Although

RobotDigg is an open warehouse for thousands of products, it's not easy

for us to be specialist for every product, but in order to help

customer better, we determined to study some integrated products of our

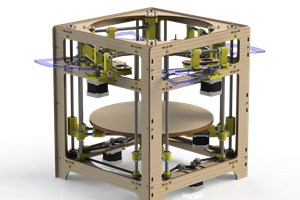

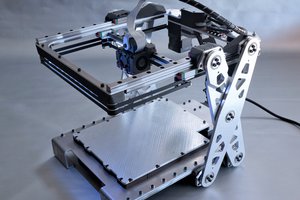

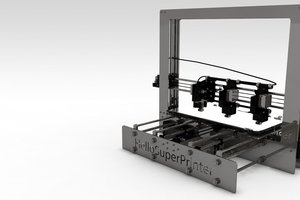

partners by ourselves better in 2017, especially 3D Printers, Delta

Robot Kossel or Rostock, Scara and Modular XYZ. New plan, RobotDigg

member start to bring desktop machine home, study it as green hand one

machine by one, and report what difficulties they meet for us to

understand customer needs better. - See more at:

http://www.robotdigg.com/news/126/Test-on-Scara-Arm-3D-Printer-by-RobotDigg#sthash.YEbi8tX7.dpuf

The picture showed one RobotDigg Lady made scara 3d printer work 1st time with no technical background but with her husband's help. Many thanks to RobotDigg families' support!

A simple worktable is setted up. Let's do it!

Steps:

1,Plug in the power connect computer, don't use win 10. Win 10 will cause vibration. Win 7 Win 8 XP works fine.

2,Set up the driver and plug-in, printer operating system and other software

3,Set up the printer, load the model file, the slice configuration is set.

4,Start printing

Problems comes:

Z-axis transfer does not move, manual operation on software does not move

Solution: The seat for leadscrew KP08 Pillow Block is too tight, Loosen it with a screwdriver

Well, start

Obviously failed

Material can not be implanted

Follow the sprinkler

This is a low-level error:

Borosilicate glass is too slippy to print

Solution:

Masking tape onto the glass

Well, start

Half of the silk half out of silk

Half of the wire can not stick

Obviously

The problem is that the print platform is not flat

Half too near half too far

Adjust the platform

Also adjust the Z-axis parameters

Hit half, do not move

Power off immediately

Encountered a problem unclear

The simplest direct and effective way is to restart the power

There may be a data line is encountered

The transmission is interrupted

It is also possible that the computer USB auto-sleep

The solution is plug-in re-play

This time they encounter a problem

Raise the Z axis when it ignores my command

Go directly to the left end of the stuck also stopped down

Decisive brain rusty funny

At this point of course, can only decisively restart

Prevention: Do not reset the Z axis alone, all the points on the OK reset.

Well, start again

(Why should I say again)

Ah, finally smooth

It takes 1 hour 17 minutes to print a small frog

Technology White can go to drink a coffee

Here omitted two thousand seconds ... ...

what! what happened

How do not spit silk baby

Above half empty?

The original is put supplies rack do too tight

The print wire is jammed.

Well, again.

Uh huh, twists and turns, and finally completed!

The general feeling:

This machine is still relatively primitive

But wins at affordable prices

The use of the process requires some manual adjustment of the place

It took a half day for them to prepare and started to print a frog, they tried several times, finally, a nice frog was ready. Good job!

Her 5-year daughter also felt its funning!

RobotDigg ME

RobotDigg ME

Tyler Anderson

Tyler Anderson

Malte Schrader

Malte Schrader

hello3dprintingworld

hello3dprintingworld

TTN

TTN