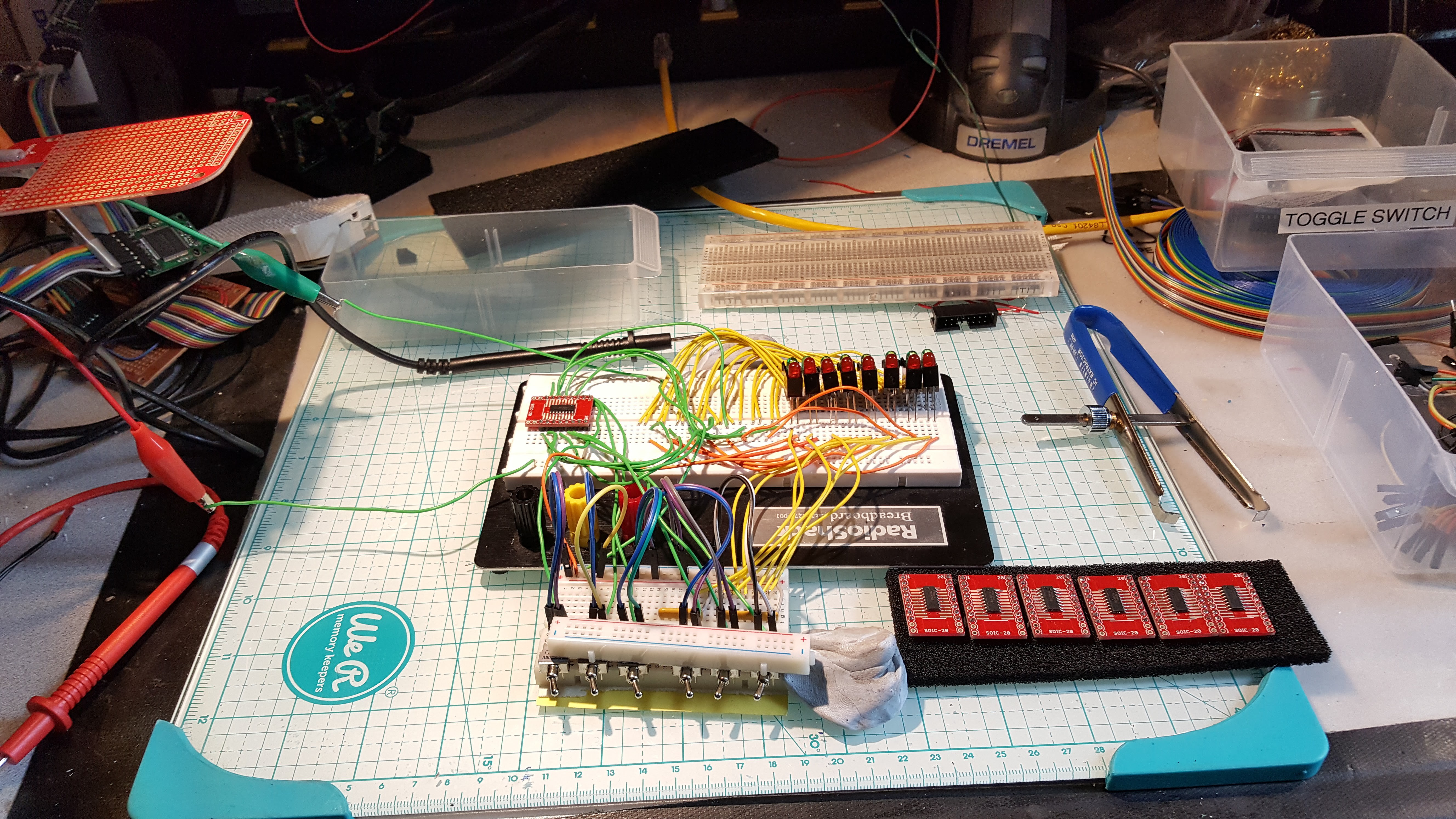

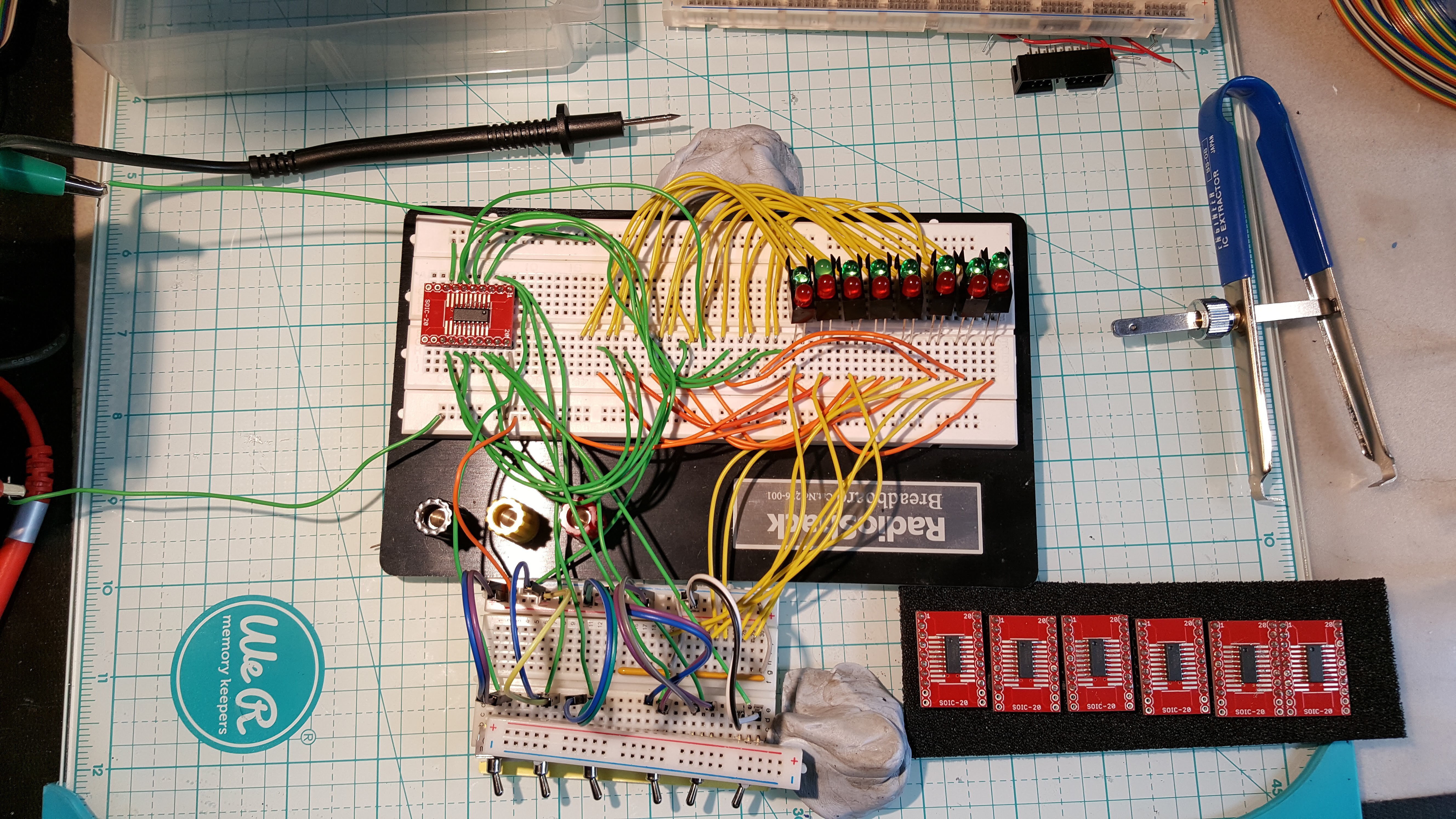

The first precursor assemblies for the full buildout are done. These are sleds that allow me to integrate a SOIC-16 74VHC139 Dual 2/4 decoder with the DIP prototype card for a BeagleBone cape. Of the 8 built, one was lost to solder gremlins in the oven, the other 7 came through the test with flying colors. The pictures show the test jig I whipped up. For simple stuff like this I would rather throw together a test jig with 5V/Gnd switches and LEDS than use the logic analyzer…. Less time wasted trying to figure out if you have the LA configured correctly J The assemblies themselves are visible to the right on small red circuit boards, and one is still in the tester.

I like trying to keep as much of the signaling with the Beaglebones at 3.3V as I possibly can. I have used various level shifters, and I find they can introduce mysteries into the comms signals that I really have no great desire to solve for. The cameras run at 3.3V and the only added complexity is the fact they can’t pull their power from the BeagleBones 3.3V rail, unless I want another magic smoke incident.

Which brings up the next (and last) precursor assembly, the camera interface board. This takes a 16 conductor ribbon cable with camera bus signaling (SPI/I2C) and an 8 conductor cable taking the 8 outputs from the 74VHC139. It also takes an external 5V connection, runs this through a pair of 5>3.3V stepdowns https://www.adafruit.com/product/1065 and feeds this to each camera bank on the 3.3V power rail. The incoming bus signals are split and delivered to two independent 4 camera busses, and the 8 signal lines are directly routed to the chip select line of the associated camera. This provides the 8 individual camera I/O connections. Oh, and the damn thing is noise sensitive. Really nastily noise sensitive. And I don’t want to do a differential. So wiring quality is important L

After that the cables get build, the camera capes to provide endpoints for the 2 ribbon cables and integrate the 74VHC139 are built and mated to the BBB’s and then the built out version goes into lens calibration. It does make for a nice break from all the nasty math.

Mark Mullin

Mark Mullin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.