I’ve seen a lot of robotic lawnmowers over the years, but I wanted build something that was capable of more than just mowing the lawn— the ability swap different attachments for various jobs. Something more like a lawn tractor.

The primary missions I’m designing for are:

- Mowing the lawn

- Snow plowing the driveway

- Towing lawn trailers around the yard

- Moving my boat trailer into its tight parking spot.

The Frame

I thought long and hard about how I would connect attachments to the robot, then it hit me— standard 2” hitch receivers make an excellent platform to attach just about anything you could think of. Other than trailers, there are all sorts of crazy things you can attach to 2" receivers, like https://ironbaltic.com/us/agricultural/receiver-mount-system. It's just a nice and easy to understand mechanical standard to build around.

After deciding to use 2" receivers as the attachment system, I figured, why not just make the frame out of the receivers themselves?

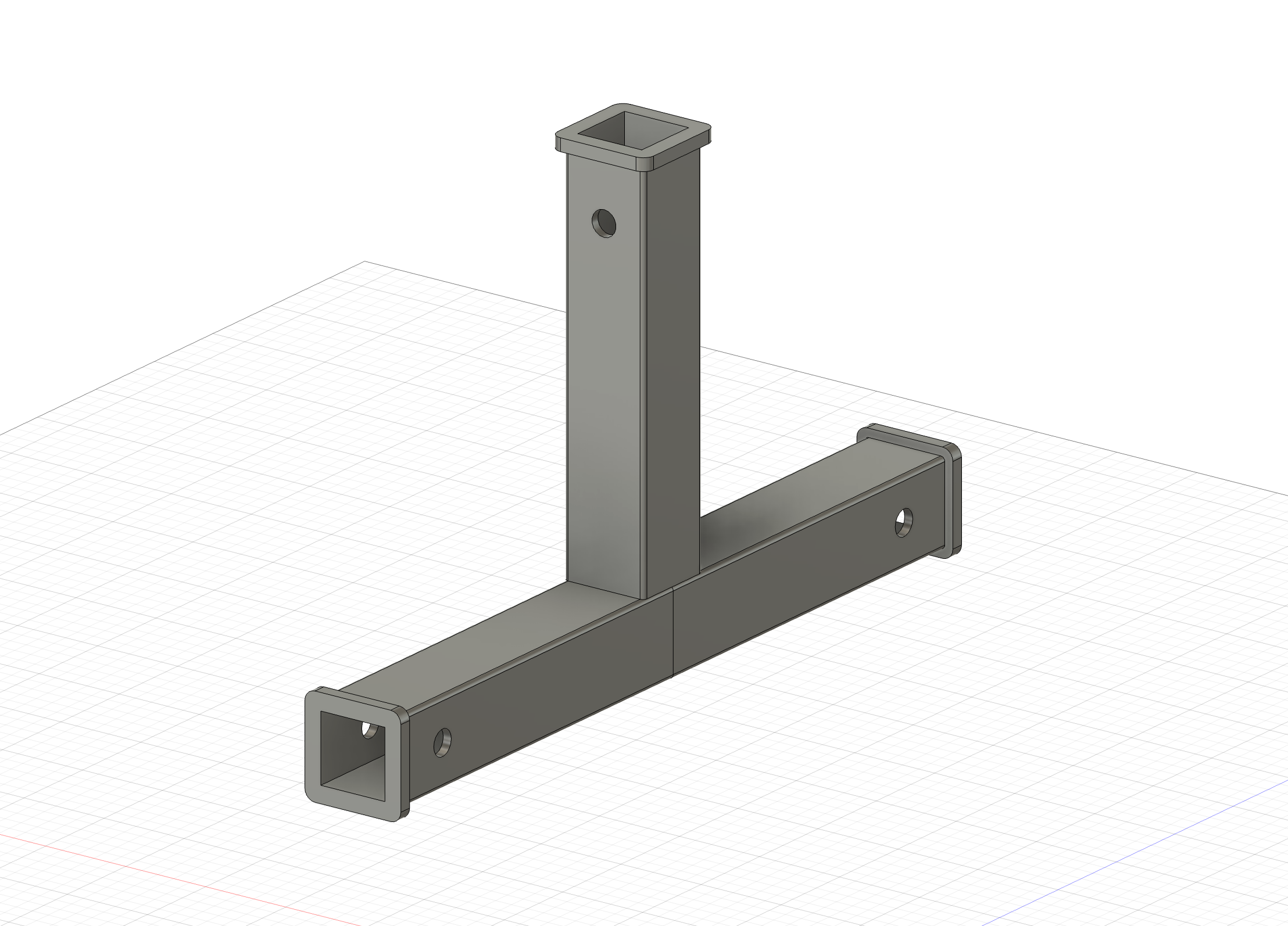

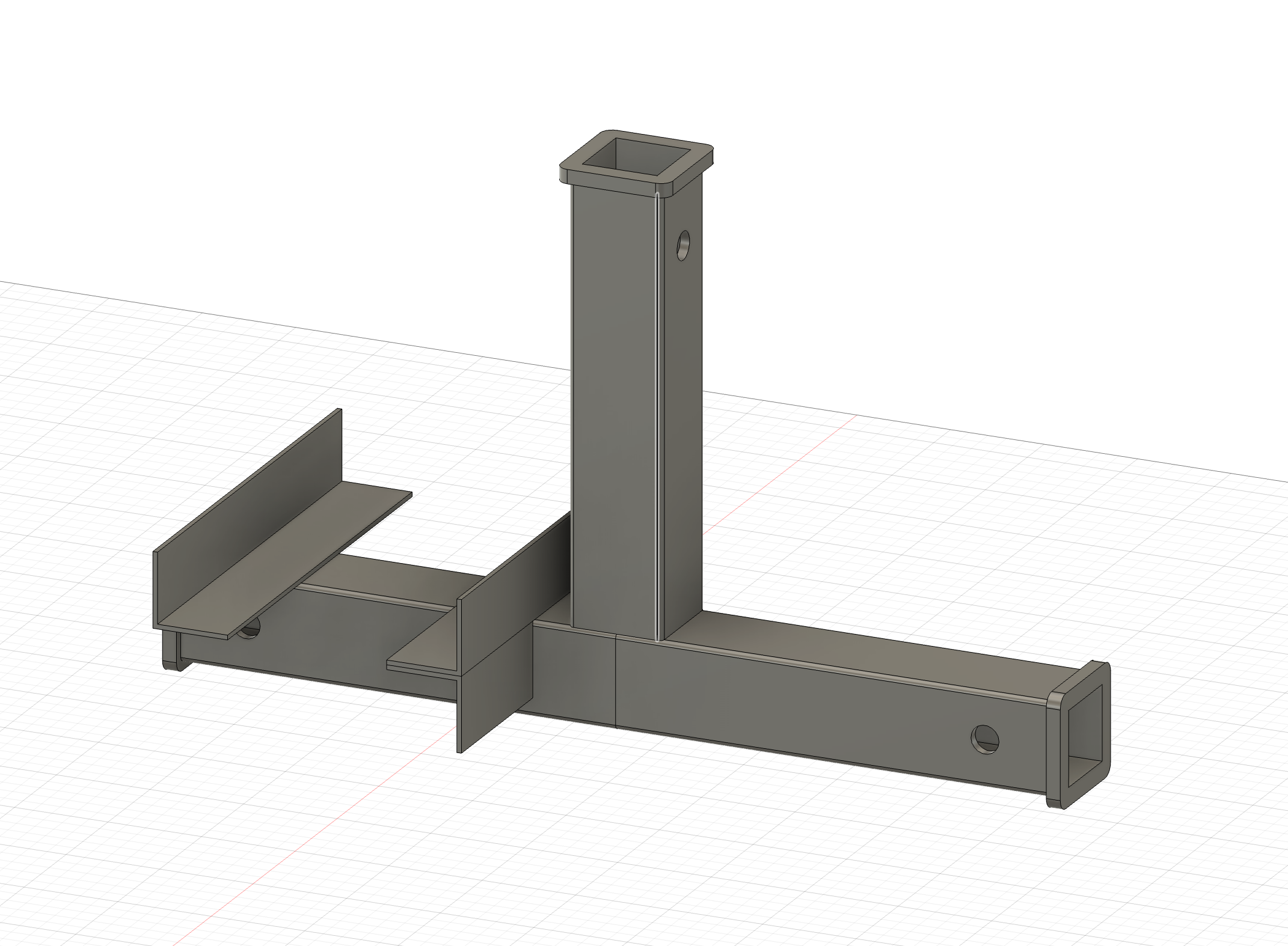

The foundation of the frame is three 2” x 12" receivers welded into an upside down T. The two horizontal receivers will be used to attach implements on the front or rear of the bot, and the top receiver will be used to dolly around larger trailers (like my boat).

Luckily Harbor Freight had just the thing— https://www.harborfreight.com/class-iii-12-in-x-2-in-standard-receiver-tube-69879.html.

Weld in a few pieces of 2" angle iron, and you now have a frame capable of mounting motors and batteries.

Note that it would not be hard to build this frame if you didn't have a welder. You could probably tie all three receivers together with a T-shaped metal plate bolted to each side. The battery tray and motor mounts could similarly be bolted to the frame as well.

Another thing to note is that the frame is heavy. I mean really heavy. But this is by design— the heavier the frame the more traction the bot will get, and I think traction is going to be key in doing a lot of the things I want to do with this platform.

The Motors

The motors weren't chosen with any particular specs in mind— I ended up just going to eBay and looking for used mobility scooter motors with a reasonable price. I eventually found a set that looked like they might work, but there was very little information other than they ran on 24 volts and they functioned. I was taking a bit of a risk buying them, but in the end it payed off. When they showed up I was able to look up the model number and found them here: https://www.electrocraft.com/products/gearmotors/MPP36/

The motors are capable of producing 144.9 Nm of peak torque, which is many times greater than the average lawn tractor, so pulling power should not be a problem.

The Batteries

Until I received the motors I wasn't really sure how to properly size my batteries. Once I got them I found that they were rated for 12 continuous amps, so that was the basis of my rough battery calculations. Since the motors run on 24V I'll need two 12V batteries in series, and unfortunately I won't be able to add their amp-hour ratings together like I would if they were in parallel. So in perfect/lossless conditions (which don't exist) if I wanted to run both motors for 1 hour, I would need two 12V 24 amp-hour batteries.

One of the big goals for this project was to be able to source as many off the shelf parts from stores that you might find in your home town. It's one of the reasons I tried to source as many parts as I could from Harbor Freight, and when I started looking for batteries, I found these: https://www.harborfreight.com/12v-35-ah-sealed-lead-acid-battery-56770.html.

The batteries are rated for 35 amp-hours which should give me over an hour of continuous runtime in ideal conditions. They are also deep-cycle which means they are better suited for running them until they are nearly empty.

The Wheels/Treads

The last of the major components to decide on was the wheels. I knew from the beginning that I wanted tank treads, because, well... tank treads are f*cking cool. But also because they have a large contact patch which should give better traction. They are also better at spreading weight over a larger surface area, so they should be more gentle on the grass.

Initially I looked for robot tank treads, but I didn't find many options that were the size I wanted and could be driven from a single axle on a single motor. Eventually I ran across "ATV snow tracks" on eBay and these seemed to be exactly what I needed. Here is an example of a set similar to the ones I bought — https://www.ebay.com/itm/394348334275. There seem to be lots of different sellers with the same exact thing, so you can pick and choose. I've also seen them on Amazon as well.

After a shipping delay from FedEx (it's always FedEx), they eventually showed up and they seemed to be exactly what I needed.

However there was one main problem I still had to figure out— how was I going to connect these things to the motors? The treads accept a spline axle and the motor has a keyway axle. The solution was a little complex, so I'll probably publish another build update with the specifics on that. Let's just say it was the most difficult part of the build.

Anyway, that's about it for the major components. I'll post other updates in the future with more detailed specifics on how certain pieces were fabricated.

Jim Heising

Jim Heising

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Do you have any more info on how you connected the treads to the motors?

Are you sure? yes | no