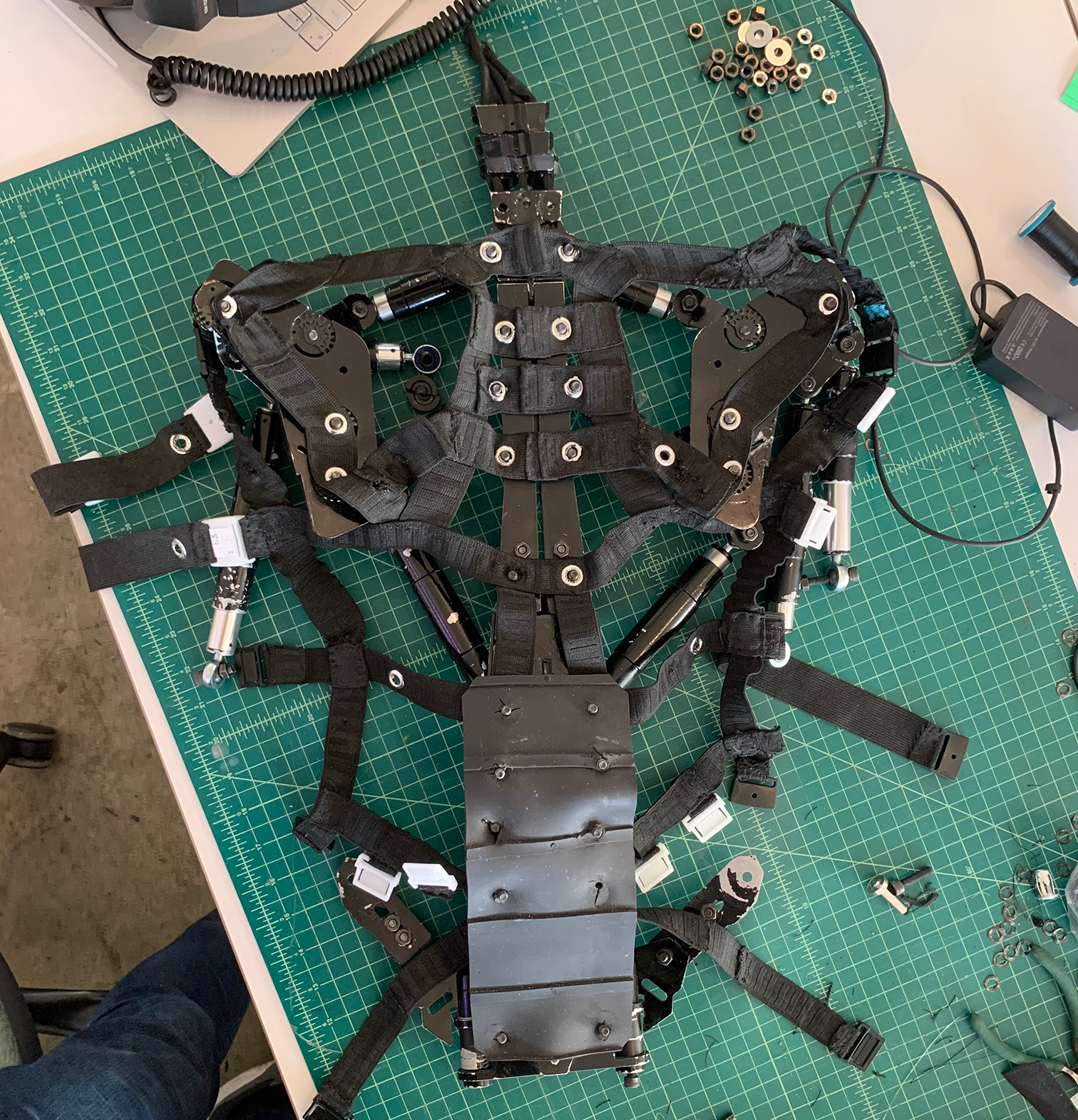

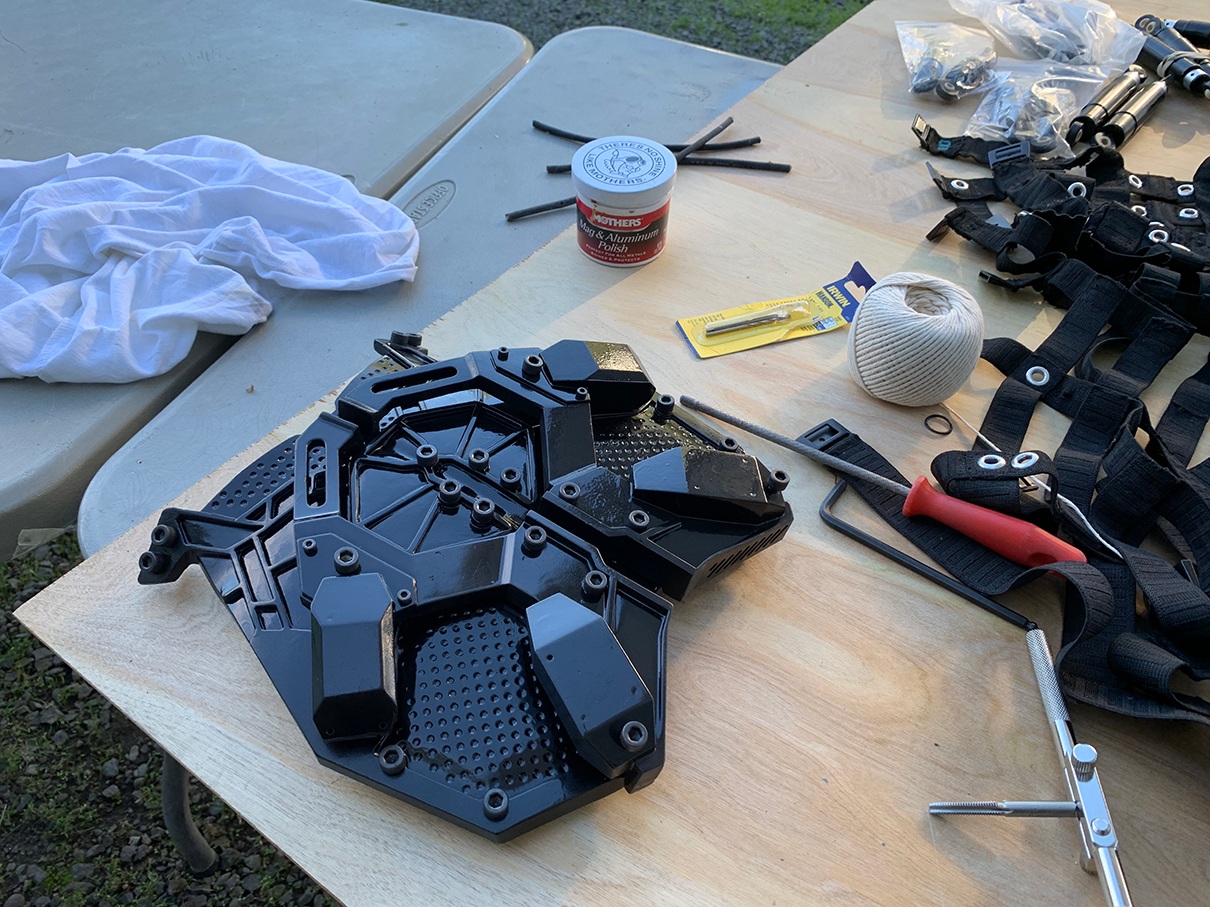

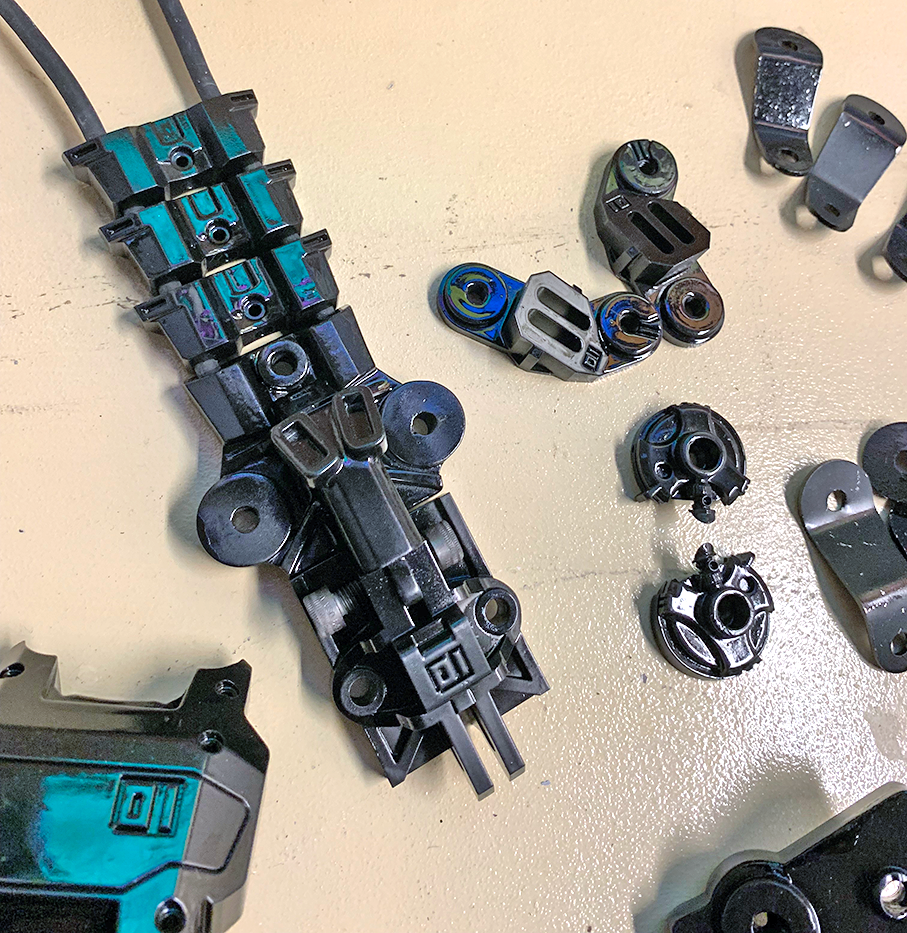

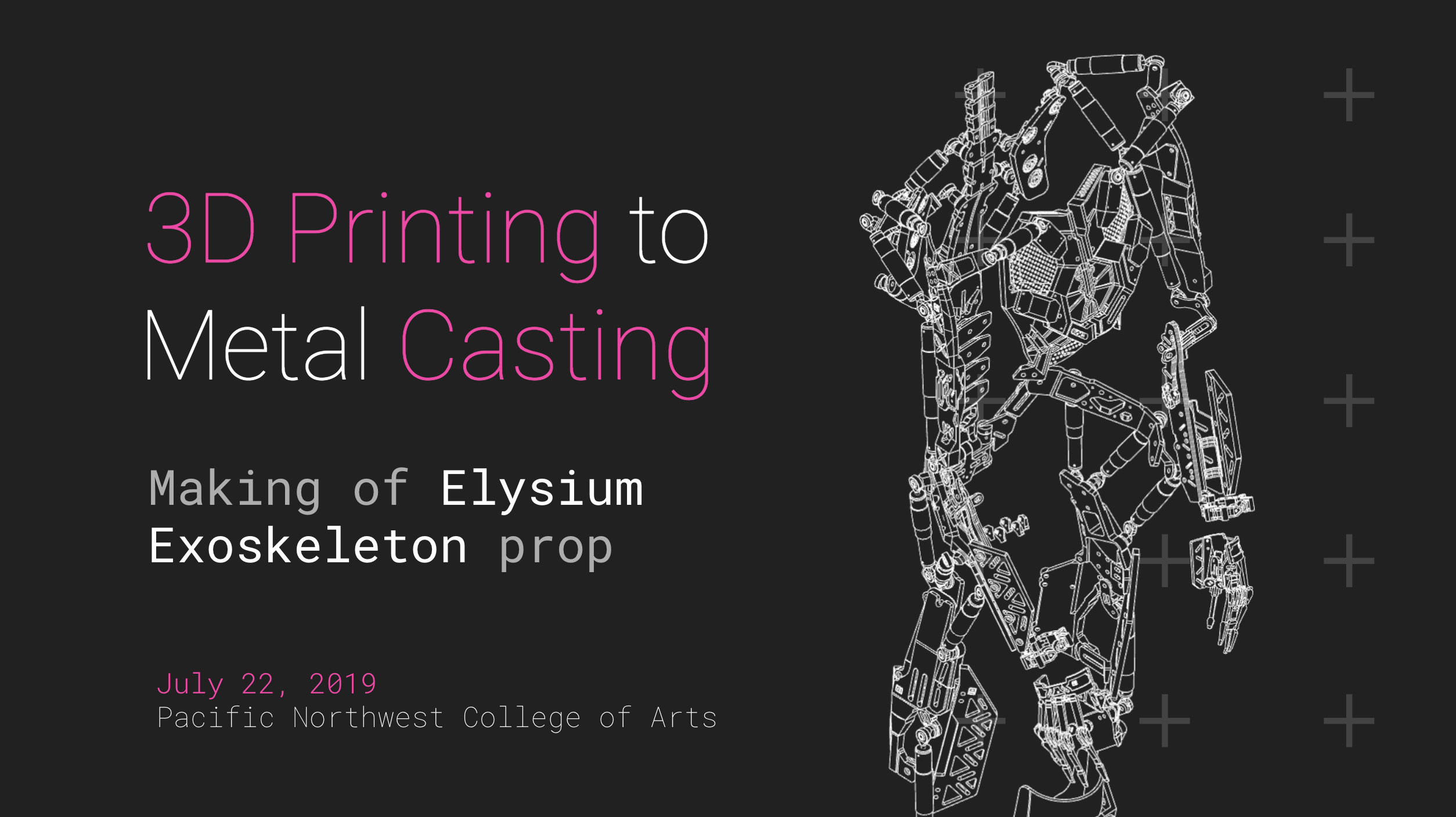

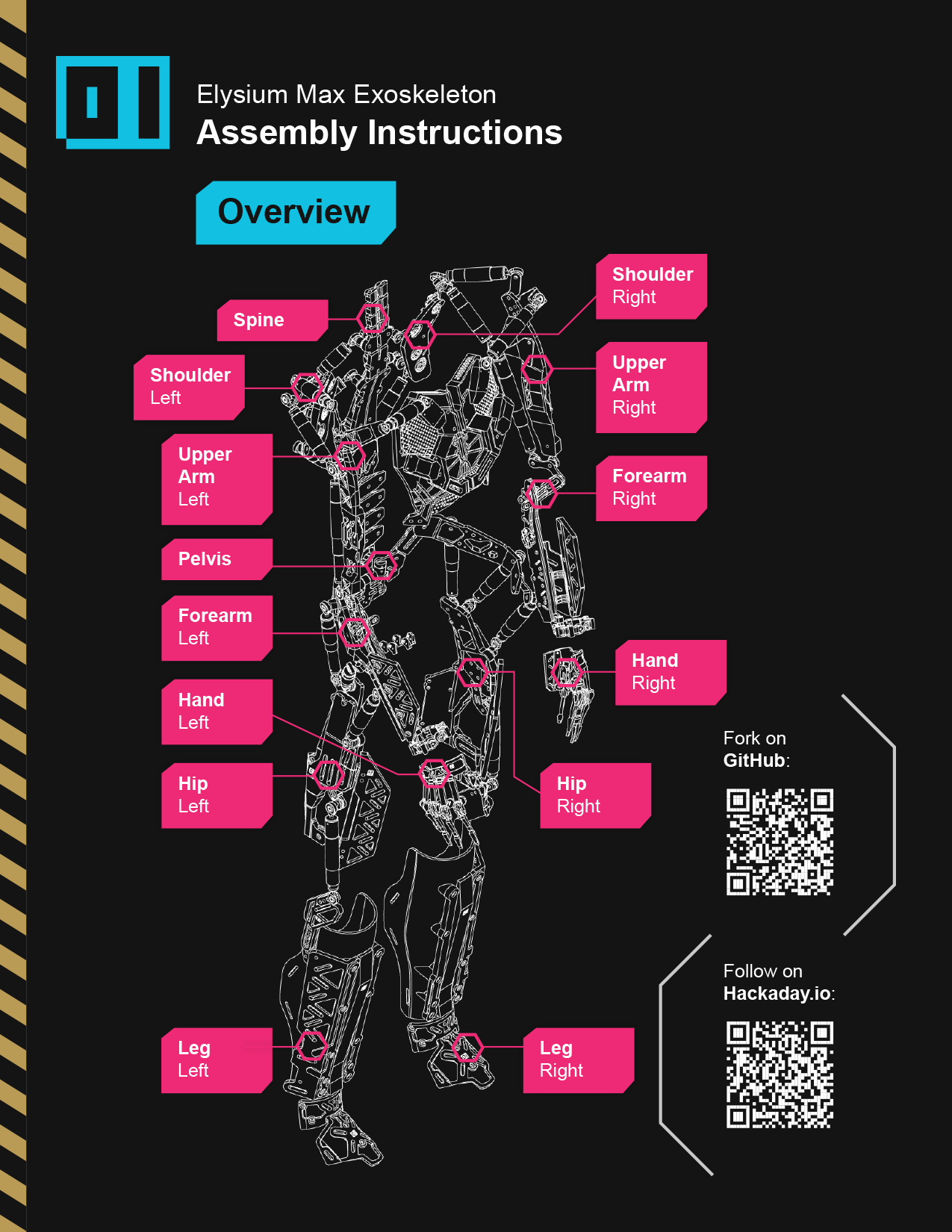

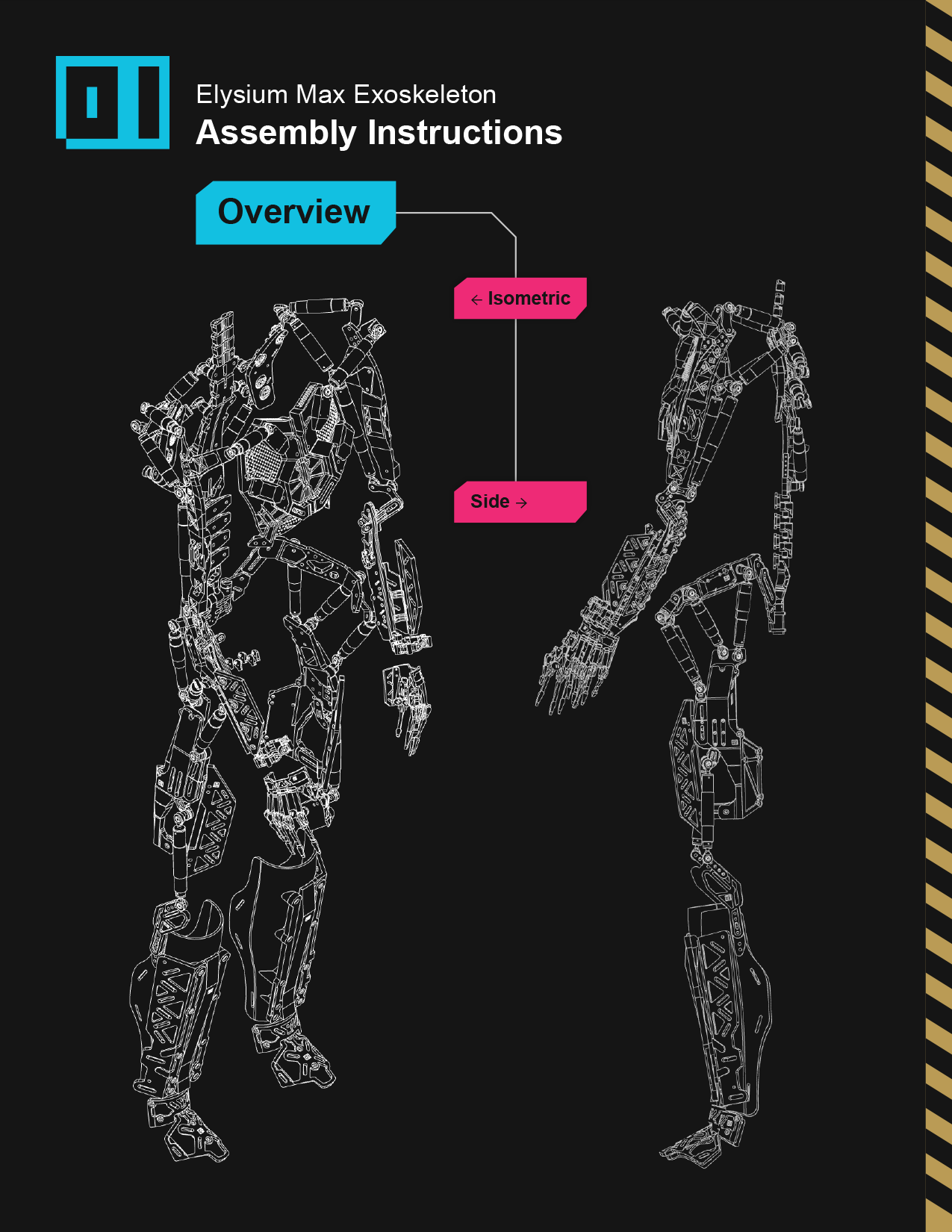

I designed the parts with Autodesk Inventor, 3D-printed and re-cast the largest or most complicated parts out of Aluminum 356, and used CNC for the rest. Pistons were machined on a metal lathe and the exosuit was mounted on a tactical plate carrier vest & hips.

The printable STLs are available here and on GitHub. See the assembly instructions if you want to put together one of your own.

My other projects: cyberpunk guitar and drumming robot.

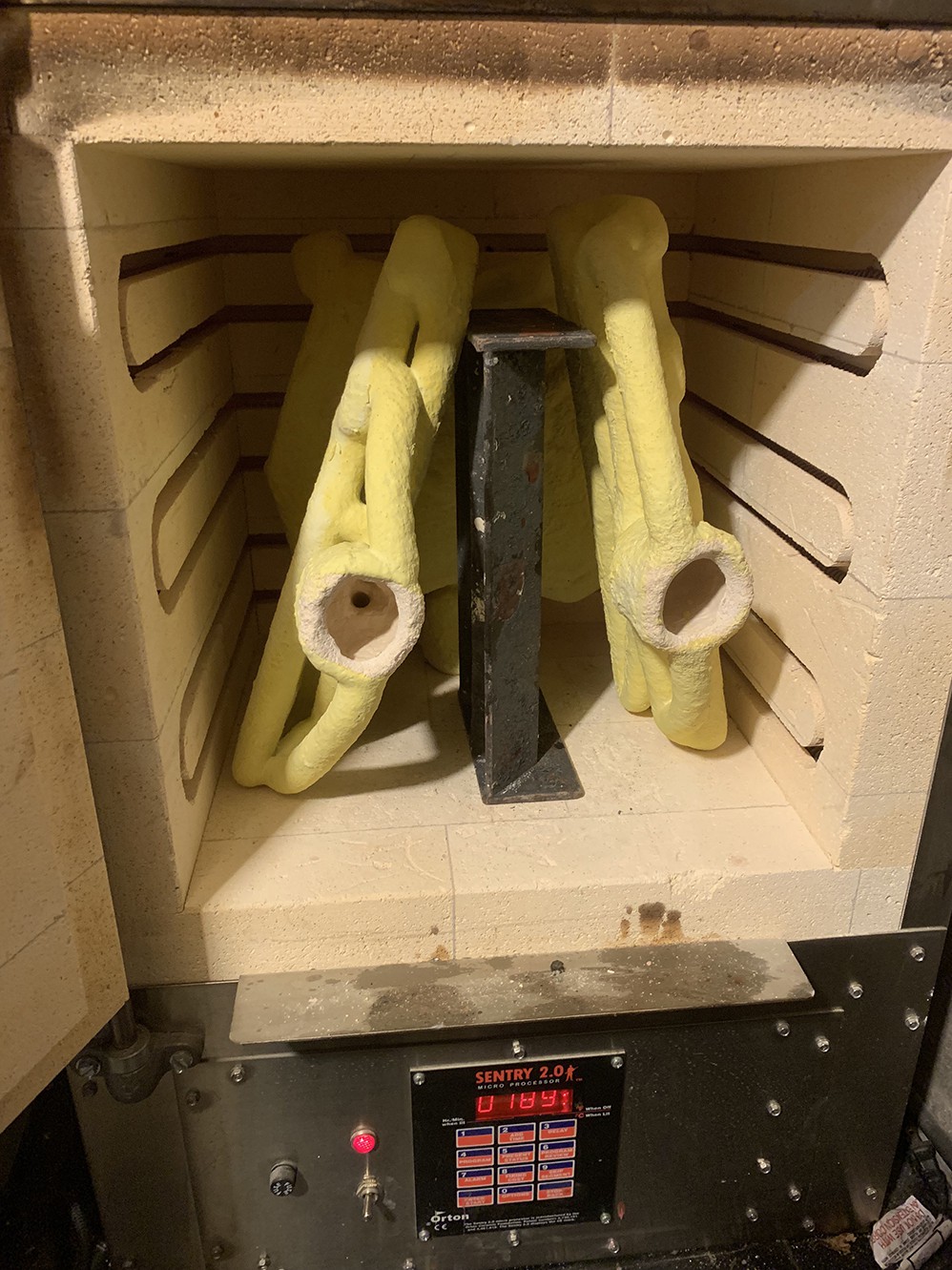

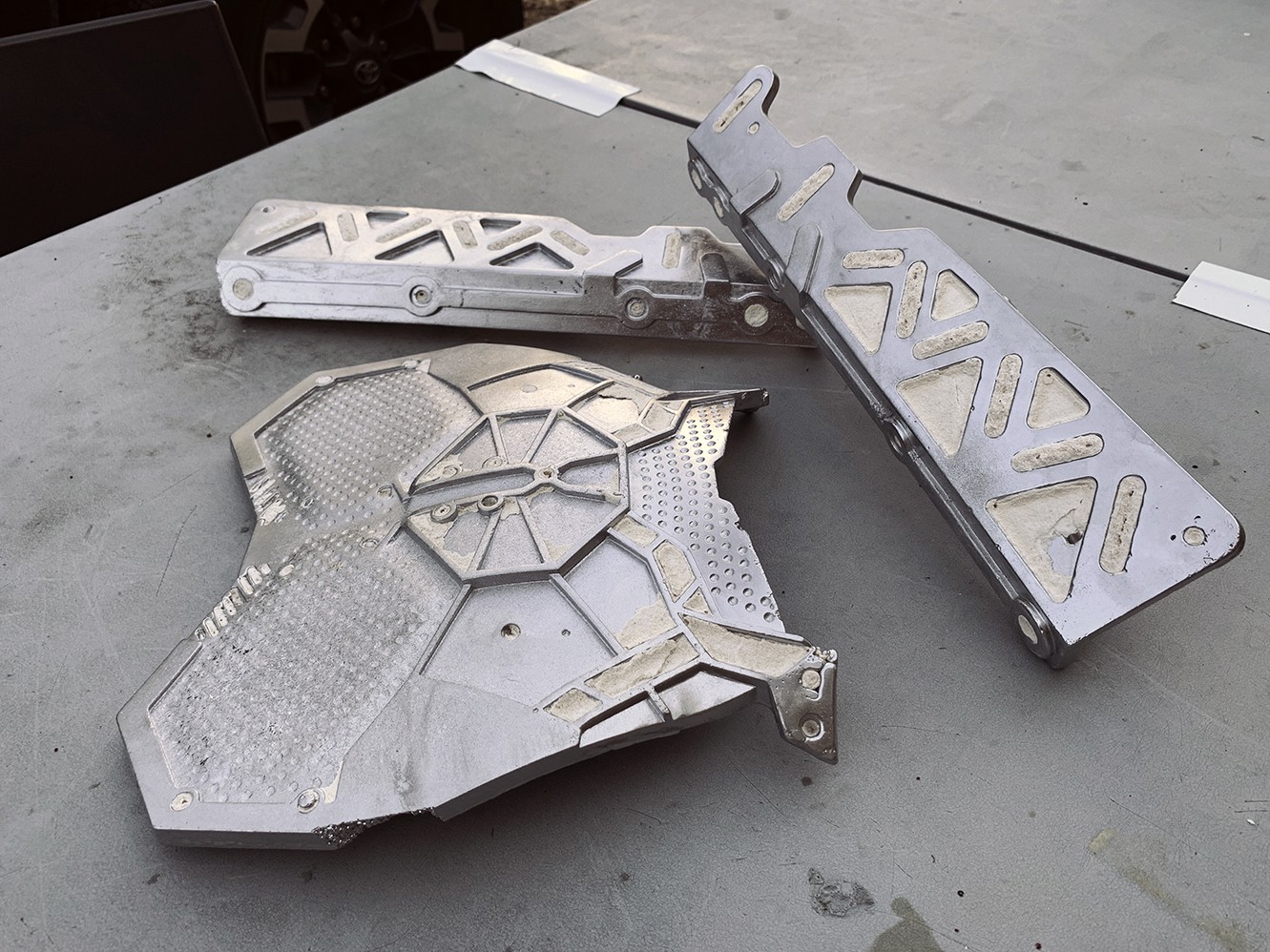

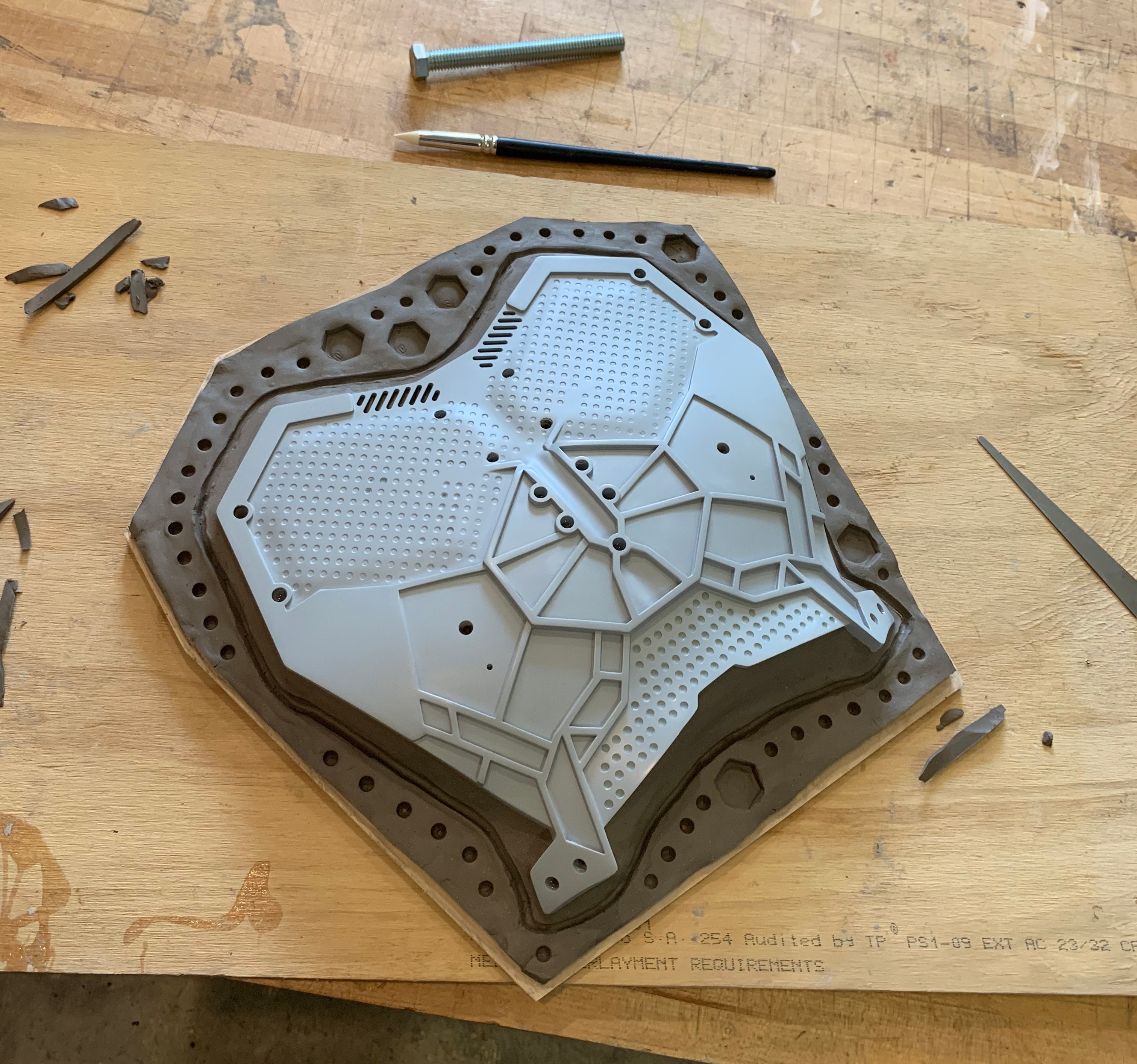

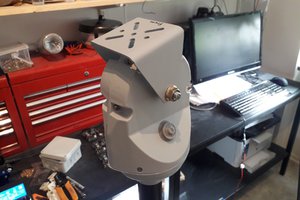

The metal casting process:

Val

Val

Second attempt:

Second attempt:

Daniel Nikolajsen

Daniel Nikolajsen

rawe

rawe

Øystein

Øystein

jupdyke

jupdyke

that is DUCKING AWESOME!!!!