Been tired of the waiting time to get my boards assembled was such a pain. I was falling short of deadlines because the PCB normally take around 10 days to arrive after fabrication, then i need to send them to PCB assembling along with the components and wait for around 5-6 days to get the boards back to testing.

The reason i send my boards for assembling is,

The parts are extremely difficult to hand solder as i use 0402 and QFN package parts in most of my designs. The 0402 parts are terrible for hand soldering as they are almost invisible and cant even be held in a tweezer properly.

The assembling cost for smaller number of boards is very high, Like suppose we have to get only 5 boards made costs me around Rs.800/- per board. That's very bad when we want to manufacture a low cost product without large volumes or on demand in 1 or 2 nos.

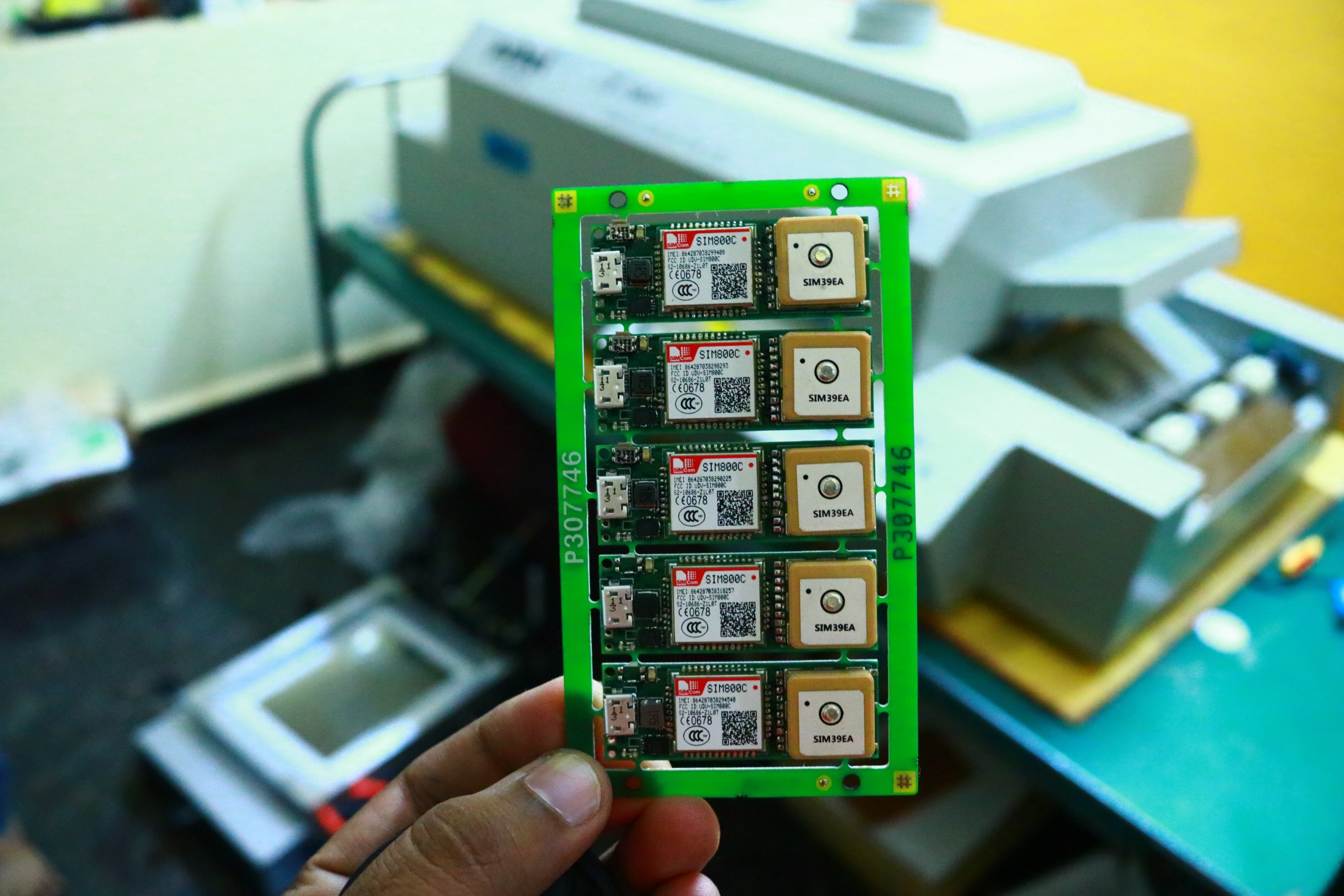

Thats' what happened with my VALTRACK-V2 GPS tracker. It costed me Rs.800/- per board to get them soldered with 5 days lead time. So i had to increase the cost of the device to compensate for the assembling charges, which will have a bad effect on price.

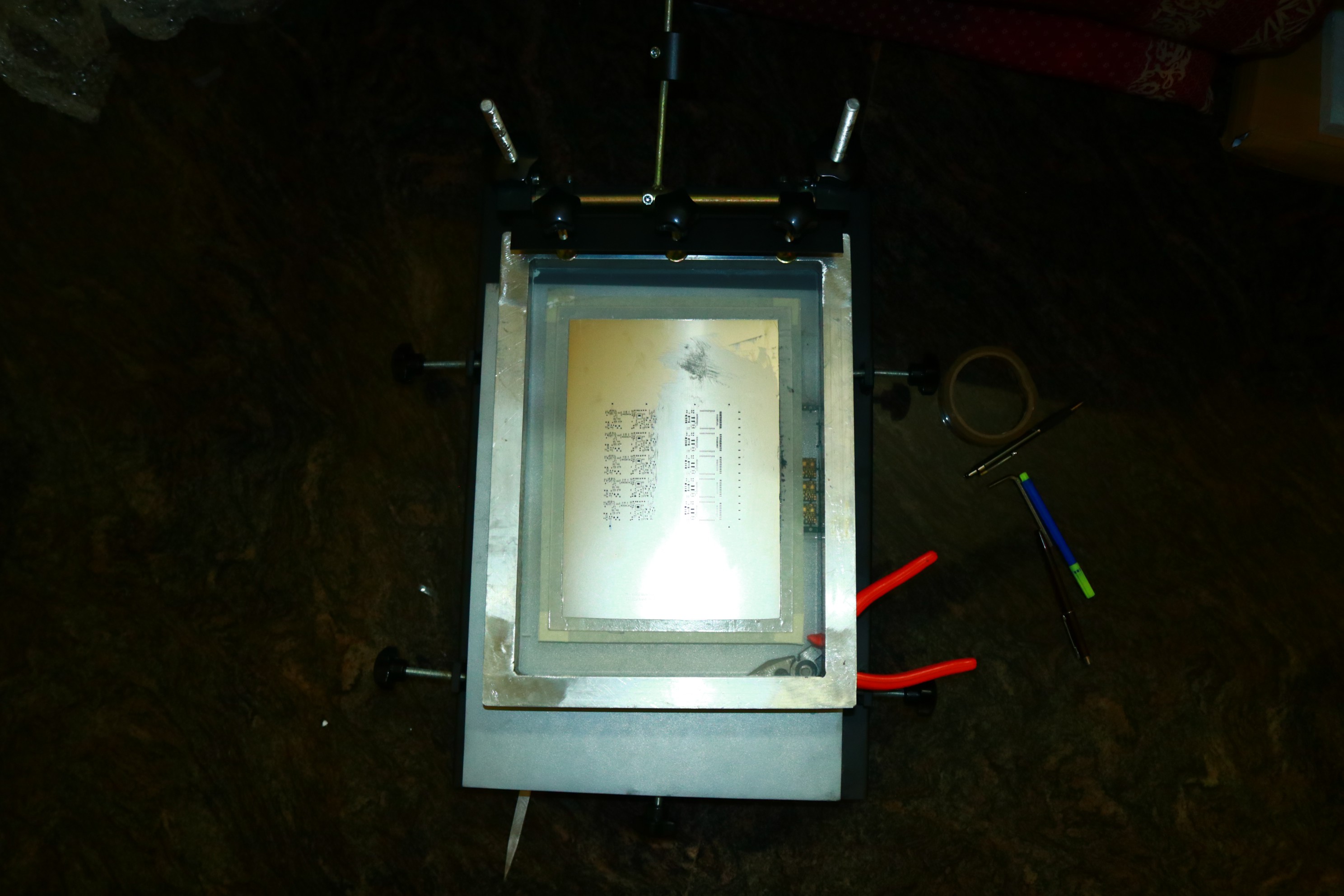

Long story short, i wanted to bring down the costs and get boards done quickly in house and provide faster turn around time for my clients in the whole design process. So i invested in this T-960 reflow oven along with manual SMT stencil printer. This will significantly speed up my next projects.

Apart from using machine to solder our own boards, will be starting assembling services at minimal charges to my clients and whoever interested.

raviypujar

raviypujar

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.