Once i had filed and sanded all the aluminium parts, i started preparing them for an initial assembly.

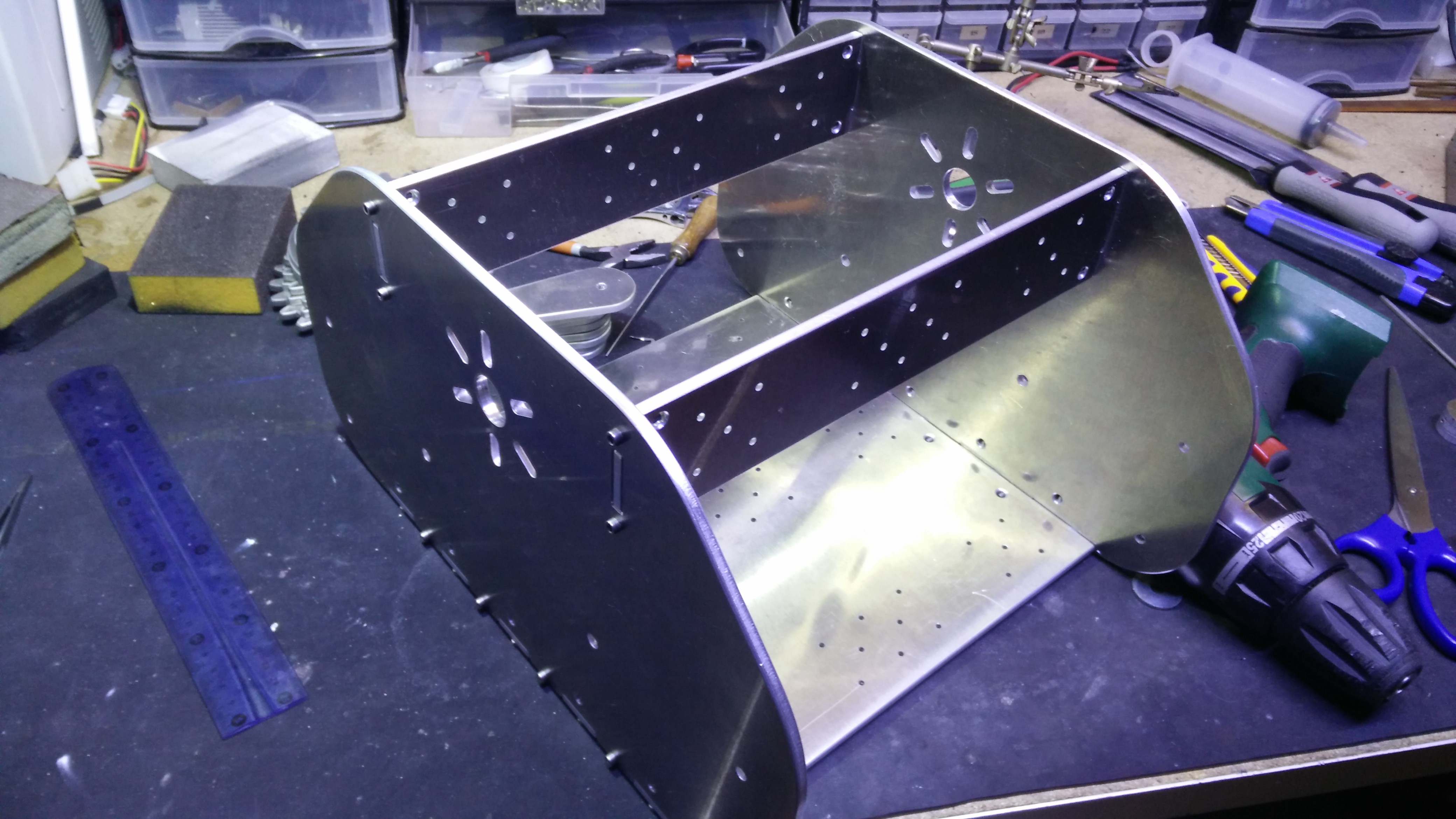

I started with the body frame. As the parts all meet at 90º angles, I designed the edges with simple box joints.

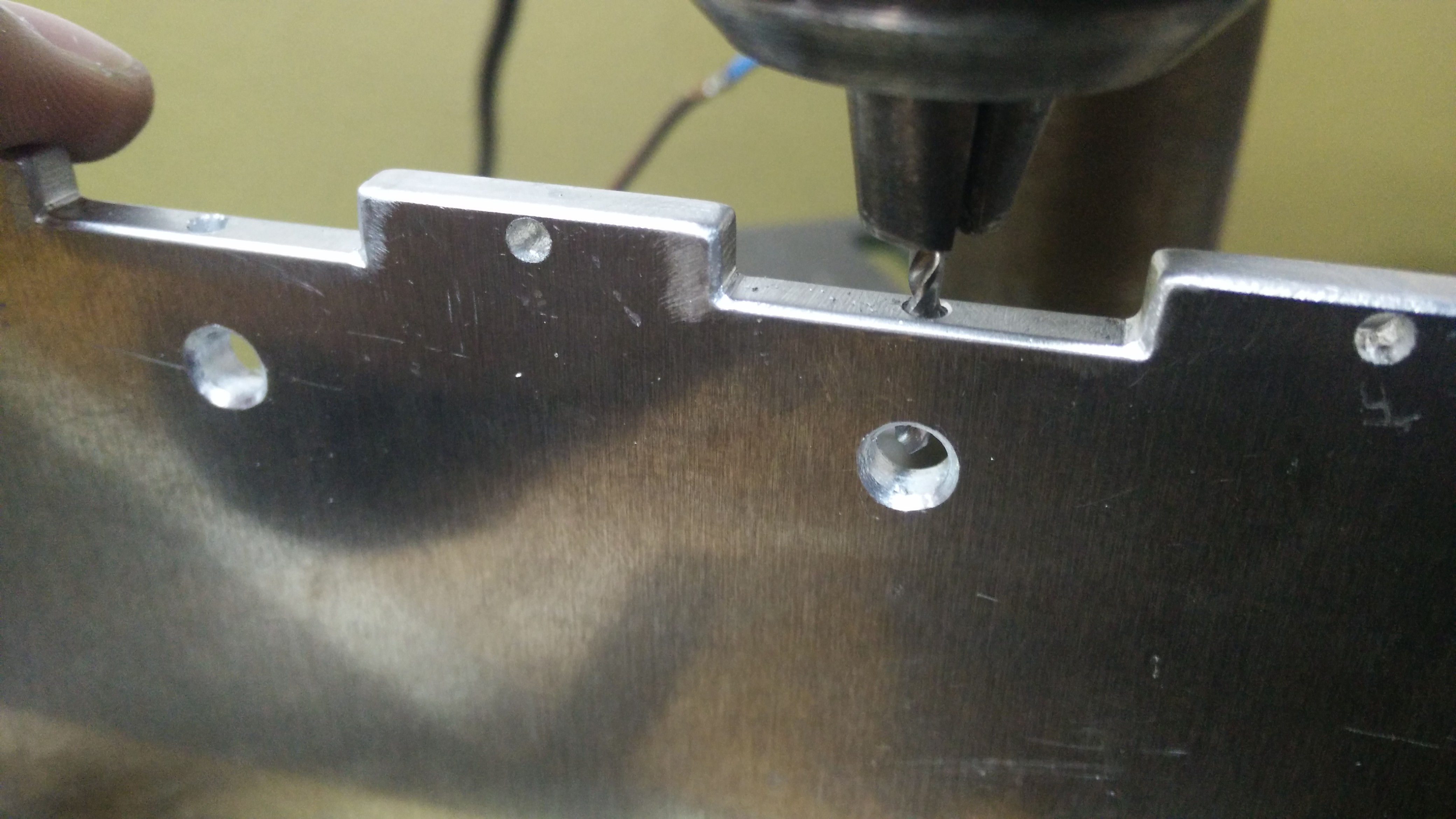

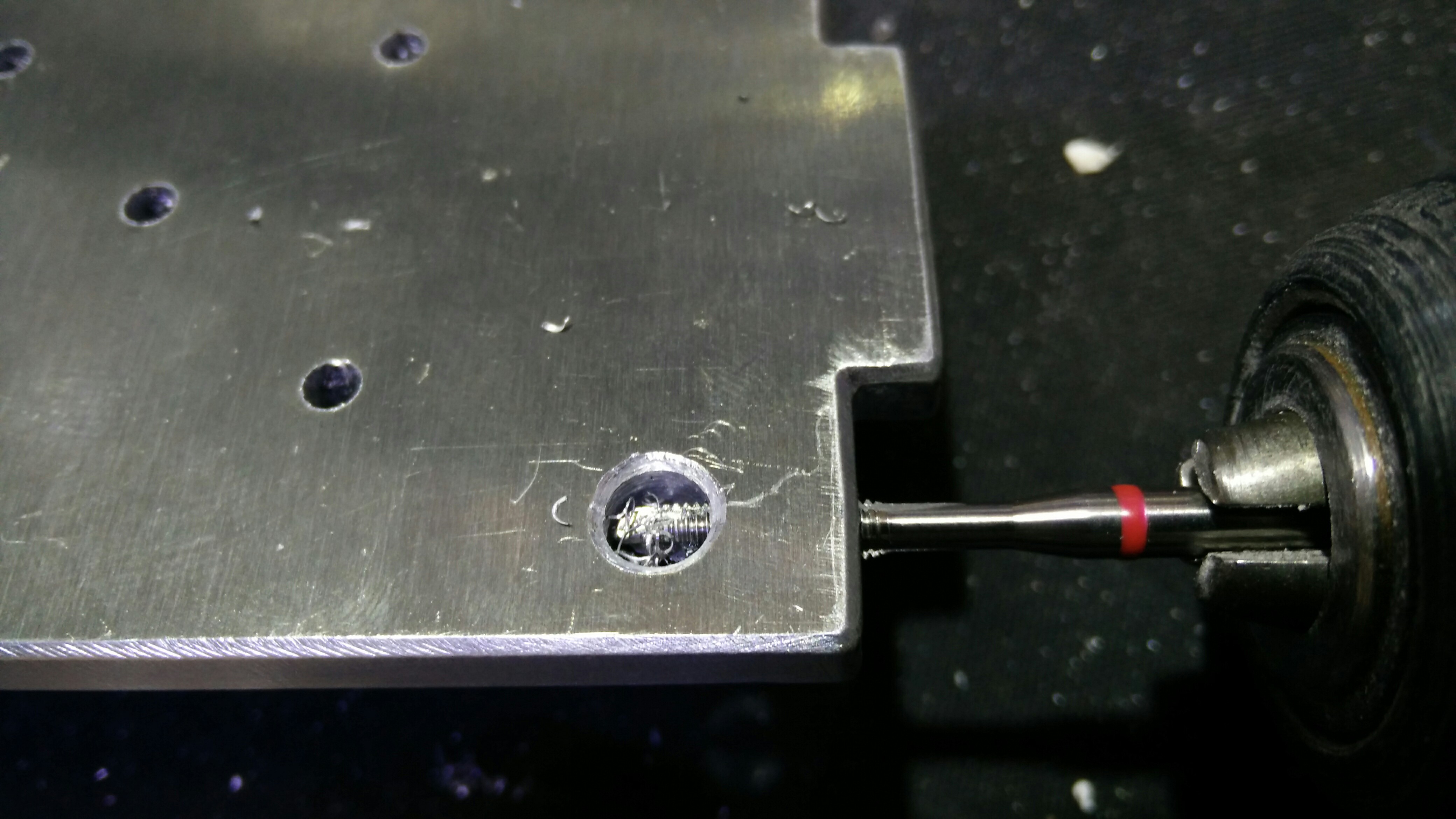

I plan on using threaded fasteners to hold the whole robot together, avoiding glue, welds or anthing permanent. For the frame this meant having to drill and tap M3 threads into the 5mm thick plate to screw the parts together.

The 5mm holes in which the threaded holes end are useful as an exit for the tapping chips.

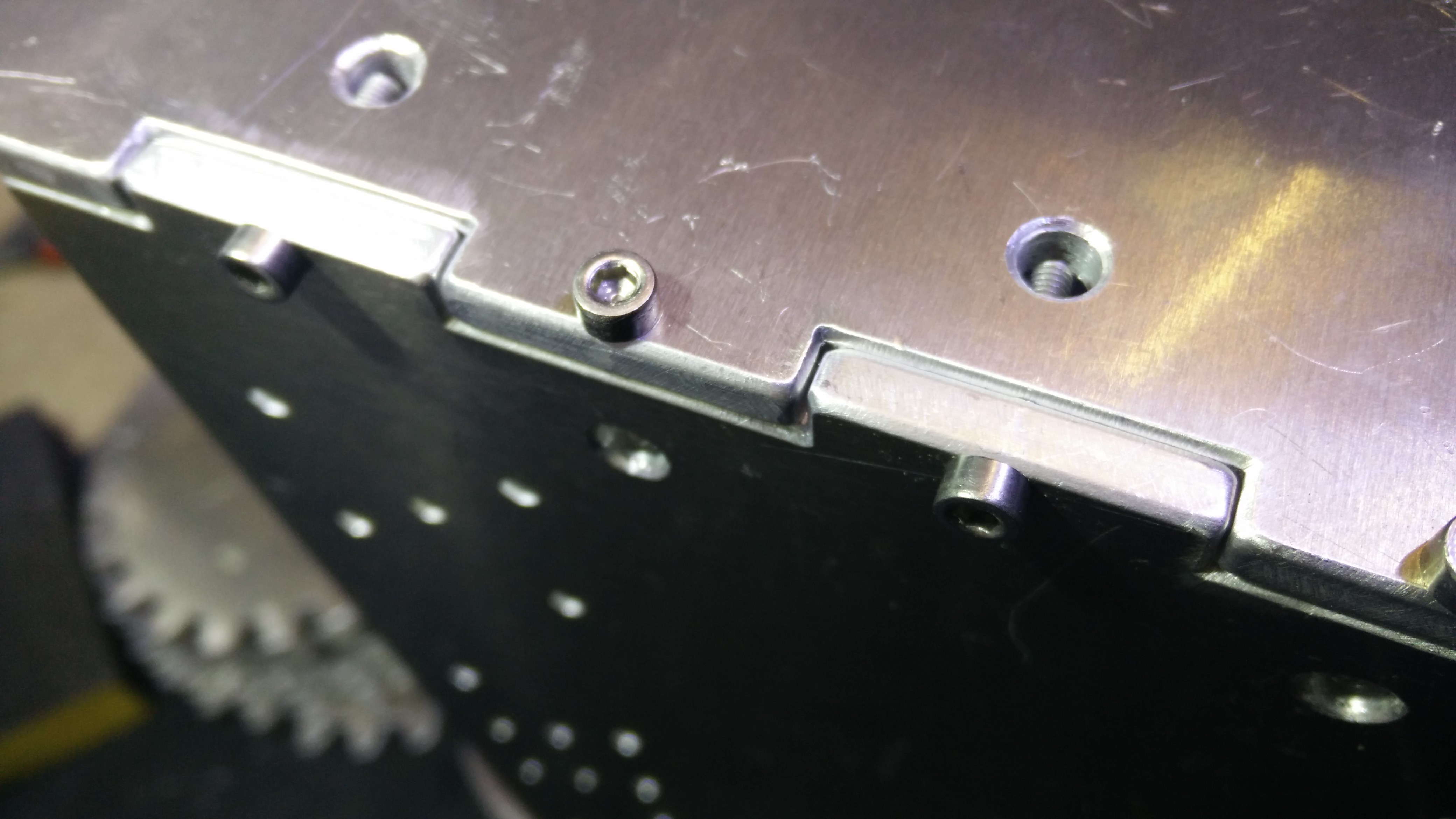

Here you can see how the parts are held together. I ended up using M3x12mm button head allen screws for all the body frame, as the don't protrude as much as the ones in the pictures.

The frame seems to fit together well, and is very rigid. There is enough space inside for the motors i plan to use (windshield wiper motors) and the batteries they will use.

Pinomelean

Pinomelean

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.