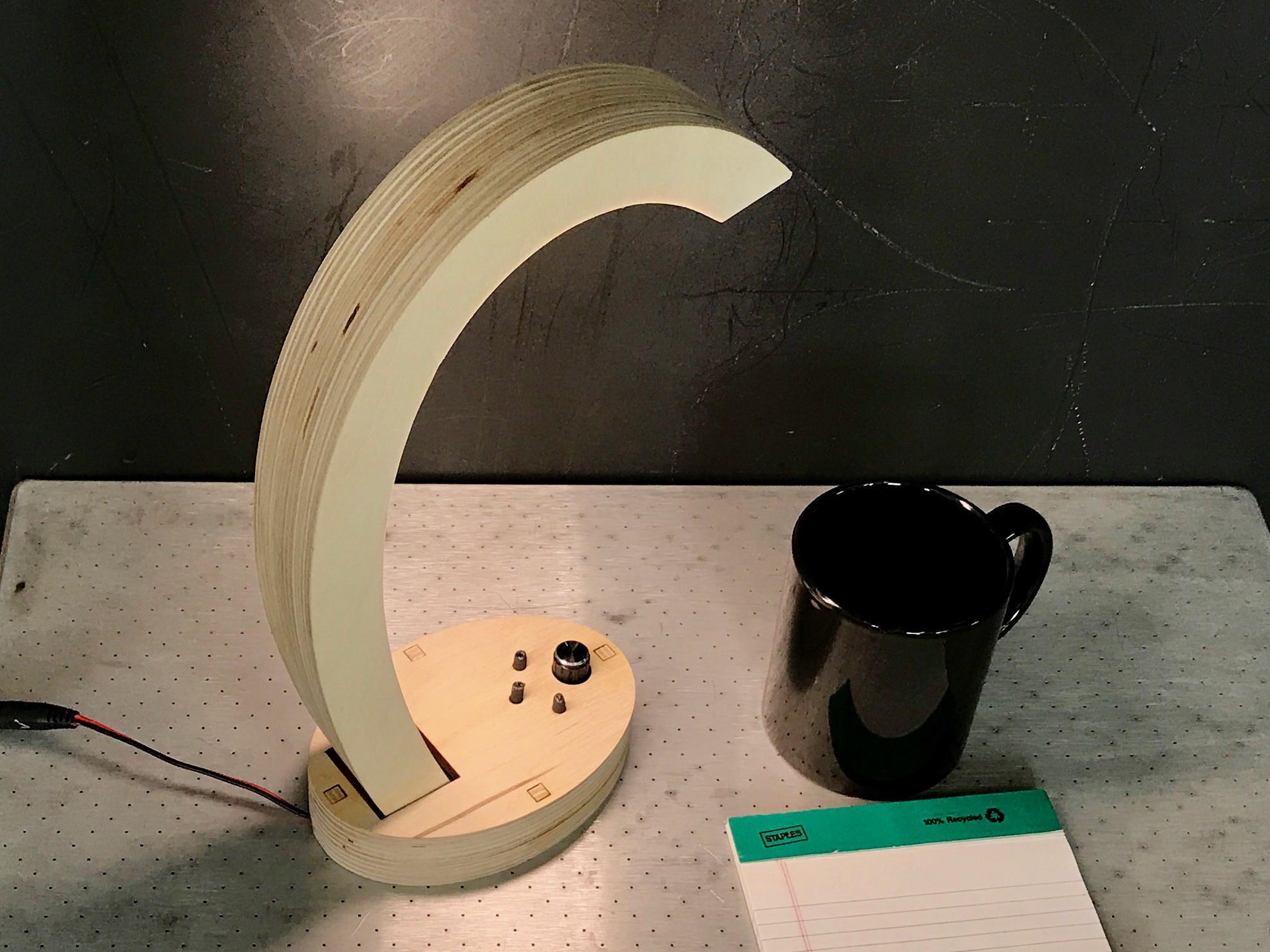

Here is my second experiment with using the laser cutter to replicate the look of CNC milled wood. I call it "woodArc3".

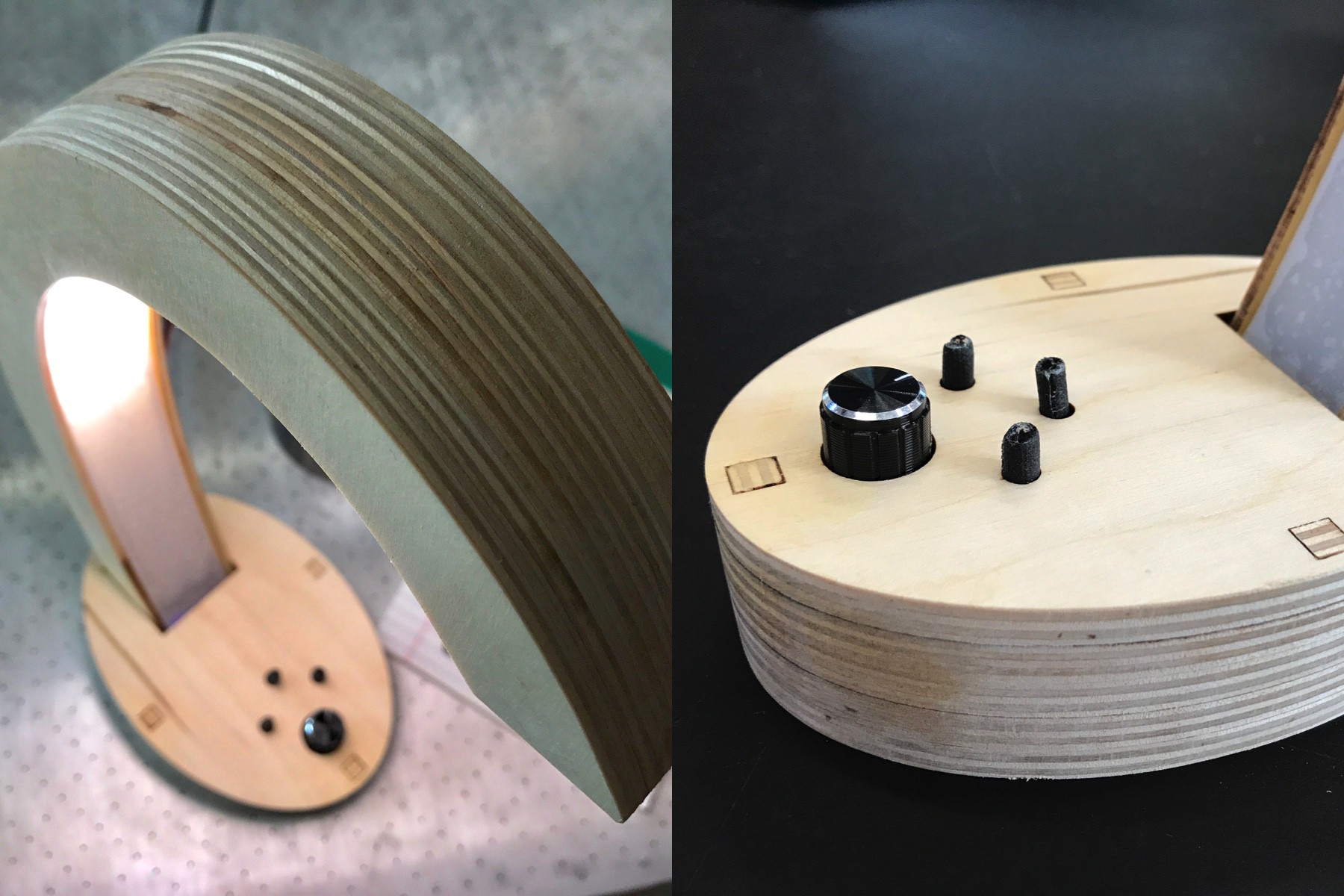

The lamp is an arc with a channel that extends from an elliptical base. Light emits from the interior side of the channel. The LED strip is set inside the channel with a diffuser made with PVC-coated PETG set into the face of the channel.

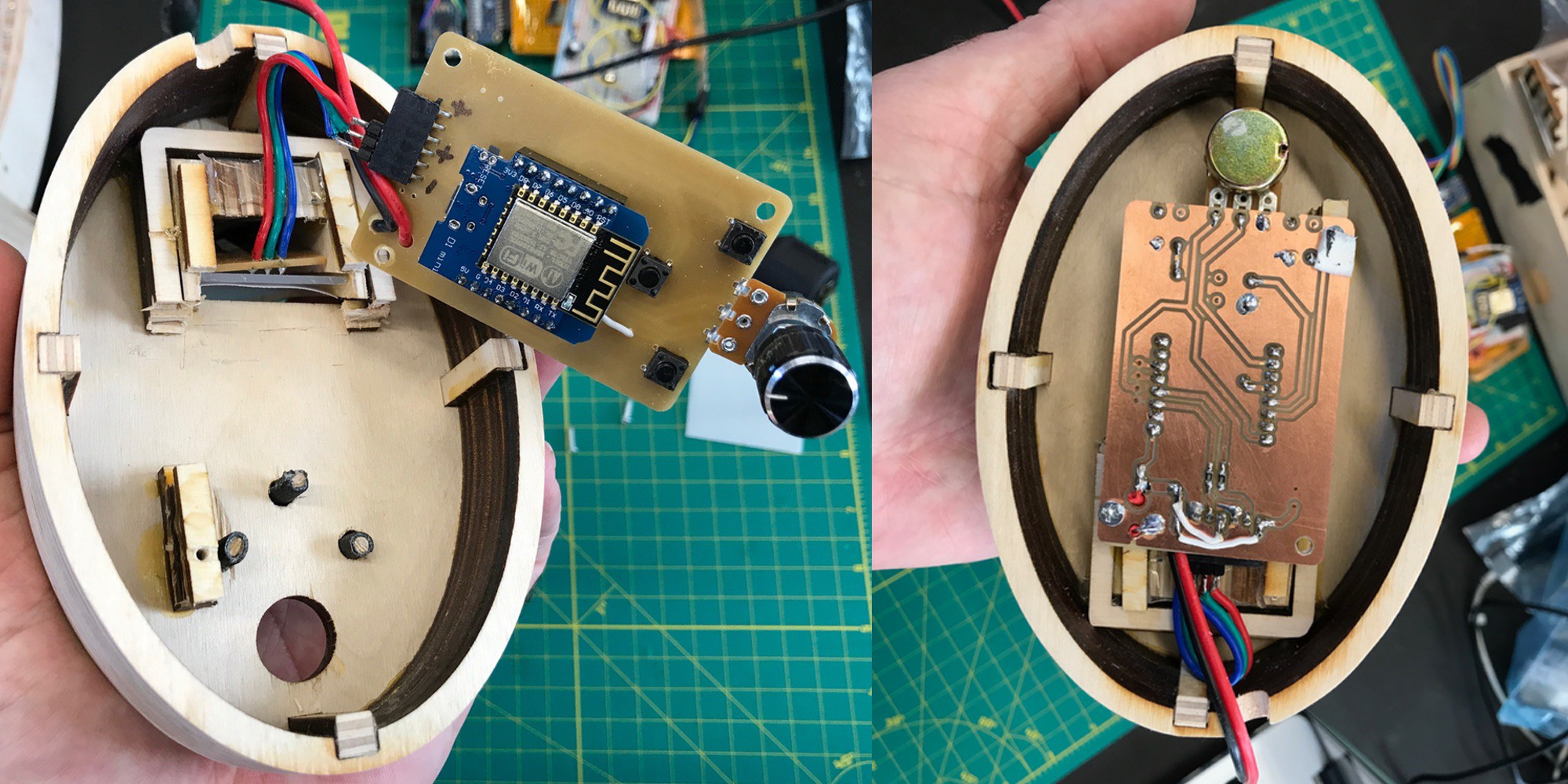

The lamp base contains the electronics. One knob and three buttons protrude from the base, allowing control of the lamp. The LEDs within are again the SK6812WWA "three color white" WS2812-compatible strips I have been using.

Here's a video showing it in action.

I really like how the striations of the plywood come out along the outside arc and the curve of the base.

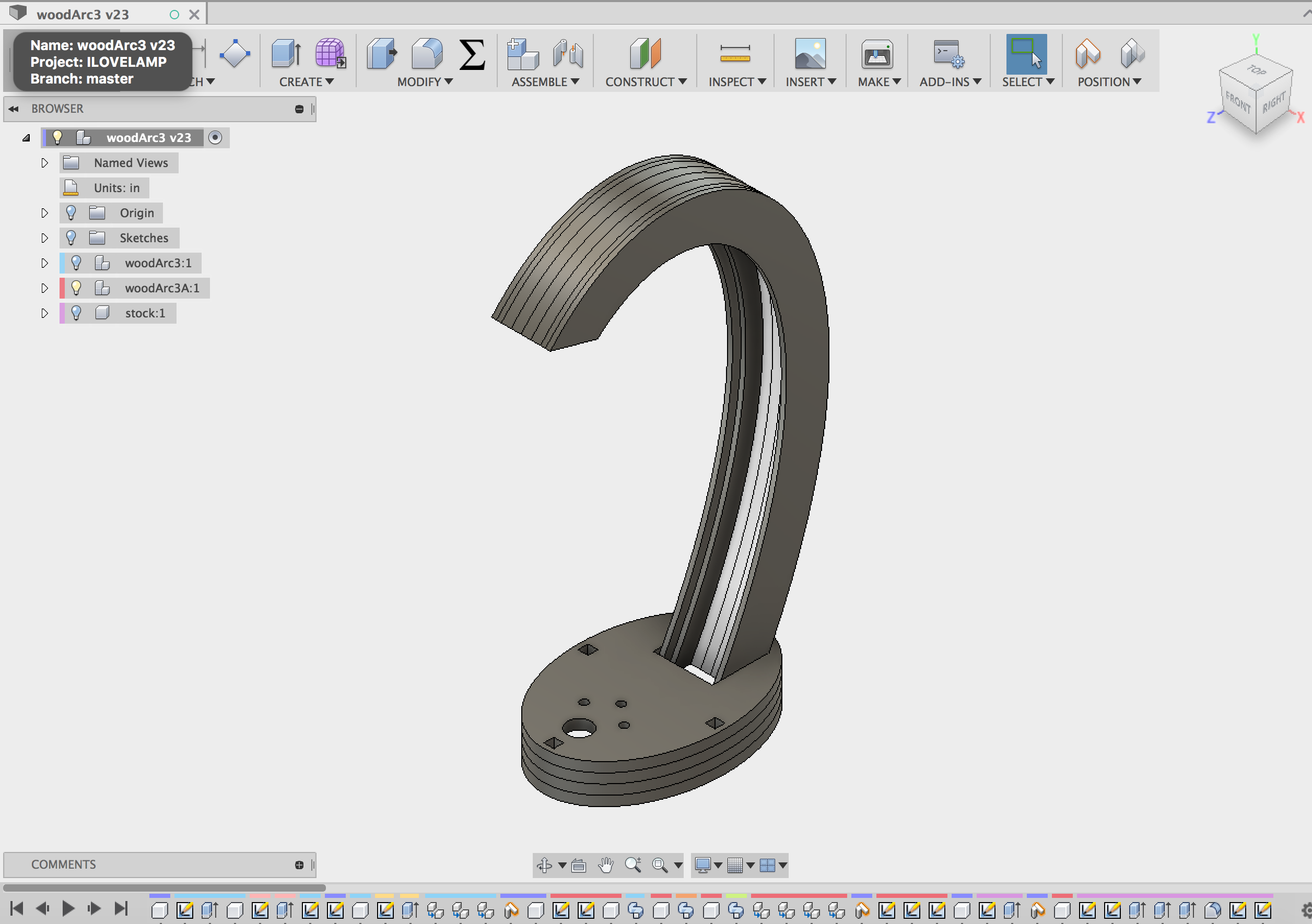

Structural Design and Fabrication

To create the structure of this lamp, I made "slices" in CAD that corresponded to the 1/8" and 1/4" thicknesses of plywood I had.

Instead of using the more explicit technique mentioned last post of making a copy of the component and re-laying out its pieces onto a stock, I found an easier way if your end result is laser cutting. Just create a sketch on a face of a part you want to laser cut, then stop the sketch. The resulting blank sketch outline will be the face of the part. Right-click on the sketch and Save As DXF. It's a very fast method to get to a set of DXF files for laser cutting. Now you still need to lay them out compactly. I used Illustrator for this.

To manufacture the lamp's main arm, I laser cut out the many pieces, glued them together (which was tough without any sort of registration), sanded off the laser burn marks, and put on a light coat of polyurethane.

For the base, I designed in registration pegs to help assembly. These pegs extended through the top. I was considering covering them with a thin top piece of plywood, but I left it as a reminder. The custom designed (and milled on Othermill) PCB fit an ESP8266, three tact switches and a pot hanging off the edge. This pot hanging off was because I had no vertical pots, just the right-angle kind. It worked out pretty well though.

What didn't work out well was the fact I didn't design any standoffs into the internals of the base for the PCB. So I quickly built-up some from glued scraps, drilled a pilot hole, and screwed down the PCB using wood screws. Not pretty or manufacturable but works for this prototype.

Firmware and Controls

As for the controls and firmware on this lamp, this was the first time I spent a decent amount of time thinking of interface and functionality. I decided to have the lamp have two main modes, toggled between with a single button:

- "lampMode" – normal daily use

- "patternMode" – fun times!

In lampMode, the knob controls number of fully-lit LEDs that are turned on, starting from the top. Thus, the lamp goes from task light to general light with the turn of a single knob. This action also effectively acts as a brightness control, just because more LEDs == brighter. A button let's you pick one of seven color temperatures for the emitted light.

In patternMode, the knob controls brightness, and the buttons let you cycle through a selection of fun dynamic patterns. Many of these were modified versions of patterns in the FastLED DemoReel100 sketch.

Overall Impressions and Next Steps

This was the first lamp I created that is usable by someone other than me. Previous lamps were all studies of form or light emission. That feels pretty good to have a lamp that's almost a finished thought.

The size is good for a desk lamp. It's aesthetically pretty good. I did not like the construction method as it's entirely not manufacturable I feel. I like how solid the arm feels but I wish I had put more thought into the internals of the base.

As a more refined experiment on how to make lasercut material look NOT like lasercut, I think it worked awesome. I'll definitely be using this technique for future personal projects.

For a future version of this lamp, I'd like to explore taking the idea back to CNC and seeing if it can be made using that technique.

todbot

todbot

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

This lamp, it is very handsome.

Are you sure? yes | no