Design Goals

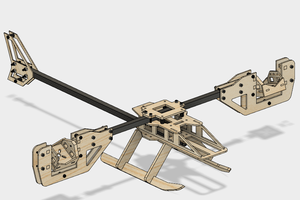

- Make the gear box work with materials that can be cut with a CO2 laser.

- Make a motor part of the design. The shaft of the motor should carry the first gear

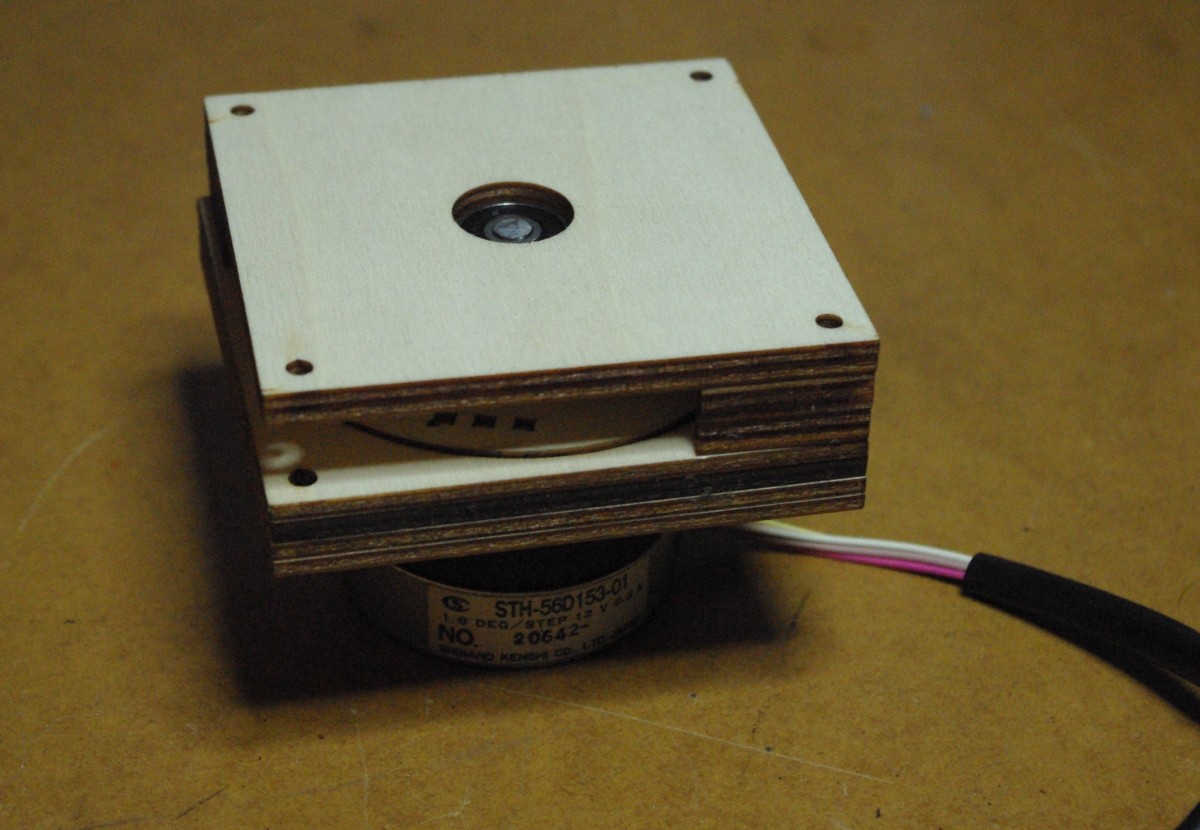

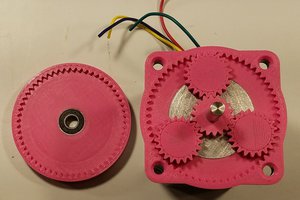

- Have a closed housing to allow lubrication with grease and avoid stuff getting into the moving parts

- Take into account that with increasing reduction torque increases also. Make later gears in the gear train stronger

- Provide proper bearings - at least for the output shaft. Allow hooking up belt drives or wheels directly to the gear box without a coupling to a supported drive shaft.

- Have parametric generators. Generate a gear box with the desired reduction. Have multiple designs spanning the range of gear ratios if necessary.

Design Patterns

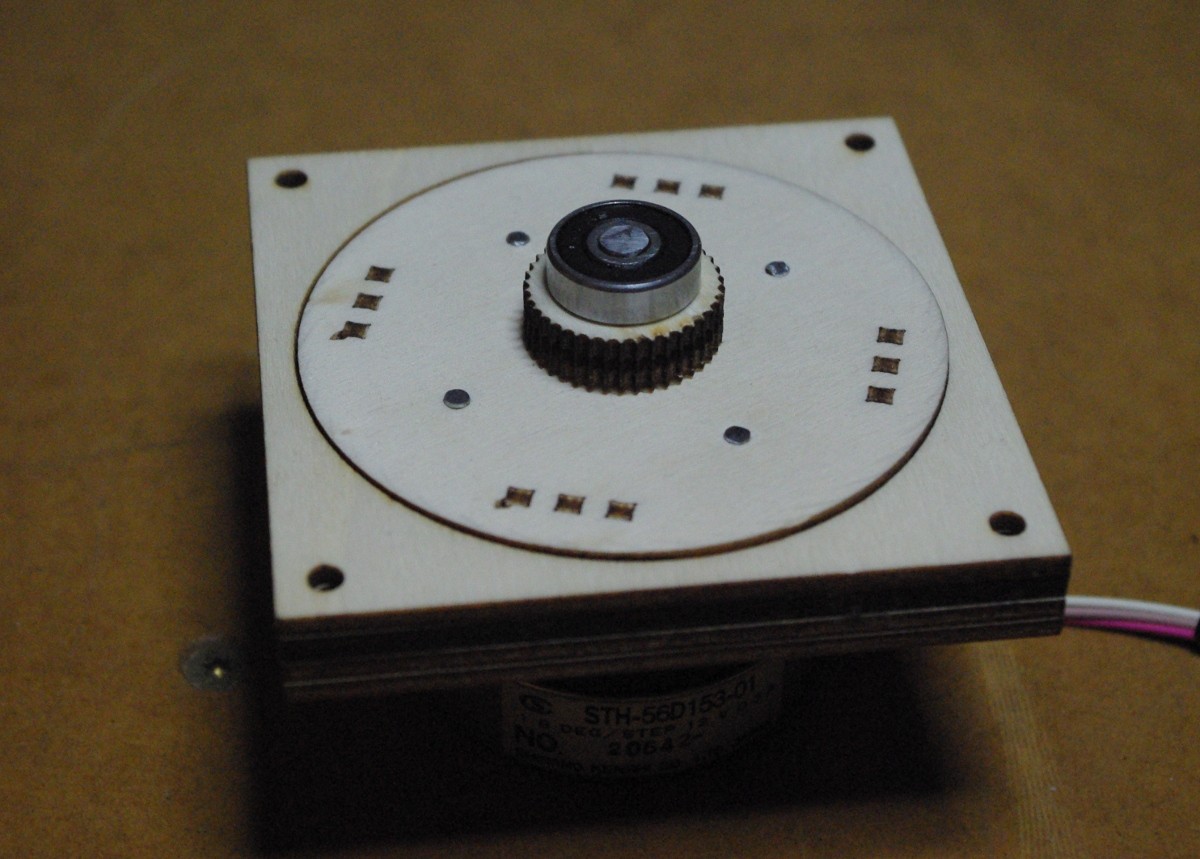

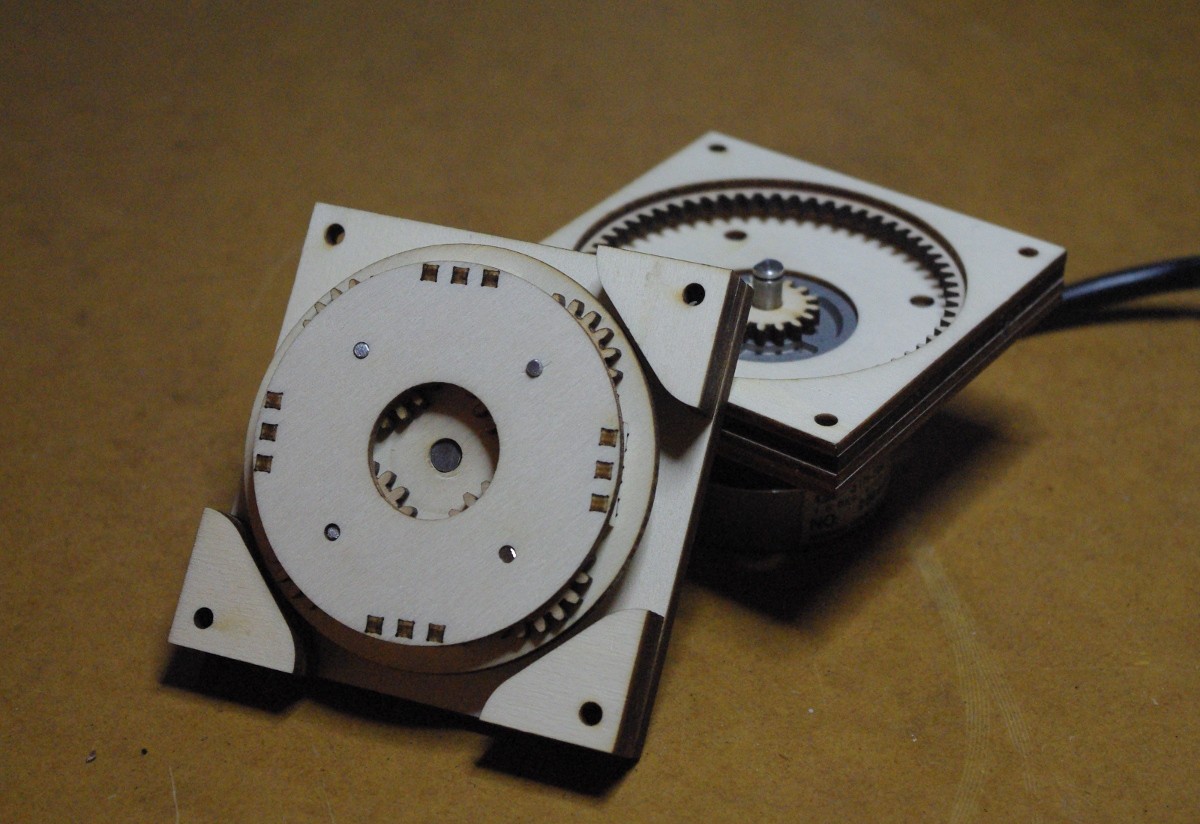

As laser cutting is pretty much 2D we need means to create 3D structures. Besides the finger joints for joining sheets in a 90 degree angle which is already extensively used in Boxes.py the gear boxes will make use of sheets glued together on top of each other. This allows creating different thicknesses from one type of sheet material and stud holes for shafts and bearings. To allow precise glue up small parts like gears with get holes for alignment pins. Bigger parts will get slots on the outside that other sheets or laser cut clamps fit into and so force the layers into alignment.

As the box will be made from relatively soft materials the output shaft will be supported by ball bearings which not only reduce friction but also increase the area supporting the forces.

I want to try if it is possible to get away with using normal machine screws as output shafts. Hex bolts should make it easy to transfer the torque. It is still unclear if they really fit a ball bearing properly. They also create the problem of mounting them as they end within the driving gear.

Florian Festi

Florian Festi

FiveseveN

FiveseveN

Spencer

Spencer

David Troetschel

David Troetschel

Daren Schwenke

Daren Schwenke