About the Project

I hope for FarmBot to become more than an idea, more than a hack, more than a product. I hope for it to become a thriving community of individuals and businesses that develop, share, and distribute the technology - much like how the RepRap project has done for 3D printing.

As you read through my entry on Hackaday, you'll notice that I link to several places: FarmBot.io, and FarmBot.cc. FarmBot.io is my brand new company that develops and is planning on distributing FarmBot hardware kits and software services. FarmBot.cc is the free-form community wiki and forum where anyone can get involved and share ideas. You can read the announcement of the new company here, and learn about why it is important to distinguish it from the community as a whole. I hope you check it out and enjoy what we're doing :)

Thanks!

- Rory

Open is at our Core

FarmBot is 100% open-source. We document everything we do on our dedicated hardware documentation and software documentation hubs, as well as on the community wiki. All of our code lives with permissive licenses on GitHub. We openly welcome feedback, replications, modifications, and questions. To facilitate collaboration, we've setup a community forum for anyone to get involved in the discussion, as well as dedicated hardware and software support forums.

Not Just Open-Source, Useful-Source

We believe that great documentation is the the key to building a community of hackers who continue to build upon this technology. While being open-source means making our source files and ideas free for others to use and modify, we don't believe this is enough. At the FarmBot Project, we're going one step further than open-source, we're going useful-source.

This means that in addition to sharing the source files, we're also sharing detailed assembly instructions, bills of materials, troubleshooting tips, past iterations, and our design intentions from the entire FarmBot journey. We're striving to design beautiful hardware that is reproducible with common tools and processes; built from low cost and readily available materials and components; and easily assembled and hacked. Our software is built to give users full control of their machine through and through. And we're even committed to operating our company with transparency and open company values at the forefront.

With all of this effort, we hope that thousands of individuals and business can learn how to use, hack, redistribute, and even monetize FarmBot just like us, ultimately pushing the technology forward and making it more accessible to the masses.

Mission and Vision Driven

The FarmBot Project vision is to:

Create an open and accessible technology aiding everyone to grow food and to grow food for everyone.

In order to achieve this vision, our mission is to:

Grow a community that produces free and open-source hardware plans, software, data, and documentation enabling everyone to build and operate a farming machine.

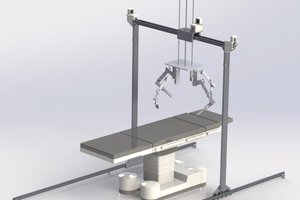

Hardware Overview

FarmBot is a CNC machine that uses special tools and software to grow plants. Our first device, FarmBot Genesis, is an outdoor XYZ machine that can scale from a planting area as small as one square meter, to as large as 20 square meters. It is estimated to cost between $1,500 and $4,000 depening on the size of the installation.

Core Components

We've chosen the following core components and materials for their utility within the FarmBot design, excellent corrosion resistance, general availability, ease of manufacturability, and relative low cost.

- V-slot aluminum extrusions and V-wheels are from OpenBuilds. These act as FarmBot's primary structural component and linear guide mechanism. These extrusions are high quality, easily cut to length with just a hacksaw, and have a completely open-source design.

- Custom designed 5mm thick plates are used to connect the extrusions, wheels, and other components together throughout FarmBot's structure. These plates can be made from sheet aluminum, stainless steel, or even plastics. They can be manufactured...

Rory Aronson

Rory Aronson

Cobinson Rrusoe

Cobinson Rrusoe

Dave's Dev Lab

Dave's Dev Lab

rgleason92

rgleason92

Alex Karadimos

Alex Karadimos

Looking for real http://www.purugupta.in at chandigarh escort service here.