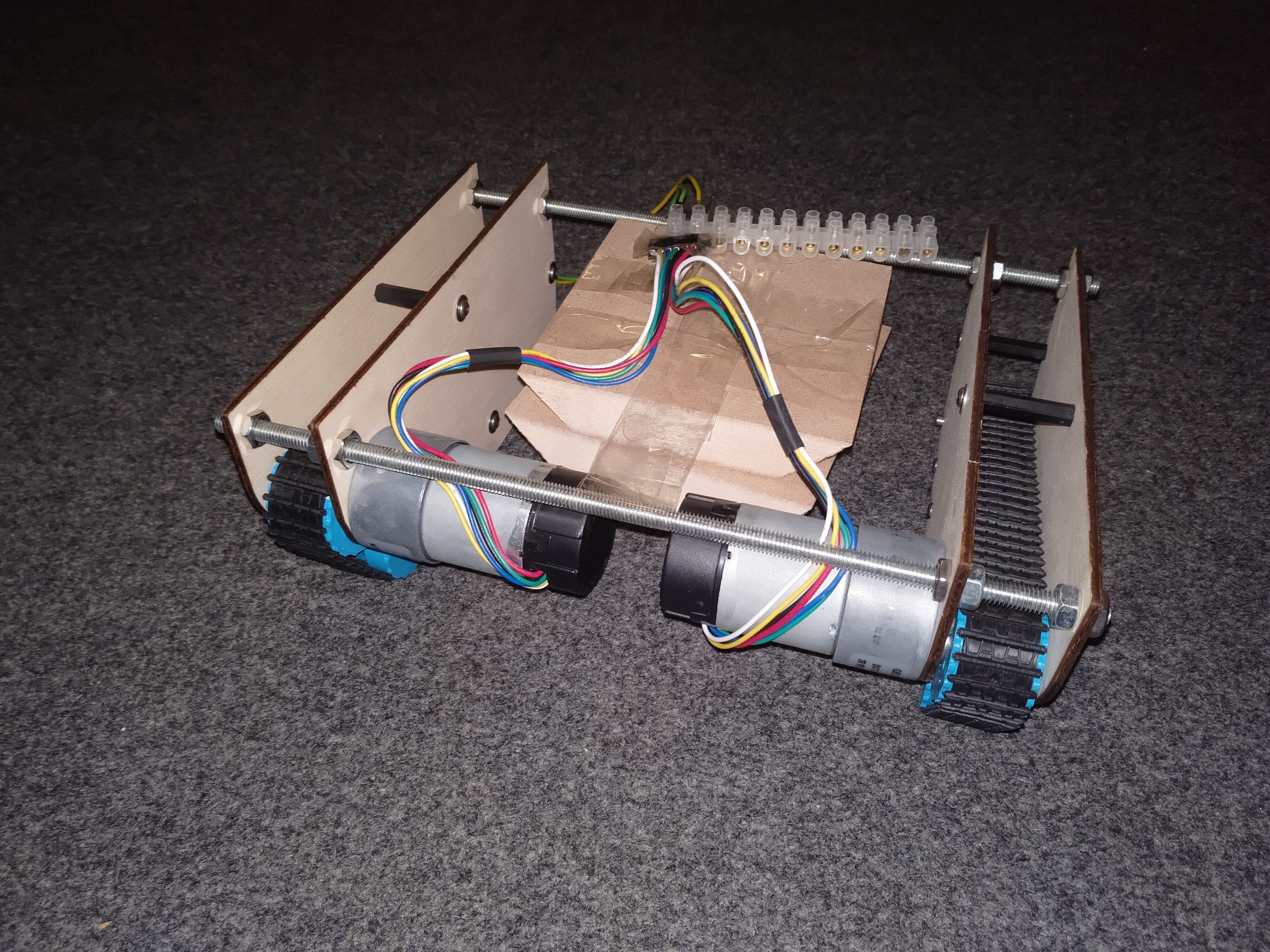

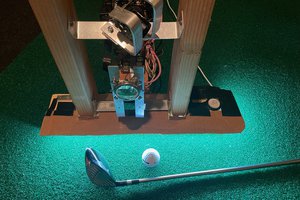

I'm working on a robot, hopefully for PiWars 2018 (http://piwars.org/) if it gets selected.

Update: Unfortunately I wasn't selected for PiWars, so this is just a fun robot project now. I'll probably still design it to complete the PiWars challenges

This project will be a pretty haphazard collection of progress reports and other ramblings.

Jacob David C Cunningham

Jacob David C Cunningham

Yuta Suito

Yuta Suito

Tobias Kuhn

Tobias Kuhn