Right now, go and look at each project log entry for design details, as I work out how best to use hackaday projects, there are presently 5...

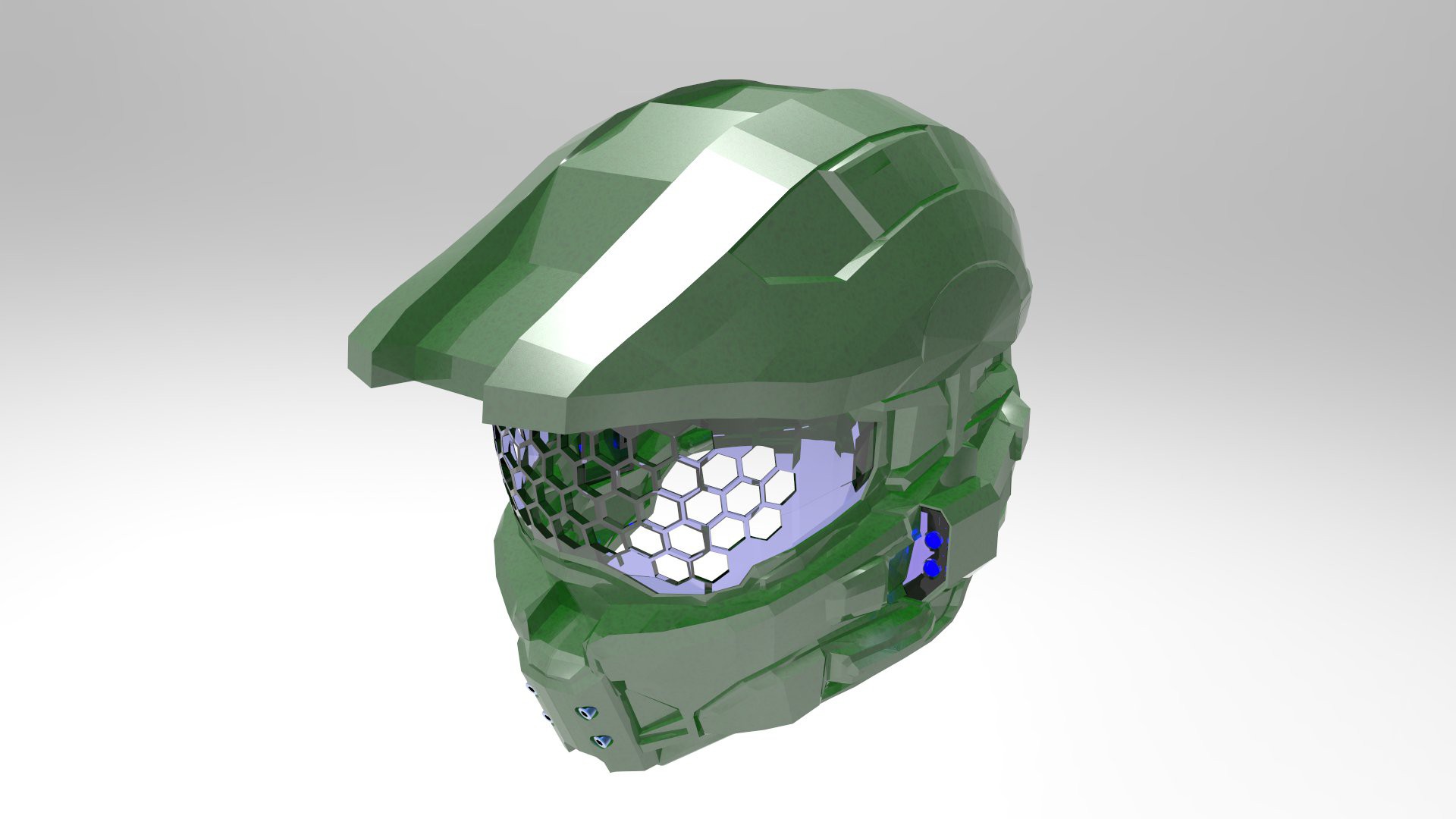

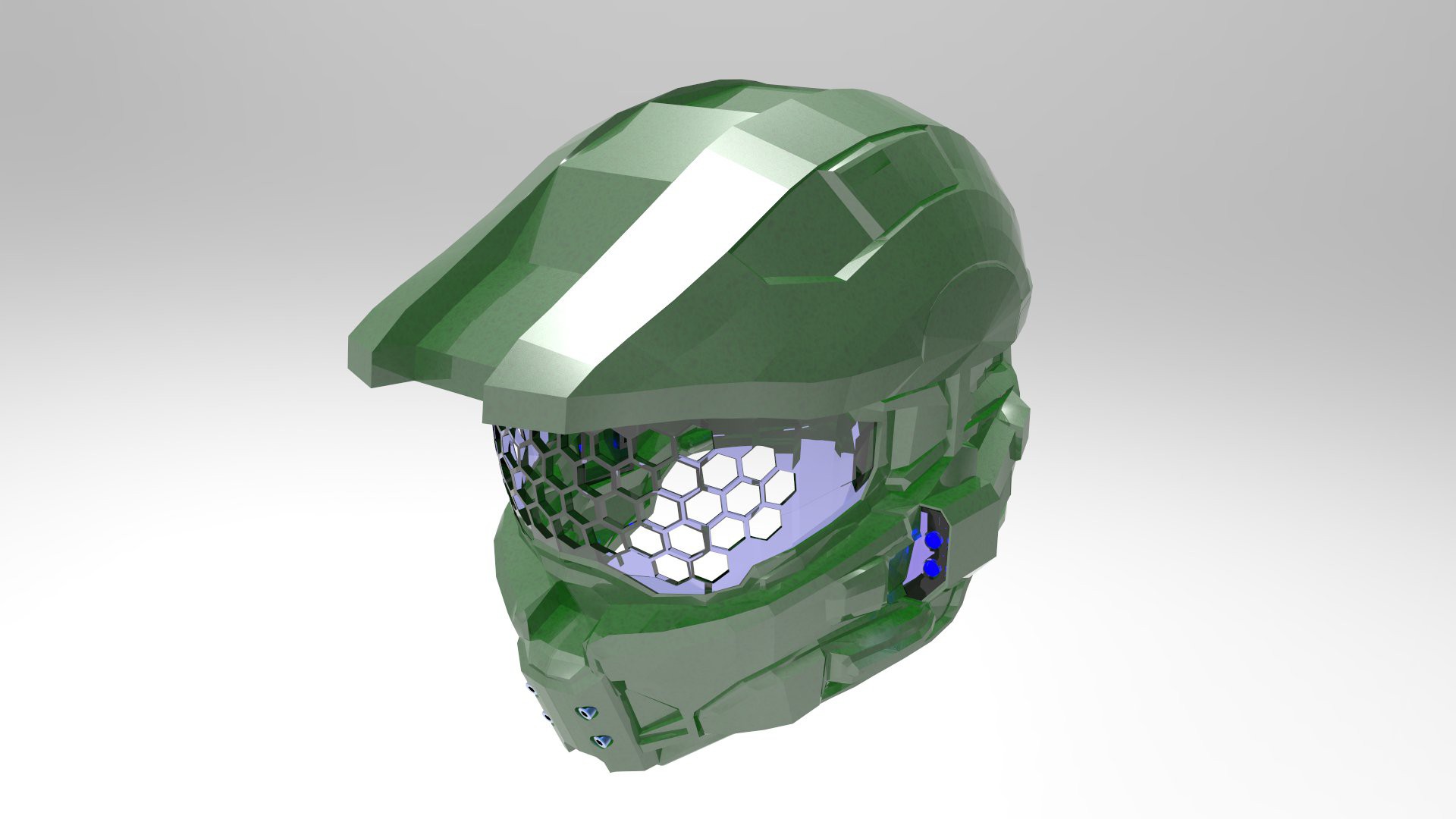

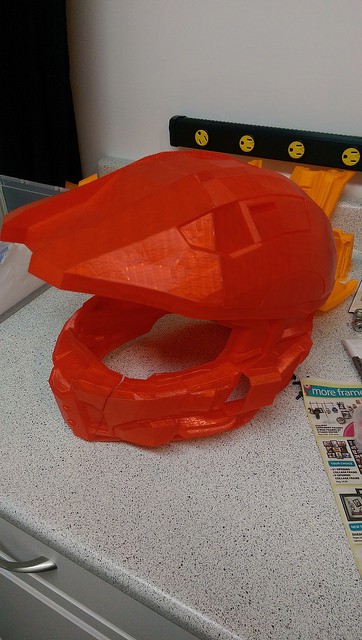

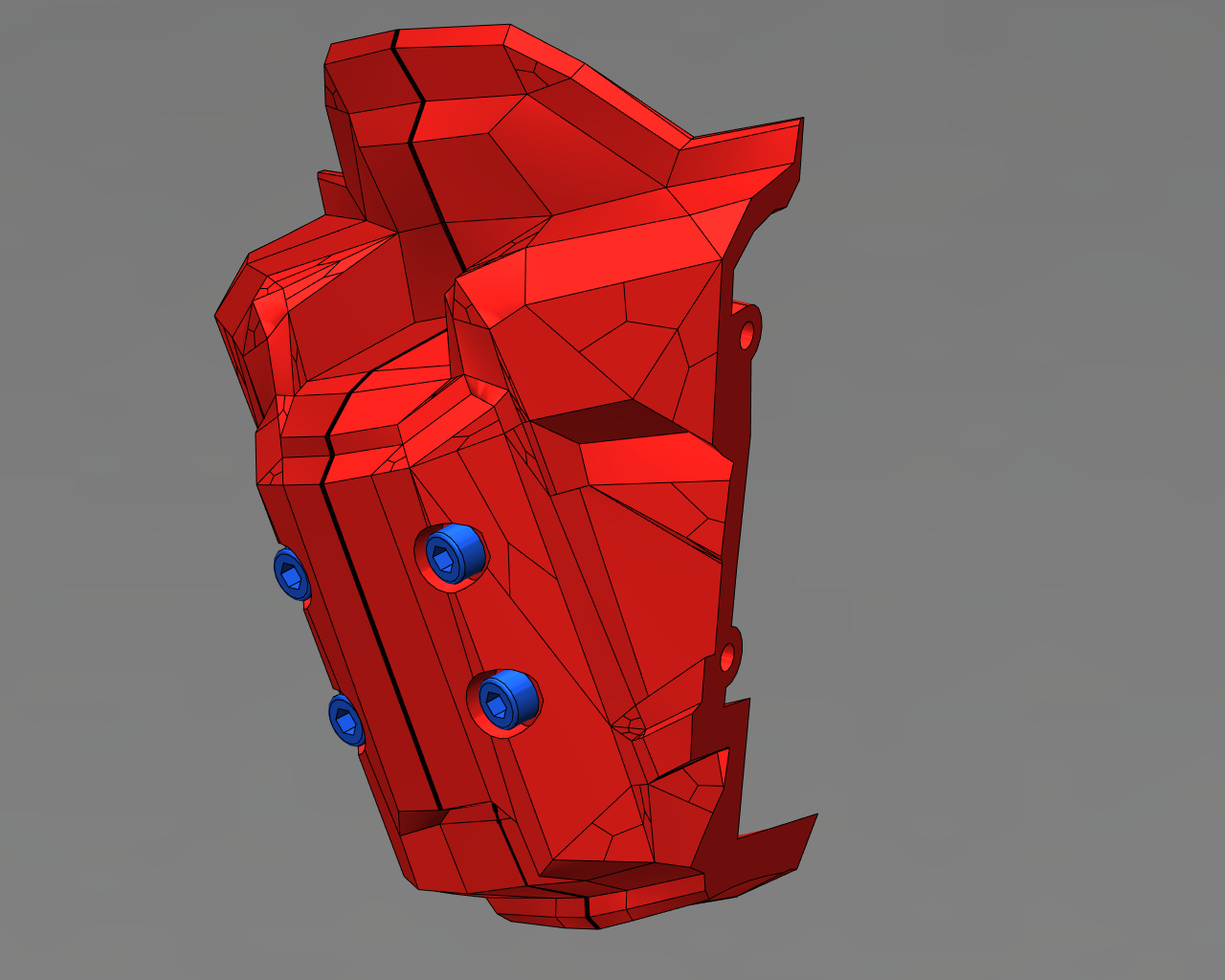

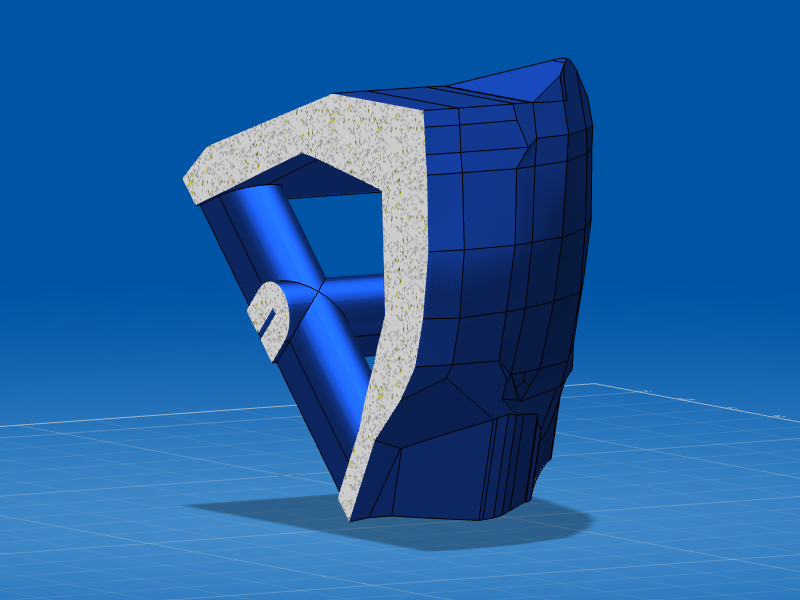

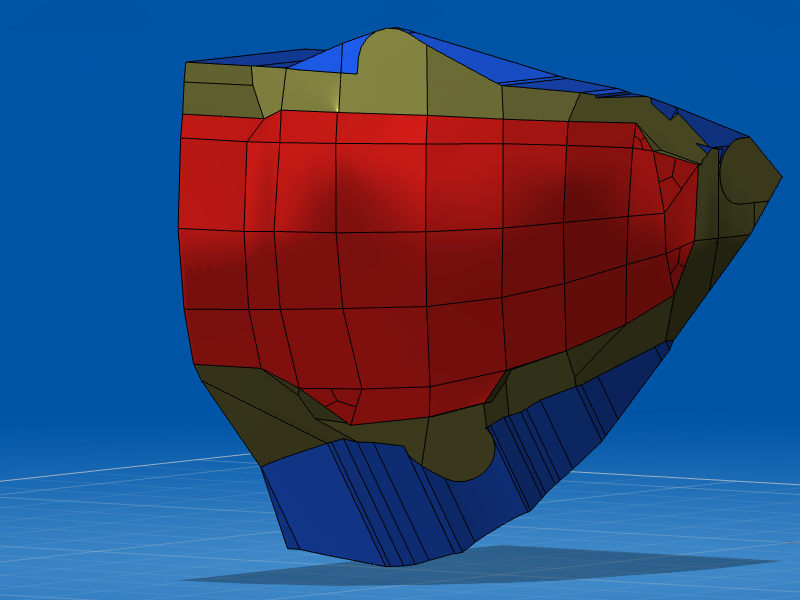

3D printable Halo 4 Master Chief helmet in various sizes...

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Right now, go and look at each project log entry for design details, as I work out how best to use hackaday projects, there are presently 5...

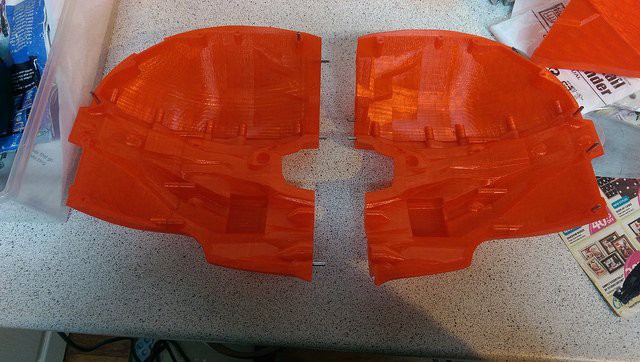

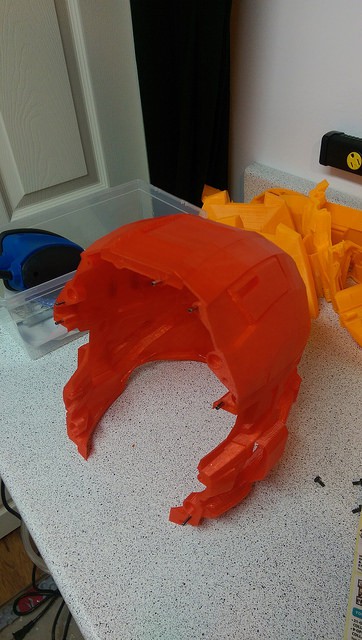

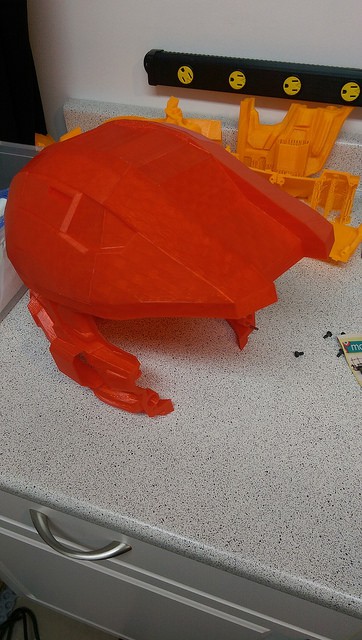

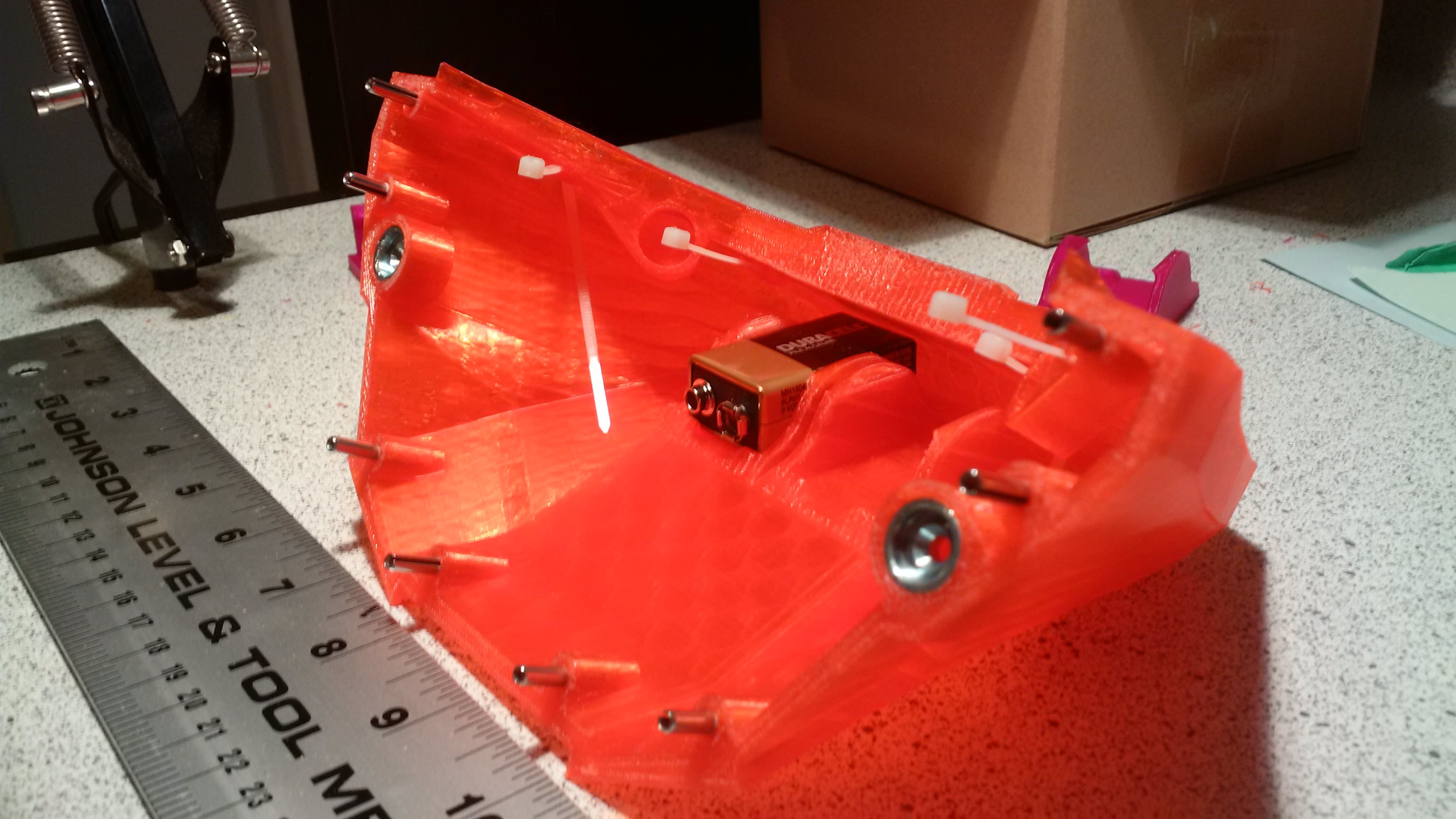

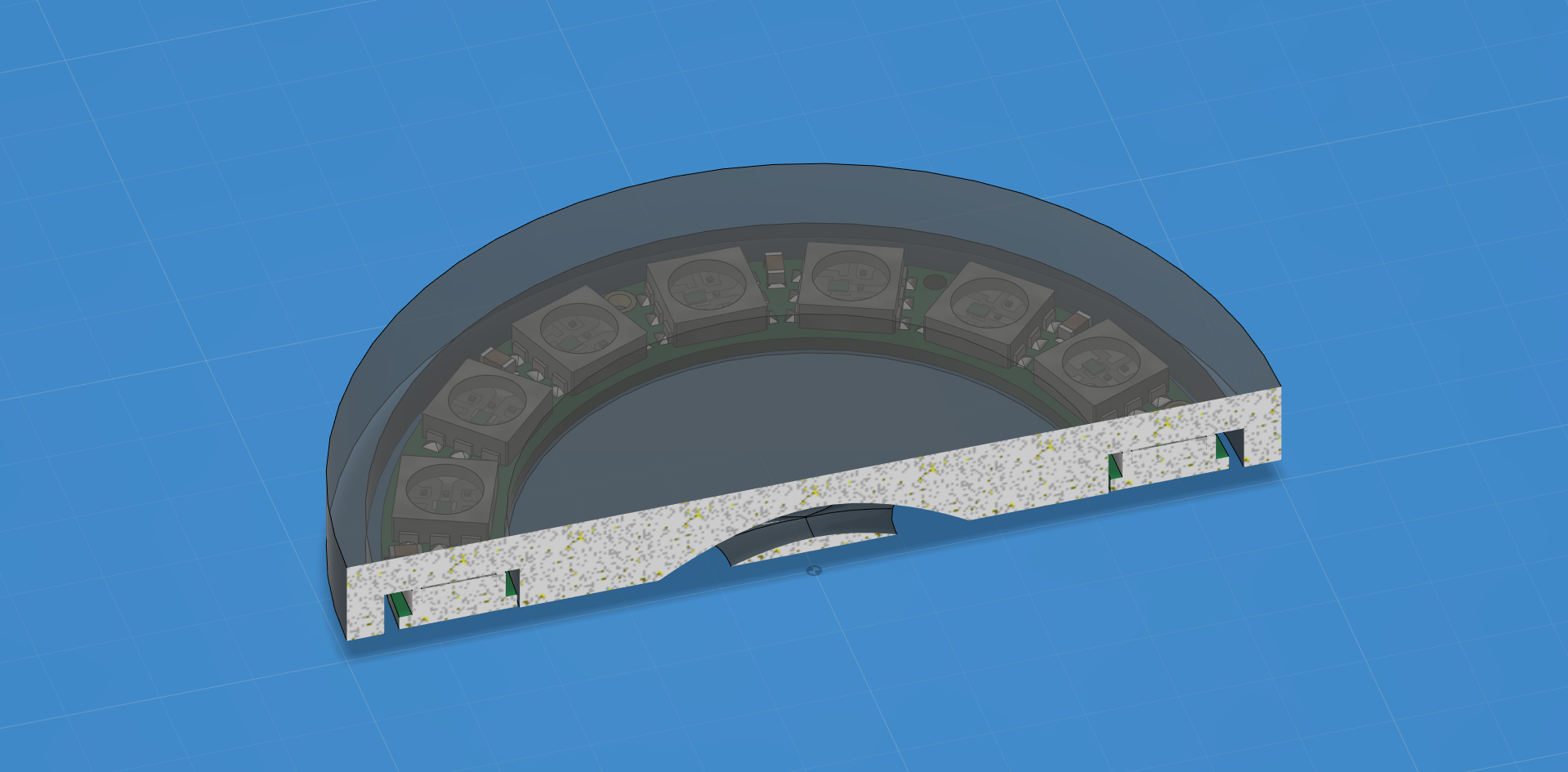

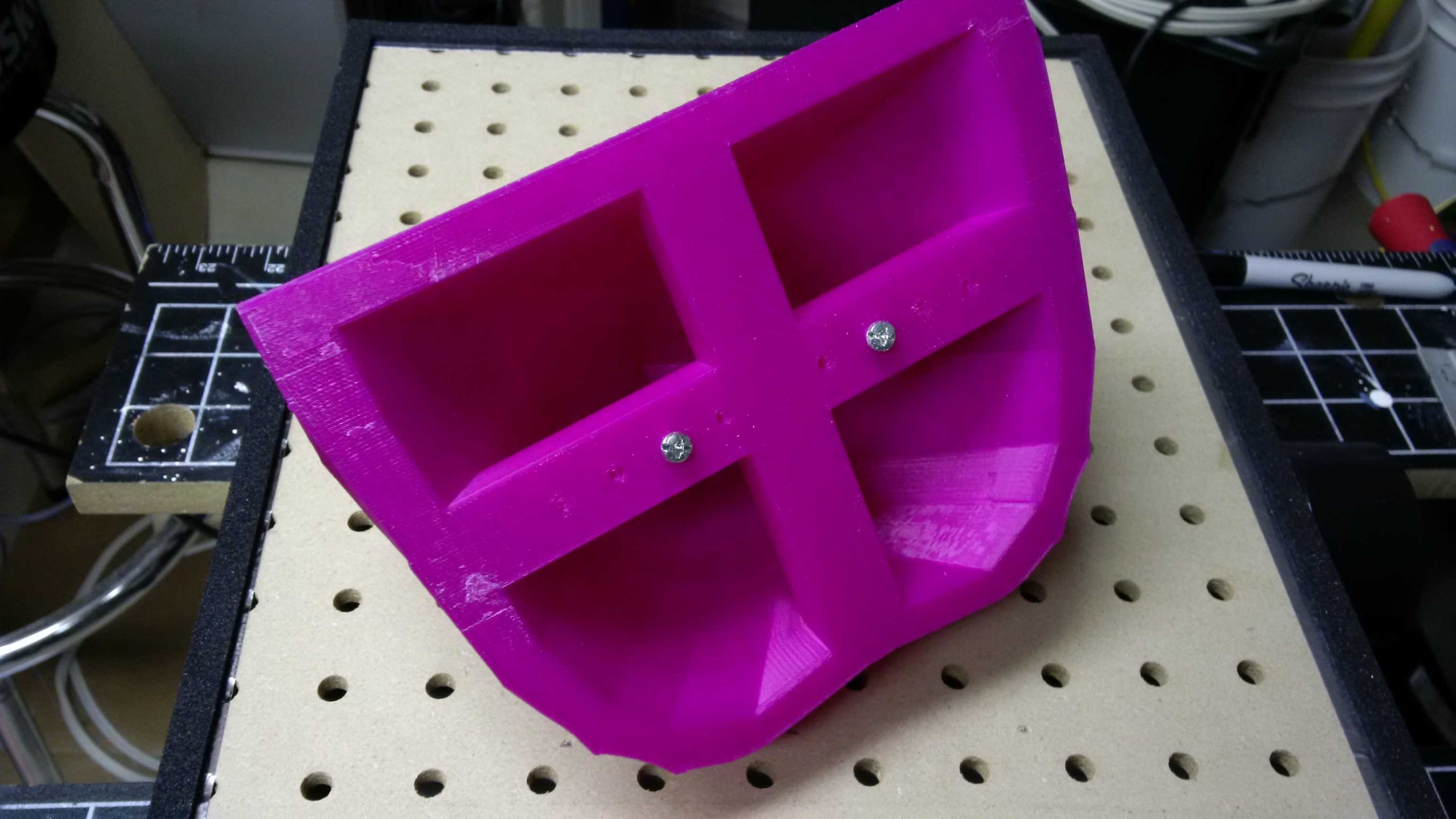

Noting I don't cover magnet inserts in these images, it is just a quick and dirty assembly order for a helmet made with large parts. plastic inserts for back fan and lights are also not shown.

Start with a jowl and rear bottom piece

Attach together

next take a temple and top piece, in this case a printed as a single large part

Attach to form a full side

Repeat for other side

Now take the roof and back piece, ( back fan and back bottom printed as one large piece )

Attach to made one long center piece

Add a full side as assembled previously

Then the other side

Add the peak

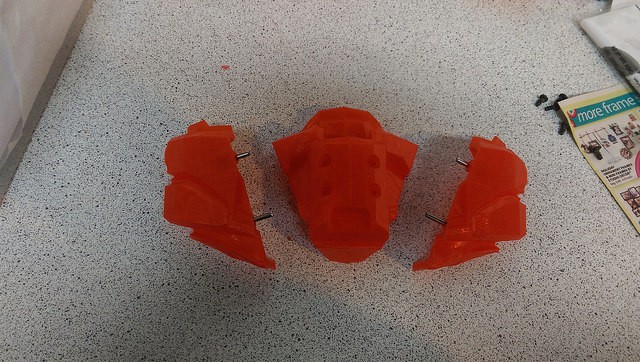

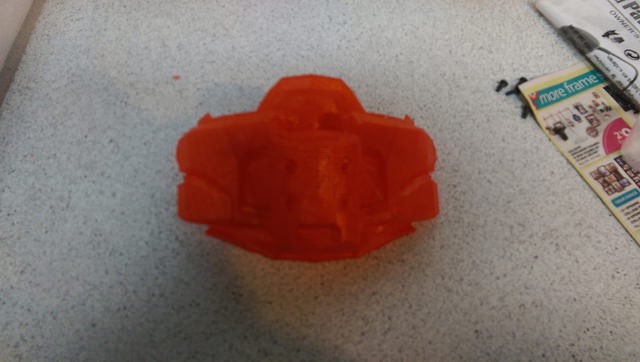

Now take the three chin pieces

Assemble

Attach to main helmet

If you are going to print the Size A, you need to understand which extended design parts are available to print...

The size A evolved as I worked the design, there are additional parts available that are either exclusive to the size A or have otherwise been combined into the base model for the size B and C

http://www.thingiverse.com/thing:163439

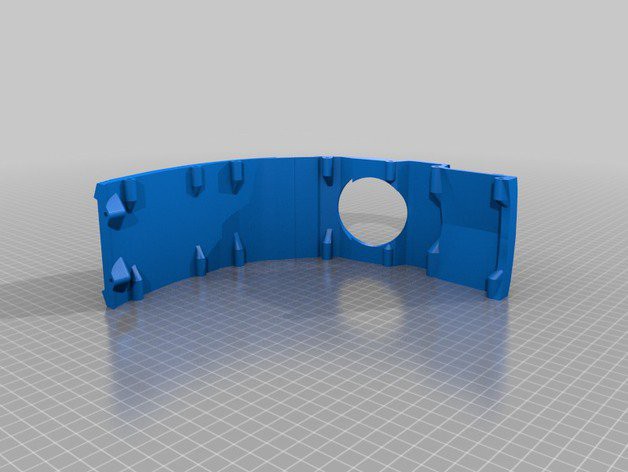

Perforated Visor for Halo Helmet - want to be able to see through a printed visor?

http://www.thingiverse.com/thing:165110

http://www.thingiverse.com/thing:168678

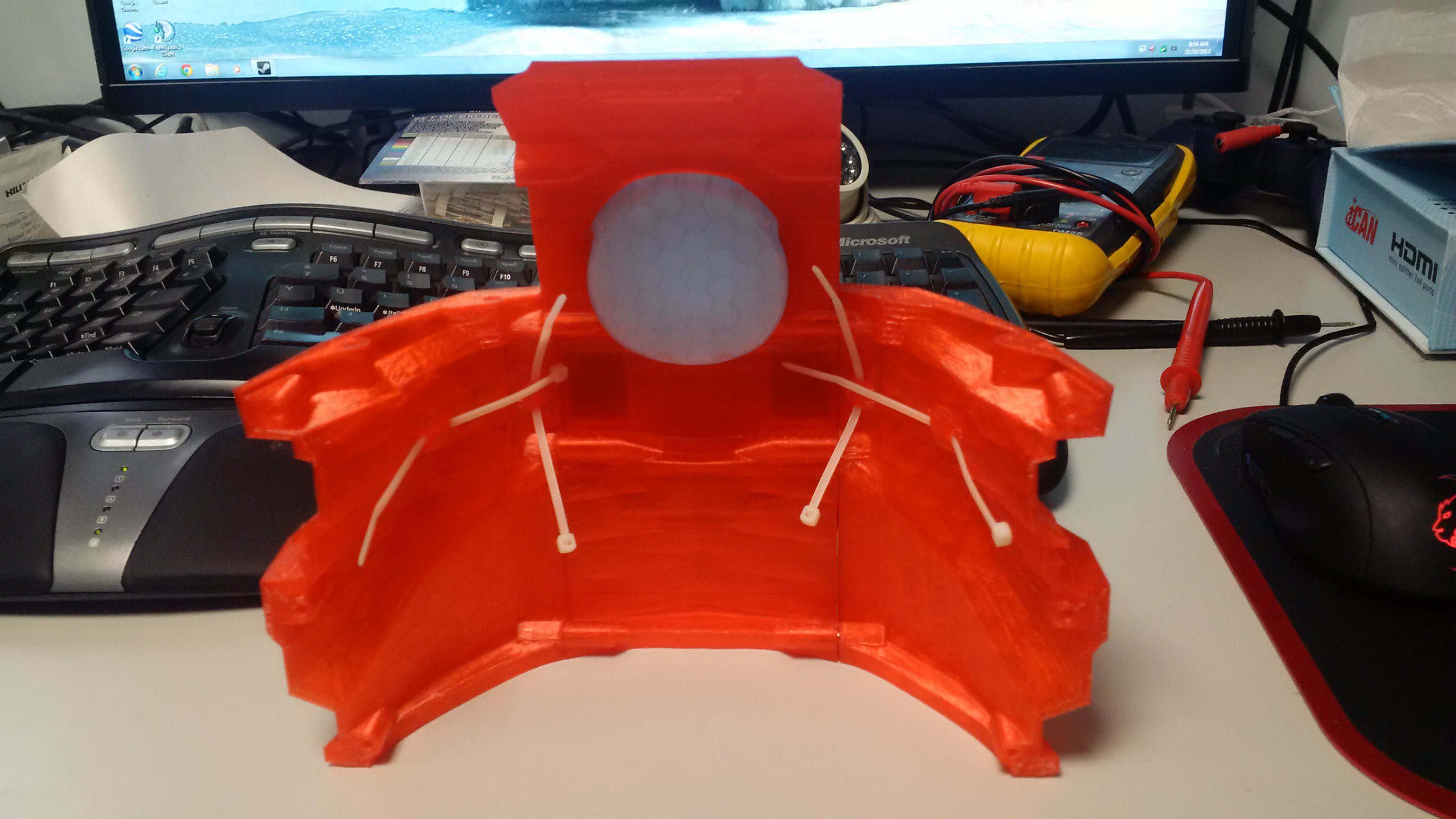

Halo 4 Helmet Full Size A with tiewraps - take control of that wiring harness, with built in tie wrap "warts" in the inside of the model.

http://www.thingiverse.com/thing:169295

http://www.thingiverse.com/thing:171912

Want a PETG vac formed clear visor ready for painting in your favorite metallic?

http://www.thingiverse.com/thing:217267

Print in place tie wrap mount points for wiring guides

http://www.thingiverse.com/thing:169295 and

http://www.thingiverse.com/thing:171912

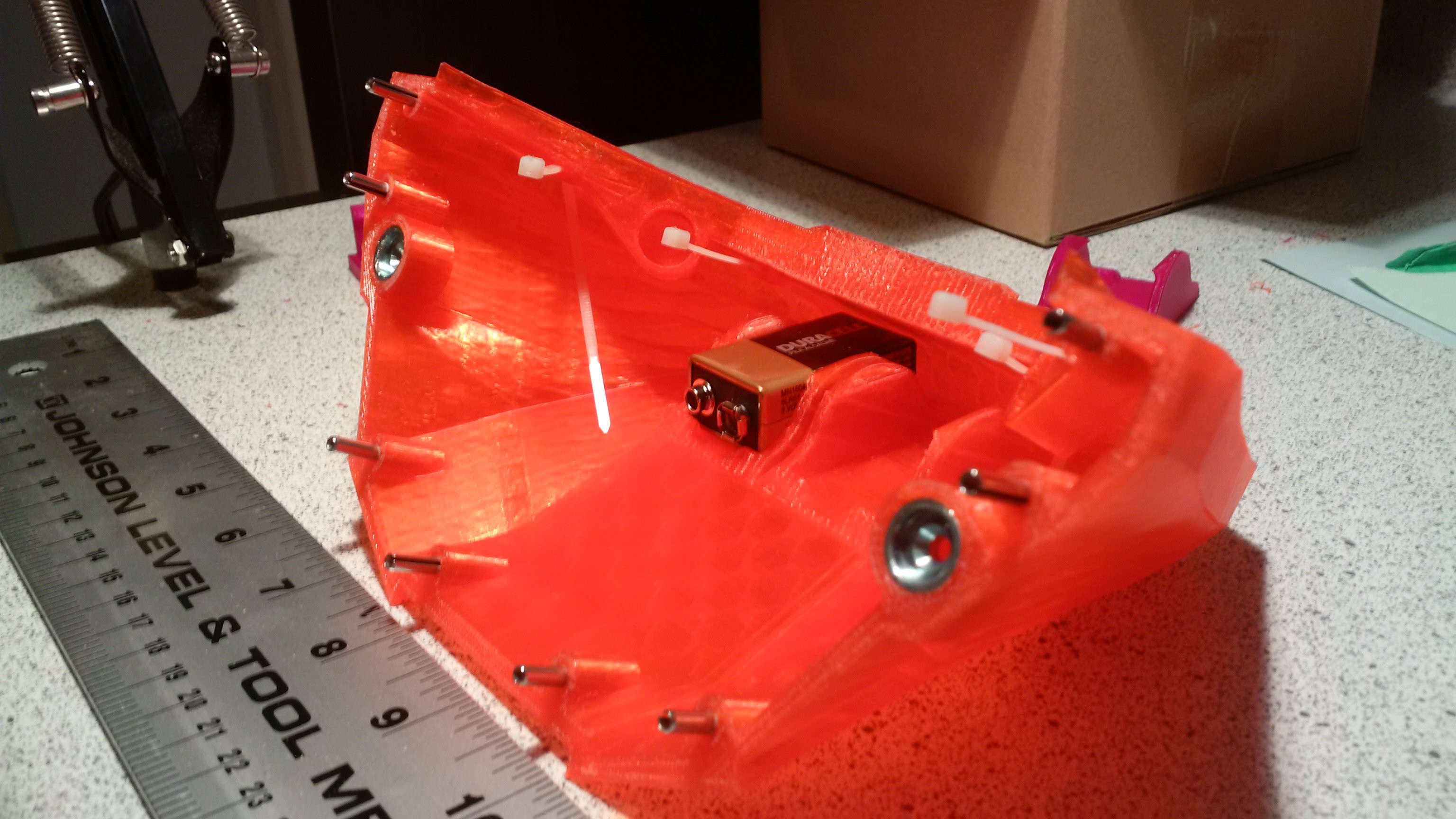

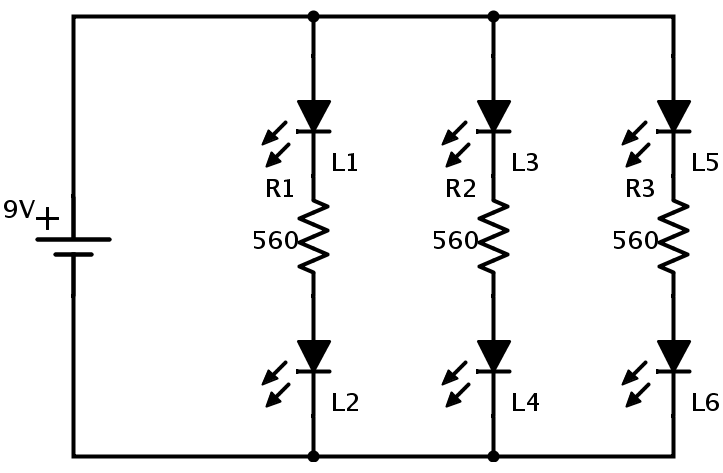

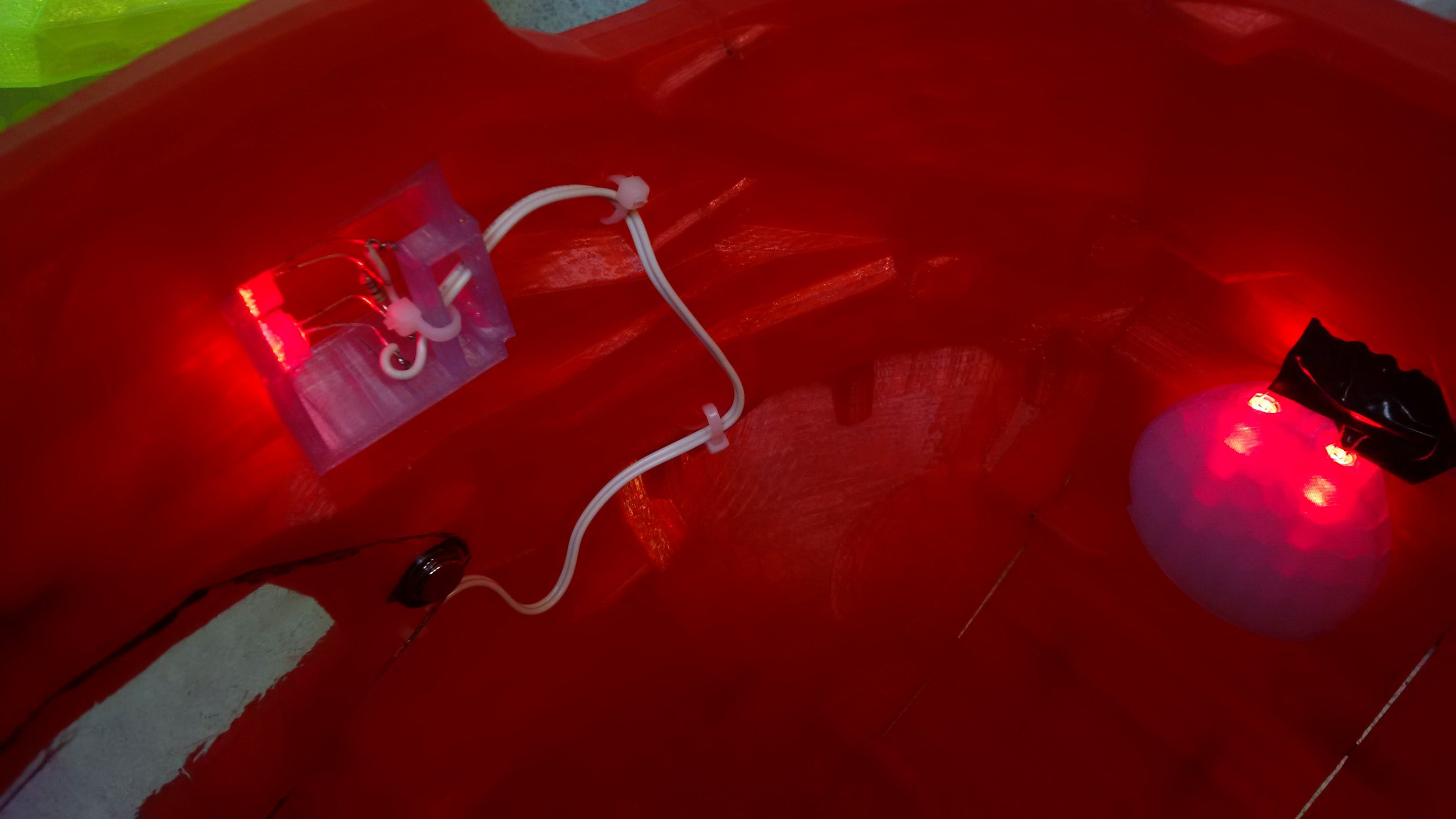

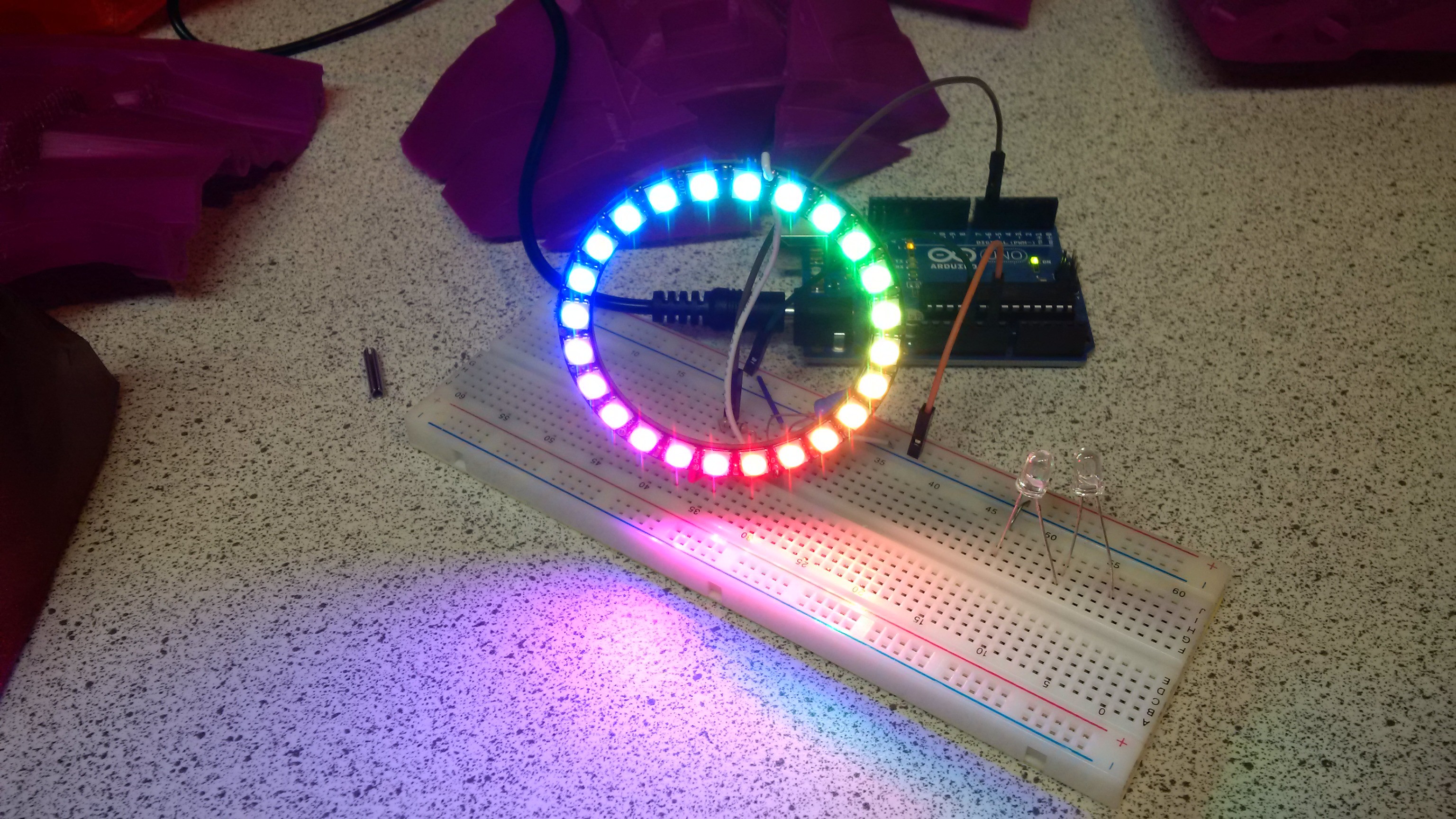

The present lighting circuit is very simple, soldering the resistor in series with each pair of 5mm LEDs. The resistor can sit directly between the LED's themselves, which makes soldering the twisted pins easy.

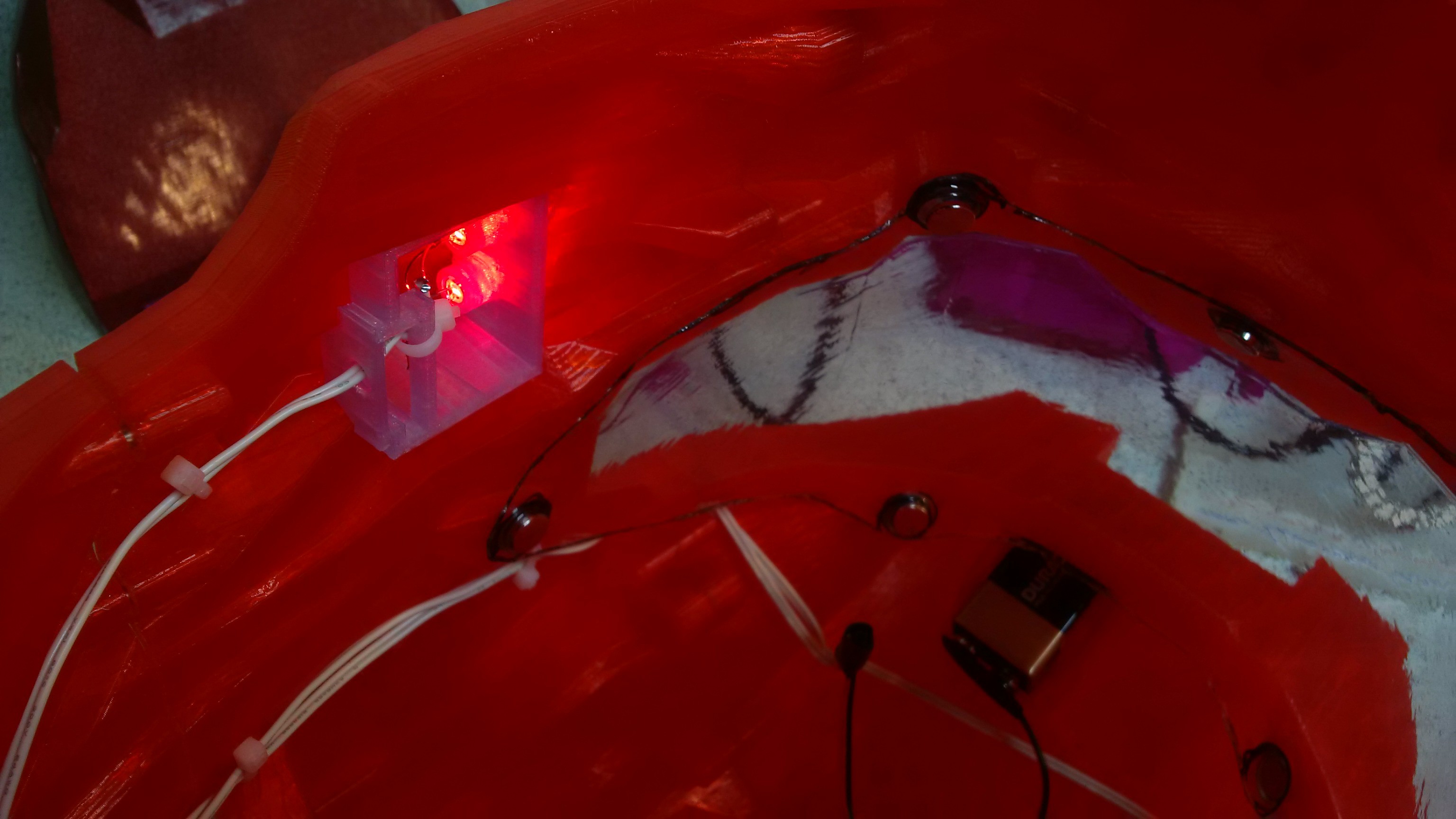

Here are the rear insert LEDs, with contacts taped off. Same combination of two 5mm LED's and a current limiting resistor.

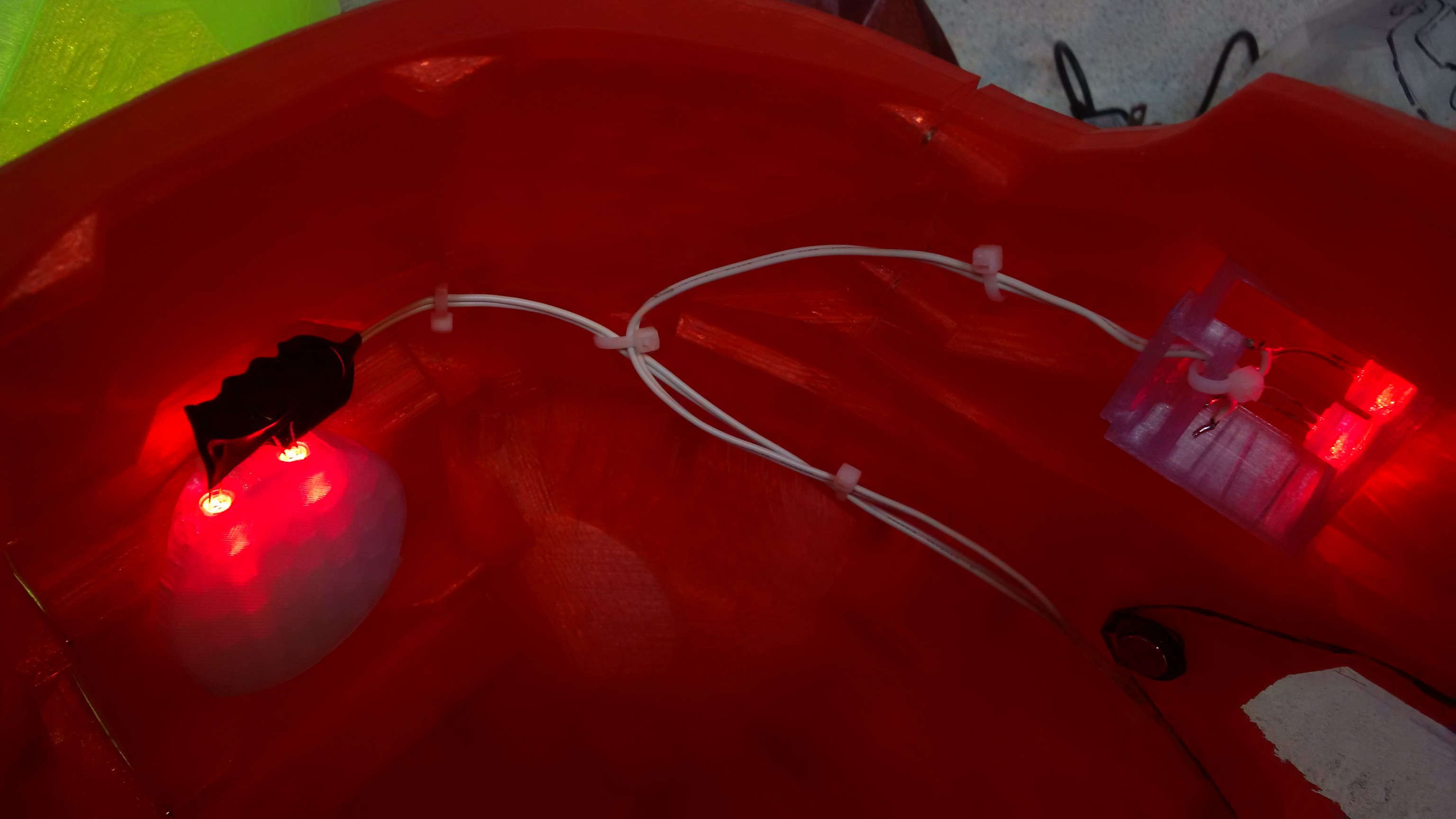

Note all three pairs, 2 Jowls and the rear insert are wired in parallel to the 9 volt.

Here is the Jowl on the other side, which wires straight to the peak to join up with the other runs.

Here is the Jowl on the other side, which wires straight to the peak to join up with the other runs.

I originally put an in line switch in the design, but it was more trouble than it was worth, and pulling the battery connector off is the preferred form of control at this time...

I originally put an in line switch in the design, but it was more trouble than it was worth, and pulling the battery connector off is the preferred form of control at this time...

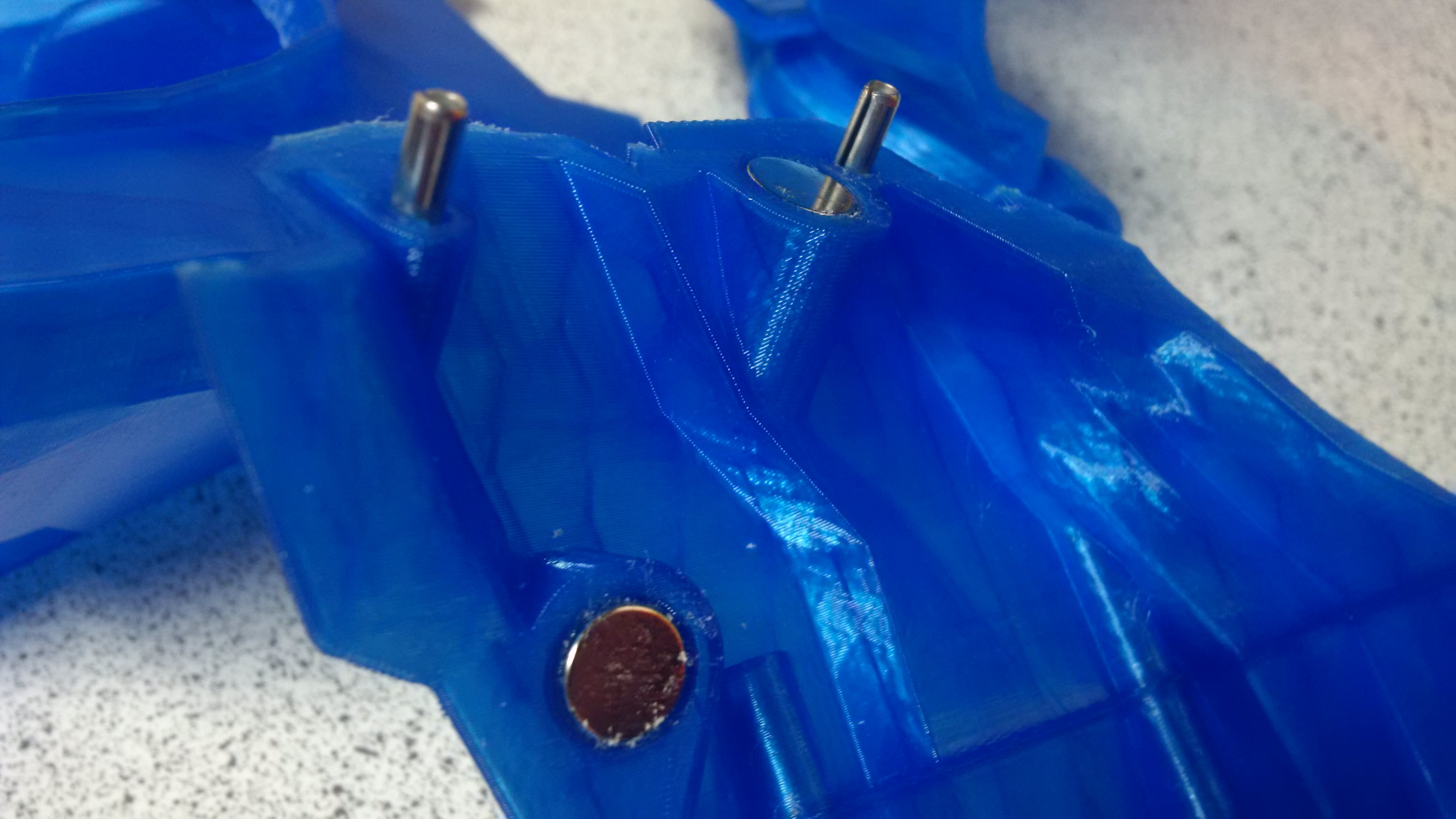

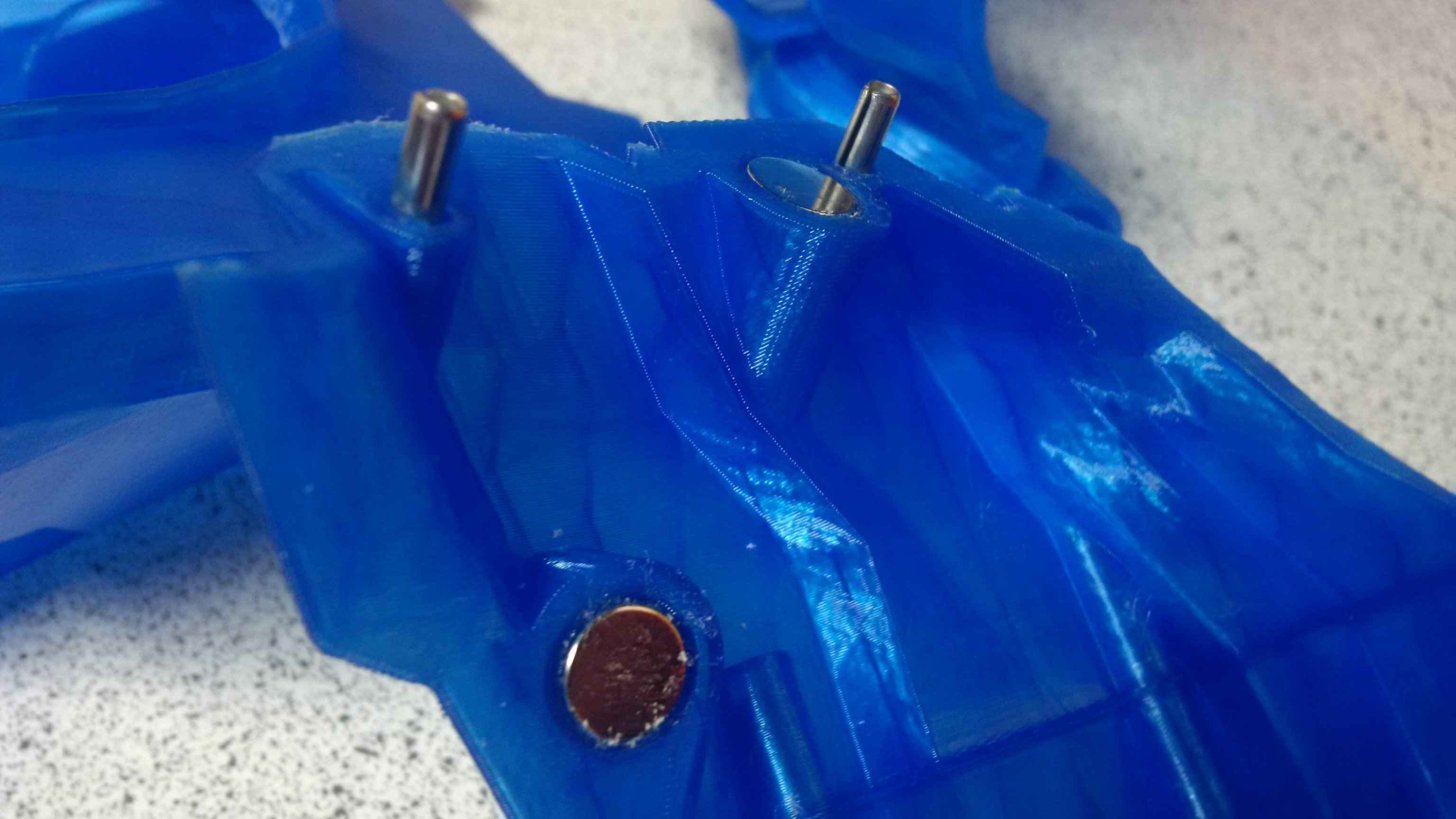

The use of tension pins allows components to be accurately aligned for gluing or in use assembly such as the chin parts.

This also allows you to print split surfaces as flats, which helps.

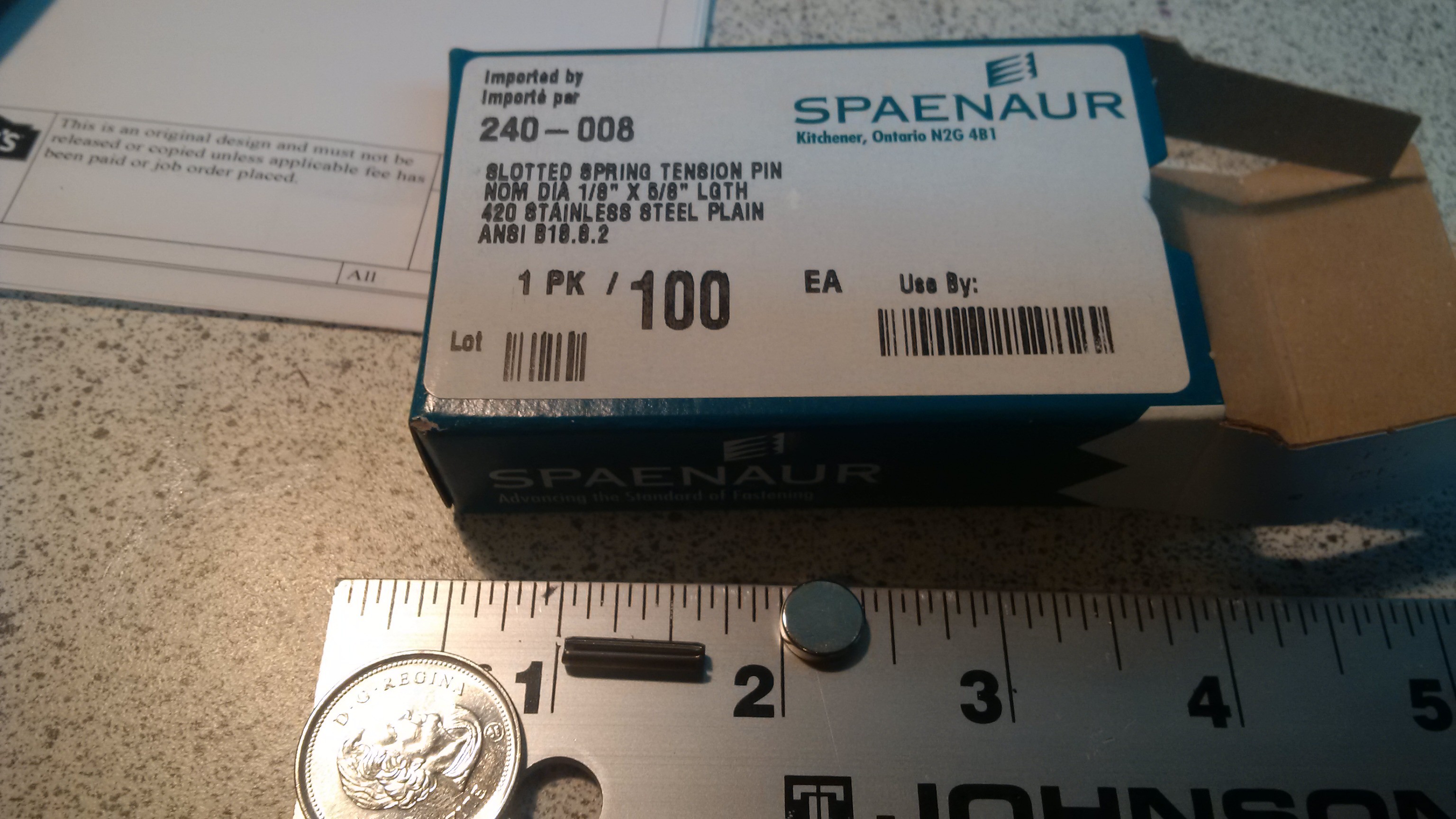

I have used tension pins purely because I knew I could get them. 3mm filament is close enough to 1/8 inch diameter, so you could just as easily cut lengths of such to use, or any other material with a nominal 1/8 diameter.

Two lengths have been used in the various models.

http://www.spaenaur.com/pdf/sectionE/E107.pdf

Size B Medium and Size C child uses 5/8 inch pins throughout, as per

They can also be bought from Amazon, not sure on those prices and delivery though. ( really, find a local hardware supplier, a real one, not a big box store who will happily charge you a dollar for 2! )

5/8 length http://www.amazon.com/Tension-Pin-20-pieces/dp/B00...

Here is a picture of a 5/8 pin next to a magnet and coin for scale, no banana was available at the time.

When printing with support it is likely that various holes in the model will end up with webbing inside them, if they are horizontal or facing down, that's fine though, the material is intended to be removed, and should give, without damaging the main body.

When printing with support it is likely that various holes in the model will end up with webbing inside them, if they are horizontal or facing down, that's fine though, the material is intended to be removed, and should give, without damaging the main body.

You will need a 1/8 diameter drill bit on a hex mount as per

Stick it in a screwdriver handle for hex bits, and you have a grunging tool to get in and do some dentistry.

Stick it in a screwdriver handle for hex bits, and you have a grunging tool to get in and do some dentistry.

Then just push in to each hole and clear out the naughty plastic. Some will already be clear, some will be easy, some will have a personal vendetta against you. Start gently until you get the hang of it, if the bit is sharp, it should be doing the work. You should be able to feel when you bottom out, and try not to drill through the end of the hole and into the main body. Its not the end of the world, but try to avoid it!

Then just push in to each hole and clear out the naughty plastic. Some will already be clear, some will be easy, some will have a personal vendetta against you. Start gently until you get the hang of it, if the bit is sharp, it should be doing the work. You should be able to feel when you bottom out, and try not to drill through the end of the hole and into the main body. Its not the end of the world, but try to avoid it!

Each pin hole is deeper than the pin needs to allow some detritus to be left, test fit a pin and make sure it goes at least half a length in. You can then pull them back out with pliers if necessary. In final assembly you will likely glue them in place.

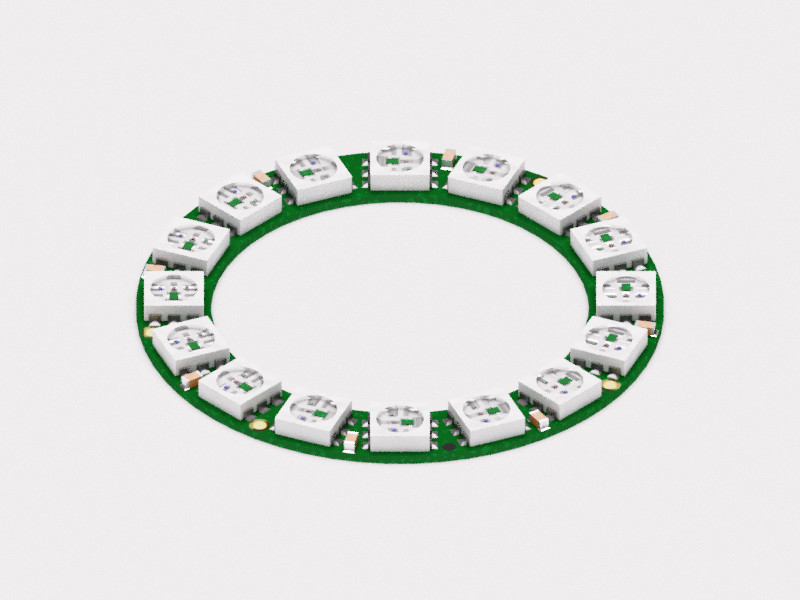

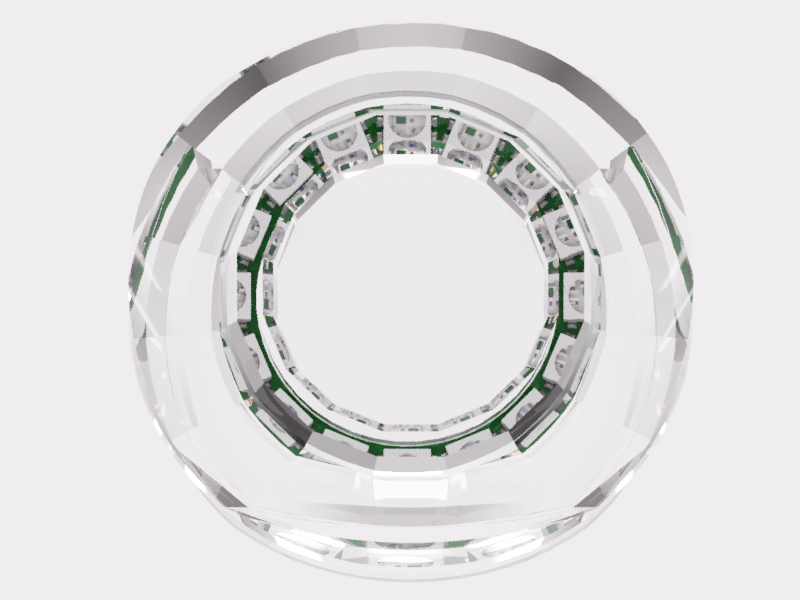

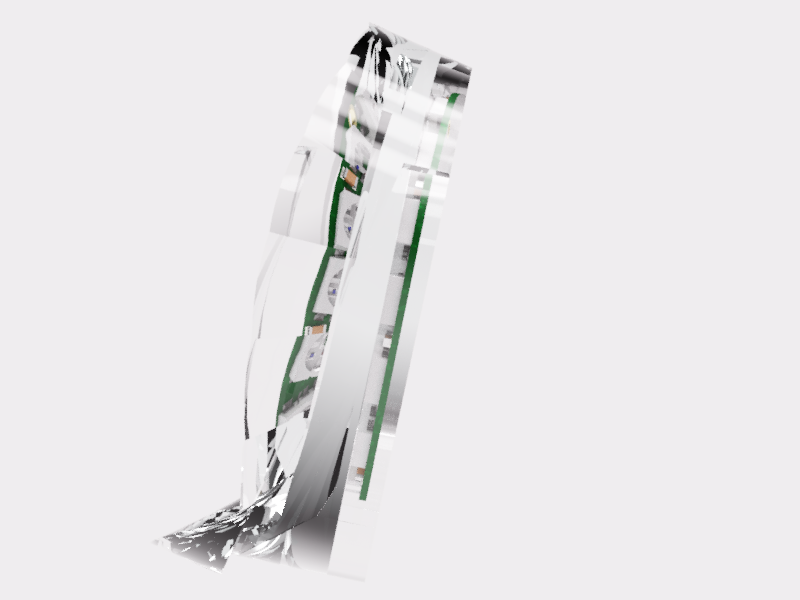

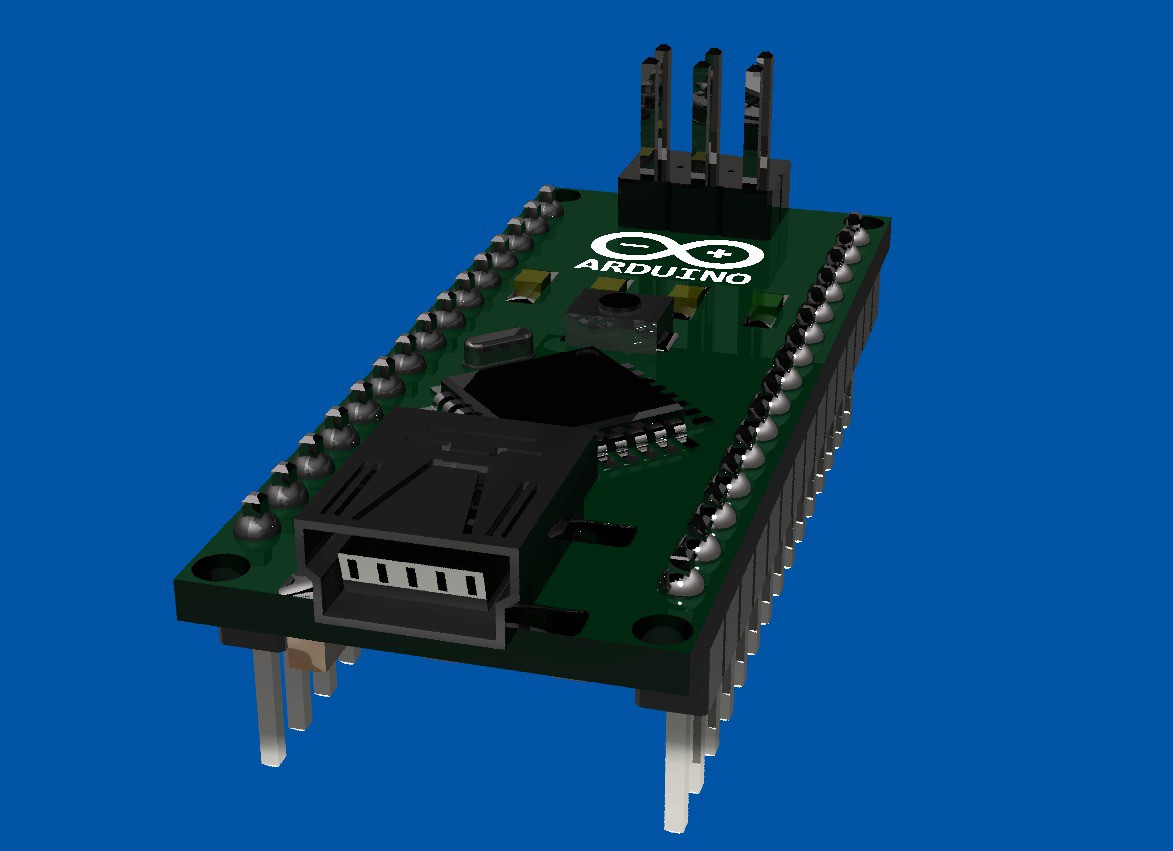

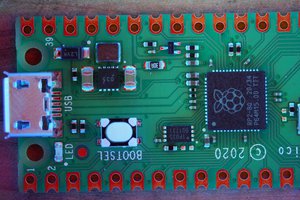

First dimensionally accurate model a 16 led Neopixel ring from adafruit

http://www.adafruit.com/products/1463

https://fusion360.autodesk.com/projects/neopixel-r...

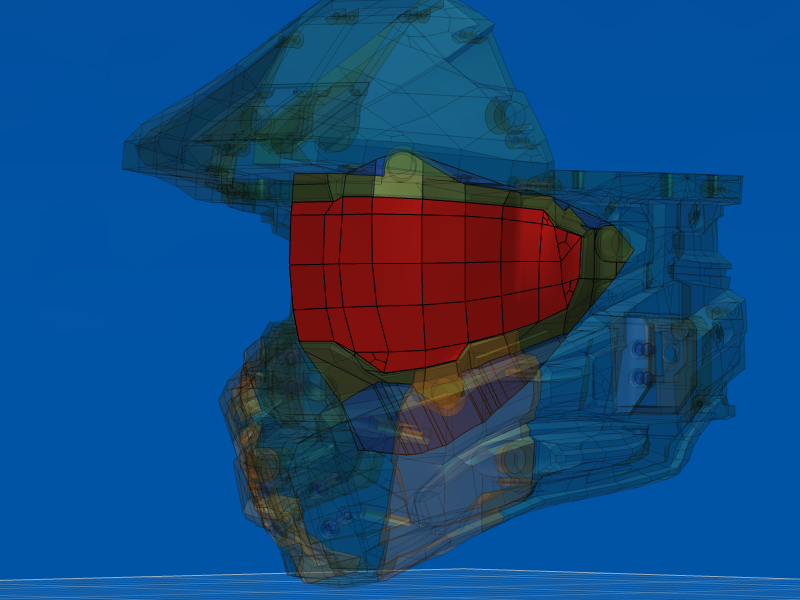

Then define a body space gap with the model so you can use it as a boolean operator against the piece you wish to mount it in.

Then define a body space gap with the model so you can use it as a boolean operator against the piece you wish to mount it in.

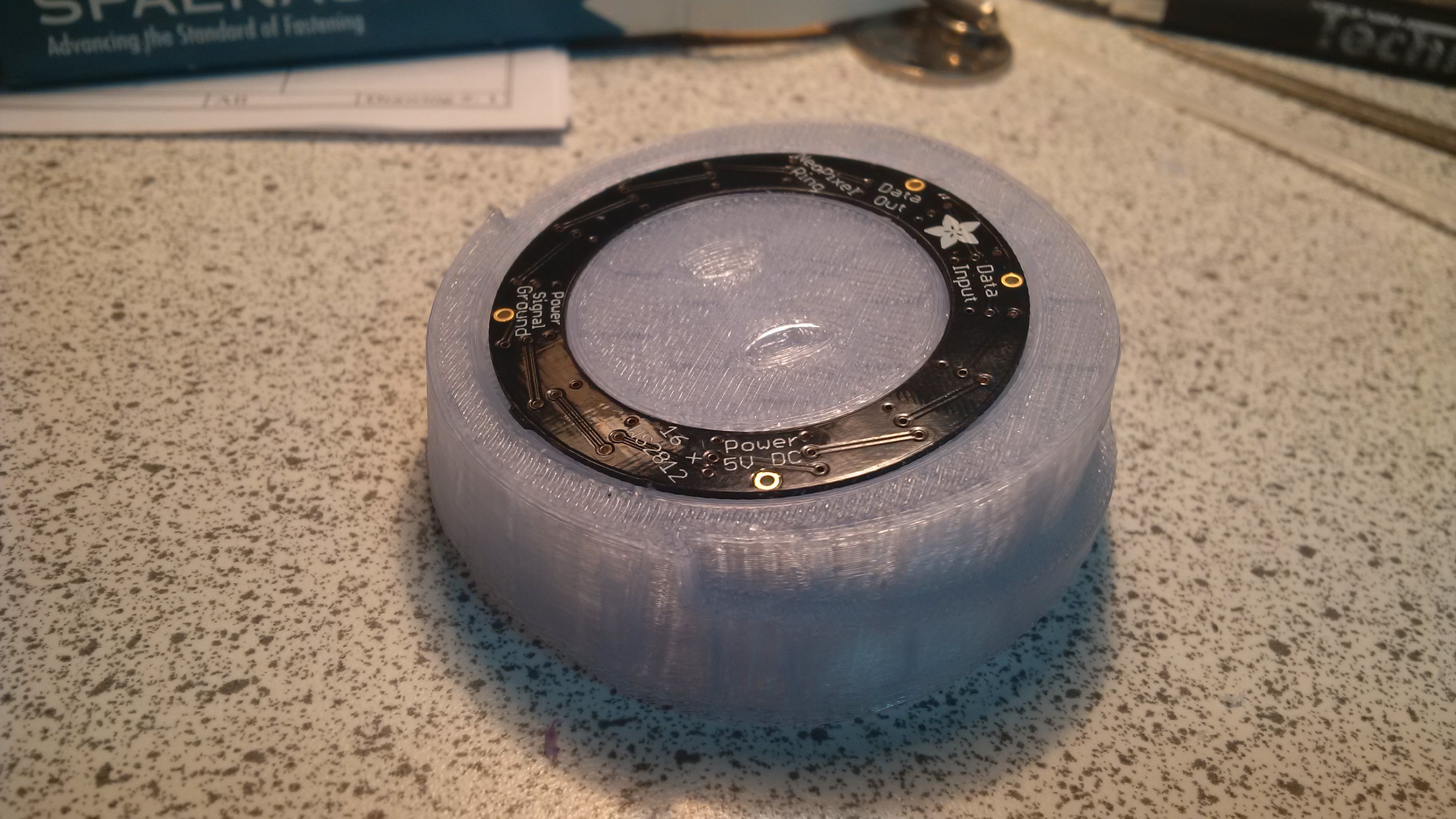

Design a test piece to test the body space fit.

Print it, low material use compared to final part, so you can afford to iterate...Be amazed when it fits like a glove the first time.

Model it directly into the target part...

Prototype your electronics.

No easier to video when in the helmet, trust me, it looks fab...

to be continued.

Original STL files are hosted in thingiverse at

http://www.thingiverse.com/thing:217267

Work out where your cut lines are

By looking where it intersects the main model.

By looking where it intersects the main model.

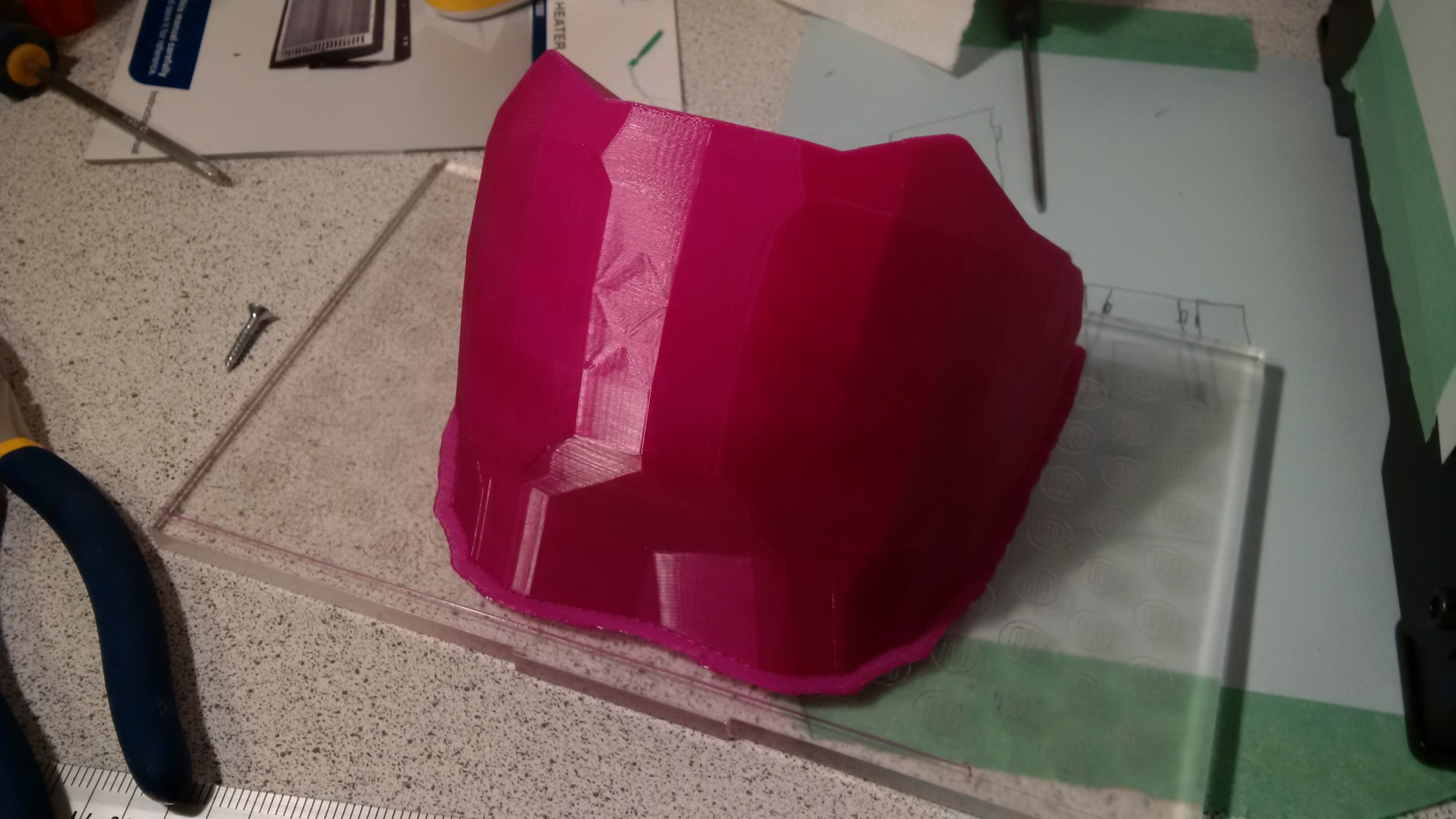

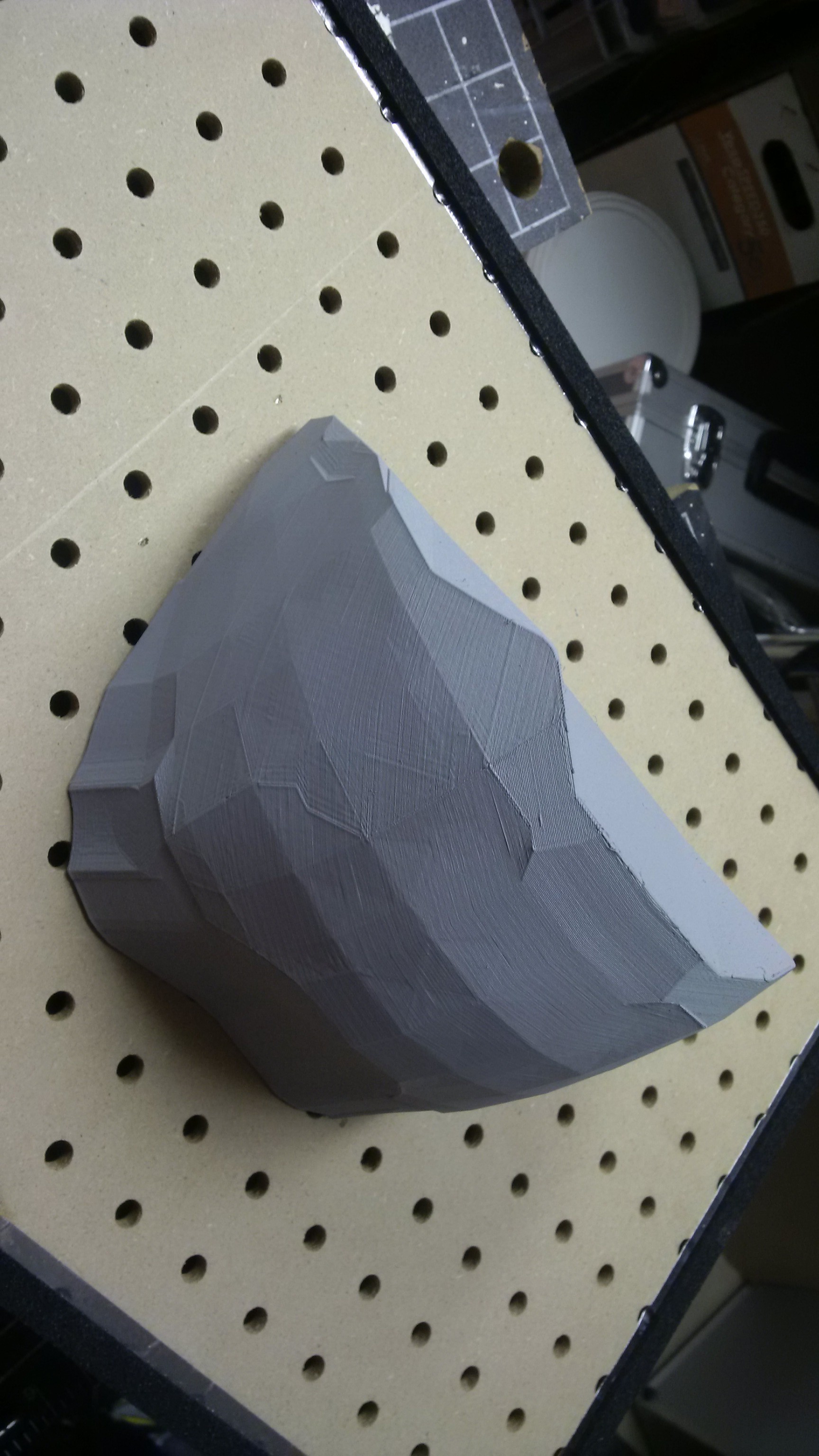

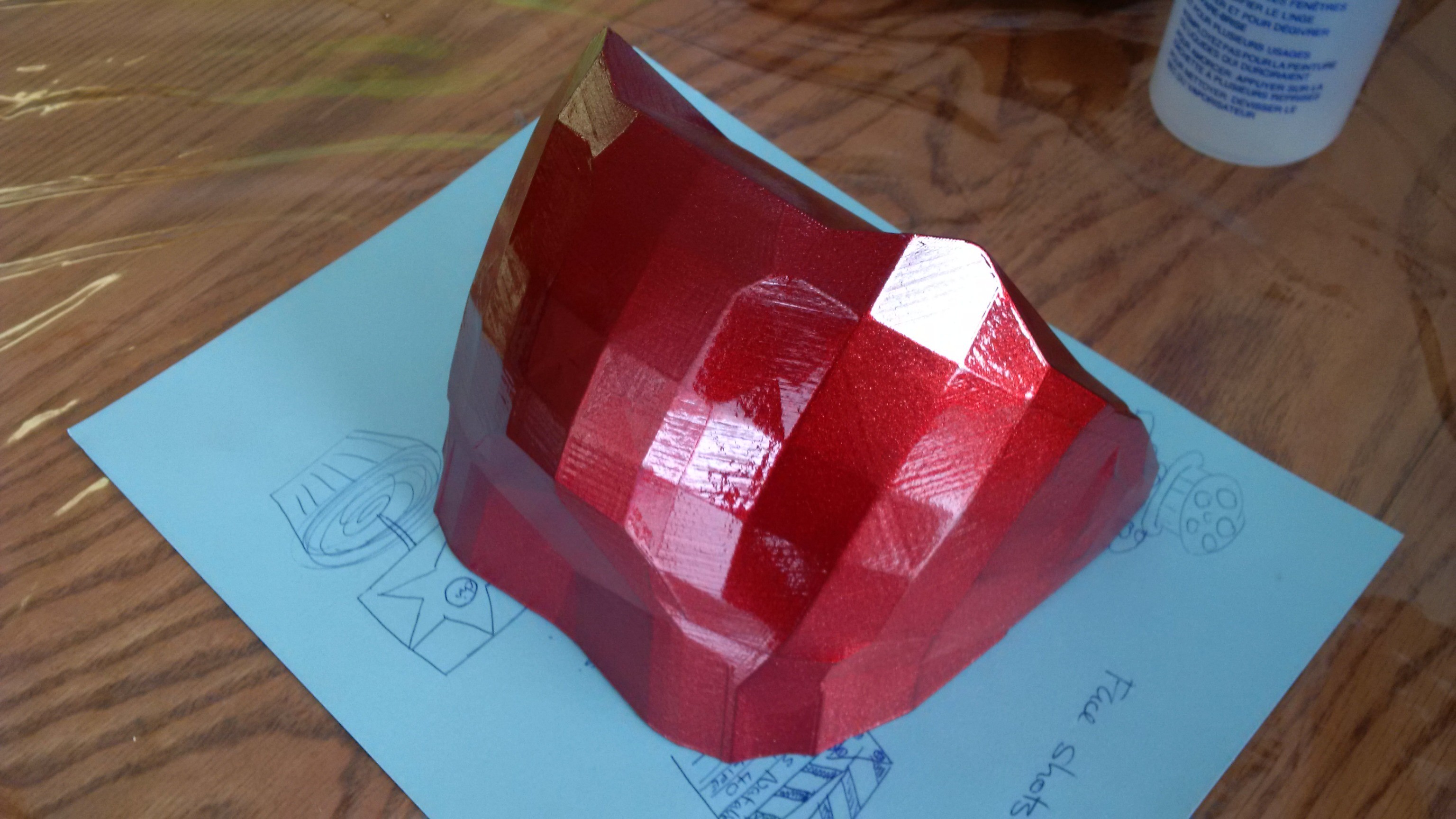

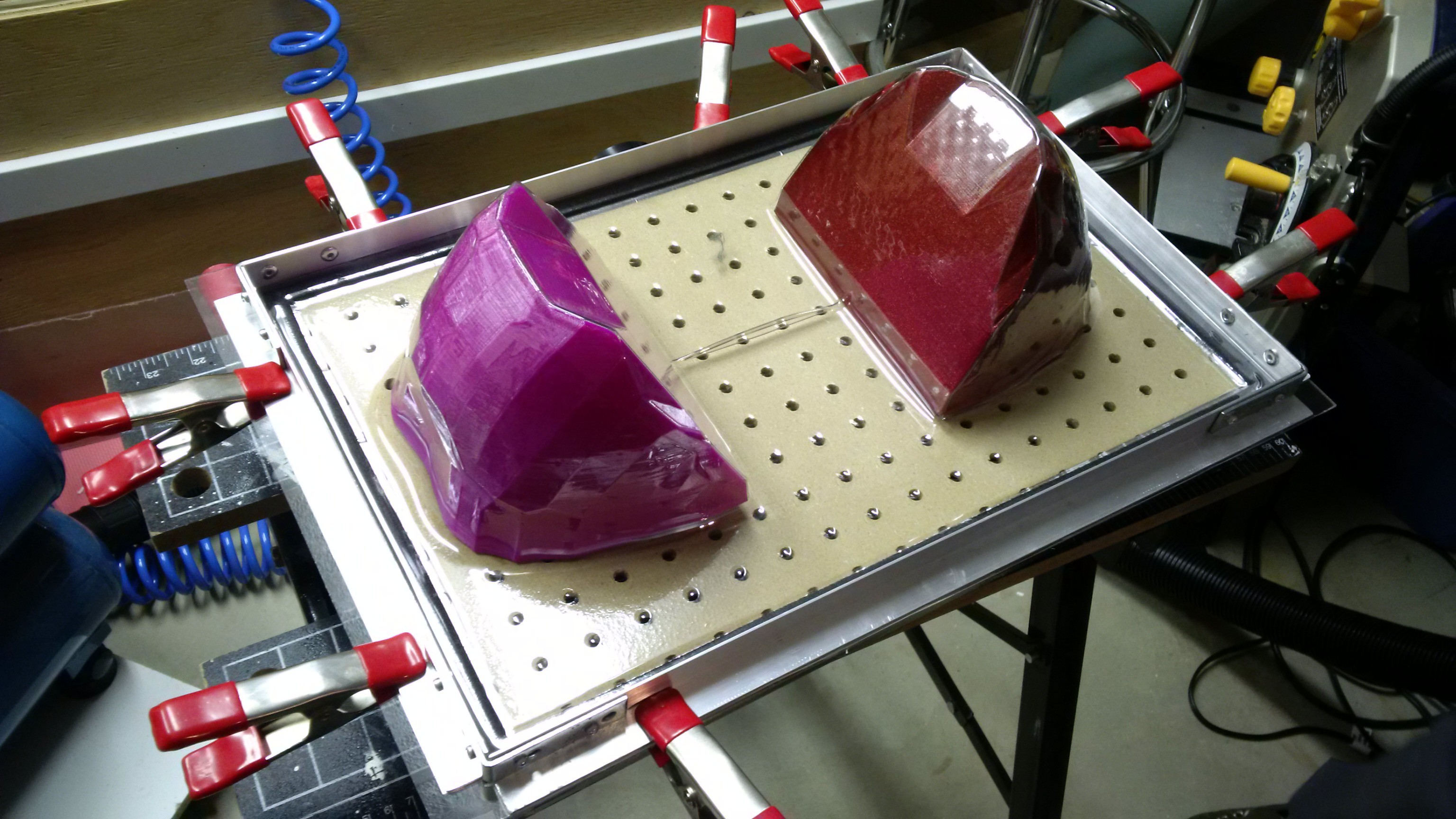

Once you have the model, print it.

Spray it.

spray it some more

spray it some more

Have pull handles and screw locators for the peg board

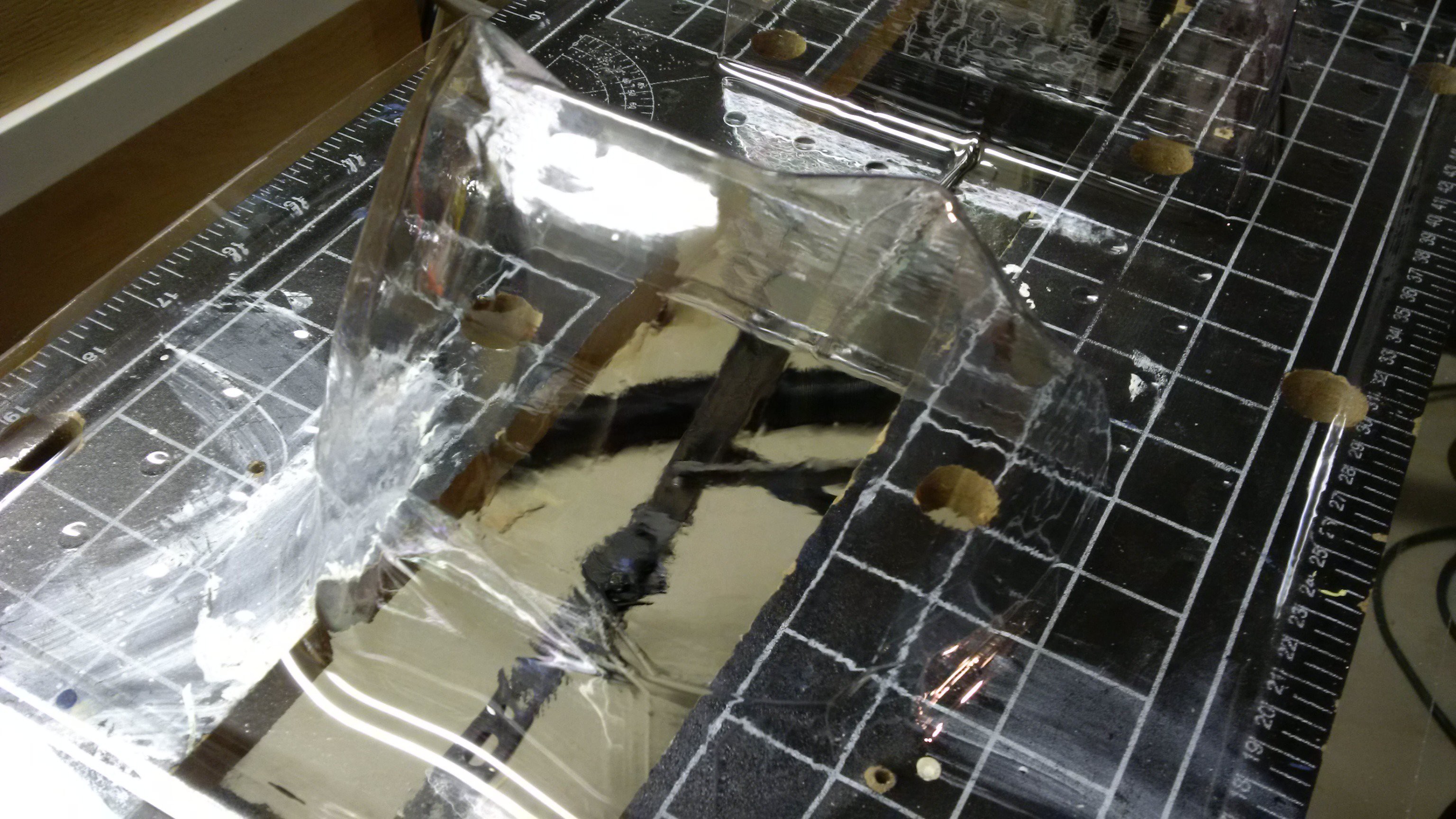

Then pull in pairs out of PETG so the webbing is on sacrificial areas, having first sprayed some furniture polish for easy release.

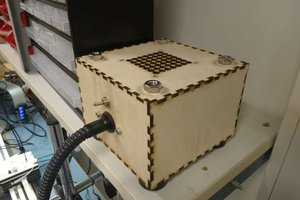

But first of course heat it on a quartz heater hot box that you can collapse for storage and transport

But first of course heat it on a quartz heater hot box that you can collapse for storage and transport

remove the molds with a bit of compressed air down the side

remove the molds with a bit of compressed air down the side

Cut out with metal shears, its just safer, easier and more accurate than a band saw. Add magnets and drop in place.

Cut out with metal shears, its just safer, easier and more accurate than a band saw. Add magnets and drop in place.

Next step is to paint the visor, but that's another adventure...

Next step is to paint the visor, but that's another adventure...

Step 1 test - these instructions are to test layout / intent of hackaday projects.

step 2 test

Step 3 test

Create an account to leave a comment. Already have an account? Log In.

how many of the pins do you need and where did you order them

what size is the adult helmet. My head is 11 inches / 279.4mm in the length and I didn't see anything saying what size it was please help.

Dunno if I missed it, but how much filament does it use (size A)

Is it possible to buy a couple vac formed visors from you? I was going to print the mold and mac a vac form bed, but it was a 30 hour print... or if there is a standard one out there that fits, can you send a link? Maybe some sort of paintball visor would fit

Thanks

Does the visor go in after everything is put together? Or will it need to be put in before the 2 halves go together?

Is it possible to make one large enough to assemble over a basic motorcycle helmet

Anything is possible. However, it would be very big if you were trying to print for clearance.

Practically you would be better off boolean'ing out the motorcycle helmet and printing the parts to stick on.

Quite a lot of work unless you had a very good model of the donor helmet.

Become a member to follow this project and never miss any updates

Øystein

Øystein

Sina Roughani

Sina Roughani

TAIBHSE DESIGNS

TAIBHSE DESIGNS

hey!how many pins and magnets do i need? And where can i order them