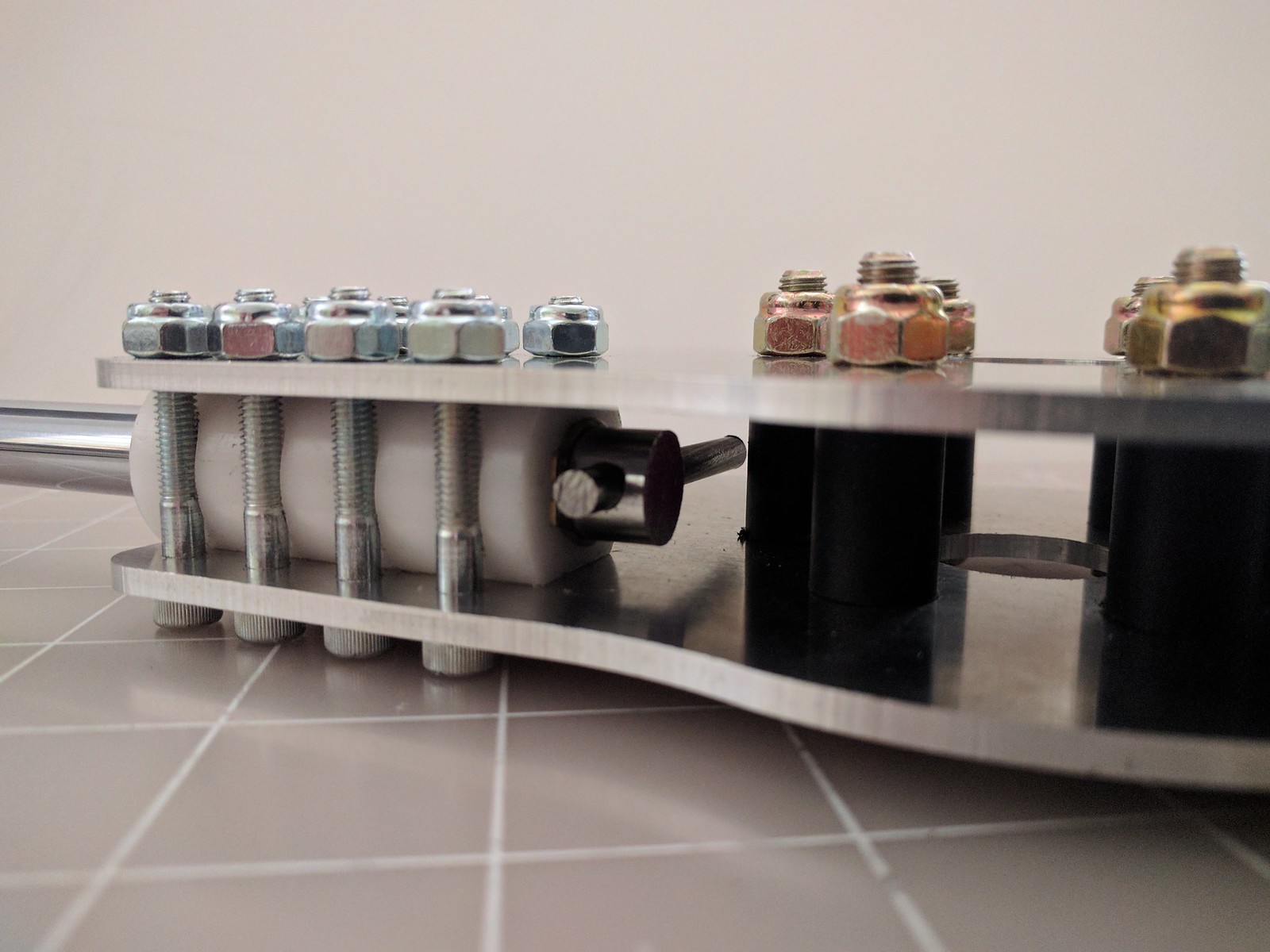

A few weeks back I assembled the major mechanical components for the first EVPR prototype. Shown below

This prototype used a simple Acetal bushing. This was done to keep the design simple and the weight down. After assembly, it became apparent that this wouldn't work as well as hoped. The dimensional stability is less than desired. When originally assembled, the shaft and bushing fit was acceptable, but with variations in temperature and the torque on the screws, the fit is quite variable.

This prototype used a simple Acetal bushing. This was done to keep the design simple and the weight down. After assembly, it became apparent that this wouldn't work as well as hoped. The dimensional stability is less than desired. When originally assembled, the shaft and bushing fit was acceptable, but with variations in temperature and the torque on the screws, the fit is quite variable.

The second issue was the lever arm concept for rotating the shaft with the servo. The mechanical movement wasn't working smoothly and the movement range on the shaft was less than desired.

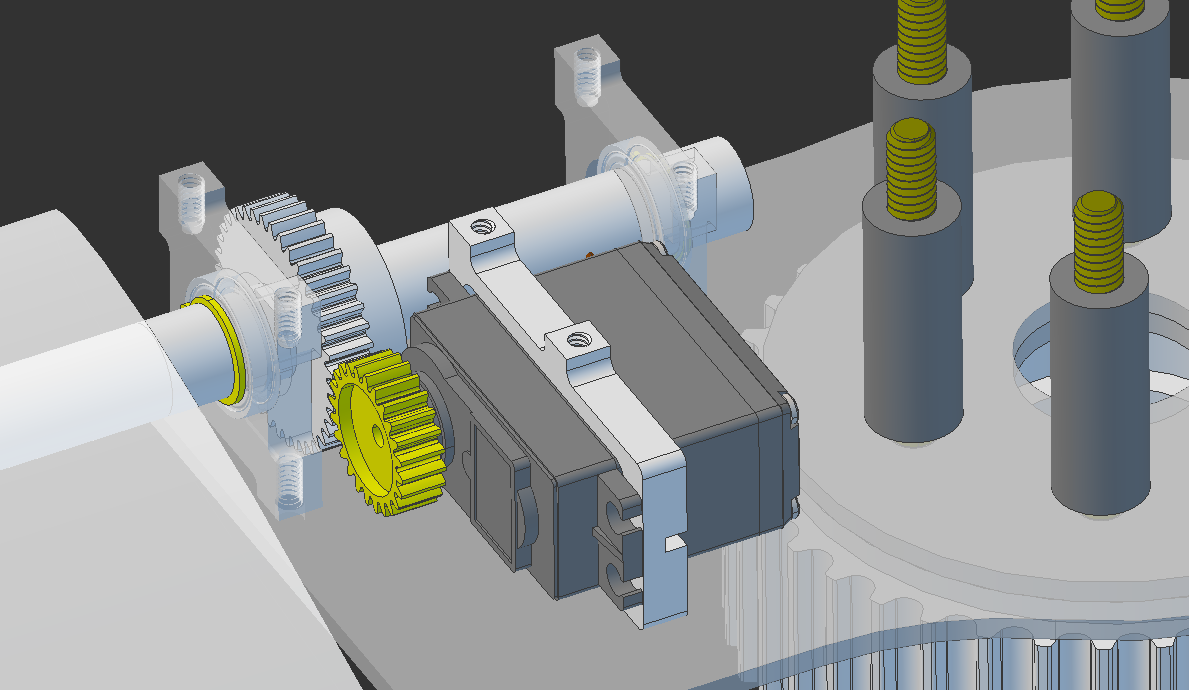

After researching different configurations, it was decided to change the bushings to bearings and use a gear drive instead of a lever arm to rotate the shafts. Even better, most of the hardware needed could be source for a reasonable price from Servo City. A new branch was created for the repository and after a quite a bit of CAD work, playing around with various configurations, a gear drive re-design was settled upon. A screenshot of the geared setup is shown below:

The hardware was ordered earlier this week and most of it's already been delivered, so if things go smoothly, the goal is to have the second prototype ready by end of Memorial Day weekend. Below are the hardware bits that came from Servo City yesterday.

I also plan to have more details of the servo sizing and selection in the near future.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.