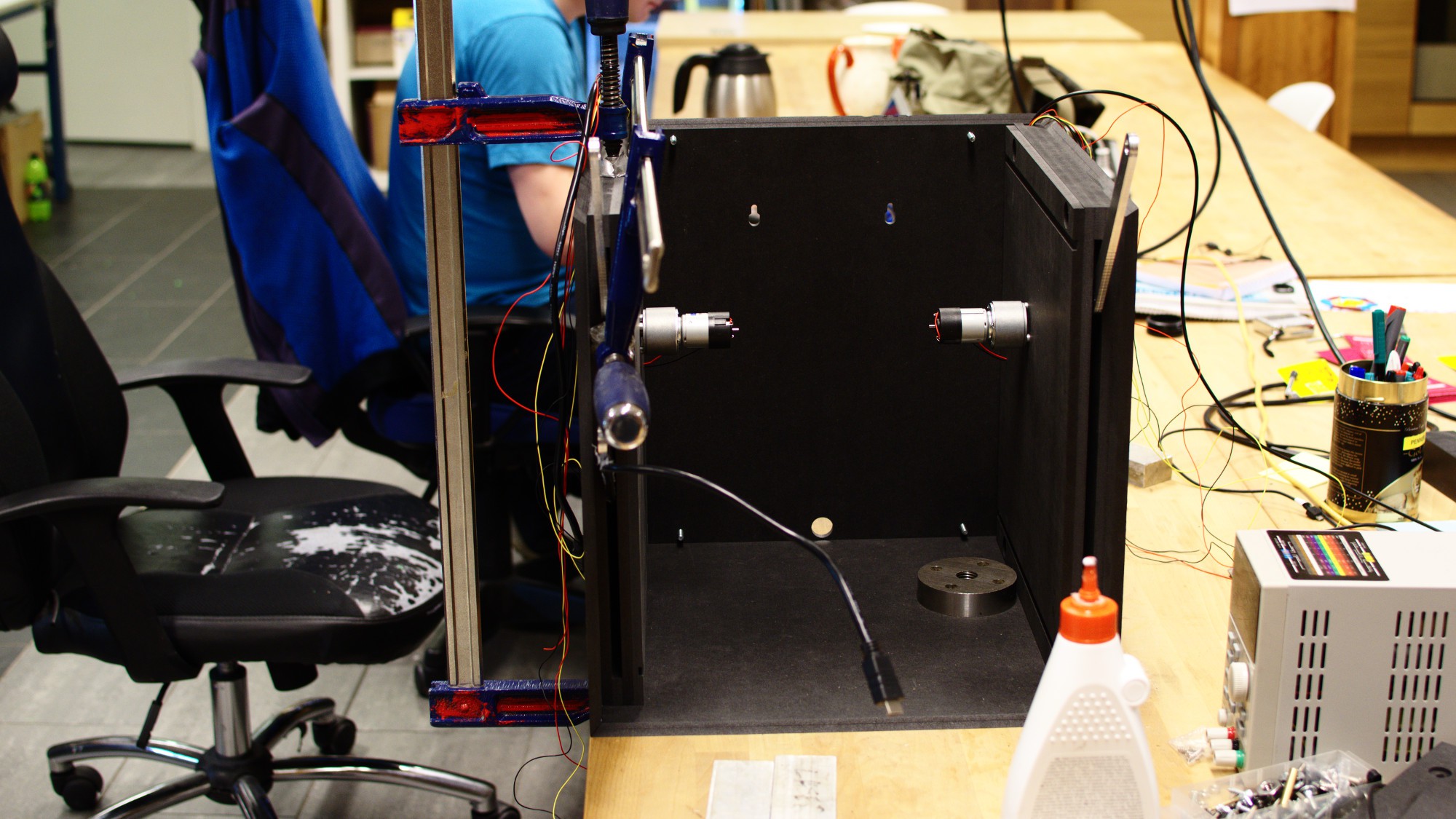

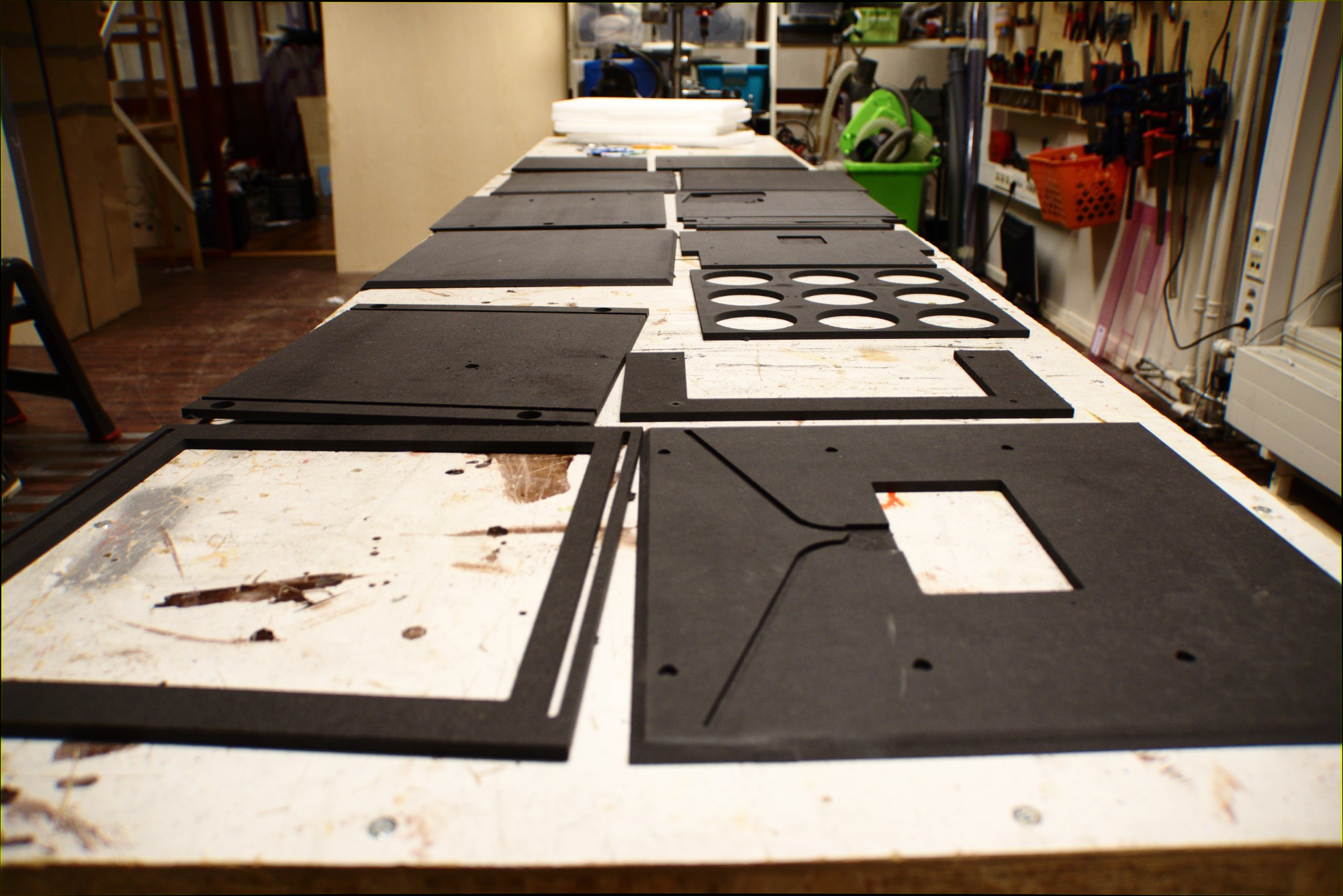

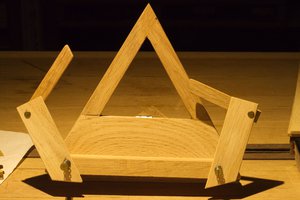

This is a semi-automatic liquor cabinet, meaning that you can choose a recipe and it will guide you through the process using lights and a weight cell. So you follow along on the screen (Manga Screen), and it will tell you which bottle to choose using lights as a guide and then using a load cell, it will tell you when to stop pouring.

Latskap is a Norwegain pun. The literal translation is "laziness", but "lat" means translates to "lazy" and "skap" translates to locker/cabinet.

This project was initiated together with my uncle Mike Moulton who has has making lockers for a long time. And it's been a running joke at dinner parties that "we really have to get going with Latskap", but we are to lazy to get started.

Well Mike, I've finally gotten started!

Elias Bakken

Elias Bakken

agp.cooper

agp.cooper

charliex

charliex

[zit] Olivier Gade

[zit] Olivier Gade