This revision was planned to have a trippler baseboard, a mini lite and a battery shield from Wemos, an ADC module (attached to the third base) all soldered to the baseboard in order to reduce the height of the device. However, following the experience with oldered battery shield for the revision 1, I decided to socket all these modules. As it turned out later, this was a wise provision to make.

A new ADC shield was constructed first. It is hanging over the protoboard, supported by the four curent limiting resistors and held in place by soldered connections. This shield is not serviaceble or replaceable (unlike the one for revision 1) but has much lower height. Breadboard wires can be convenietly connected to either female pine headers (like in the revision 1), or to screw terminals (like in the photograph below)

or to turned pins header (which to some extent limits applicability of the voltmeter to other uses). In order to keep the height low the third option was selected for the revison 2:

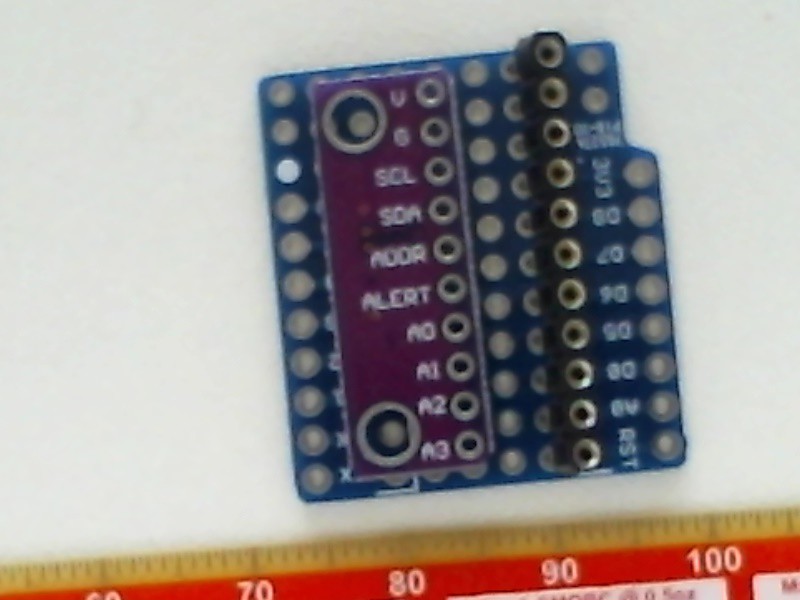

layout before soldering

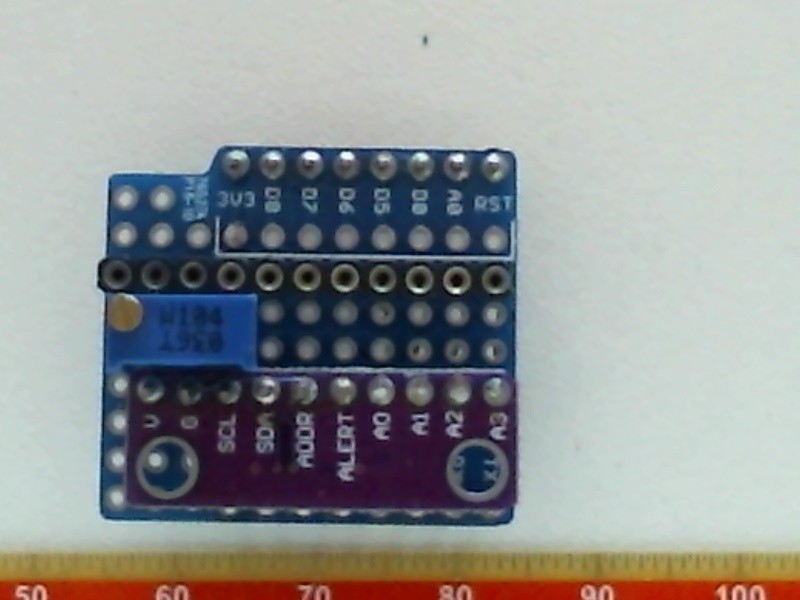

fully assembled shield, top view

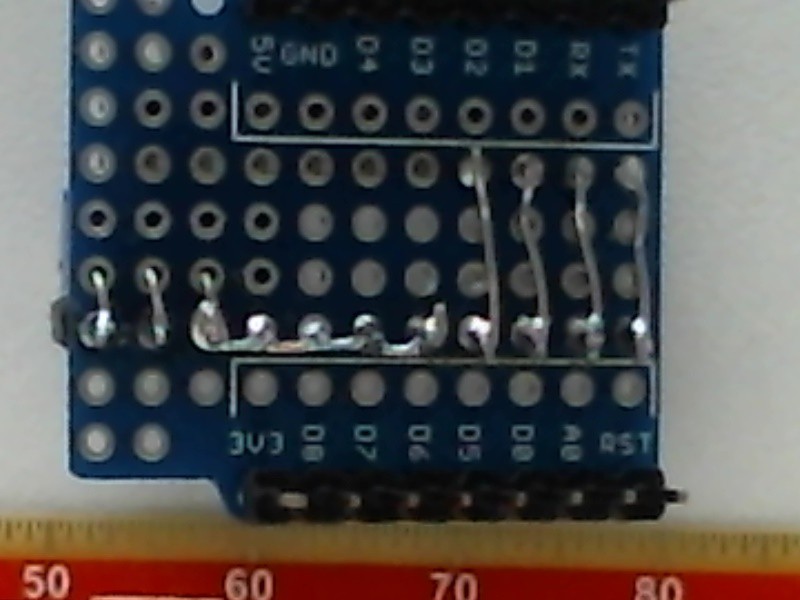

partially soldered shield, view from the bottom

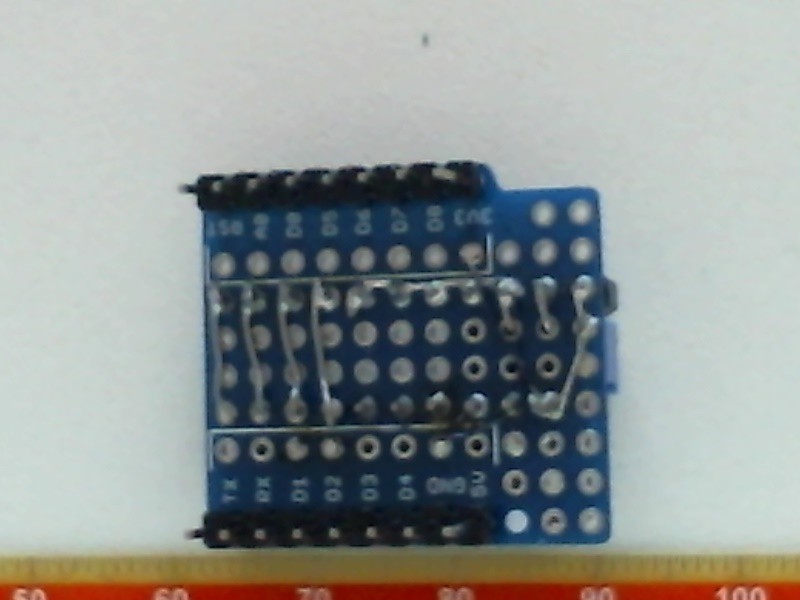

fully assembled shield, view from the bottom

Four pins on the right were soldered to the protection resisotrs' leads, the following four pins were grounded (you can never have enough ground pins, this is for sure), and three remaining pins were connected to the on shield potentiometer in this order ground, wiper, +3.3V. The potentiometer was added for the ease of testing and calibration of the voltmeter. The remaining connections were realised using solderable enamel insulated wire - it is almost invisible and thin. Unfortunately it is not easy for me to use it even for a few required connection although some people can do wizardry with it.

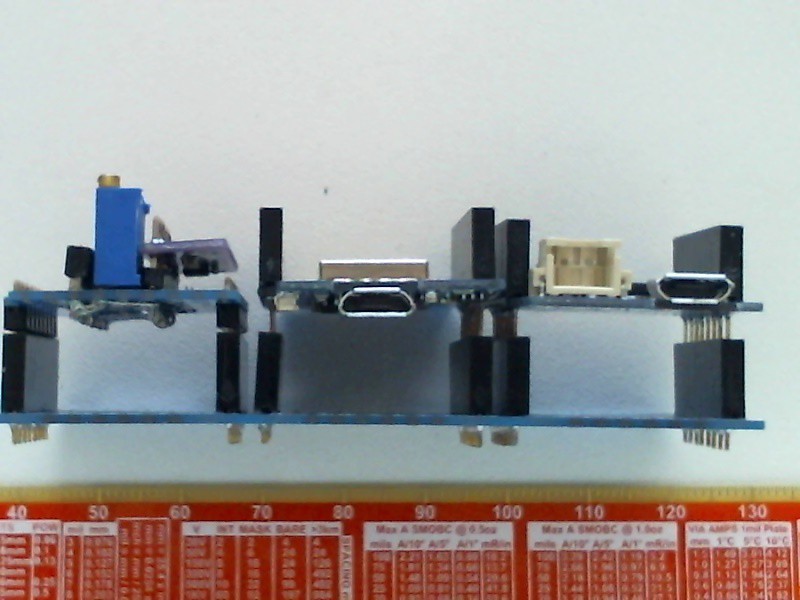

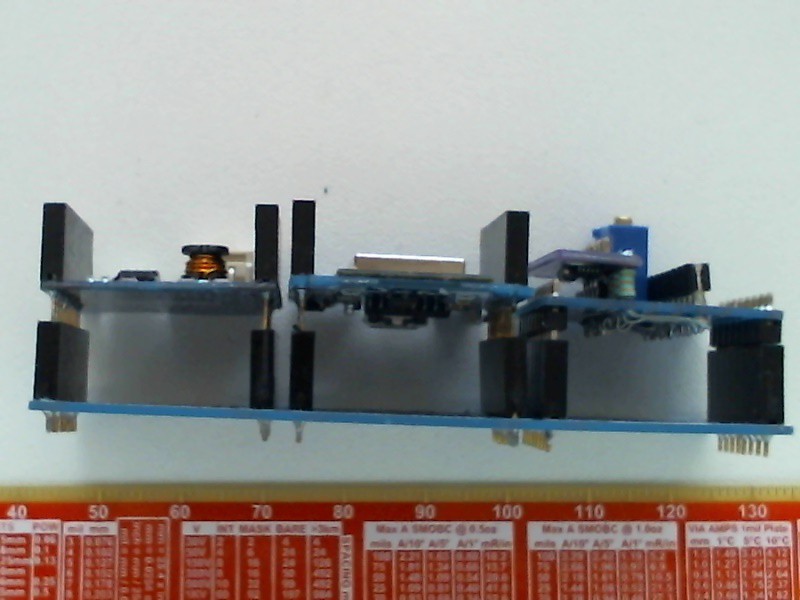

Socketing the shields brought about an obvious drawback of increased height of the prototype

So what was the benefit? It was nothing to do with the physical dimensions but it simply made it possible to continue with the development. Mini lite module should have been a cheaper and smaller option for the fully developed design comparing to the mini module. I have acquired two Wemos mini lite modules, one of which was soldered to stackable connectors and could be abused by inserting it incorrectly but the second was not soldered at all. I tried to flash the freshly generated firmware into both the modules using the NodeMCU flasher, making a compulsory change from default DIO to DOUT setting and 4MB to 1 MB in the Advanced tab (I laso lovered flash sped to 20 MHz just in case). The socketed module could take the firmware after a few attempts but the second one refused to accept any firmware bigger than about 500 kB (may be half of the flash became unusable for some reason or could not be written to by the NodeMCU flasher ?). I also noticed that both the ESP and the on board voltage regulator were running very hot indeed. May be this was the reason for intermittent stoppages of communication between the ESP and the ADC shield. Unfortunately Wemos did not released the schematic of mini lite module yet, and it is difficult to say whether this behavior should be attributed to some my misunderstandings or ignorant actions, design oversight, components working outside of their specified operating conditions or being faulty, assembly mistake(s) etc. (Maybe the battery shield is not even compatible with the mini lite?)

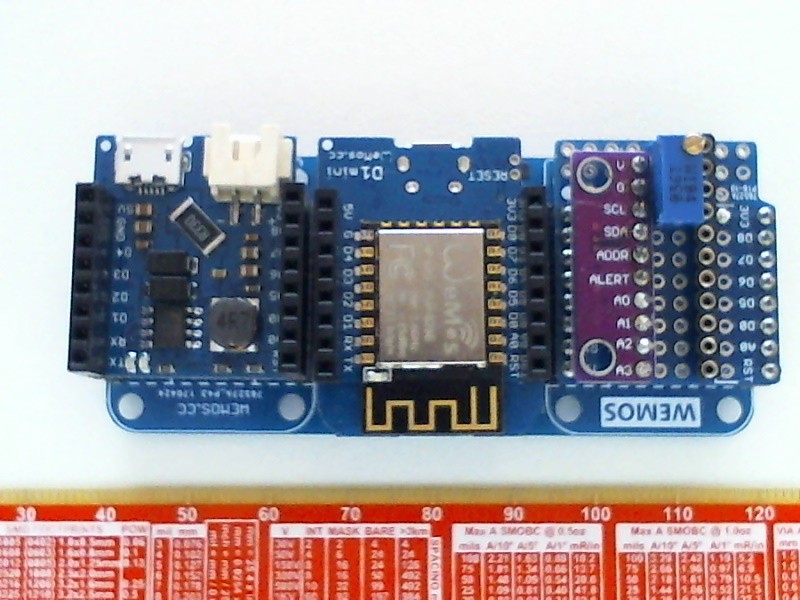

Not soldering the mini lite module allowed me simply to insert a mini module instead, and complete the development of a completely prototyped device. I may want to revisit flashing and operating the mini lite shields in the future but for now I am sticking to Wemos mini modules.

Therefore the hardware used for finalising firmware and web page developments looked as follows

Final warning - do not forget to unplug the programming USB cable from the mini module before plugging the battery (or USB charger cable) into the battery shield.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.