The laser module is nearing a stage of what I believe could be a minimum viable product. The customer has to decide on this though. The earlier design in Freecad was upgraded to a closed box using the Freecad LCInterlocking module.

The copper laser module has been removed from the housing to safe cost and space. The laser was also not in the center of the black housing which is a problem with alignment.

The MVP will be sold without two cylinder lenses, this saves space and reduces cost.

A user can then upgrade afterwards. The cross scan error can be kept low by keeping the focus point near the exit of the box. The final version will also feature prism with edges parallel to <1 arcminutes instead of <5 arcminutes.

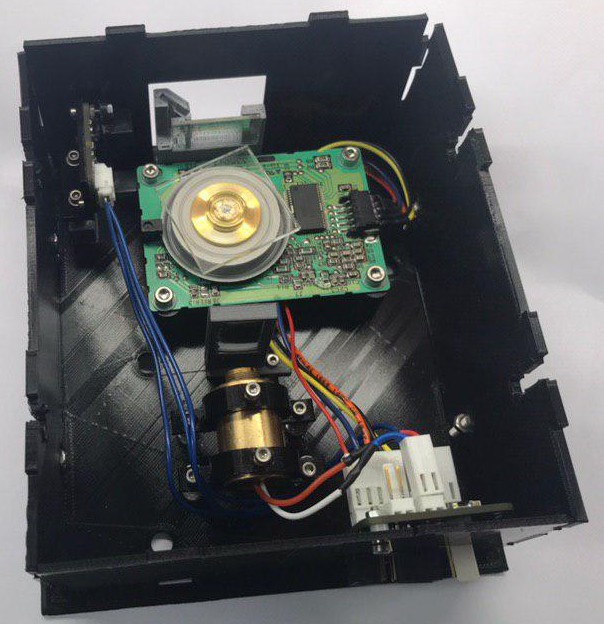

A top front view of the system.

A top view from the system from the reference point of the laser. A mirror can be seen that is used to redirect the laser to the photo-diode which is protected by a black cap.

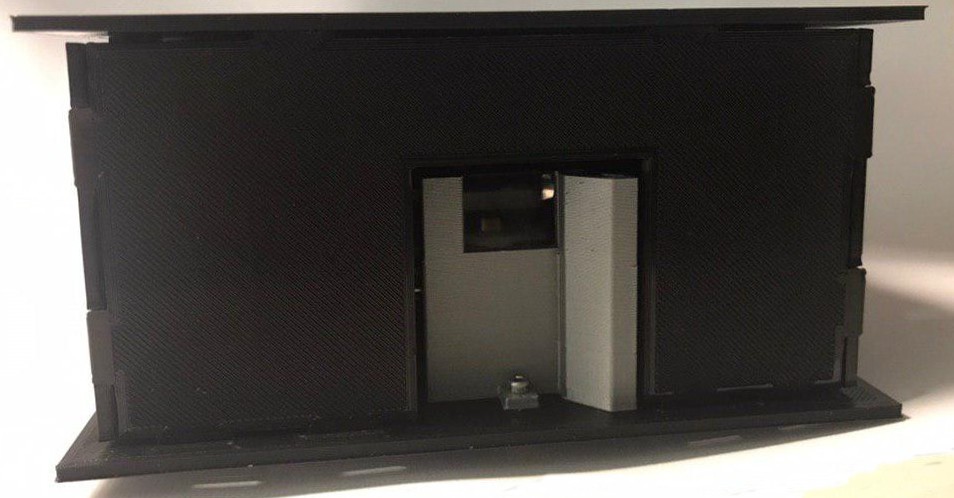

The module is quite small, 140x130x60 mm. The back has two connectors one plug for power; 12V, 5V and GND. The other plug is for a ribbon signal cable.

The module is quite small, 140x130x60 mm. The back has two connectors one plug for power; 12V, 5V and GND. The other plug is for a ribbon signal cable.

In the front only a small opening is left for the laser bundle. The scan line is typically in the order of 8 mm. Possibly, in a future version an automated shutter is added so it can be protected from dust.

The product shown is close the minimum viable product I plan to release. I am making a second module and will then demonstrate the technology by making a PCB.

Hereafter, I intend to test market appetite for the technology and see if there is demand for 10 units. Another approach would be to measure metrics like likes or views of the video.

Hexastorm

Hexastorm

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.