It's still very early in the game, but after reading & following some advice I got the next jump in quality:

- Keep metal cooler. The hotter the metal is at the time of pouring, the more it will bind with air & water in the atmosphere to create hydrogen inclusions, which results in a horrible looking surface.

- Keep metal from getting too cool. Wrap the crucible and/or the ceramic mold into a ceramic blanket to curb heat loss on transfer.

- Pour slowly (just like with wax) to let gasses escape from the vents while metal is going into the sprues.

- Maintain a large thermal mass of metal just above the mold, to increase the force pushing the metal inside the mold. This is a low-tech alternative to vacuum casting or spinning centrifuge. The result is improved fills on thin and intricate mold cavities.

- Carefully degass with tablets just before the pour

- Fire ceramic molds as long as possible (but not higher than 500 F) to remove all water. Any remaining water will convert into hydrogen upon contact with molten metal and result in gas entrapment.

Parts being extracted and quenched:

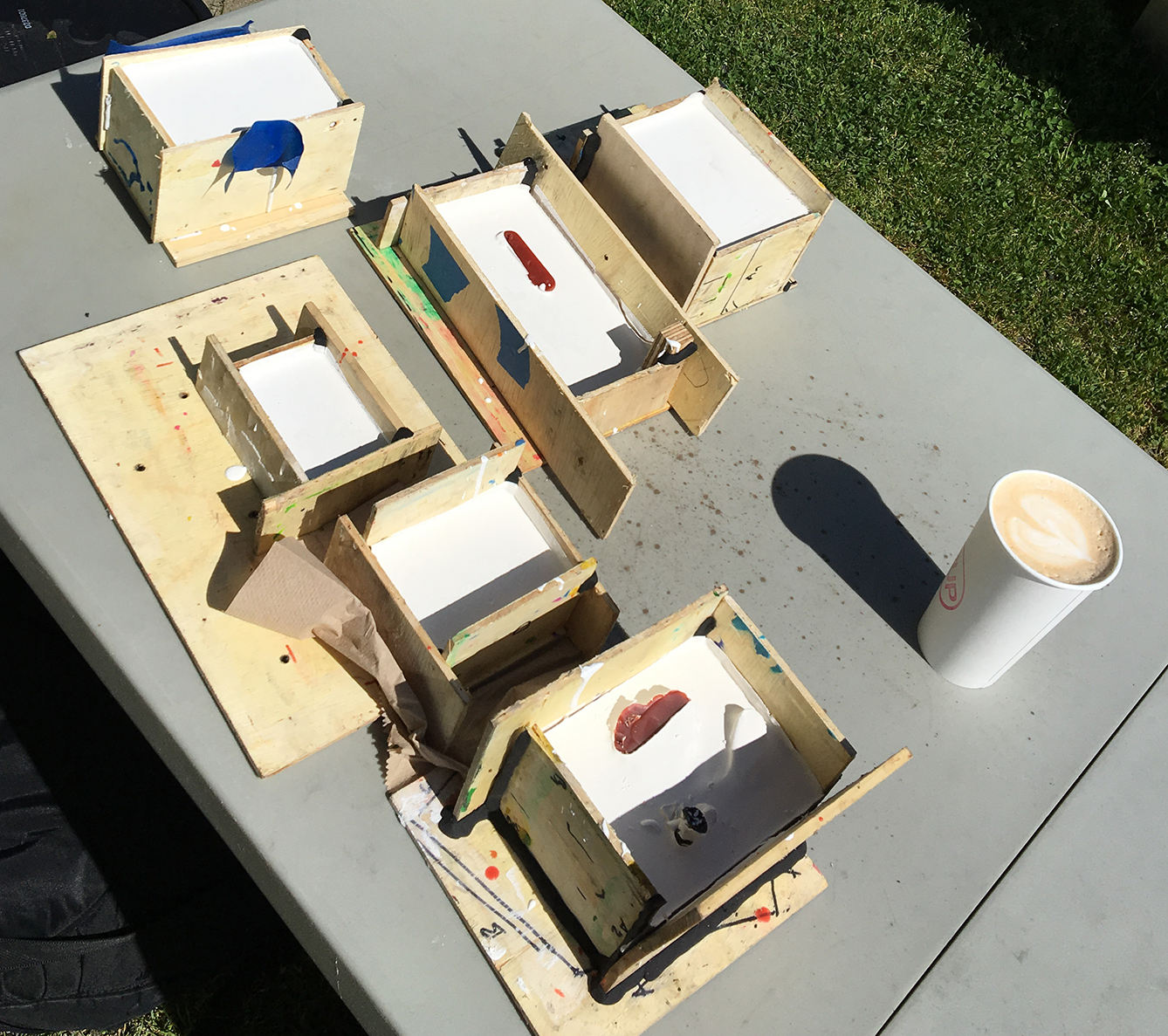

Wax casts prepared for box molding:

Another batch: parts attached inside respective boxes for pouring UltraVest investment:

Another batch: parts attached inside respective boxes for pouring UltraVest investment:

Removing from boxes after investment solidified overnight:

Wax burnt out and investment de-watered:

Val

Val

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I spent some time watching Myfordboy last year, but he was getting really rough results. There is also another person at my hackerspace that's doing sand casting, and likewise, everything coming out of that process looks like it was made by a monkey out of clay, then spent 1000 years under water. The results from investment casting are supposed to be better, but due to complexity of the process, just doing the steps doesn't automatically mean you get great results. Each step has many conditions that all have to be determined and controlled. So far I am (inconsistently) controlling 2-3 of 50+ conditions. I want to get to razor-sharp detail that requires no more than a week of grinding and sanding to get to a mirror polish.

Are you sure? yes | no

Any particular reason you're not trying sand casting, a la Myfordboy on youtube?

Some of those have a weird shape that won't work, obviously, but it looks like you could save a few steps on the parts that are just two sided with no overhangs.

(Great job, btw, looks awesome)

Are you sure? yes | no