I had a few problems assembling the PCB into the PVC tube, this was because I had not thought in detail about two things:

* how to solder on the wires, so that afterwards the PCB could be pushed into the tube.

* how to secure the PCB in the tube.

When I had an offer from PCBWay to sponsor another iteration I decide to do something about these issues by redesigning the PCB. I made two changes:

* Added a JST SH 5 way socket so I could plugin in a connector with all the wires.

* Added a hole in the PCB just behind the USB socket, so that I could use a small screw through the PVC tube to secure it.

I also removed the extra connection holes around the Attiny85 for programming, as the programming clip worked so well I never used these.

I had not used PCBWay before, so it was interesting to try a new service. The online order page is well organised with help available under the ? for each specification item. I read the excellent capabilities page in conjuction with filling in the specification to make sure I understood what was possible and that these lined up with the settings in my PCB design tool.

For my simple PCB only three specification items needed to be changed from the default values:

* Size

* Quantity

* Colour

If you are just beginning with ordering a simple PCB this will almost certainly be the case for you too. Online chat is available if you do have questions.

Once I went ahead with the order, the progress through the review, manufacturing and shipping process was clearly displayed and I received an email at each stage. Production took about 4 days and shipping with DHL ($20) took less than a week, so a very efficient service!

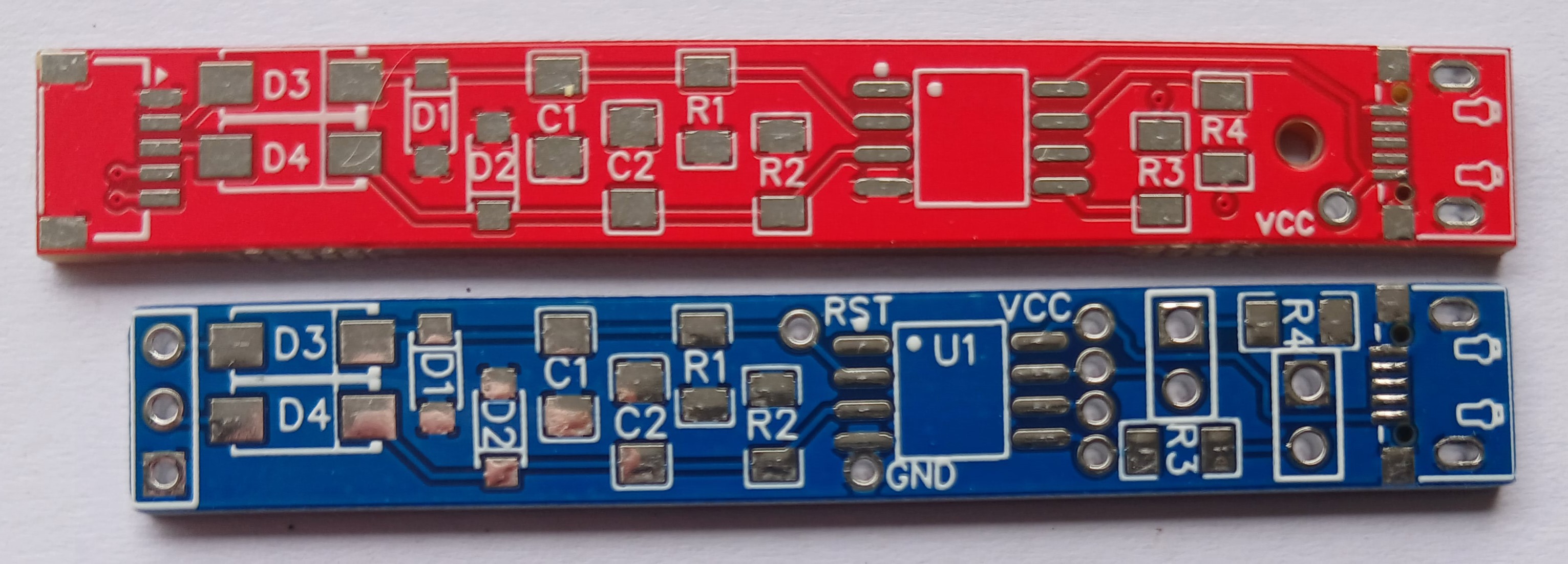

Both sides of the old (blue) and new (red) PCB versions are shown below.

On the back of the new PCB the labels for the connections are the minimum supported character height of 0.8mm, these are very clear and readable, something I have found not as good from other manufacturers.

Next step is to solder on the SMD components, I will report on this shortly.

Chris

Chris

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.