CsI(Tl) scintillators are slightly hygroscopic – they absorb some moisture and this affects their crystal structure, worsening their performances. However, the magnitude of this worsening is very small as shown by this paper and this paper.

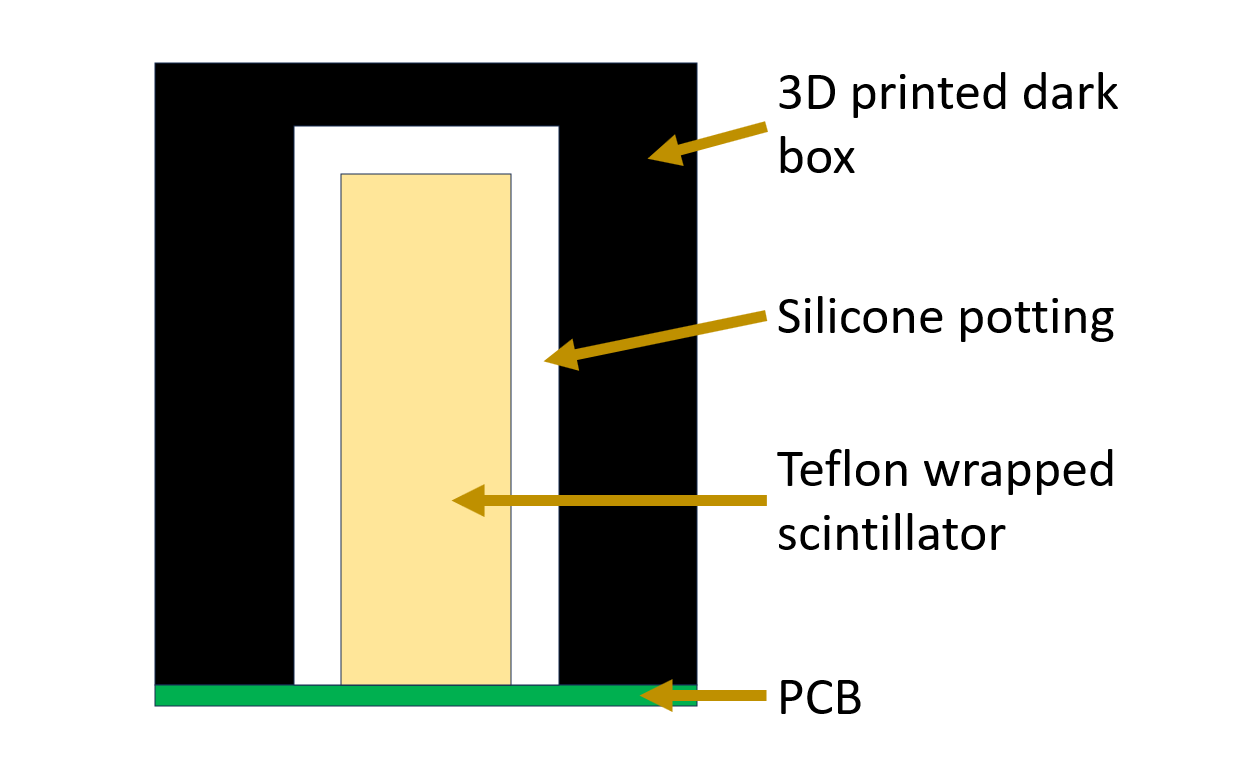

In any case, my plan is to limit the amount of moisture that can reach the scintillator by adding silicone in between the Teflon-wrapped scintillator and the 3D printed detector case that serves as a dark box. Using a somewhat rubbery silicone will also work to provide some cozy mechanical support for the scintillator. The resulting internal structure of the detector assembly should look like the following diagram:

Detector assembly structure. The scintillator is attached to the SiPM (not shown) that is soldered to the PCB. I plan on filling the gap between scintillator and dark box with silicone

Room-temperature vulcanizing silicone curing test

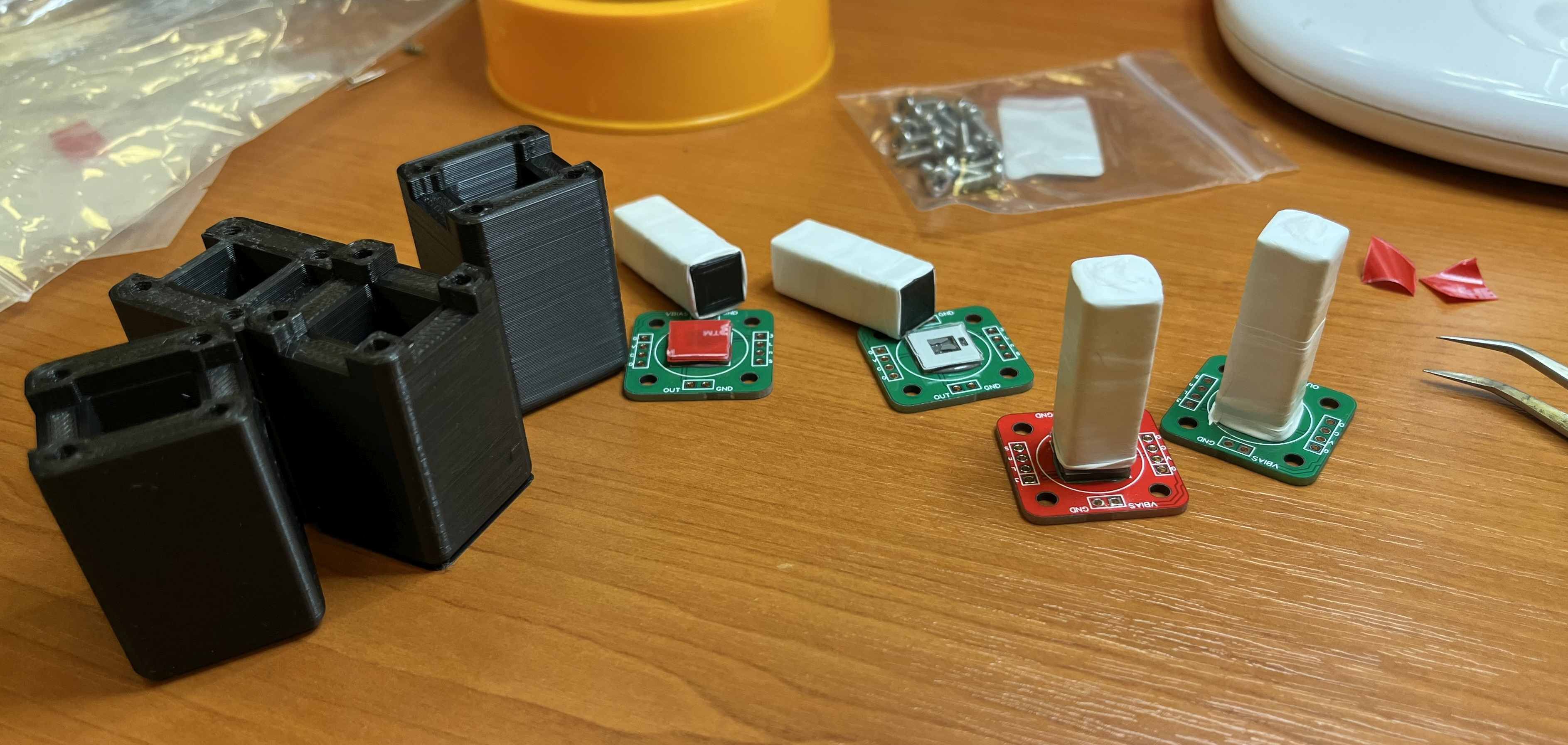

As I’m using a one-component RTV silicone I wanted to make sure that curing still happens inside the 3D printed box, as the exposure to outside air is quite limited in that case. To test this I printed a fake “scintillator” block that I wrapped in Teflon and I made a few test runs that I could then break and look inside for how the curing went.

Test pieces for testing potting and curing. No expensive components (SiPM or CsI(Tl) crystals) were hurt in these tests

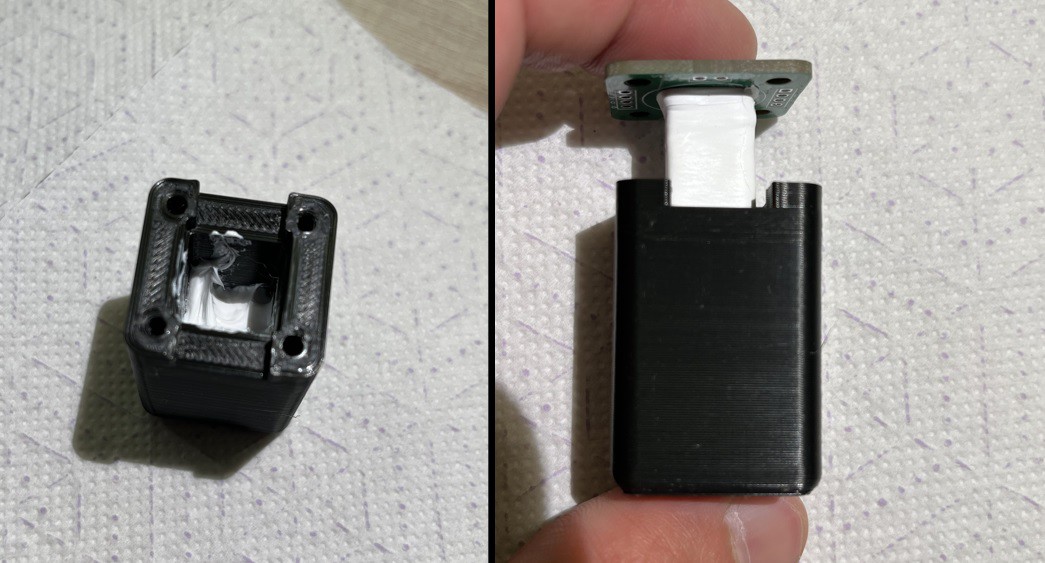

Loading some silicone into the dark box and then squishing the assembly in

Having assembled these units I let them cure for ~1 week. I then broke a few and extracted the plastic fake “scintillator” and its Teflon wrapping to find this very nicely cured shell around the scintillator block.

Broken test assembly. The silicone cured nicely everywhere, but I did not manage to get it completely centred

One thing I did not consider is that the fake "scintillator" I 3D printed with ~30% infill was full of air. While it was covered in Teflon, I'm not sure this was an air-tight barrier, so some of the curing might have happened because of that empty space. In any case I assume that it will still cure just through the shell, even if it will take longer.

With this test successful I went on to pot an actual scintillator and see how this affects its performance.

Detector performance after curing

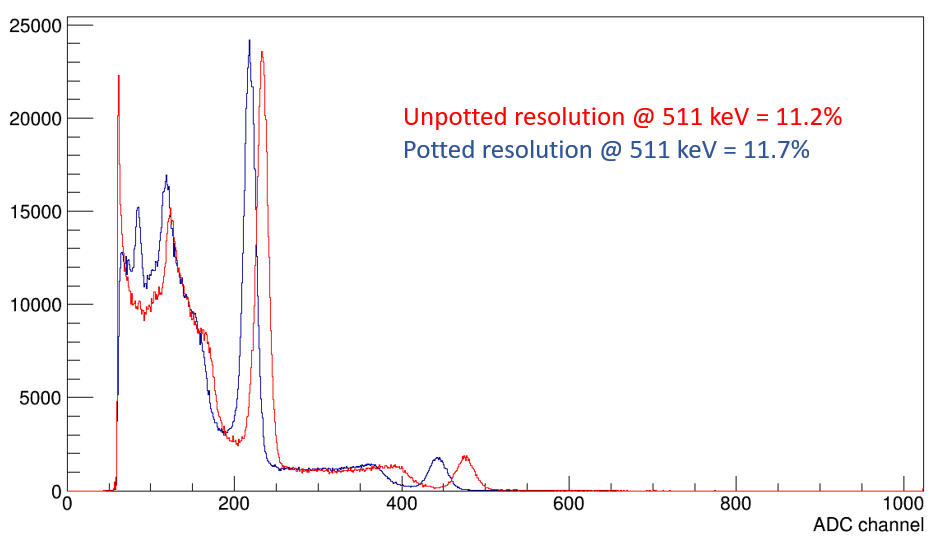

I potted a real detector and took Na-22 spectra before and afterwards to obtain the following spectra.

Na-22 spectrum and resolution for the 511 keV gamma line before silicone potting (red) and after potting (blue)

The peaks are shifted a little to the left after potting, so the pulse height is somewhat lower, suggesting that light collection is not as good as before potting. This is also indicated by the slight worsening of the energy resolution. While there is some loss in light that gets collected on the SiPM, the added resilience of the detector assembly is worth it.

mihai.cuciuc

mihai.cuciuc

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.