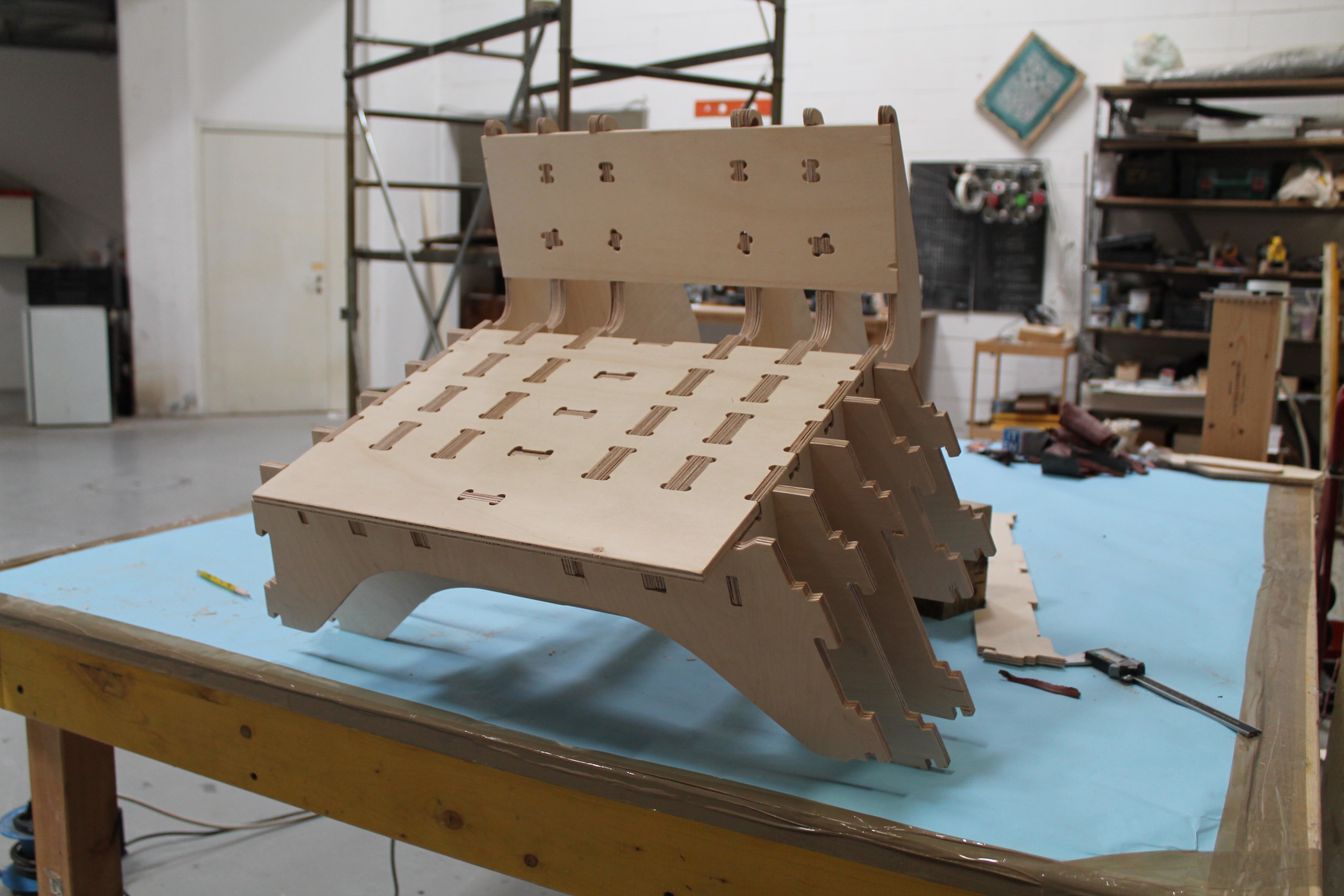

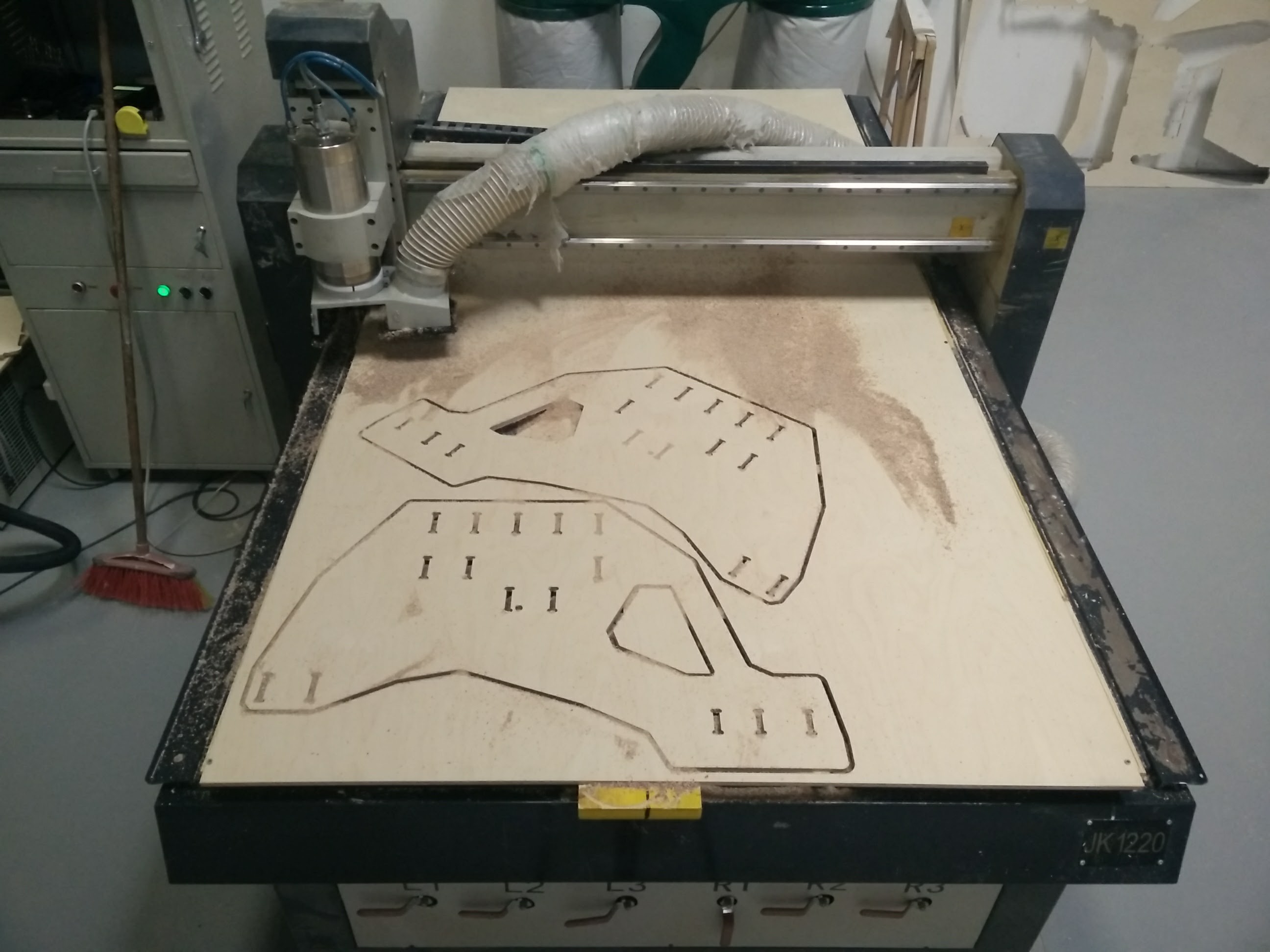

Toowheels is a DIY wheelchair, you can build using simple materials and tool like plywood, pipes and bicycle parts.

You can change dimension and size, and if you want you can make a custom wheelchair for any needs you have!

Toowheels is easy to make, and customizable using local materials and resources. We are working on setting some hub in developing countries to involve people with disability for local production, generating jobs opportunity, social benefits, and device for mobility.

The advantages of this project are different:

- it's customizable ergonomically and technically in order to create a wheelchair for the needs of each ones, and for the available local materials;

- it's 10 times cheaper than a sport wheelchair with the same performances;

- it's adaptable to answer different needs, starting from the same frame you can build a sport, an off-road, or a city wheelchair changing only some details;

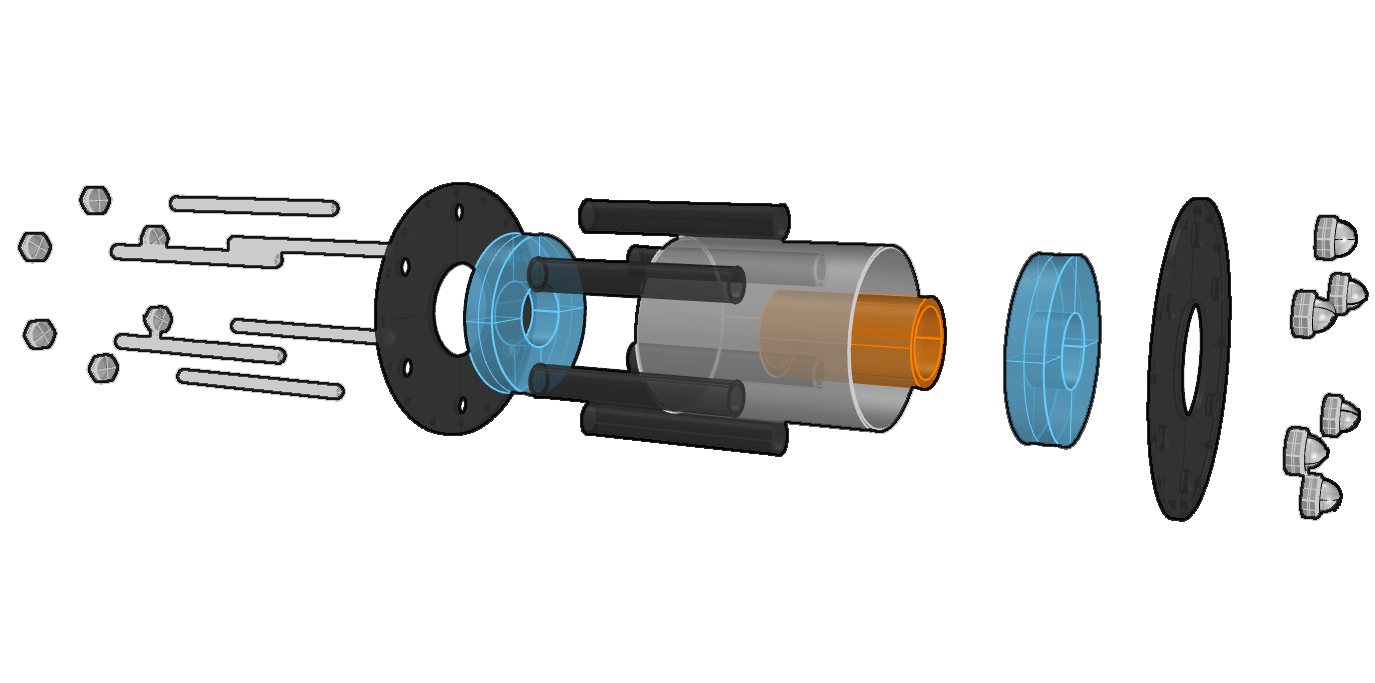

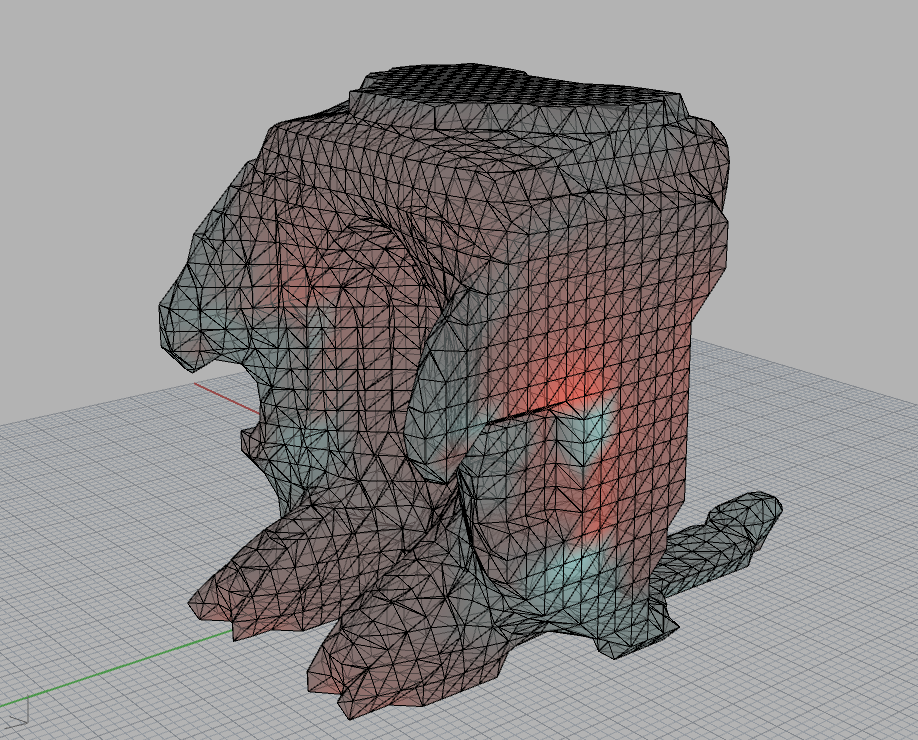

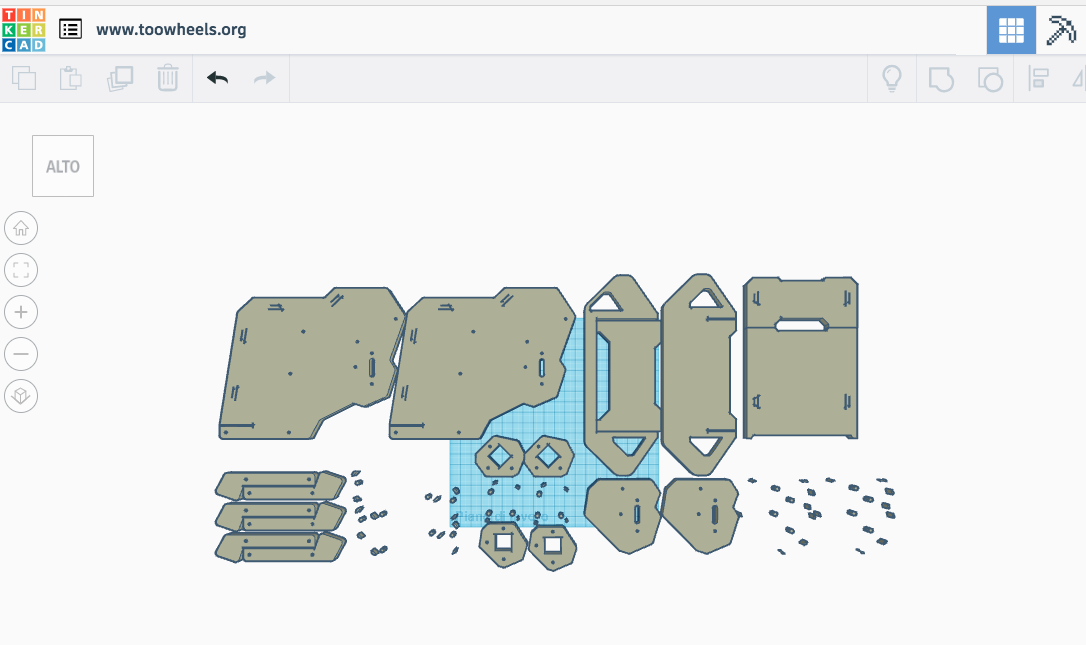

- it's an opensource project, you can download 3D files or printable plans from the website, and make it with digital fabrication technology in places like Fablabs, or you can use simple DIY tools like a saw and a driller.

I started this project in 2012, creating a network of people working and suggesting new improvements. After several collaborations we are searching new goals, ready for new challenges!

Alessio Fabrizio

Alessio Fabrizio

Jocelyn Pietro

Jocelyn Pietro

Pato Montalvo

Pato Montalvo

May be a more general comment:

I've not yet done vehicles made out of plywood but my experience with smaller things has been that plywood gains its strength from joining the sheets at an (typically 90°) angle. Most strength can be achieved by completely enclosing an volume basically creating a box like part. Even flimsy 3mm poplar plywood can withstand the weight of a person this way (given the box is small enough).