Whole setup

Whole setup

I needed one month. However I saw my first self made electron beam. I have had to over come multiple challenges.

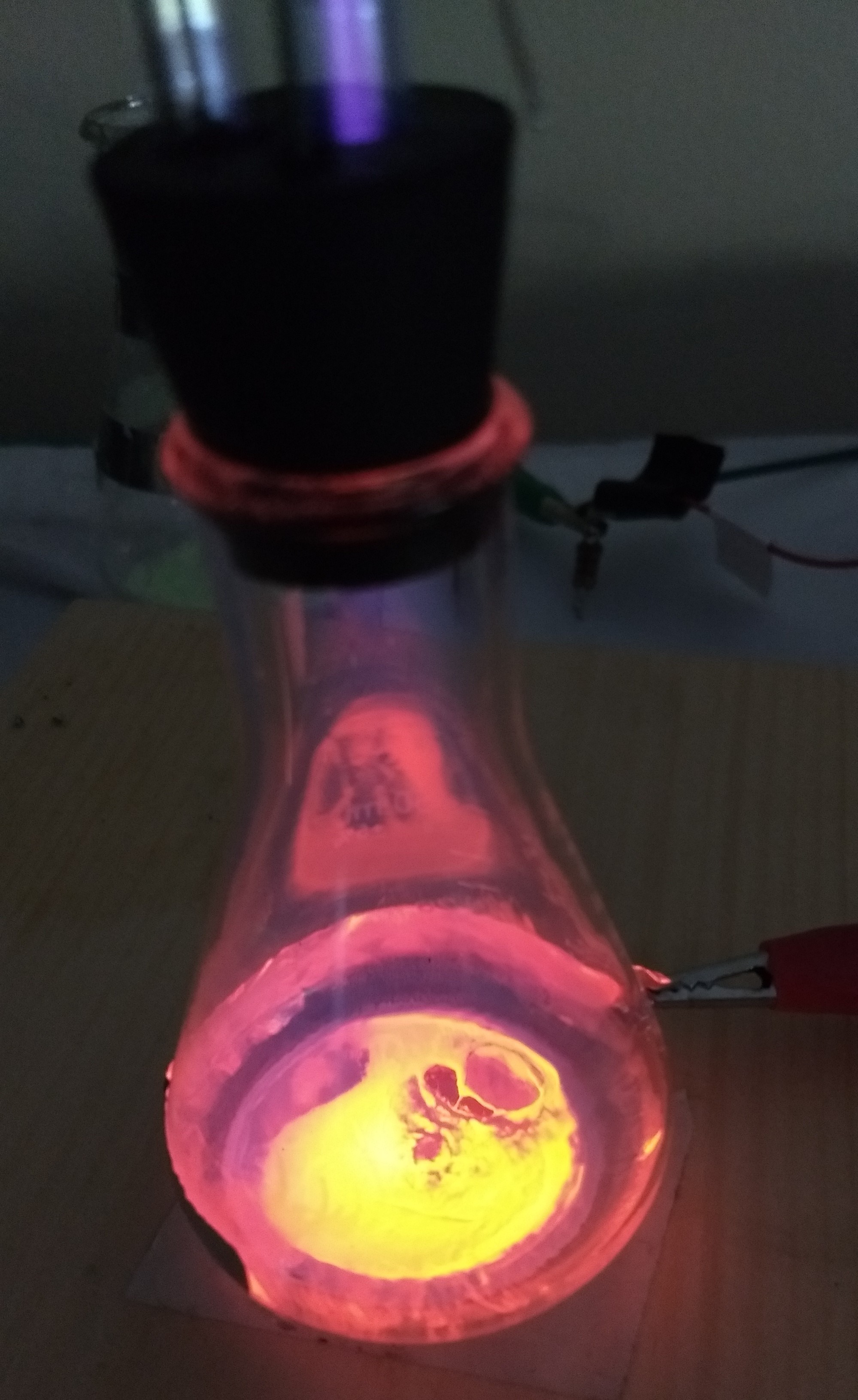

pure zinc sulfide glows red by electron detection

First of all I wasn't sure what the right material was to make an electron beam visible. I thought that I needed a type of phosphor because the most web pages speak about a phosphor screen for the visualization of an election beam. Luckily, I found some pages that mentioned zinc sulfide is the right material.

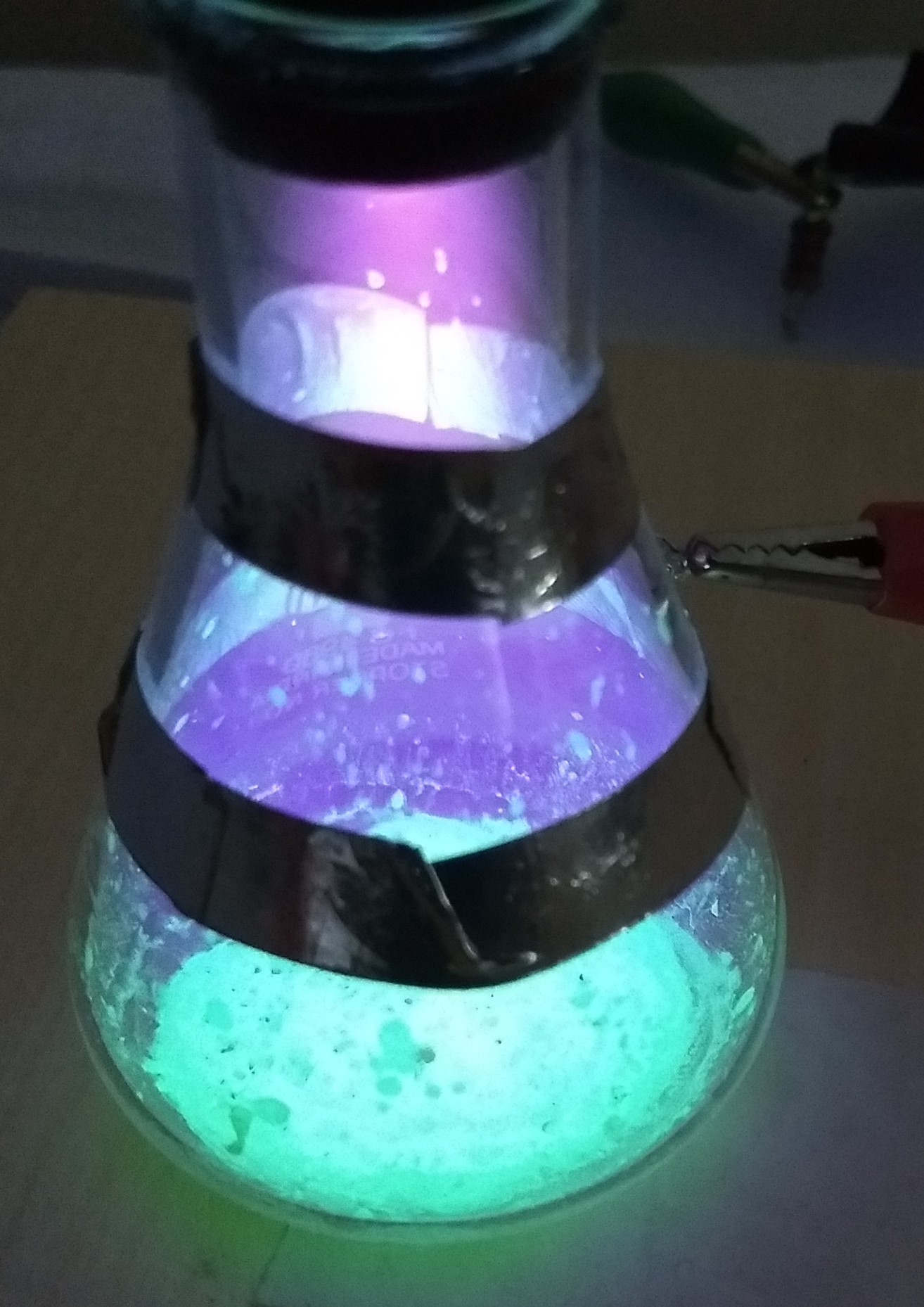

glowing in the dark powder also called zinc sulfide with copper (ZnS:Cu) glows green A very common and good available mixture is zinc sulfide with copper (ZnS:Cu) or also called glowing in the dark powder. It has a long after glow effect even on light. To build a screen mix zinc sulfide powder with water and a little bit of glue and let it dry on the bottom of the chamber. I recommend glue because without it the screen isn't stable. Otherwise it could happen that the screen blows away by returning air when the vacuum is released.

glowing in the dark powder also called zinc sulfide with copper (ZnS:Cu) glows green A very common and good available mixture is zinc sulfide with copper (ZnS:Cu) or also called glowing in the dark powder. It has a long after glow effect even on light. To build a screen mix zinc sulfide powder with water and a little bit of glue and let it dry on the bottom of the chamber. I recommend glue because without it the screen isn't stable. Otherwise it could happen that the screen blows away by returning air when the vacuum is released.

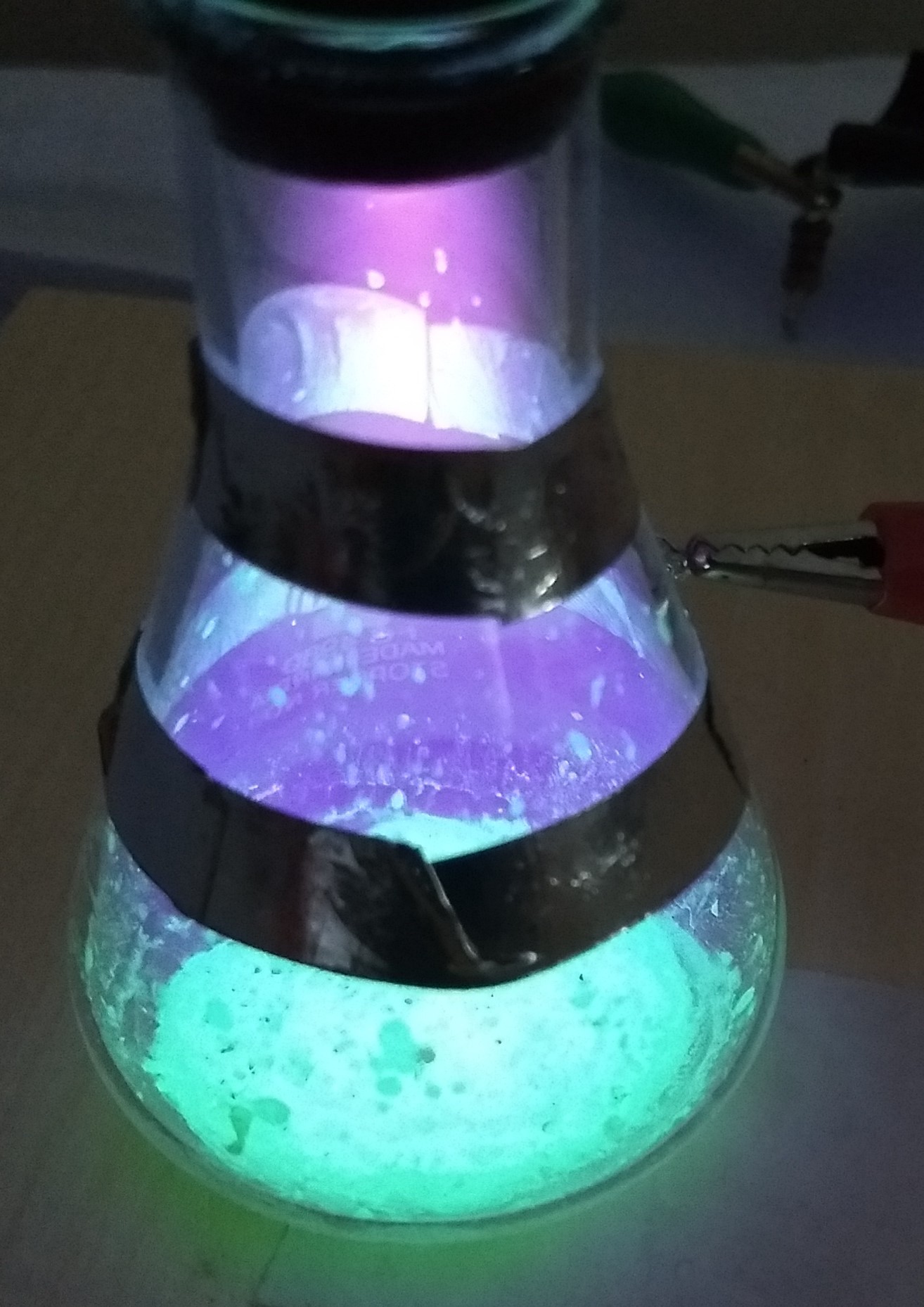

glowing caused by light

glowing caused by light

Unfortunately, I thought a long time that I see electrons even if I saw just light. The effect that the spot didn’t move either by an electrical or by a magnetical field made me distrustful.

Spark gap

The second main issue was that the voltage collapses from 6kV to 500V by applying it to the plasma tube. Whereas the high voltage is required to accelerate the elections enough to build a beam. Maybe the reason that the voltage collapsed was a non-suitable vacuum or not strong enough power supply. Anyway, I solved this issue by including a spark gap in the circuit of the plasma tube. This spark gap let the voltage rise until it's big enough to create a spark. Once the spark appears, the high volt is applied and accelerate the electrons properly. The spark gap is made by a piece of the LDPE vacuum tube and two spikes.

Discharge rings made of aluminum foil

Discharge rings made of aluminum foil

A third issue was that the out part of the tube need a anode to discharge the chamber. I putted just a little bit of aluminum foil around the chamber and connected it to the anode.

The video show the whole set-up and further more what happens if

- The Discharge ring isn’t connected to the anode?

- How adjust the voltage?

- What happens without a spark gap?

- What happens with a wrong polarity?

- What do the plasma in a magnetic field?

Chris.deerleg

Chris.deerleg

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.