NEW VIDEO FOR SEMIFINALS

ORIGINAL VIDEO

How the vest works:

This project uses a matrix of 48 vibration motors that wraps around the torso. The vest sends tactile feedback to the user in such a way that they can perceive the environment in front of them in 3d. This is done by using varying levels of vibrations. Eight levels of vibration were used of the possible 4096 levels. The closer something is to the wearer (or the louder the sound in gaming), the higher the intensity of vibration in the motors that correspond to the location of the object (or sound). Each motor used a maximum of 60 milliamps. If all 48 motors were running at the maximum speed for an hour, 2.88 amps would be consumed. A depth sensor, a computer, battery pack, and a microprocessor with IC’s (Integrated Circuits) are needed to run the vest. The computer, the battery pack, and the electronics are contained inside a backpack.

The depth sensor used in this project is the Microsoft Kinect. By using the Kinect the vest can still work in complete darkness. This was because the Kinect uses an infrared camera sensor.

The vest would use a stereo video camera (like one from an Xbox Kinect), processors, a computer, and a battery supply. The electronics other than the Kinect would be stored in a backpack.

The skin, a sense organ, contains the biological sensors of touch which are the thermoreceptors (responsible for thermal sensing), the nociceptors (responsible for pain sensing), and the mechanoreceptors (sensitive to mechanical stimulus and skin deformation.) Of the four kinds of mechanoreceptors, the one that is relevant to this project is Pacini corpuscles which respond to vibration.

The ability to discriminate stimuli on the skin is different throughout the body. The two-point discrimination threshold (TPDT) is a measure of how far apart two pressure points must be in order to be perceived as two distinct points on the skin. The measurements shown in the link were used in the design of this project. The link shows the TPDT for different areas of the body.

http://www.robotica-up.org/PDF/Wearable4Blind.pdf

The final product used neoprene squares that were put on a 1” piece of foam. Vibration motors were mounted on the neoprene platforms. The neoprene platforms were mounted on the neoprene vest to be 2" apart. This vest worked significantly better because the motors did not spread vibrations throughout the entire vest.

Figure 2: Vest

The final design is a purchased neoprene vest with 48 motors on neoprene pads attached with Velcro. The vest has a 50-wire ribbon cable and a ground cable that connect to the electronics box. Solder was used to connect the ends of the wires to the ribbon cable at the back of the vest. Connections were insulated and fabric glue was used to attach double fold bias tape to cover the wires. All ground wires were connected together to a long ground wire.

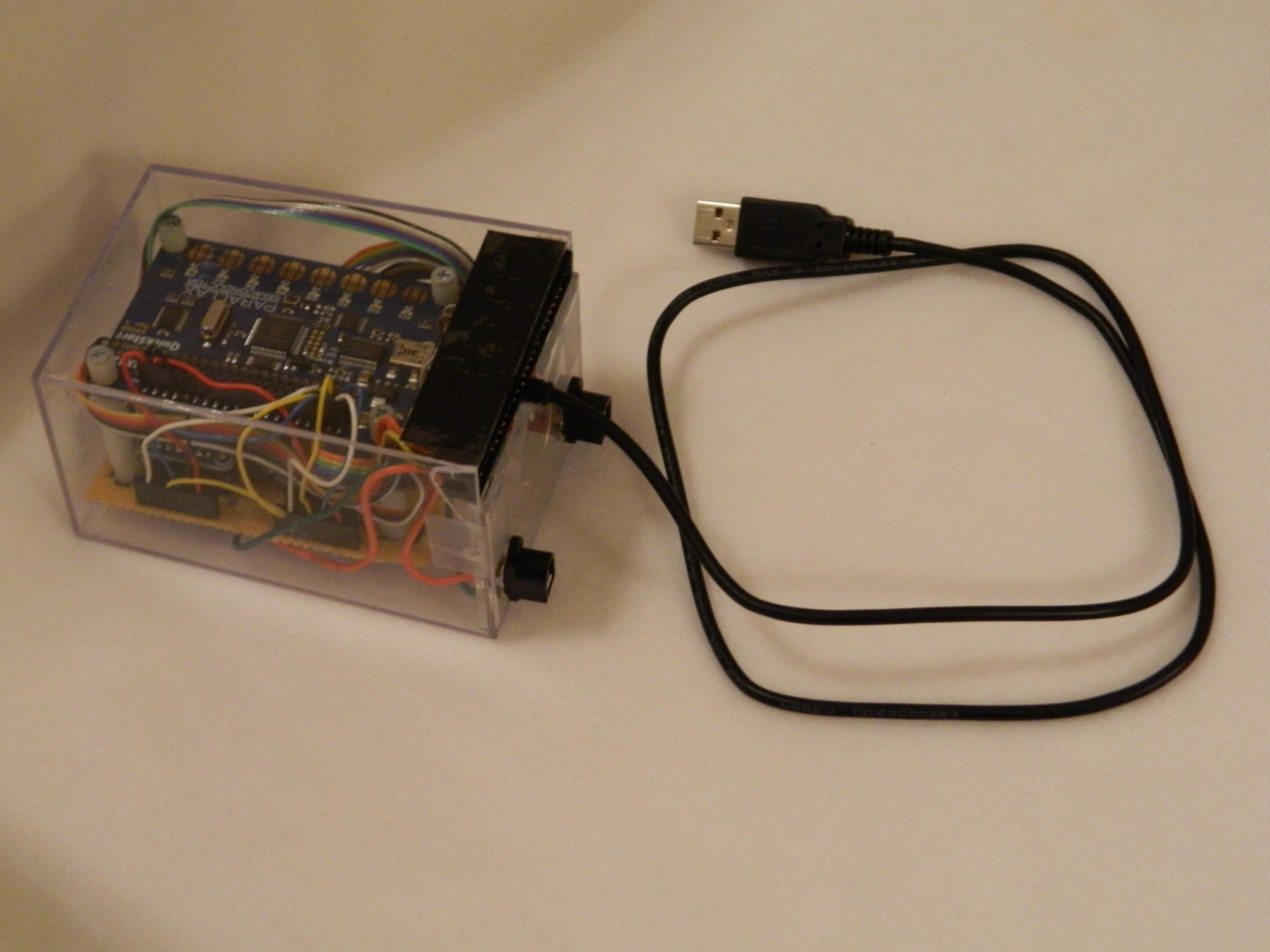

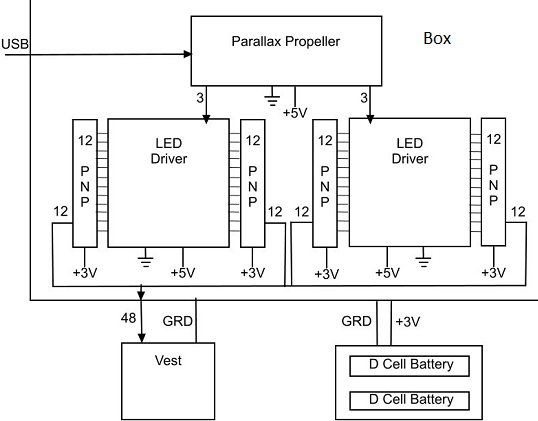

Both the ribbon cable and the ground cable were attached to an electronics box. This box (see Figure 3) contained a specialized circuit board (see Figure 4) with 48 transistors and two LED driver boards attached. Also in the box was a propeller board, a ribbon cable plug, a USB plug and two power plug adapters.

Figure 3: Electronics Box

Figure 4: Circuit Diagram

Figure 5 shows the flow of information from the depth sensor to the vest. The C# Master Controller Program (MCP) collects data from the depth sensor (which is the 3D video camera) and converts it to low resolution 3D video. That picture is sent to a communicator program. The C# Communicator Program takes the information from the MCP and sends it to the propeller microprocessor through the USB cable. The Parallax Propeller program takes the low-resolution 3D video and sends it to the LED drivers in the circuit box. The LED drivers convert the depth video to vibrations of the motors in the vest.

Figure 5: Flow Chart

The vest was designed so that the 2 D-Cell Batteries could power the motors at least 4-8 hours depending on usage.

Bugs, Future upgrades, and Applications

Additional features that could be added are

- A better, smaller depth sensor (less power required for use; less bulky; one that could work outside)

- An audio sensor for gaming

- Smaller, lighter-weight computer (less power required for use)

- A surface mount version of all the electronics in the project box.

Additional Applications this can be used in are

- To prevent spatial disorientation in the Armed Forces which accounts for many casualties.

- For an officer to give commands to troops

- To relay information to pilots

PRODUCTIZED DESIGN

Licenses:

Raspberry Pi - "Our educational resources and documentation are released under a Creative Commons licence." http://www.raspberrypi.org/creative-commons/

Parallax Propeller - "The Propeller 1 (P8X32A) is now a 100% open multicore microcontroller, including all of the hardware and tools: Verilog code, Spin interpreter, PropellerIDE and SimpleIDE programming tools, and compilers. The Propeller 1 may be the most open chip in its class." http://www.parallax.com/microcontrollers/propeller-1-open-source

Kinect for Windows SDK end-user license agreement http://www.microsoft.com/en-us/kinectforwindows/develop/sdk-eula.aspx

Python 2.7 license https://www.python.org/download/releases/2.7/license/

C# Microsoft uses ECMA license standards http://www.ecma-international.org/publications/standards/Ecma-334.htm