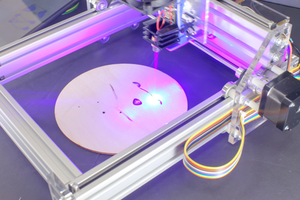

The laser modules are just pressed in. The holder itself is just pressed on the laser head. The "hole" in the holder needs to be a few tens of a milimeter smaller to provide enough friction for the laser to stay in place. The lenses of the lasers need to be glued in place to not be shaken loose by the movement of the laser head.

Be aware that these cheap laser modules only have a very limited range of depth in which they focus the beam properly. Keep them sharp in the focus point and don't worry too much about everything else.

The focus point can be adjusted by sliding the holder up and down. Focus the laser conventionally and then slide the holder to the height in which the point lasers hits the center of the cross.

The position of the lasers cannot be adjusted and the precision of targeting cross relies on the precision of the holder itself. You need to adjust the angle of the line lasers, though. They should go through the focus point no matter of their angle. Drive the target far out of the focus and do a test shot with the laser. Then adjust the line lasers to hit the spot. This should result in the targeting cross being on spot for all heights - assuming your laser cutter is properly aligned.

Florian Festi

Florian Festi

ThunderSqueak

ThunderSqueak

georgefomitchef

georgefomitchef

cpsprocket

cpsprocket