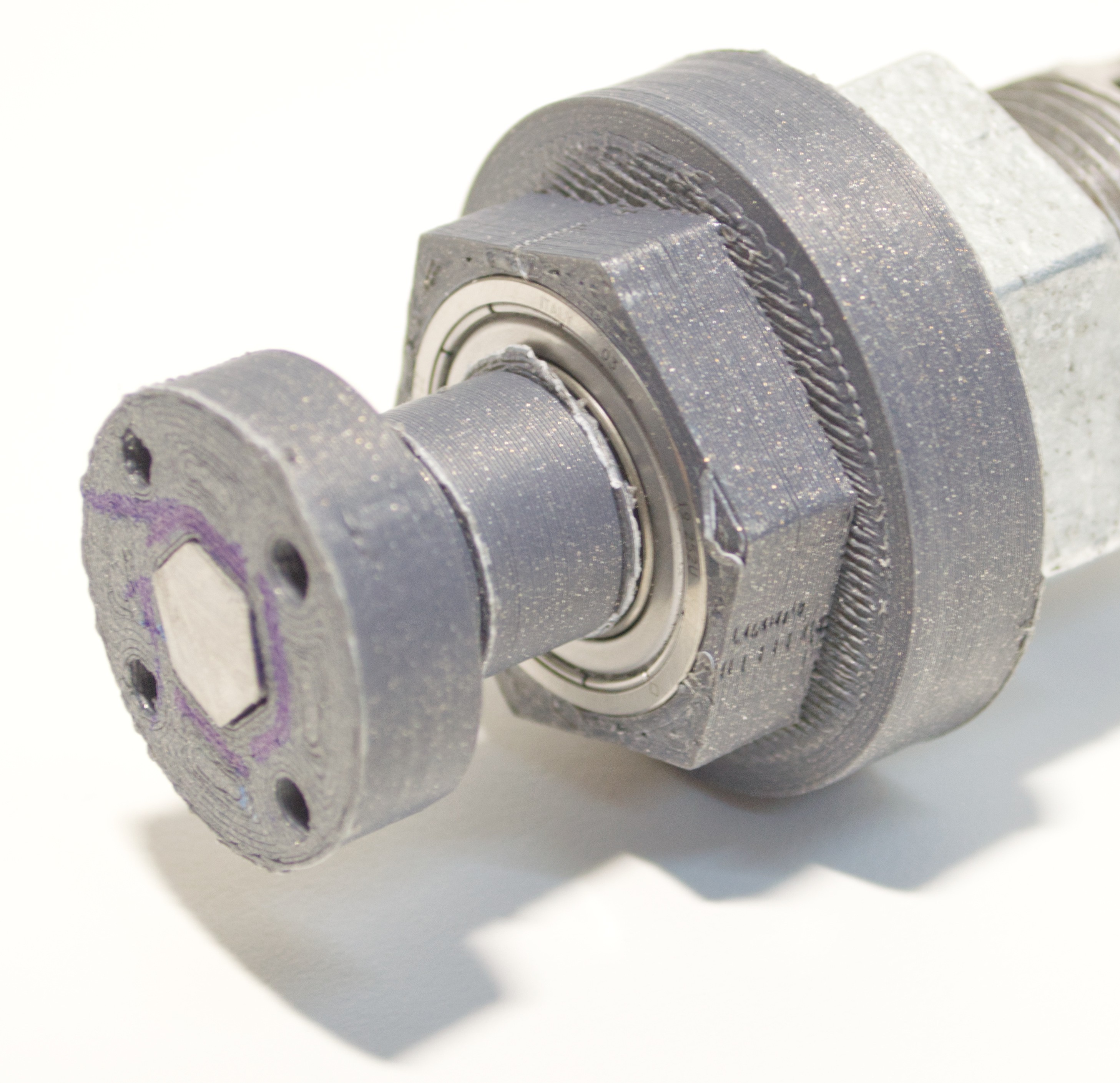

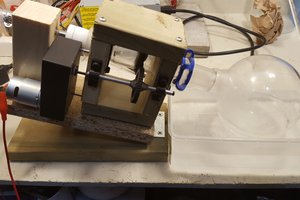

I grabbed some pipes that are normally used for water plumbing and a large auger for wood drilling.

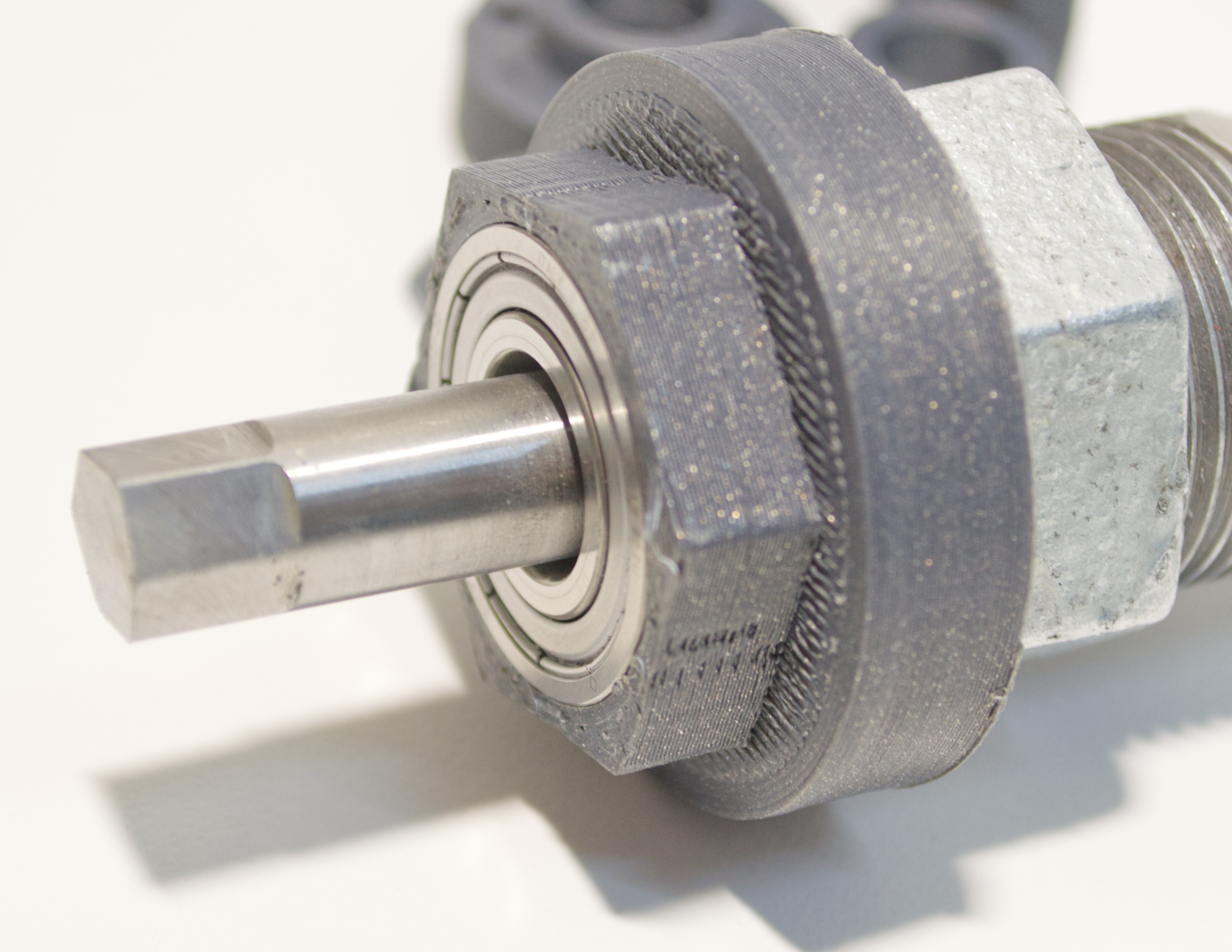

Now I had to figure out how to drive the drill and connect it to my 3D printer.

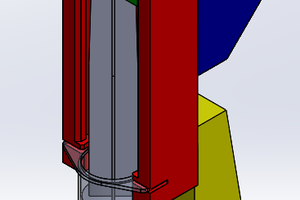

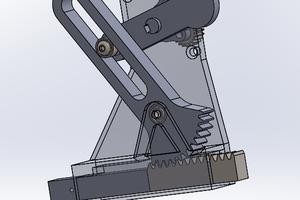

I jumped into CAD (Fusion 360) and designed a 3D print head with part cooling and cooling for the pellet section. The dimensions I chose for the distance to the heated area and the fans were completely subjective. I hadn't designed a machine like this before, so I was a bit worried that the printed parts might deform close to the heated zone.

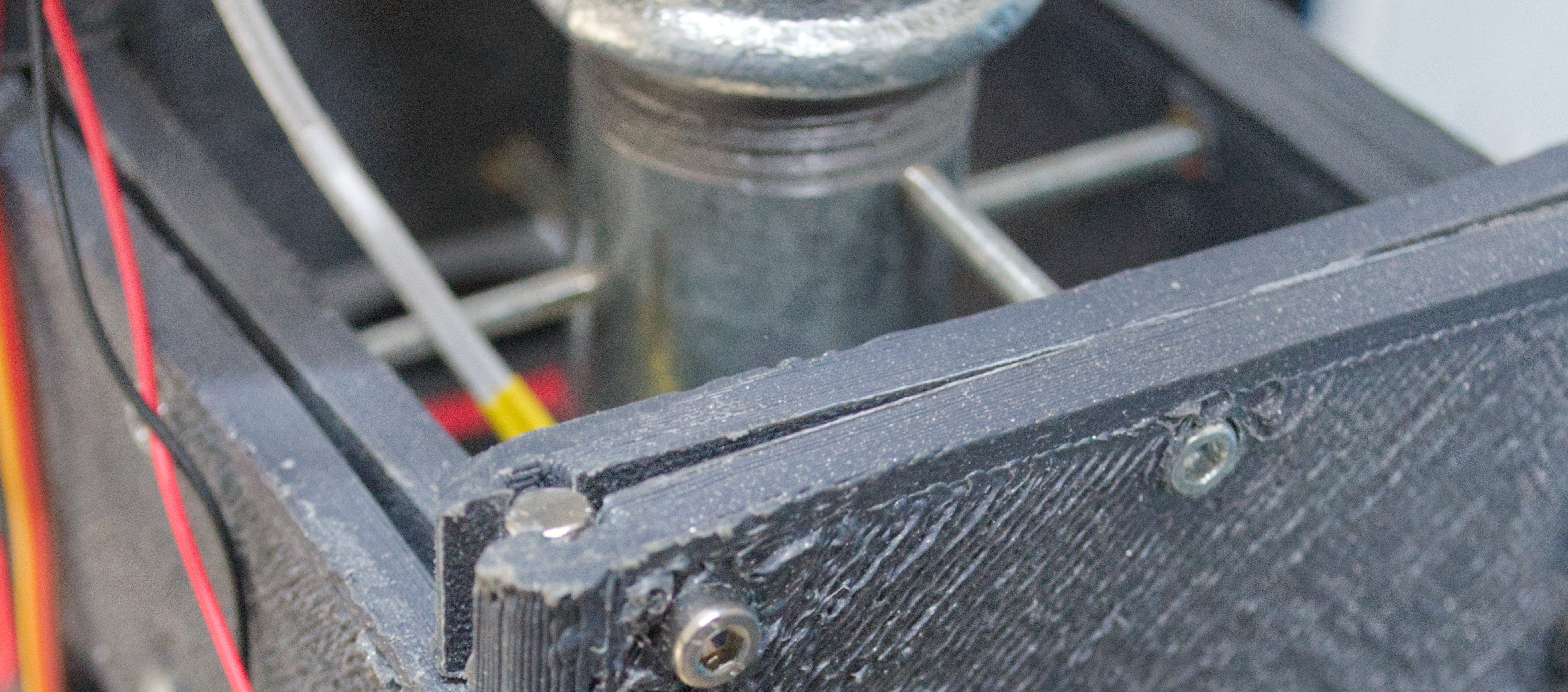

To hold the 3D printed parts, I used a 5mm iron rod that I cut to size. As you can see in the picture, the 3D printed parts act as a sort of clamp to hold on to the rod.

Heating Element

There is a Problem

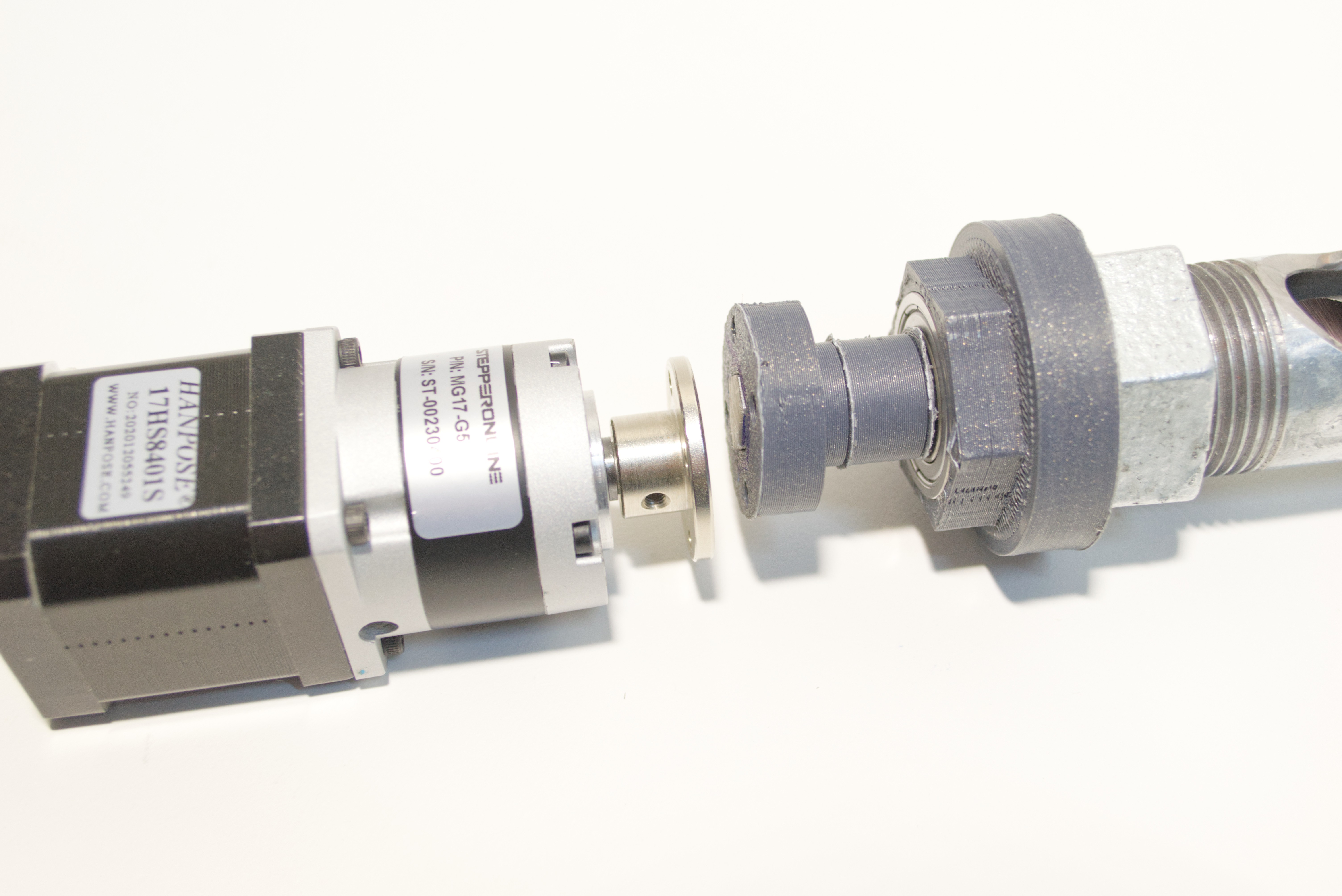

While testing the Extruder I discovered a problem. My Nema17 motor with a 5:1 gearbox was having trouble turning the drill. It seemed that the torque required to turn the drill was too high for my configuration. I then tested the rotation by hand and was able to extrude molten PET plastic that I had previously shredded.

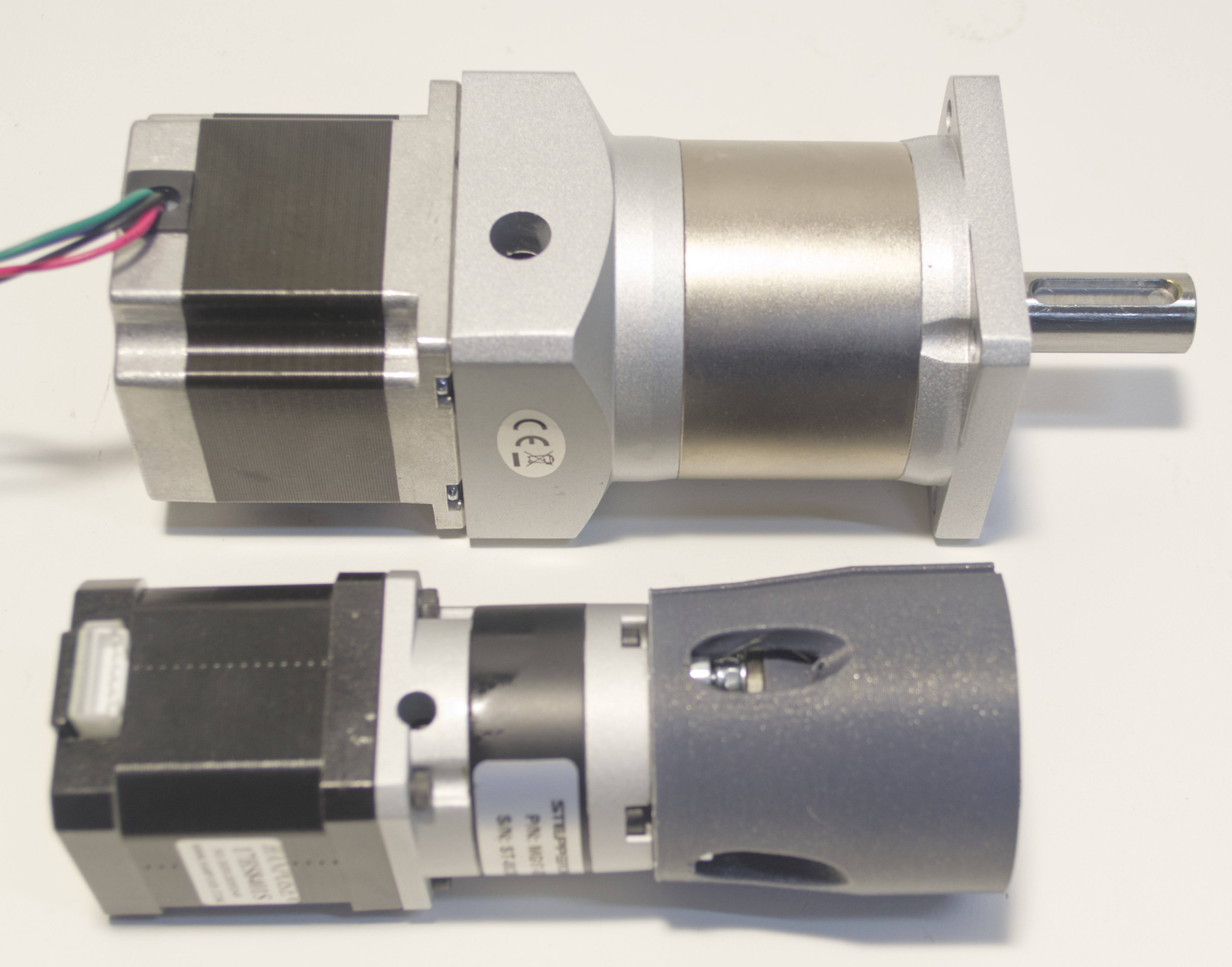

The solution seems to be to improve the power by getting a stronger nema23 motor with a stronger gear box.

The weight of this Nema23 motor with gearbox is more than double and I do not want to mount it the way I did with the old motor. So I will have to make a design that turns the orientation 180° basically upside down.

Therefore this design is still a work in progress and not fully functional.

I release it under the Creative Commons Zero v1.0 Universal Licence. I invite you to give comments and ideas for future development or to use it in your projects if it is useful.

Otto Gloeckner

Otto Gloeckner

Dante Kienigiel

Dante Kienigiel

BogdanTheGeek

BogdanTheGeek

Russell Munro

Russell Munro