Upon replacement of the battery I noticed that the base of the battery connector where the battery make contact with the posts on the bike had cracked. The plastic part had weak points in its design meaning that gluing it would most likely break again.

Thankfully, Diego Porqueras from @Deezmaker at the 2015 Hacakday Zero to Product workshop showed us how to use Tinkercad .

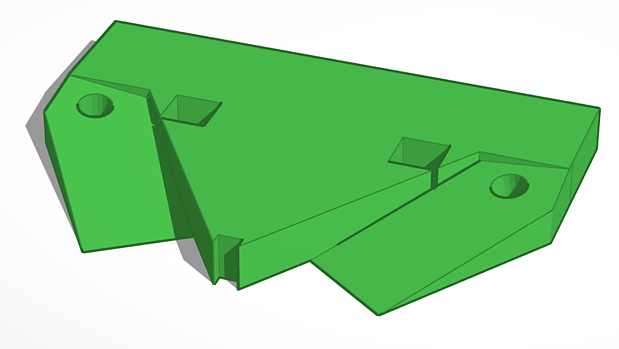

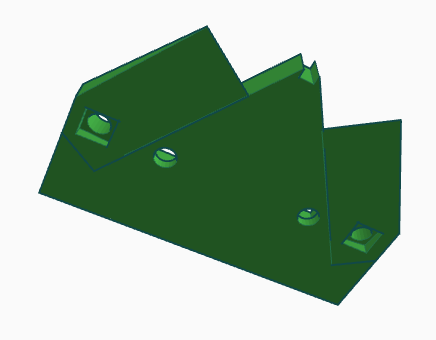

Following his tutorial, I measured the sizes and spacing of the holes, the slope where the metal flaps rested, and various thicknesses with calipers. In my design, I made the part thicker and added more material to the base so that the holes were not near an edge. I started by making the main shapes and used voids to remove areas. Slopes were made by changing the plane so I could precisely control the angles. Holes for the bolts needs material for the square nuts to fit in so those were made by grouping two shapes to create a larger complex void. The hard part was making sure I had enough room on the bottom for the angled bolt and nut to fit on the bottom side of the part. Turns out I didn't and had to dremel some material away.

Here is the finished part: https://www.tinkercad.com/things/kNUMJKz7jSd-electric-bike-battery-base-connector

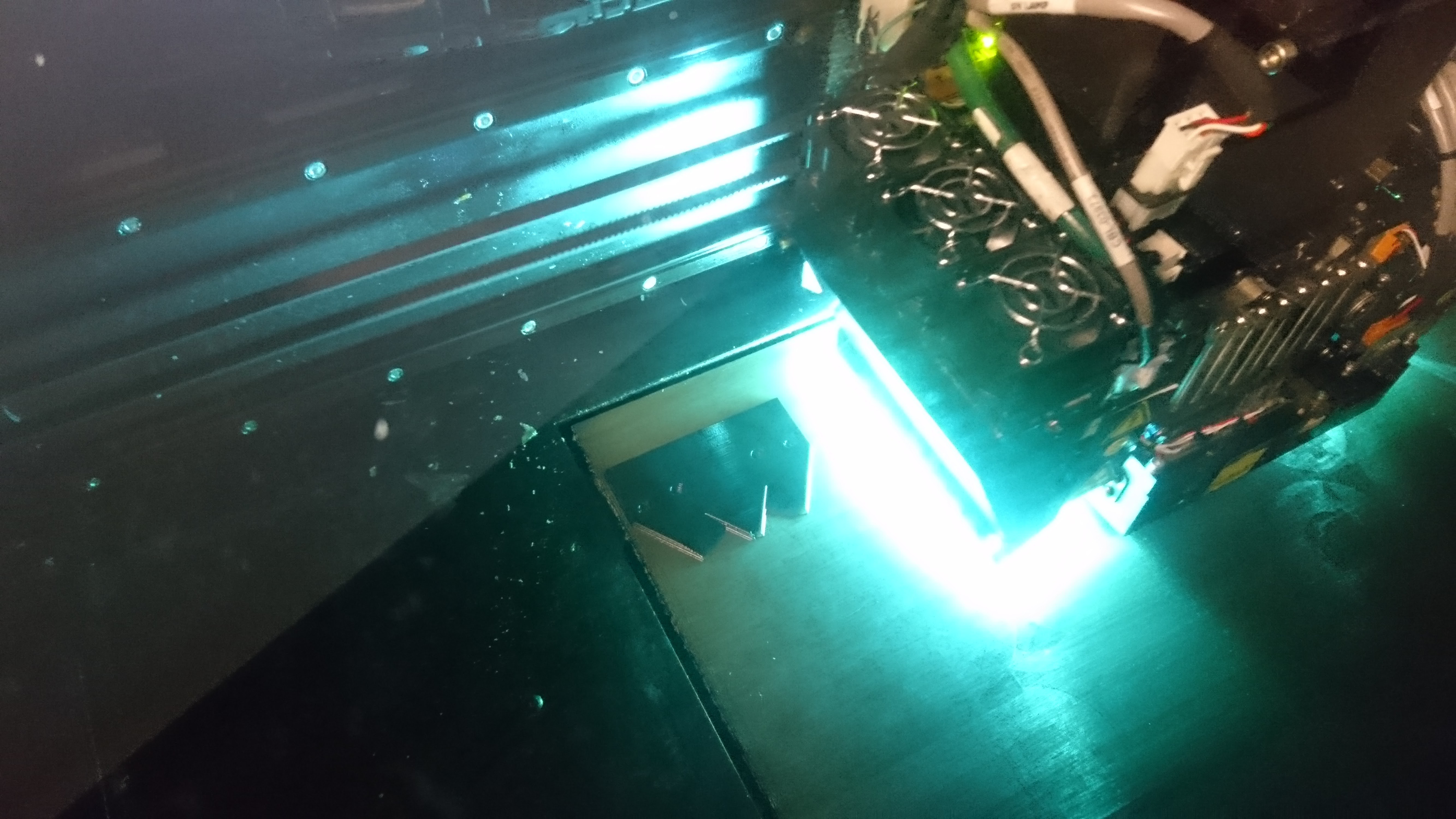

I printed it using a Stratasys Connex500 PolyJet printer I had access to. So far the part is holding up great under vibration.

Lucas Rangit MAGASWERAN

Lucas Rangit MAGASWERAN

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.