Project Links:

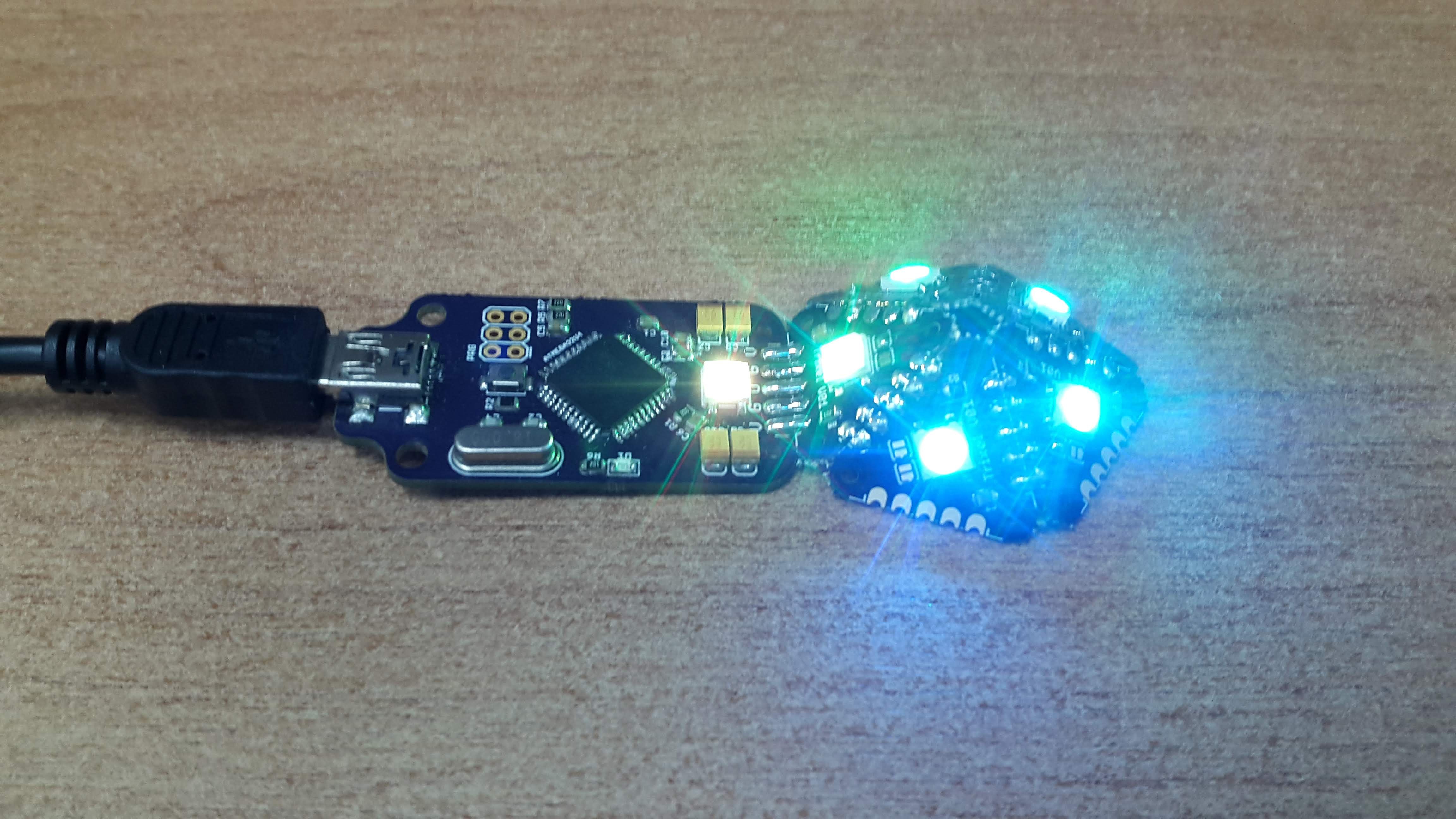

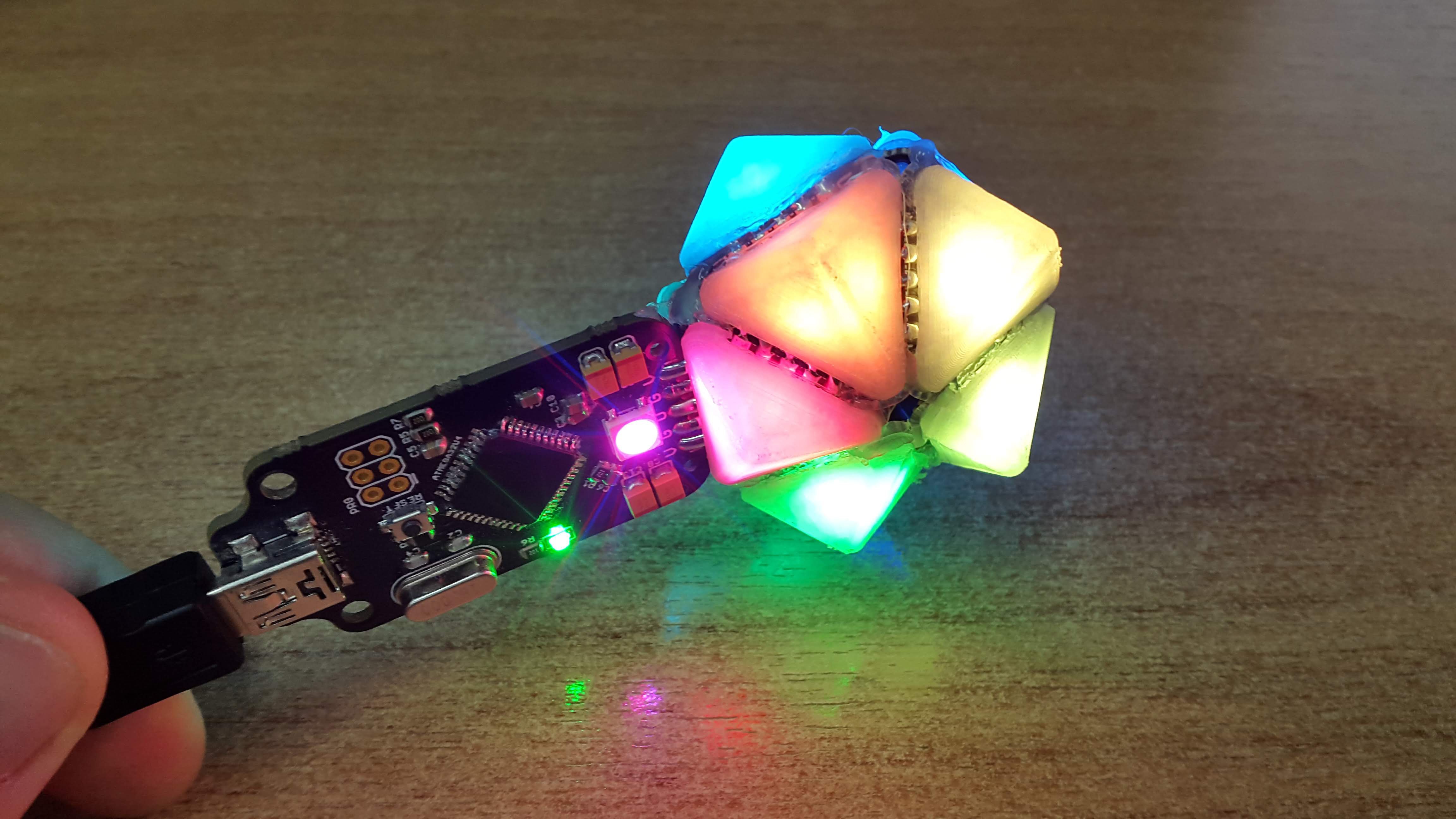

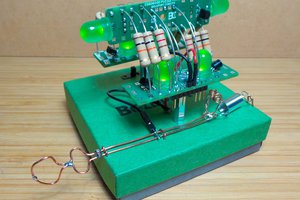

Youtube Simple MCU with triangles:

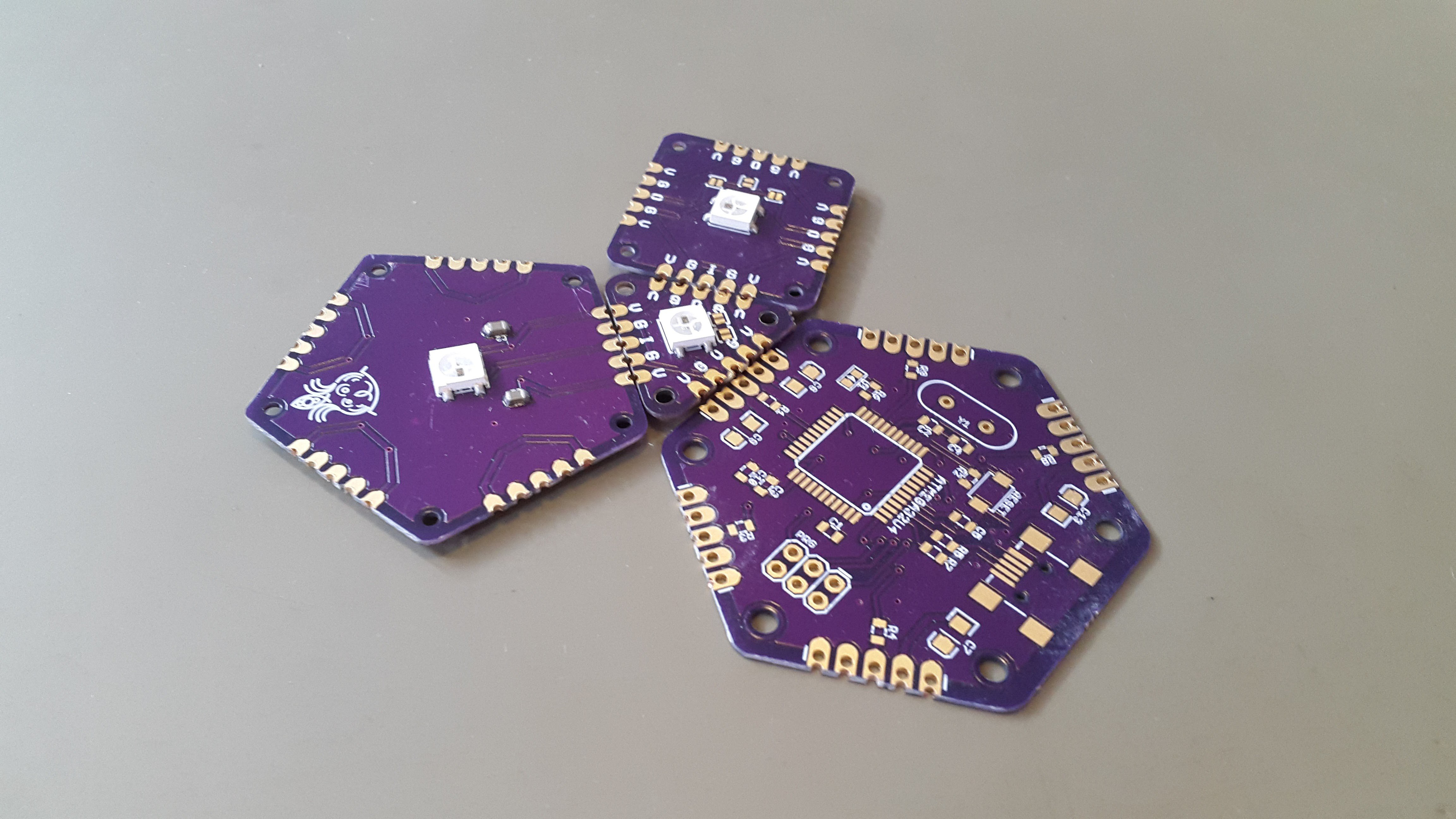

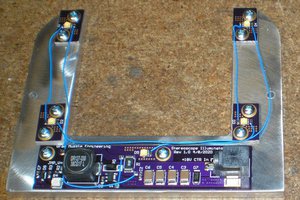

OSH Park Circuit Links

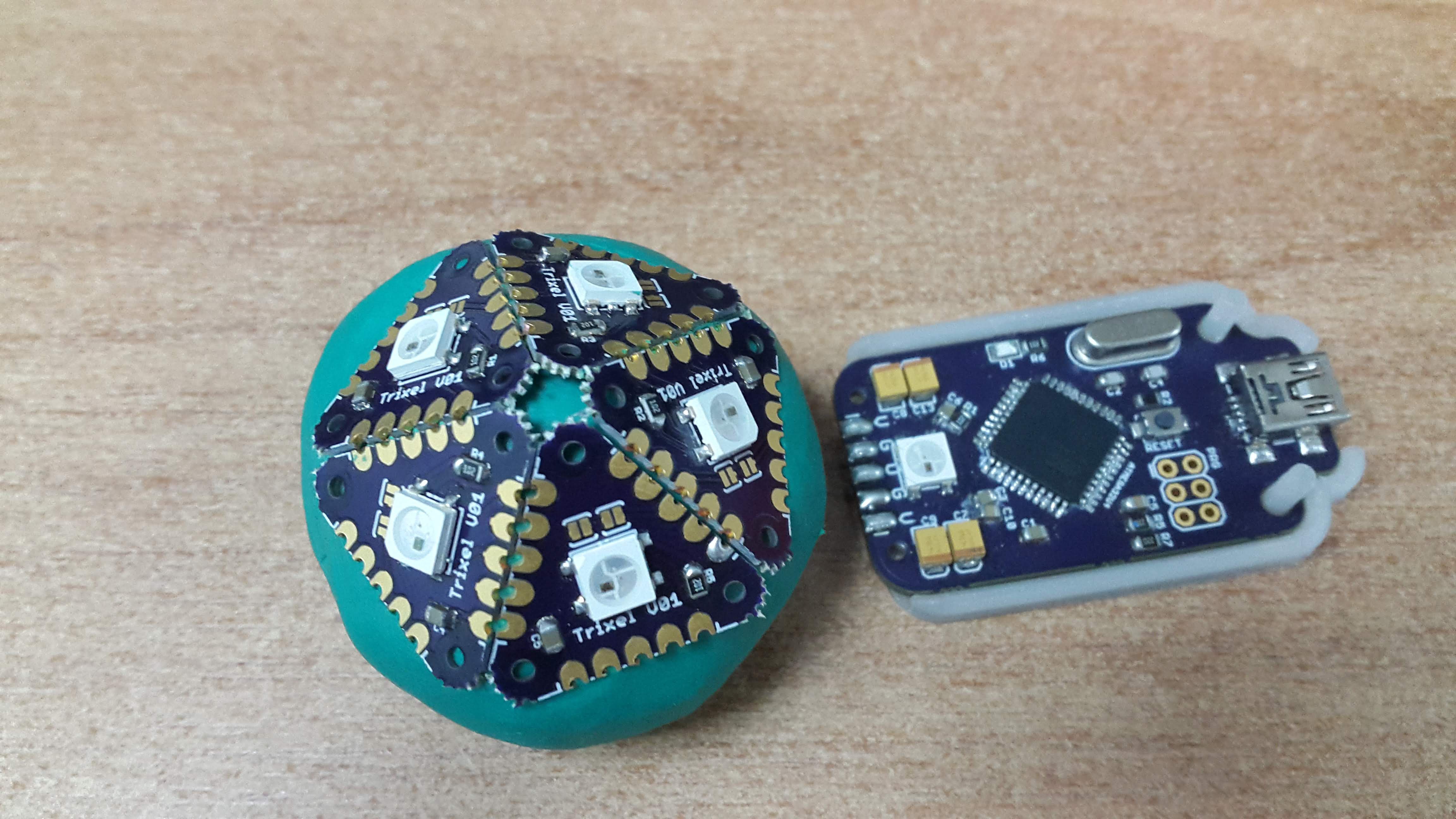

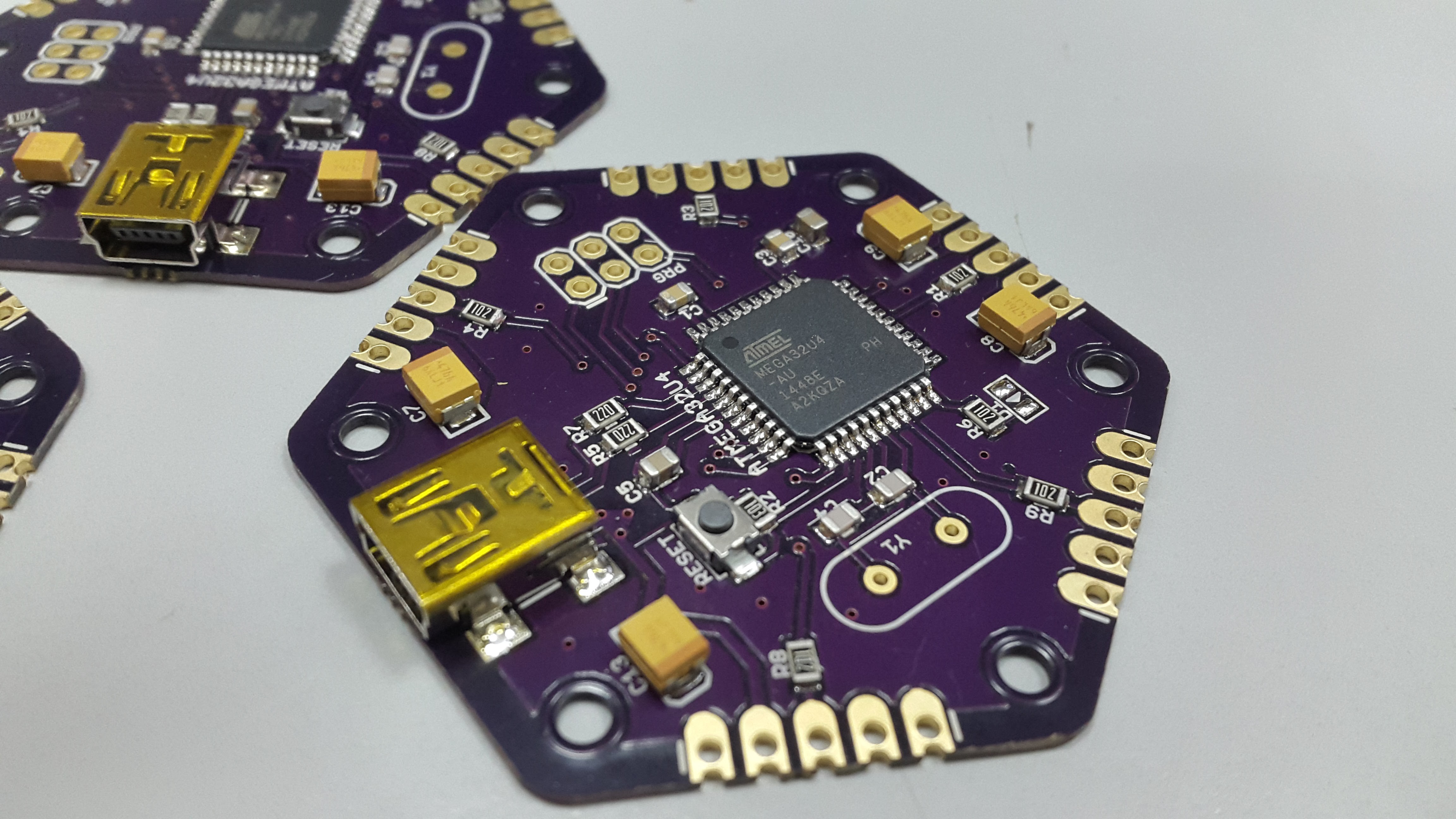

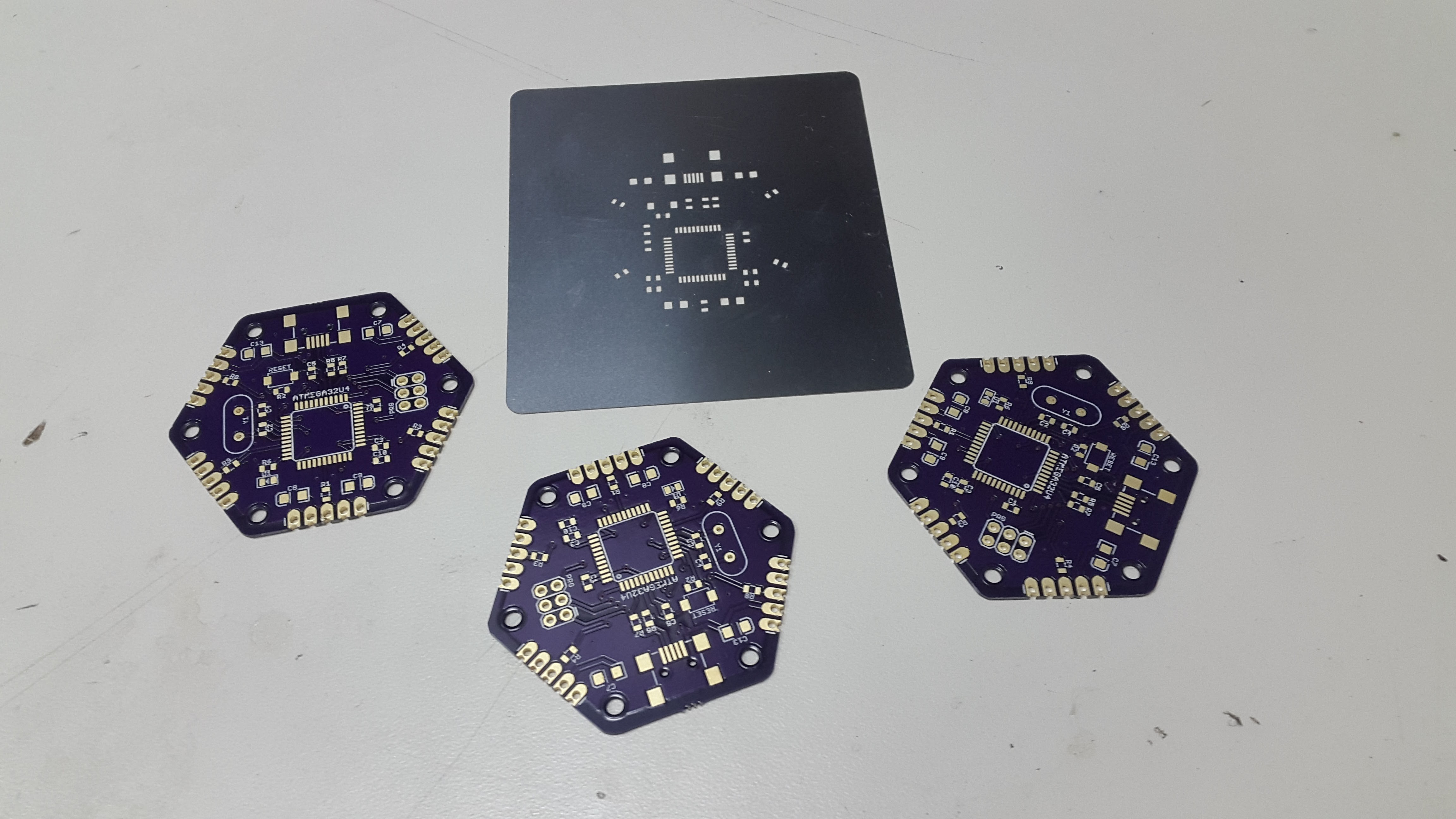

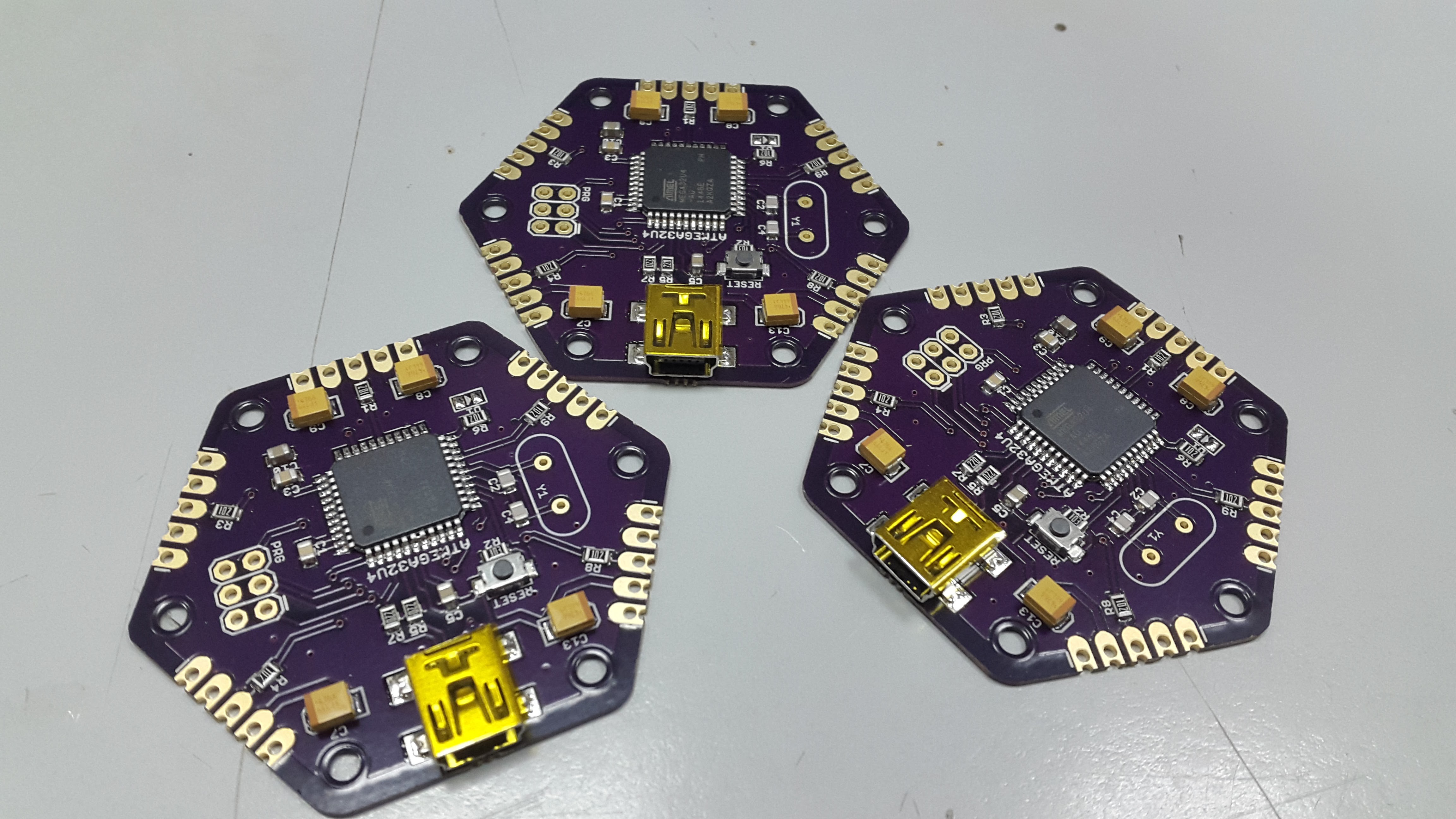

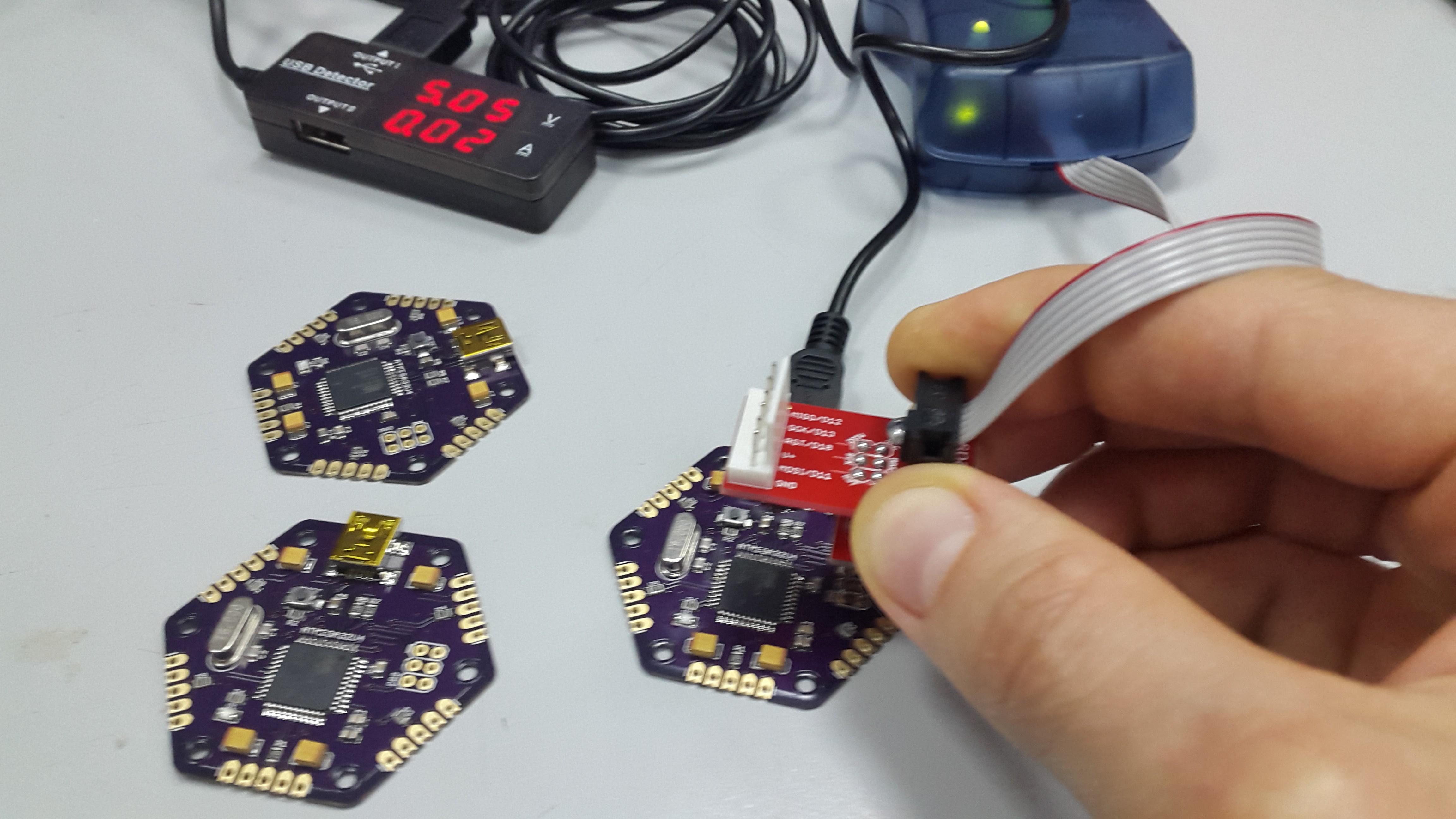

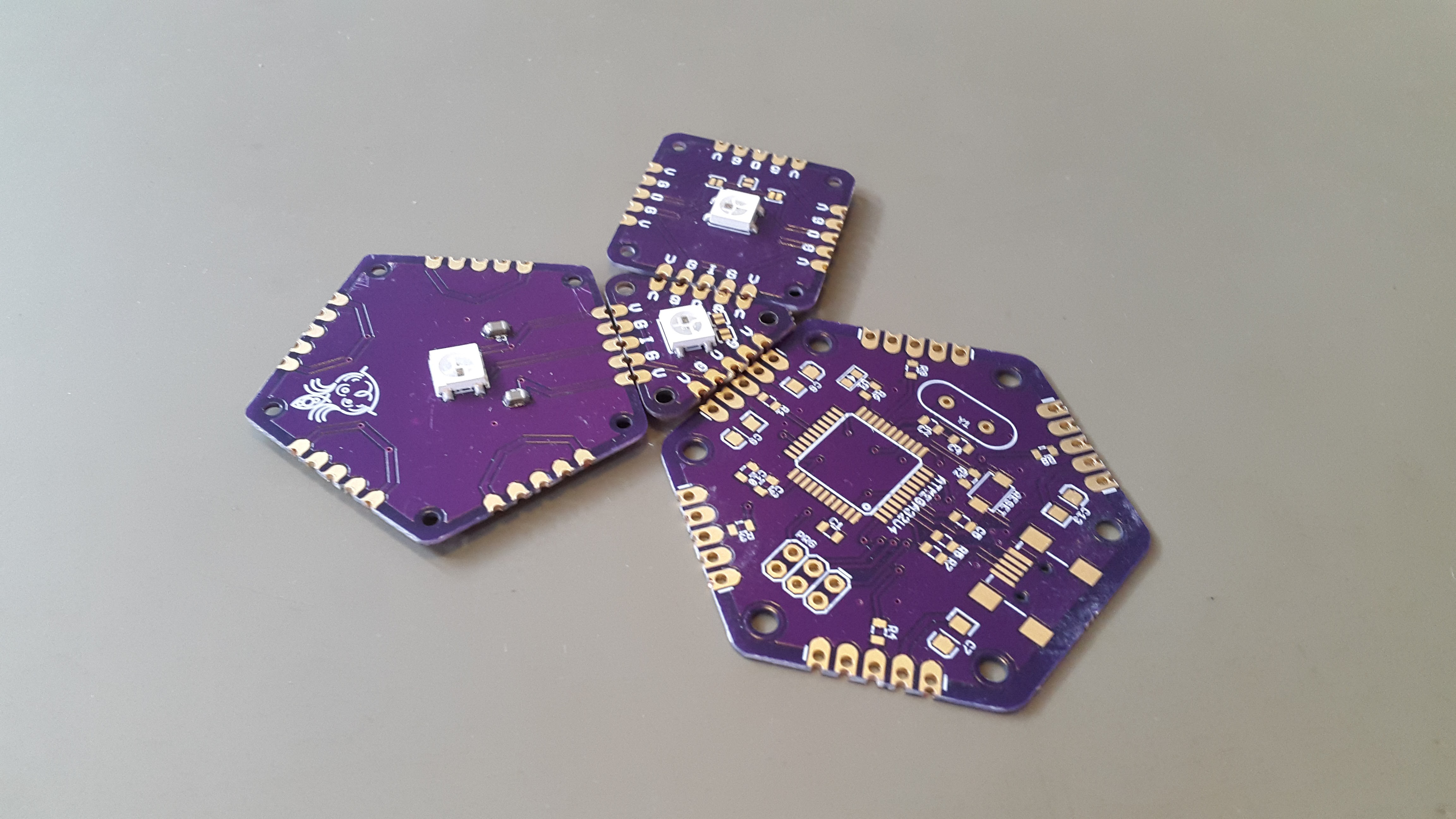

Hexagonal MCU : https://oshpark.com/shared_projects/xangB68O

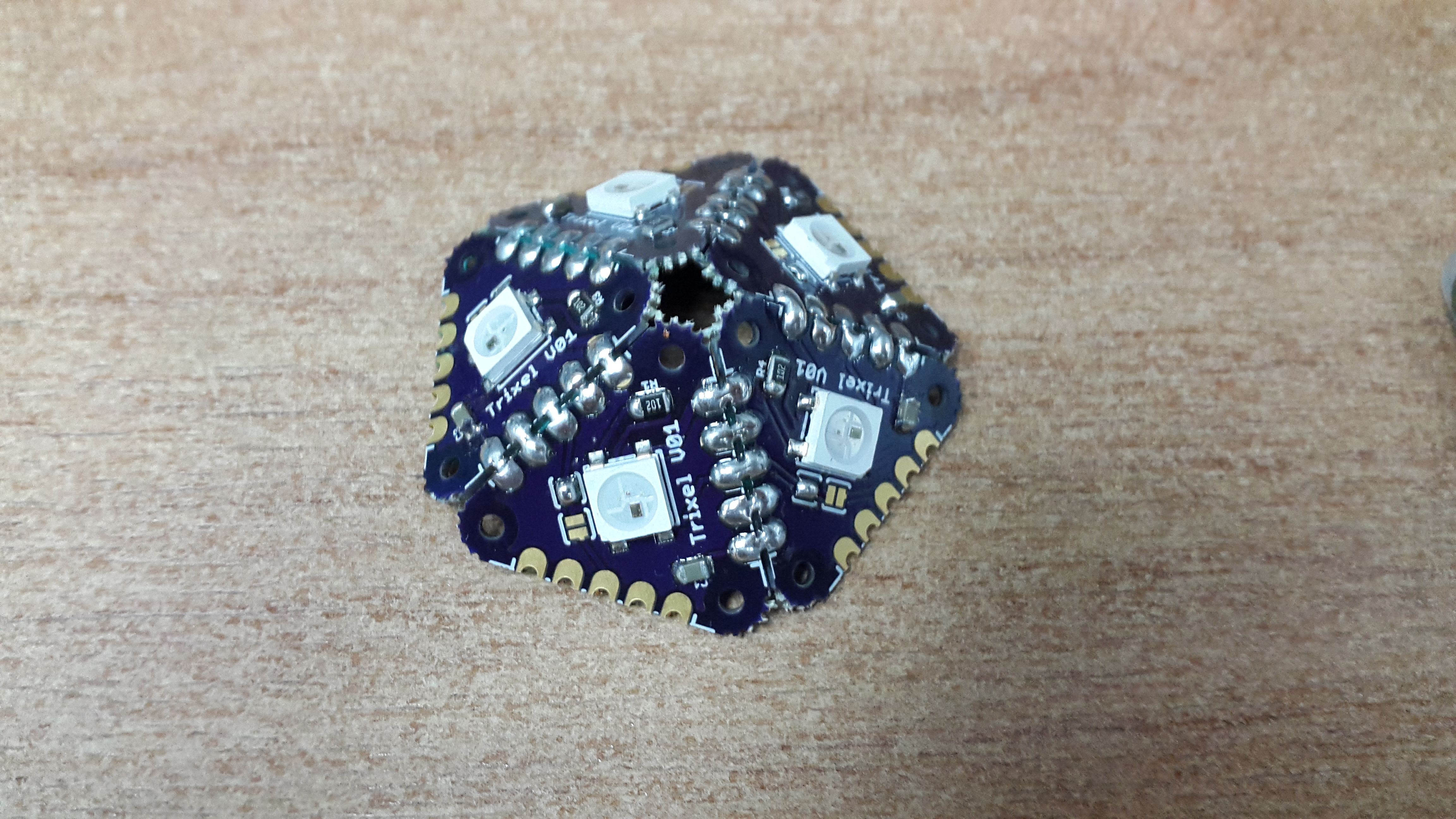

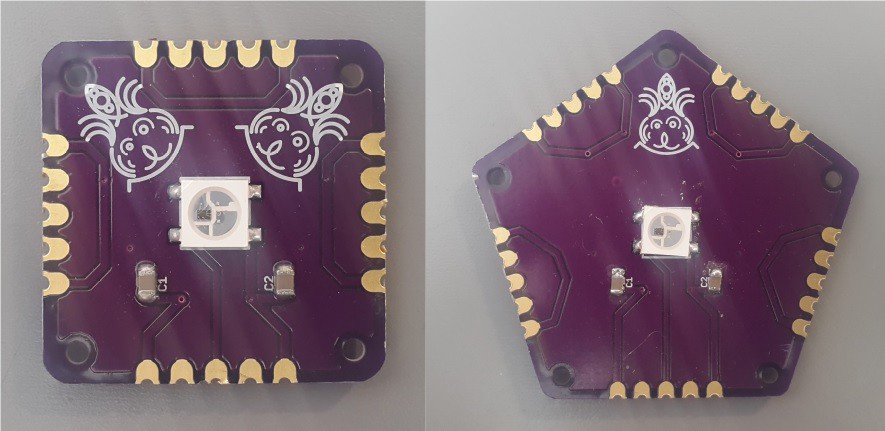

Pentagon LED : https://oshpark.com/shared_projects/5bxh1ML1

Square LED : https://oshpark.com/shared_projects/2S5FQ5g4

Triangle LED : https://oshpark.com/shared_projects/3ms9FD8s

Simple MCU : https://oshpark.com/shared_projects/gn4UkQom

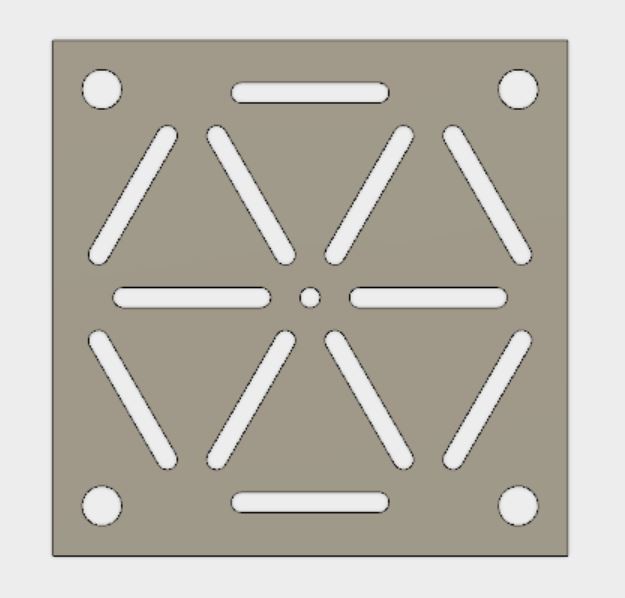

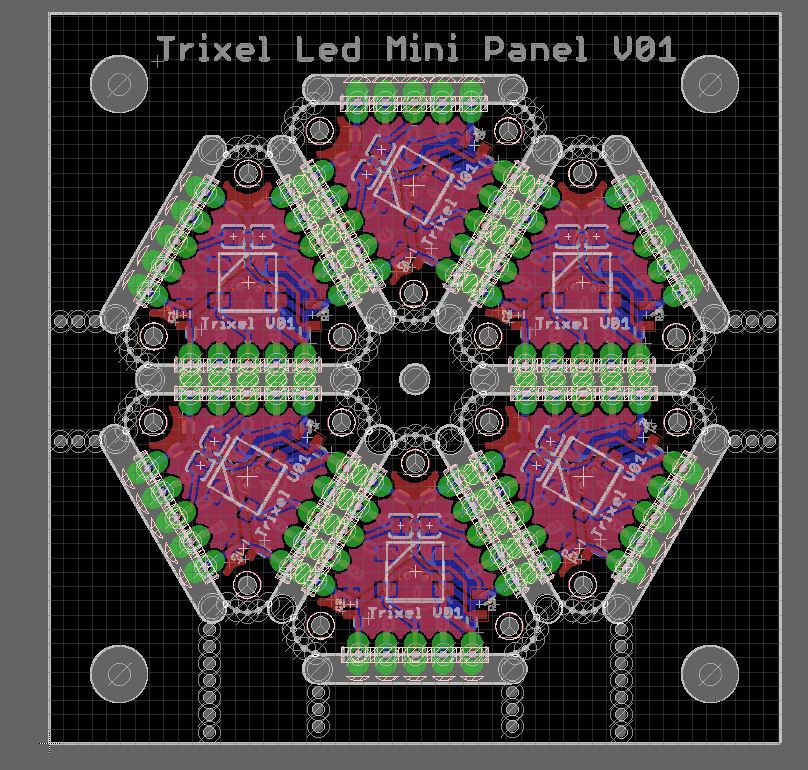

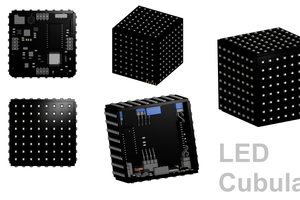

Panels

Trixel mini Panel V01: https://oshpark.com/shared_projects/wMtWZjMH

Arkadi

Arkadi

Jack Flynn

Jack Flynn

Lucas Rolfes

Lucas Rolfes

Paul Gallagher

Paul Gallagher

Bharbour

Bharbour

Well, I was just working on the layout for practically the same thing (the triangle one)... Maybe now I'll just buy yours instead.