Snake Hips again

These should now be functional but still need joining to something. To give the system a bit of swagger I've decided to cant the hips out a little way to emulate human hip motion better. That familiar shape at the top of the femur is responsible for our toes turning out slightly and in again as we stride, bringing the foot under the body to balance on it keeps both moving in a straight line while your hips describe a zig-zag. We also flex our spines to accommodate it while keeping the shoulders still, but the extra weight will be too much for the ankle servos here so it wont have a torso.

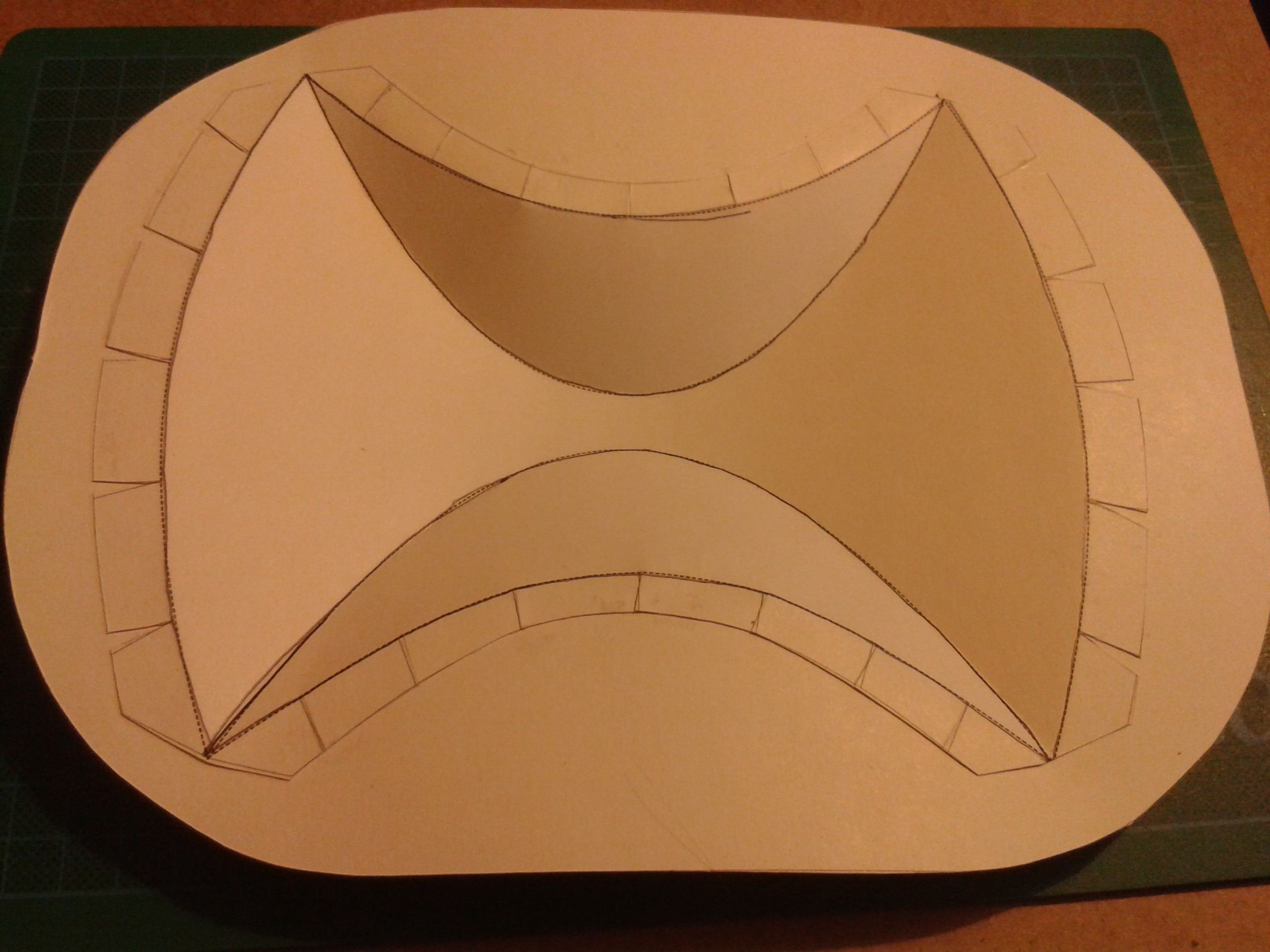

Nice Parabolics tho To keep the weight down in the superstructure much of it is single layer. Those curves arent there for decoration although they do look beautiful. There isnt anything stronger than intersecting curved forms in plane surfaces - to get those hip angles would have required a lot of small polygons and still had floppy plane surfaces inbetween the stronger ridges formed by the mesh. That's completely rigid in comparison.

To keep the weight down in the superstructure much of it is single layer. Those curves arent there for decoration although they do look beautiful. There isnt anything stronger than intersecting curved forms in plane surfaces - to get those hip angles would have required a lot of small polygons and still had floppy plane surfaces inbetween the stronger ridges formed by the mesh. That's completely rigid in comparison.

Proof that those are true parabolic surfaces; The top sheet would be warped unless it intersects the dome and crescent-shaped bites out of it on a mathematically straight line.

Forging a chopper

You wish, Robin.

I had noticed the possibility of using these forms as moulds myself, and I will be experimenting on this when I have more time. Thermoplastics spring to mind as a good candidate, and I do have green sand and a helical forge that will melt aluminium. I've only got one set of tentacles though, and meantime they are engaged in trying to create a decent rotational bearing surface in cardboard.

Prototype Pelvis

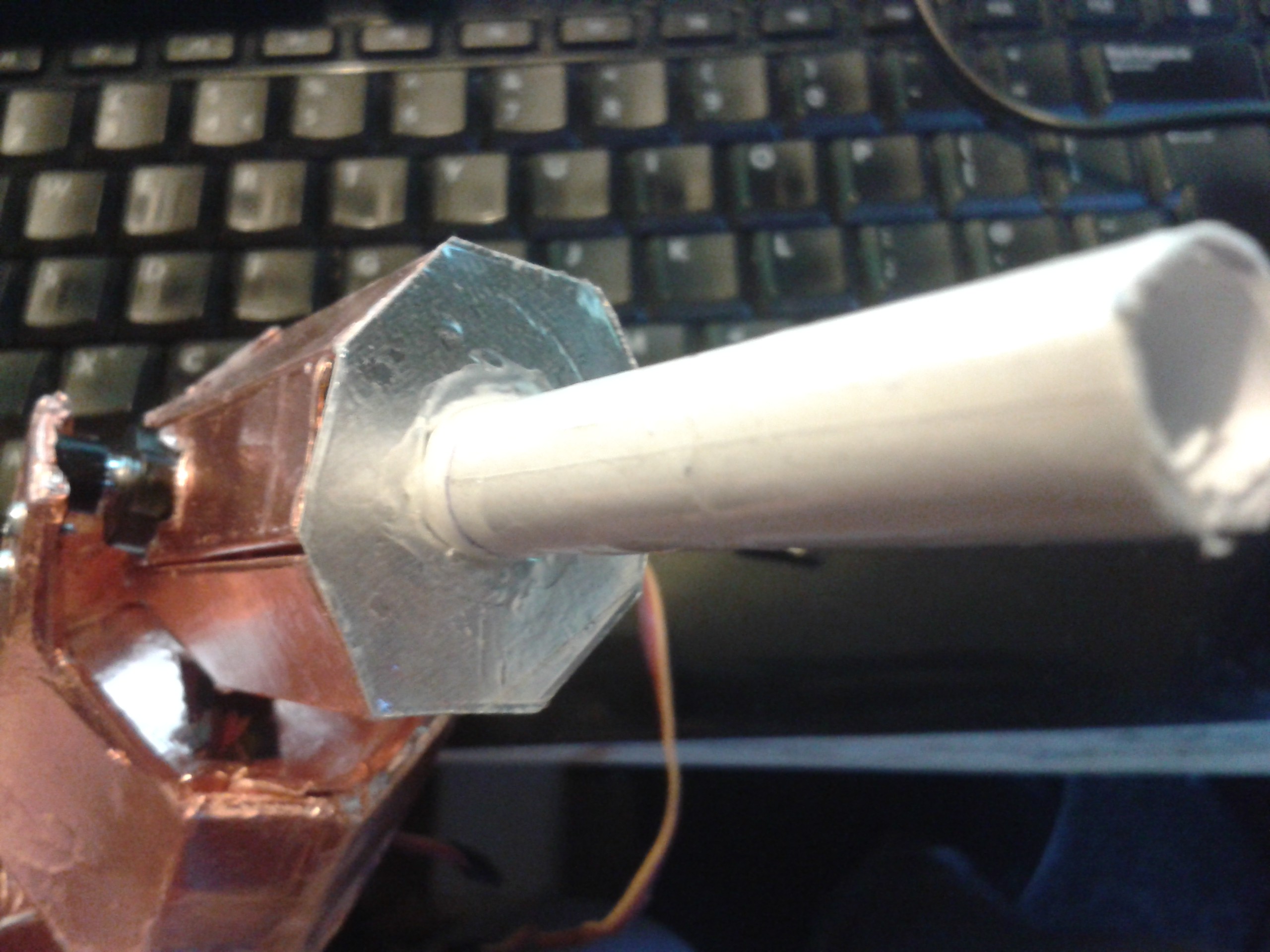

I've assembled the bearing from paper rolled around a rod and sealed with sticky-back plastic. another coated sheet went around that so the two fit together nicely and dont bind. The servos will turn the tops of these from the centre.

I've assembled the bearing from paper rolled around a rod and sealed with sticky-back plastic. another coated sheet went around that so the two fit together nicely and dont bind. The servos will turn the tops of these from the centre.

Servo mount and brace

This part just screws to the base and fits over the bearings as a module so it's all replaceable and just interfaces to the tops of the legs. This really would be a lot easier if it were a one-off but never mind.

The tops of the hip bearings will be cut down and plugged, then copper taped so I can solder plates to them to screw the servo actuators to.

Morning.Star

Morning.Star

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.