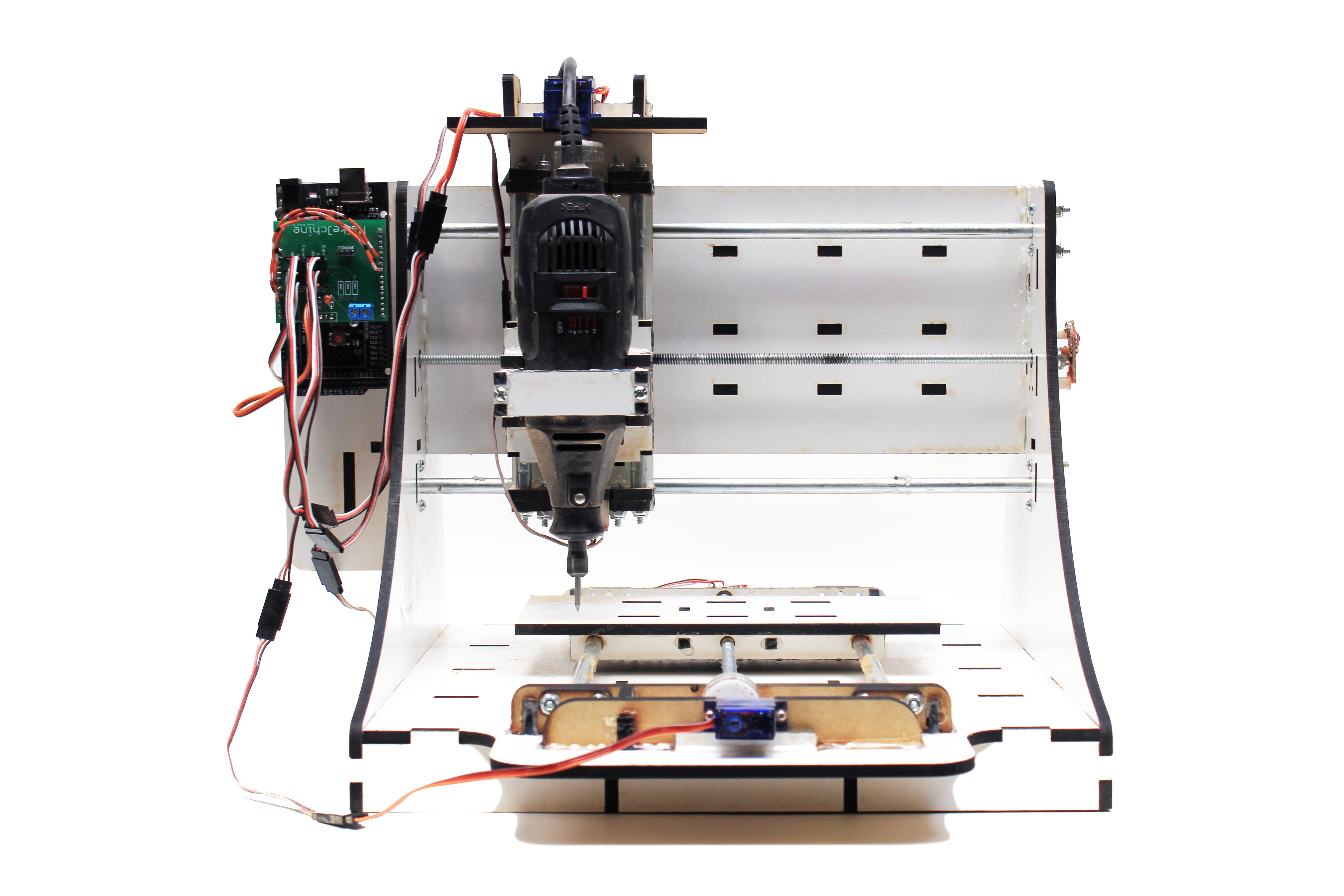

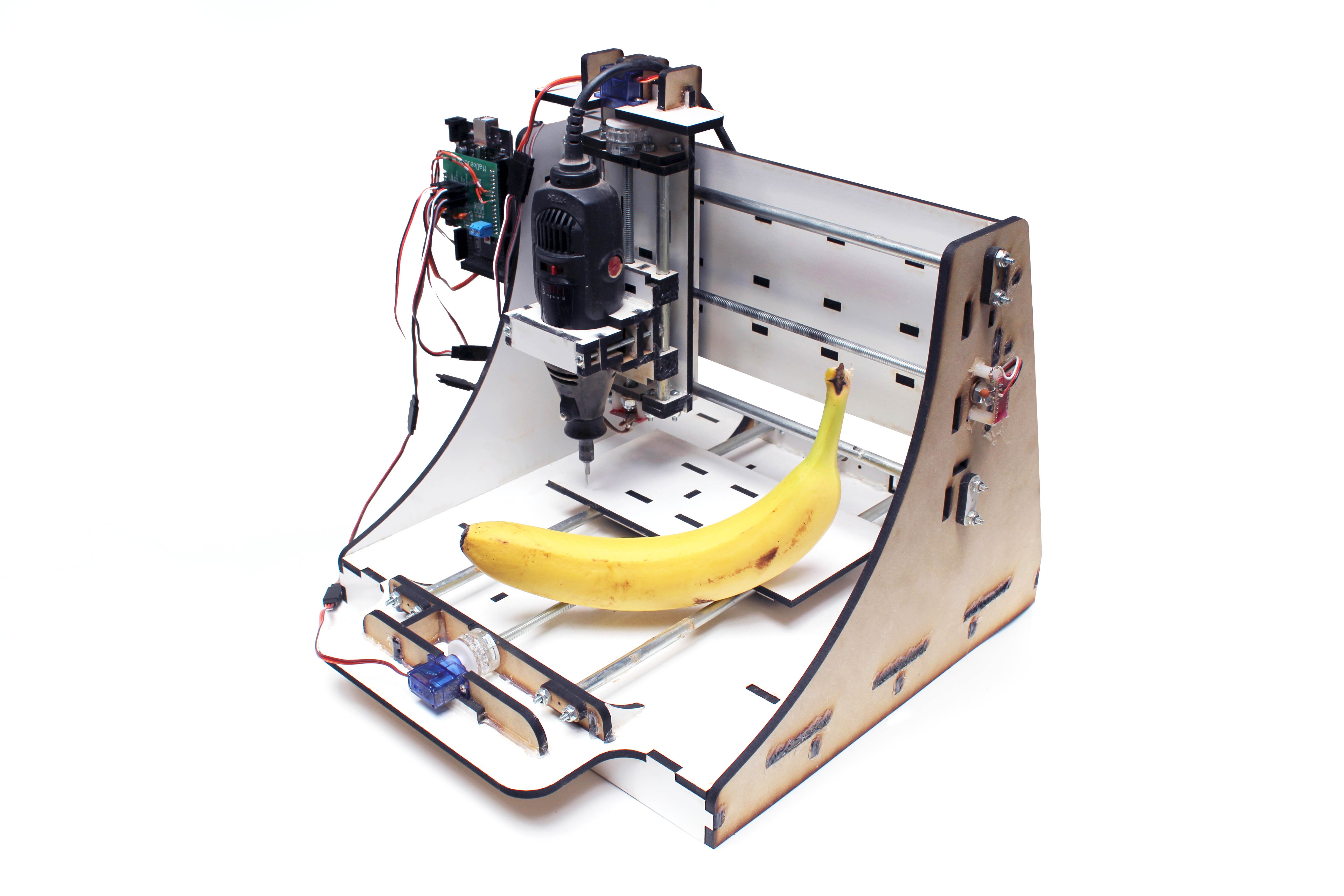

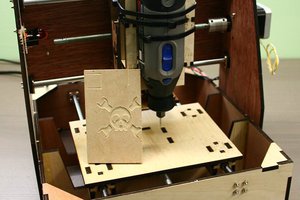

Our CNC router takes a two or three dimensional computer model of an object and very precisely mills, cuts, or shapes the object out of any soft material. This low-priced high-quality desktop CNC router cuts intricate and accurate pieces. The machine allows an individual to shape objects that would otherwise be too tedious, difficult, or impossible to complete by hand. Our router can cut wood, plastic, foam, and many other soft materials. It is not intended to cut metals, however we learned recently that it can easily carve basic red bricks. We regularly experiment with new materials to increase the potential applications of our machine. For an updated list of materials we have tested, visit the “Tools and Materials” page on our website as well as the “Updates” section on our Kickstarter page. The frame and mechanical components of our CNC router are custom designed from the ground up to minimize the cost of the machine without incurring any unacceptable loss of performance. We are trying to provide something that people have been able to purchase for a couple of years, but at a fraction of the price.

The Router’s Specs:

- Custom closed loop controller

- 9.2in x 8.7in x 1.9in workspace (234mm x 221mm x 48mm) (cutting/working area)

- 12in x 14in x 14in machine size (dimensions of the entire machine)

- .00005in (.001mm) minimum step size (the minimum amount the machine can be instructed to move)

- .1mm – .5mm repeatability depending on feed rate and material (the ability to return to the same spot after a process; accuracy)

- 5in/min (127mm/min) maximum feed rate (the rate it can move in any one direction). For those unfamiliar with feed rates, compared to more expensive CNC setups, this is very slow.

Tools: End Mills, Drill Bits, V-bits

Materials: Wood, Plywood, Brick, Foam, Copper Clad PCB Board, Leather, Steel, 3D Printed ABS, Delrin

End Mill:

An end mill is a bit which is designed to cut in as it moves through material in any direction. End mills are useful for cutting out a shape by cutting all the way through, or to create pockets or slots by cutting only partially through the material. The general rule is that an end mill should only cut to a depth of about 1/2 to 1/4th of it’s diameter with each pass, so a 2mm end mill might step down 1mm with each pass. If you are using a .8mm end mill it’s probably not practical to follow this rule, but it’s worth keeping in mind.

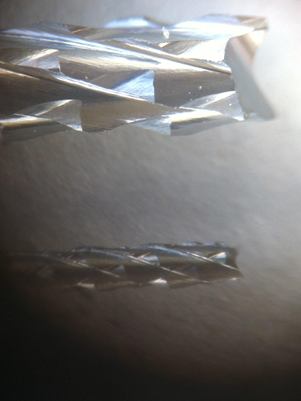

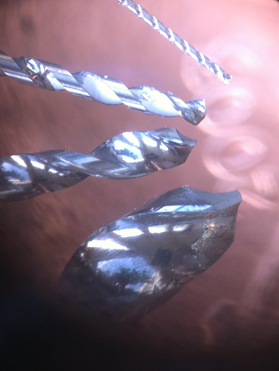

The picture below is of a 2mm end mill. The second picture is of the same 2mm end mill with a .8mm end mill next to it for comparison. Both pictures were taken through a microscope.

Shown are a 2mm and a .8mm toothed end mill.

V-bits:

V-bits are mostly useful for engraving text or routing circuit boards. V-bits are nice because they leave an attractive v-shaped groove and they are typically much cheaper than an end mill of comparable size and material. Buy the tungsten carbide ones, they are worth it. You can find these on ebay pretty easily.

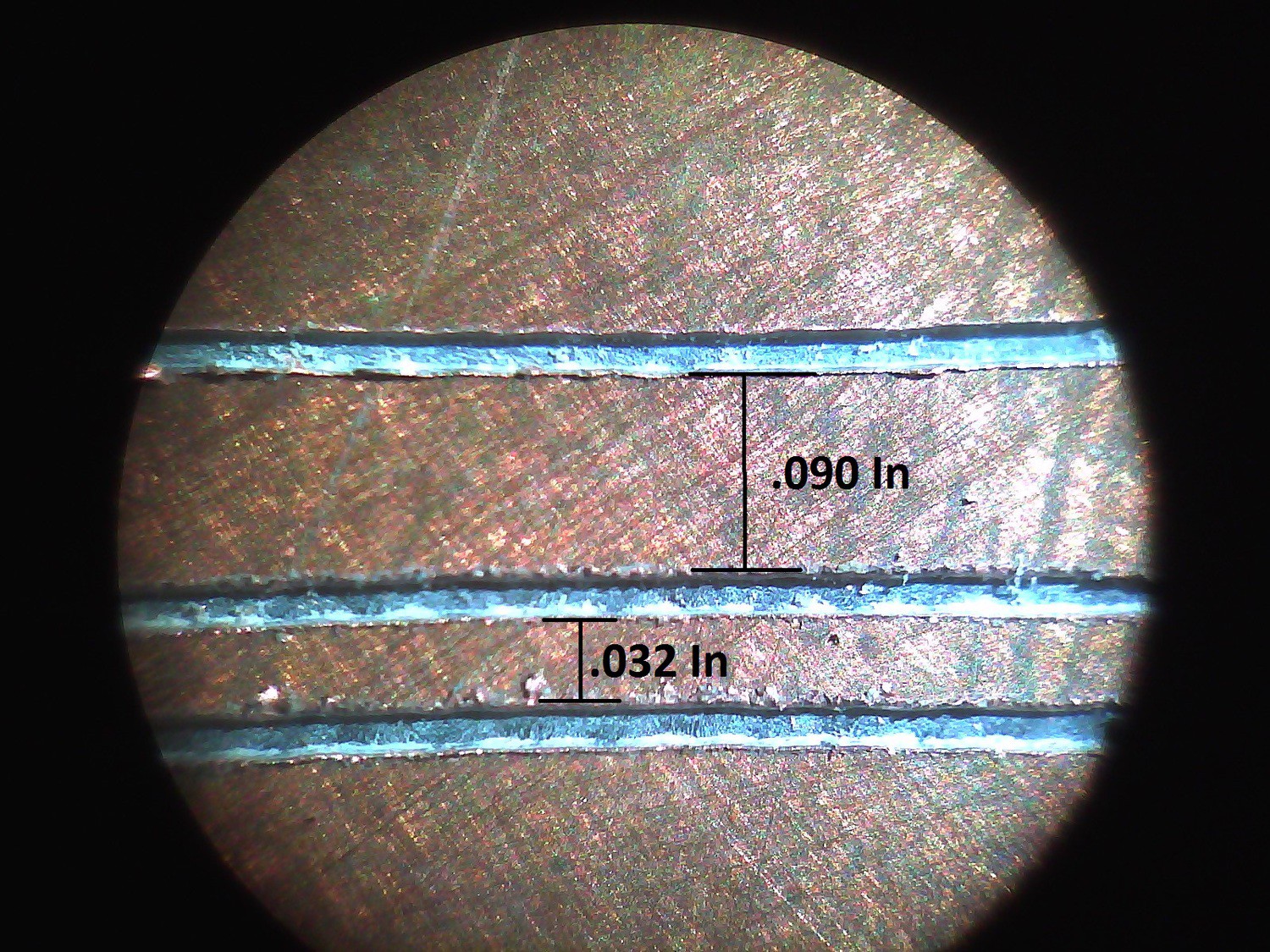

The picture below is a view of the upper right corner of the ‘M’ from the engraving seen through a microscope. The engraving was made with a 45 degree v-bit.

Materials:

Wood is one of the best materials out there. It is strong, light, easy to work with, beautiful, readily available, and inexpensive. Wood is a broad category ranging from balsa wood to iron wood, so you will have to do some experimenting to see what works best for any particular wood. In general, wood will yield accurate and beautiful objects and can either be cut or engraved. When cutting wood it is important not to burn the wood or your end mill. Rotary tools often can be set to very high speeds (30,000 RPM or higher). These kinds of speeds will cause your end mill to heat up rapidly and burn the wood you are cutting. To prevent this from happening, when cutting wood, use a lower spindle speed in conjunction with a relatively high feed rate (feed rate is how fast the bit is moving laterally) and a small step down (a step down is how much deeper the bit cuts...

brashtim

brashtim

Josh

Josh

BaiLiping

BaiLiping

Wudagem

Wudagem

Mark Langford

Mark Langford

Yeah really nice, question: would it be good for PCBs? or that needs more precision?