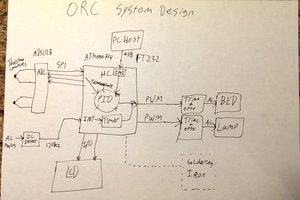

This project is one of those ones that start out of neccessity. My manual 90's civic felt that it was too cool to have a tachometer. To remedy this, I began to work on the project this summer. Right now the hardware is pretty much all off the shelf kit and the end goal is to move over to a custom single PCB implementation. Additionally, while testing the filters I just used Arduino code to get things done fast. Now that the hardware is verified and the code flow work to my satisfaction I will be porting over the code to C along with the hardware revision. I'm hoping that reading the input pulse from the car counts as connected. :p

The goal is to release the code and hardware files all as open source. I hope others try my design out so I can see just how many different Hondas this design actually works for.

Current Features:

4 Digit 7 Segment based RPM Output.

2 RGB LEDs for a shift light and redline.

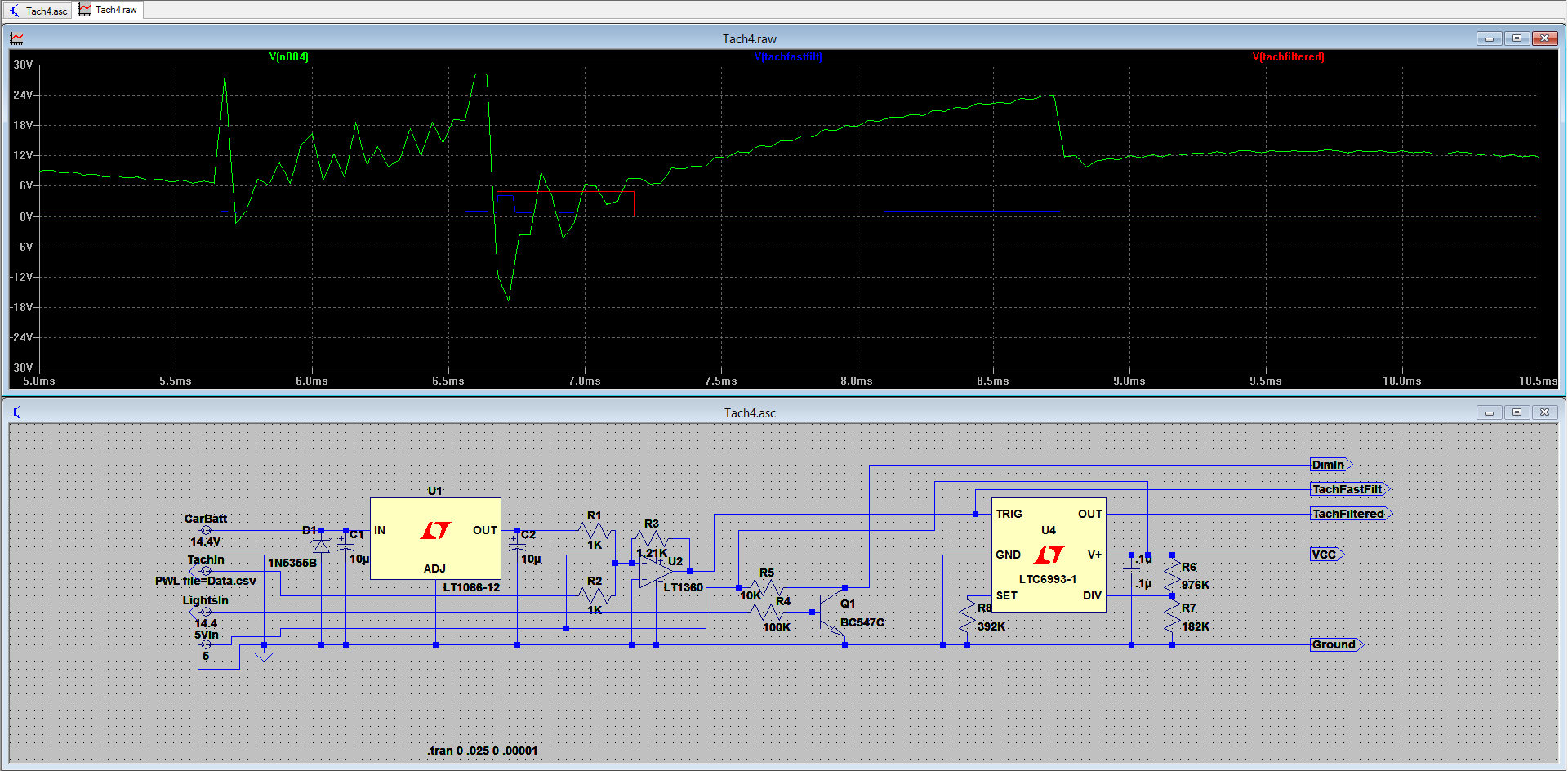

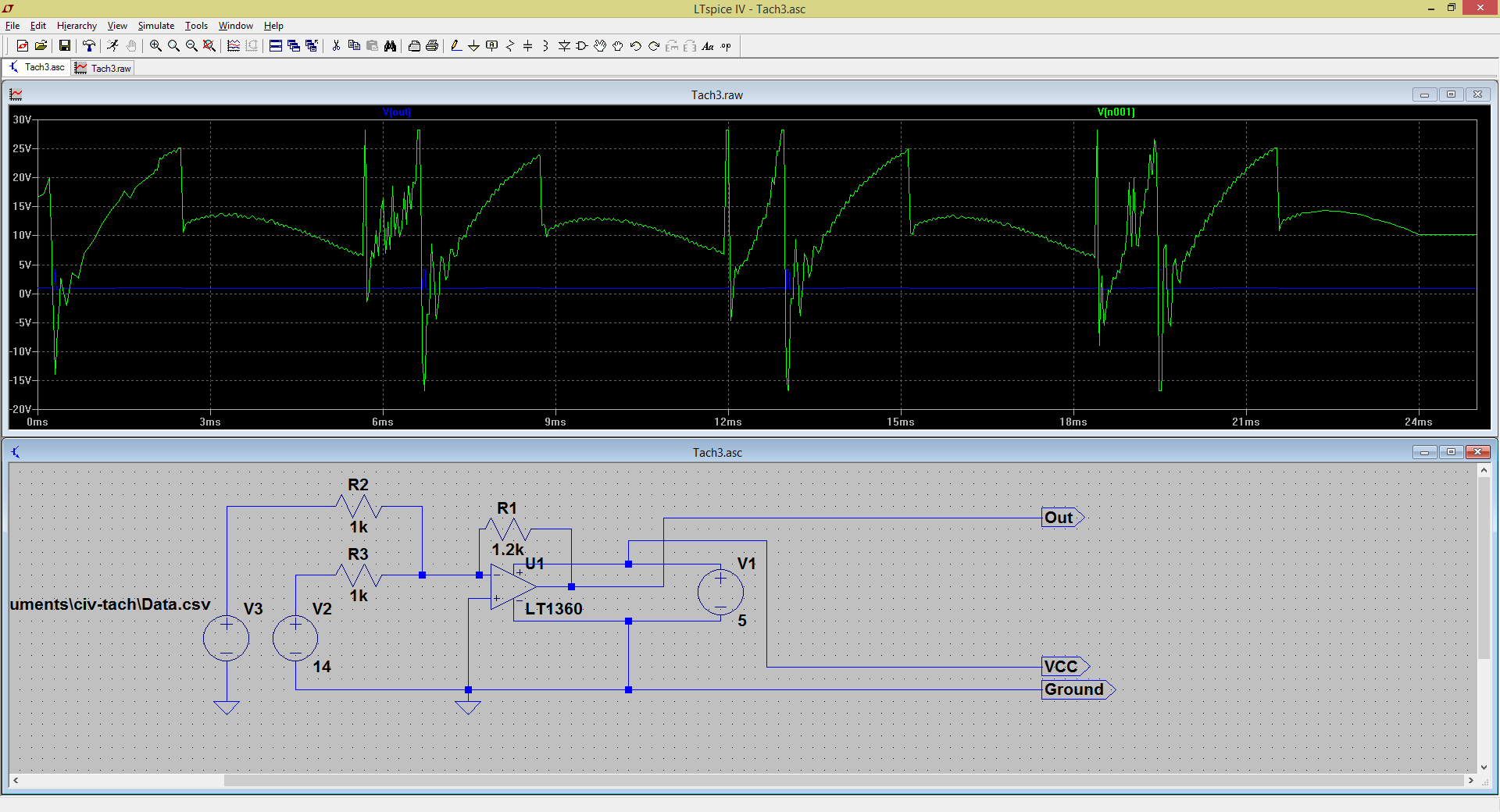

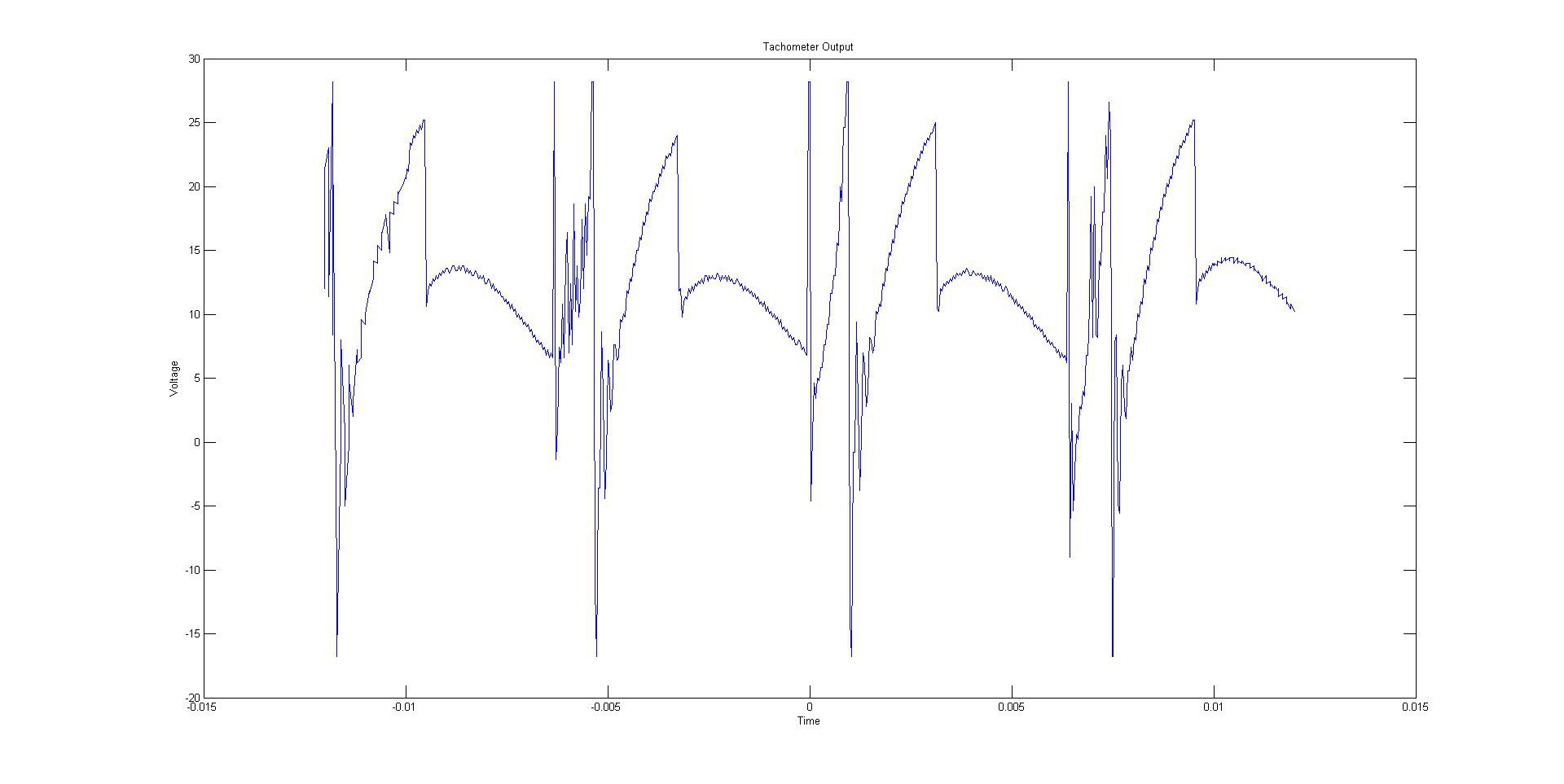

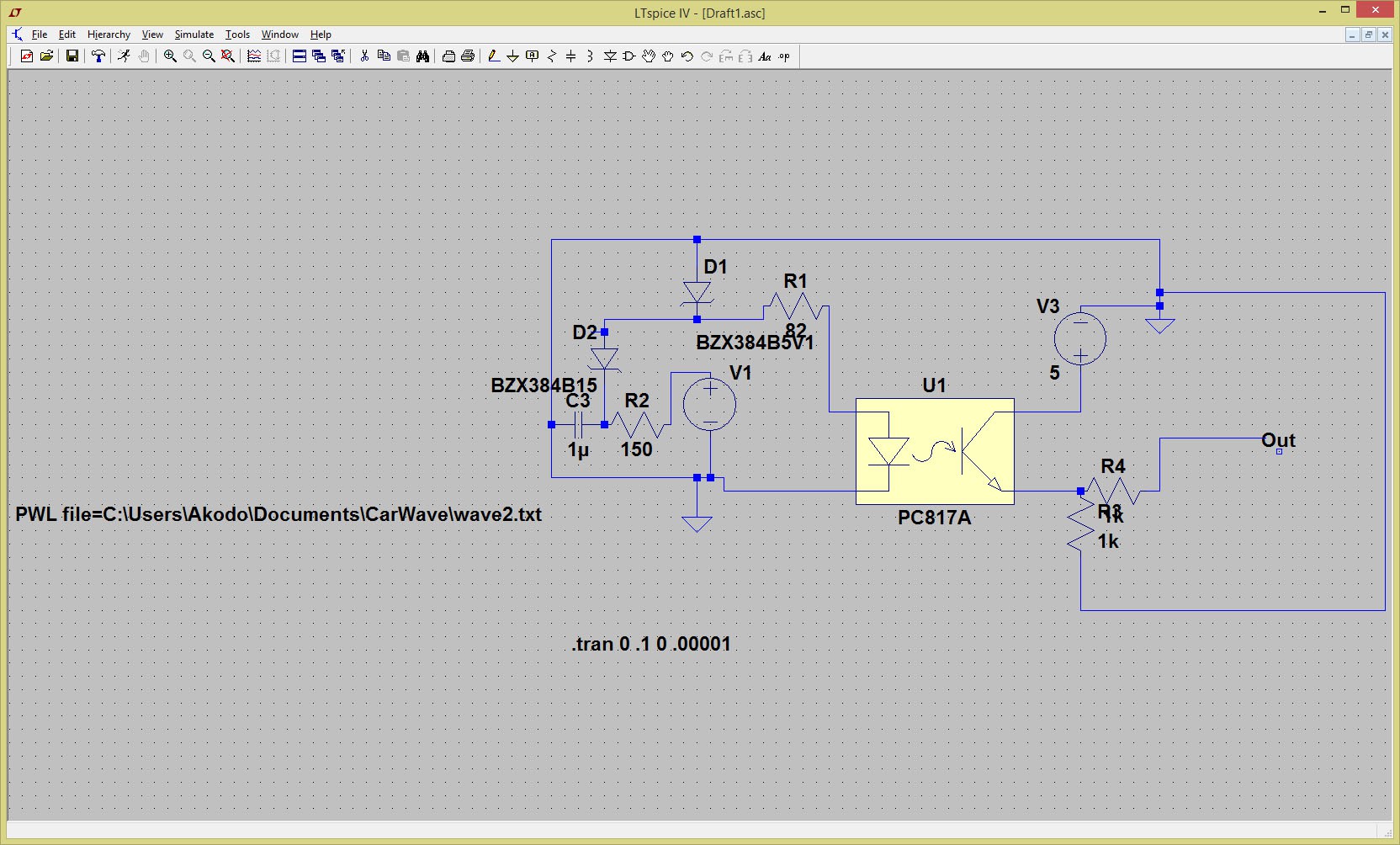

Rolling averaging and jitter reduction for readability while keeping a fast response time.

Connects to car via a 4 pin connector spliced into the cluster loom.

Automatic dimming when instrument cluster lights are turned on.

Car off detection.

Nigel

Nigel

Reed Foster

Reed Foster

Eric Wiiliam

Eric Wiiliam

amiravni

amiravni

Any news on this project? I am trying to do the same. Get the tachometer signal from distributor to measure the RPM and with that drive a LED BAR with gear shift..