I've had a portable tool case with dual soldering irons, tools and pretty much everything I need for soldering. Often though, I would be working somewhere that I needed to protect the table when working. Scrap cardboard often worked, but it was not a great solution, and not great for ESD. When cleaning out a lab, a rubber ESD mat was being tossed out because a large portion of it was damaged, and it was no longer useful on a bench. Part of it however was in reasonable shape, and it occurred to me that I could convert it to a portable mat that fits in my tool case.

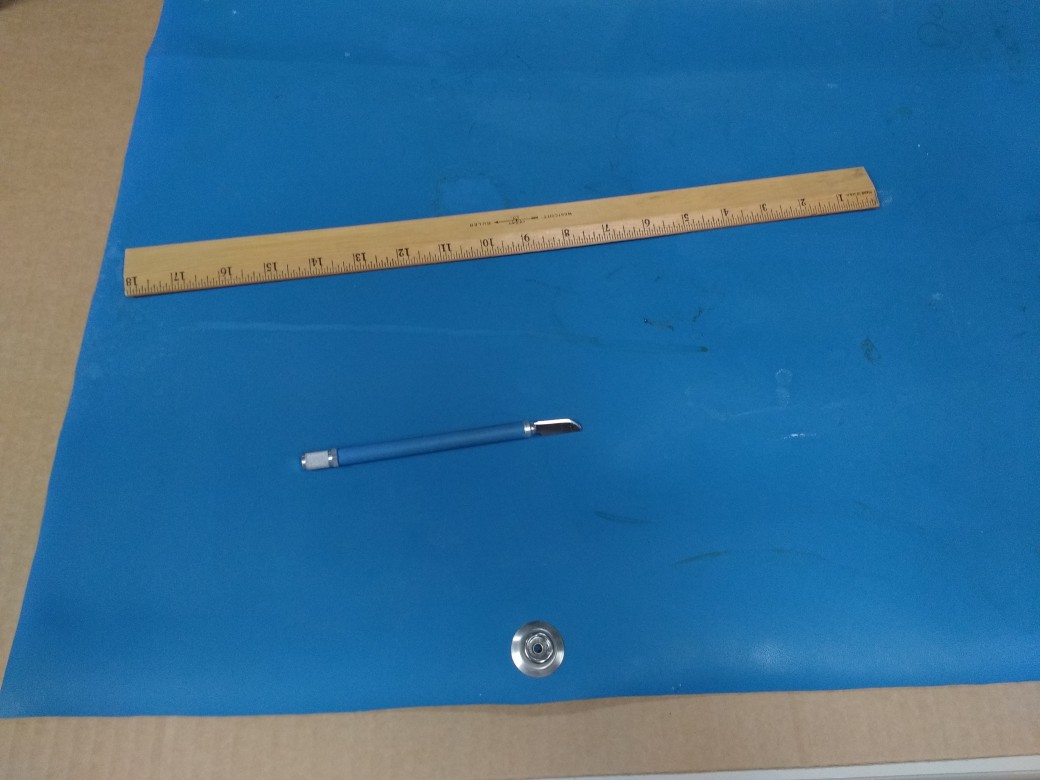

Certainly one can just roll a mat and put it in a case, but this takes much more room, and results in a curled mat that you have to flatten when you want to use it. Using the fact that a good quality mat is a laminate of rubber sheets, this project simply scores it so it folds neatly, and when laid out, sits flat.

This cannot be done with a PVC mat, or mats which do not have a conductive bottom side.

Quinn

Quinn

Peter Buckley

Peter Buckley

The Reverend

The Reverend

Badmonky

Badmonky

Gary

Gary